A stirring tank

A technology of mixing tank and mixing blade, which is applied in mixer accessories, dissolving, mixer and other directions to achieve the effect of reducing labor cost, fully mixing, and improving quality accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

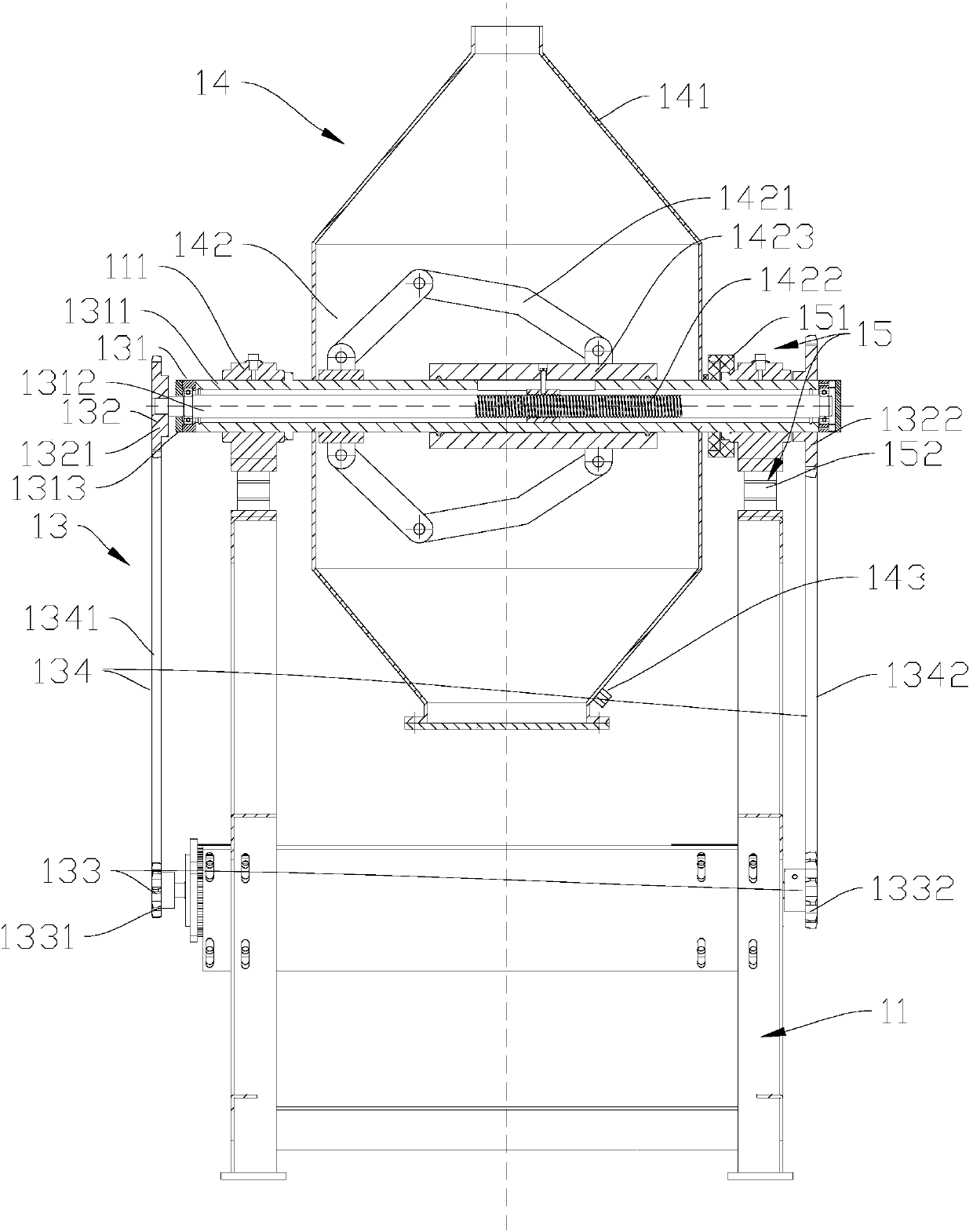

[0023] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

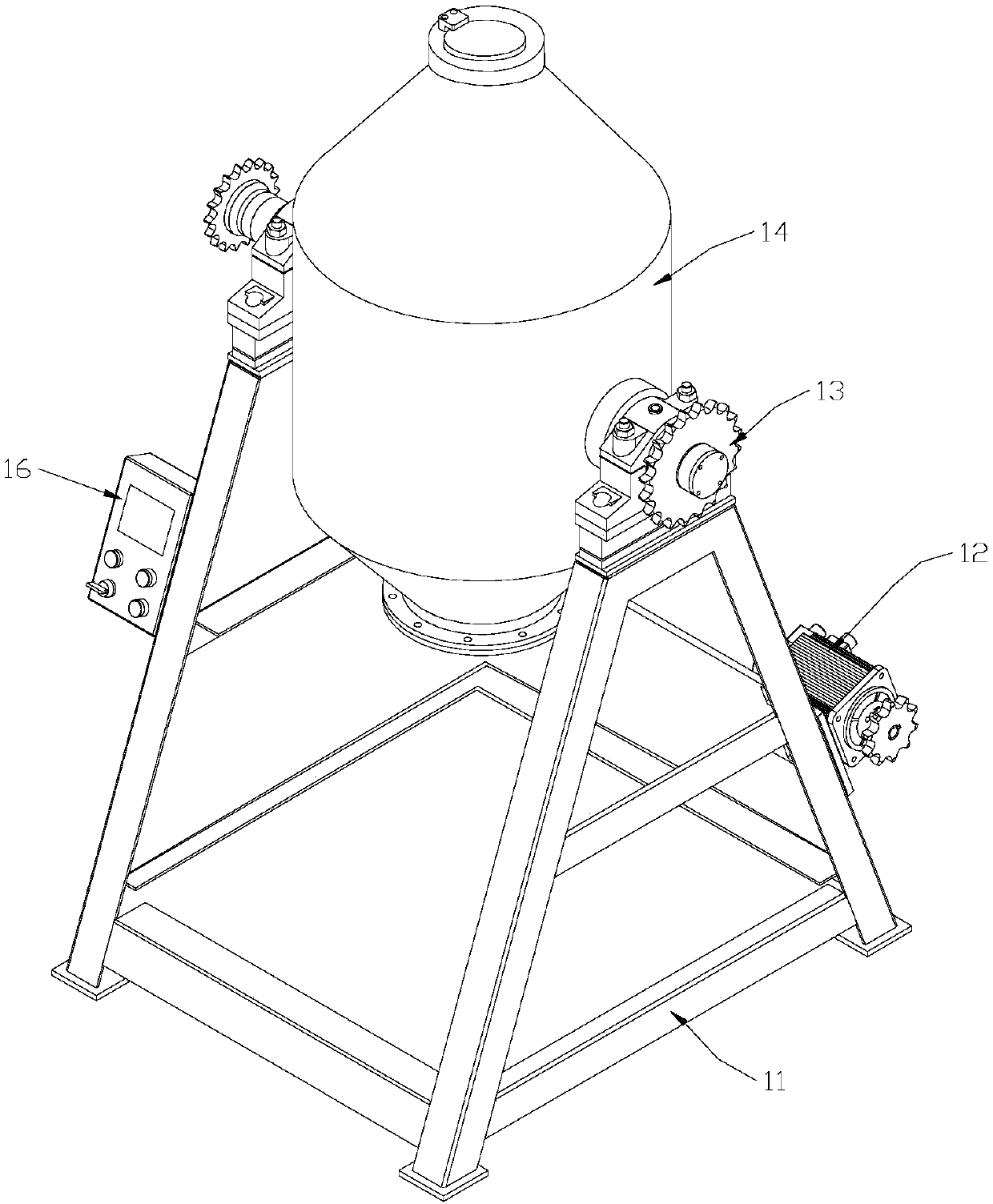

