Step-by-step molten iron KR stirring desulfurization method

A stirring desulfurization, step-by-step technology, applied to chemical instruments and methods, mixers with rotating stirring devices, mixers, etc., can solve problems such as unsatisfactory, loss of blade effect, poor entrainment and dispersion effects, etc. It achieves the effects of reducing blade wear, increasing the floating distance, and improving the reaction kinetics conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

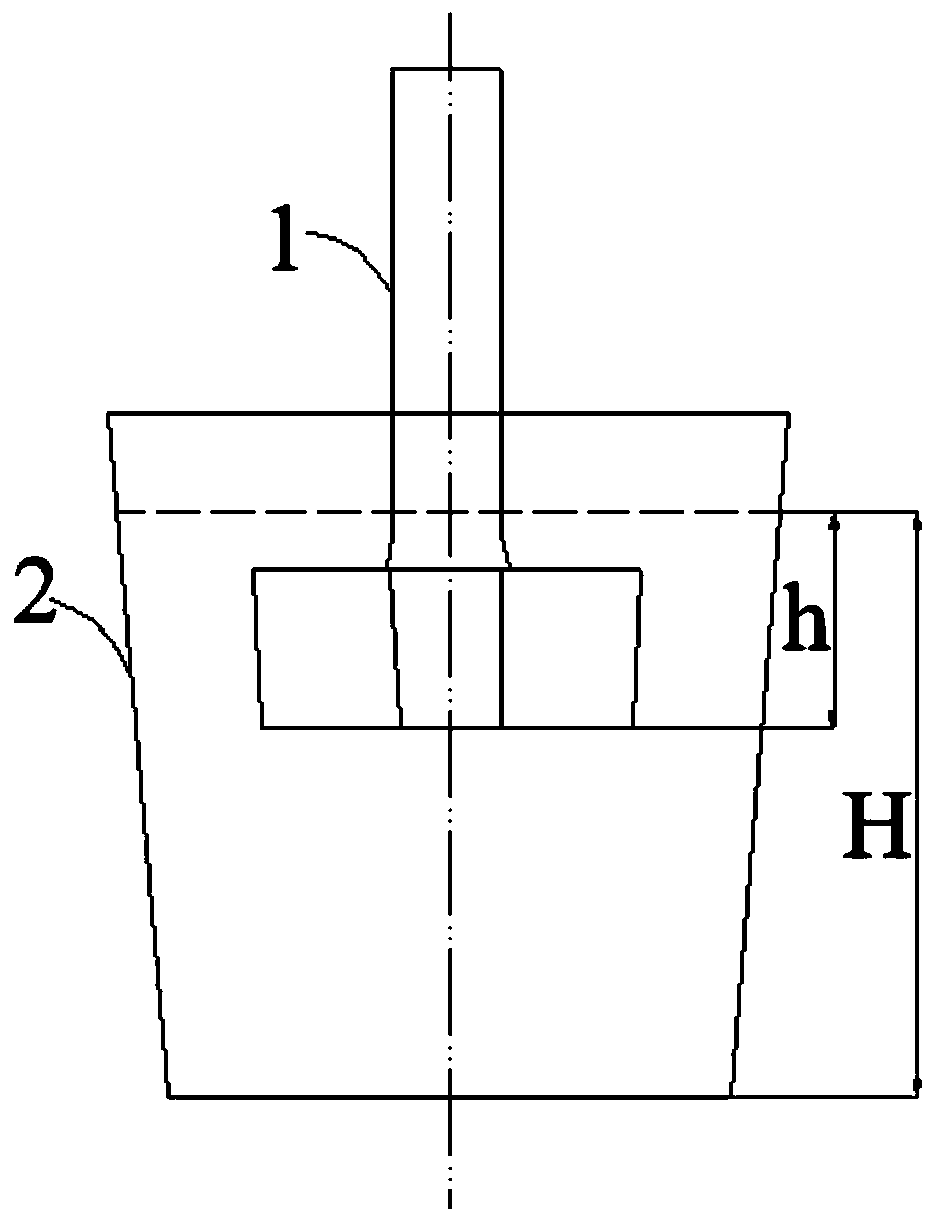

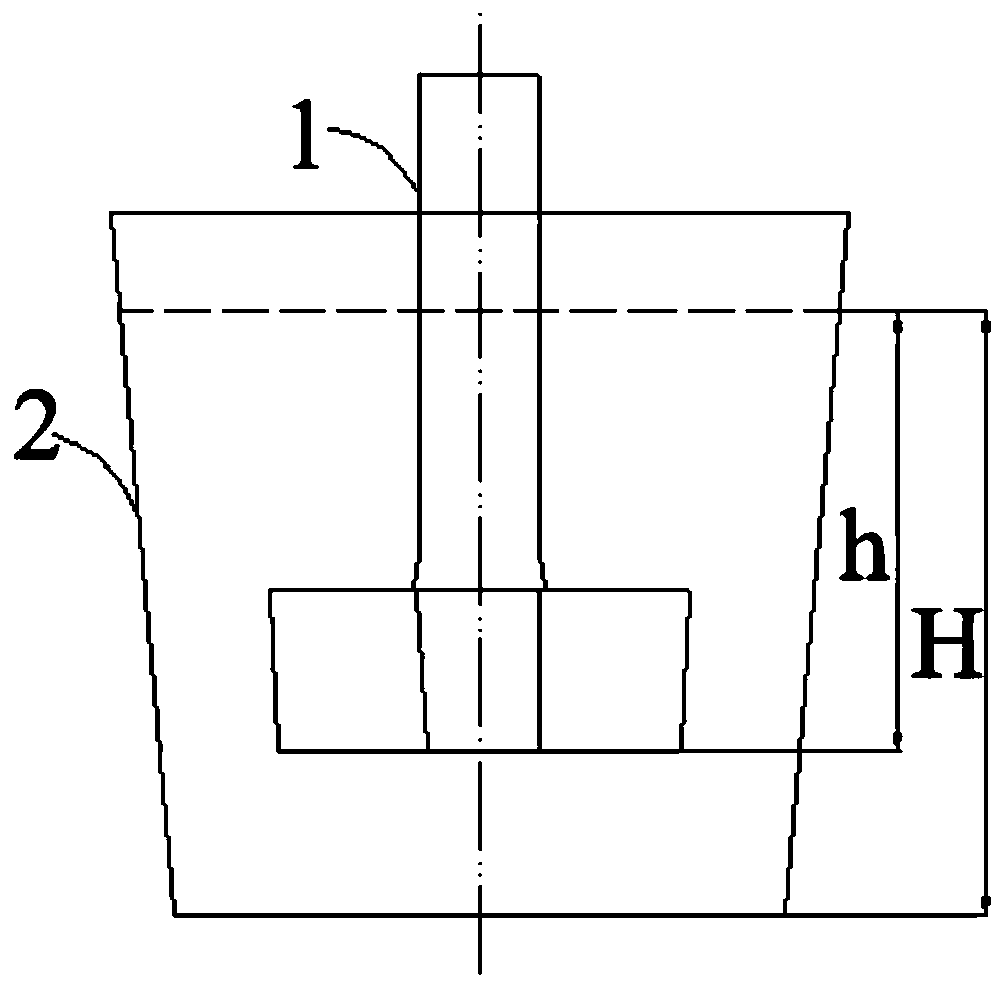

[0038] combine figure 1 and figure 2 , a step-by-step molten iron KR stirring desulfurization method of the present embodiment, the steps are:

[0039] Step 1. Remove slag from the molten iron until the exposed area of the molten iron surface reaches more than 60%, measure the depth of the liquid surface, record it as H, and measure temperature and sample;

[0040] Step 2. Insert the agitator 1 into the 1 / 4 height of the depth of the molten iron level, that is, the insertion depth of the agitator 1 is h=H / 4, and rotate to the working speed;

[0041] Step 3: Add desulfurizer, keep the insertion depth and working speed of stirrer 1 for 4 minutes;

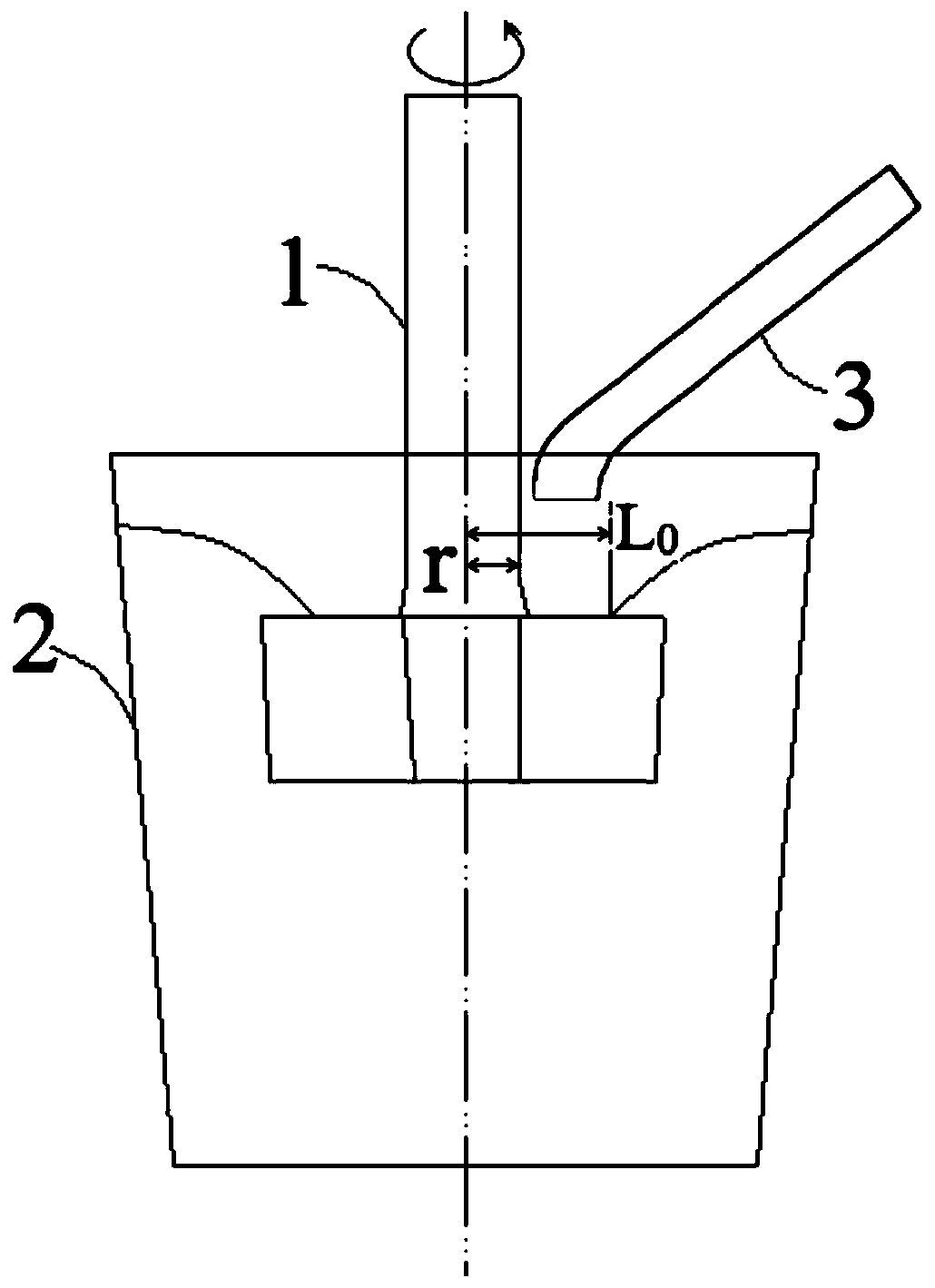

[0042] In this step, the desulfurizer is blown from the silo to the molten iron tank 2 with nitrogen at a blowing pressure of 0.1 MPa, and the feed silo and the molten iron tank 2 are connected by a feeding pipe 3, which includes an inclined straight pipe section and a curved For the short pipe section, the feeding port is verti...

Embodiment 2

[0050] A kind of step-by-step molten iron KR stirring desulfurization method of the present embodiment, its steps are:

[0051] Step 1. Remove slag from the molten iron until the exposed area of the molten iron surface reaches more than 60%, measure the depth of the liquid surface, record it as H, and measure temperature and sample;

[0052] Step 2. Insert the agitator 1 into the height of 3 / 8 of the depth of the molten iron level, that is, the insertion depth of the agitator 1 is h=3H / 8, and rotate to the working speed;

[0053] Step 3: Add desulfurizing agent, keep the insertion depth and working speed of stirrer 1 for 4 minutes; the injection pressure is 0.12MPa, the particle size of desulfurizing agent is 0.5mm, and its mass percentage components are: CaO: 58%, Al 2 o 3 : 14%, SiO 2 : 4%, MgO: 10%, CaF 2 : 2%, soda ash: 3.5%, K 2 O: 5%, Na 2 O: 3.5%;

[0054] Step 4, adjust the stirring insertion depth and stirring speed, insert the stirrer 1 to 5 / 8 of the depth of...

Embodiment 3

[0057] A kind of step-by-step molten iron KR stirring desulfurization method of the present embodiment, its steps are:

[0058] Step 1. Remove slag from the molten iron until the exposed area of the molten iron surface reaches more than 60%, measure the depth of the liquid surface, record it as H, and measure temperature and sample;

[0059] Step 2. Insert the agitator 1 into the height of 1 / 8 of the depth of the molten iron level, that is, the insertion depth of the agitator 1 is h=H / 8, and rotate to the working speed;

[0060] Step 3: Add desulfurizing agent, keep the insertion depth and working speed of stirrer 1 for 4 minutes; the injection pressure is 0.15MPa, the particle size of desulfurizing agent is 1mm, and its mass percentage components are: CaO: 59%, Al 2 o 3 : 13%, SiO 2 : 3%, MgO: 10.5%, CaF 2 : 2.5%, soda ash: 4%, K 2 O: 4%, Na 2 O: 4%;

[0061] Step 4, adjust the stirring insertion depth and stirring speed, insert the stirrer 1 to 7 / 8 of the depth of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com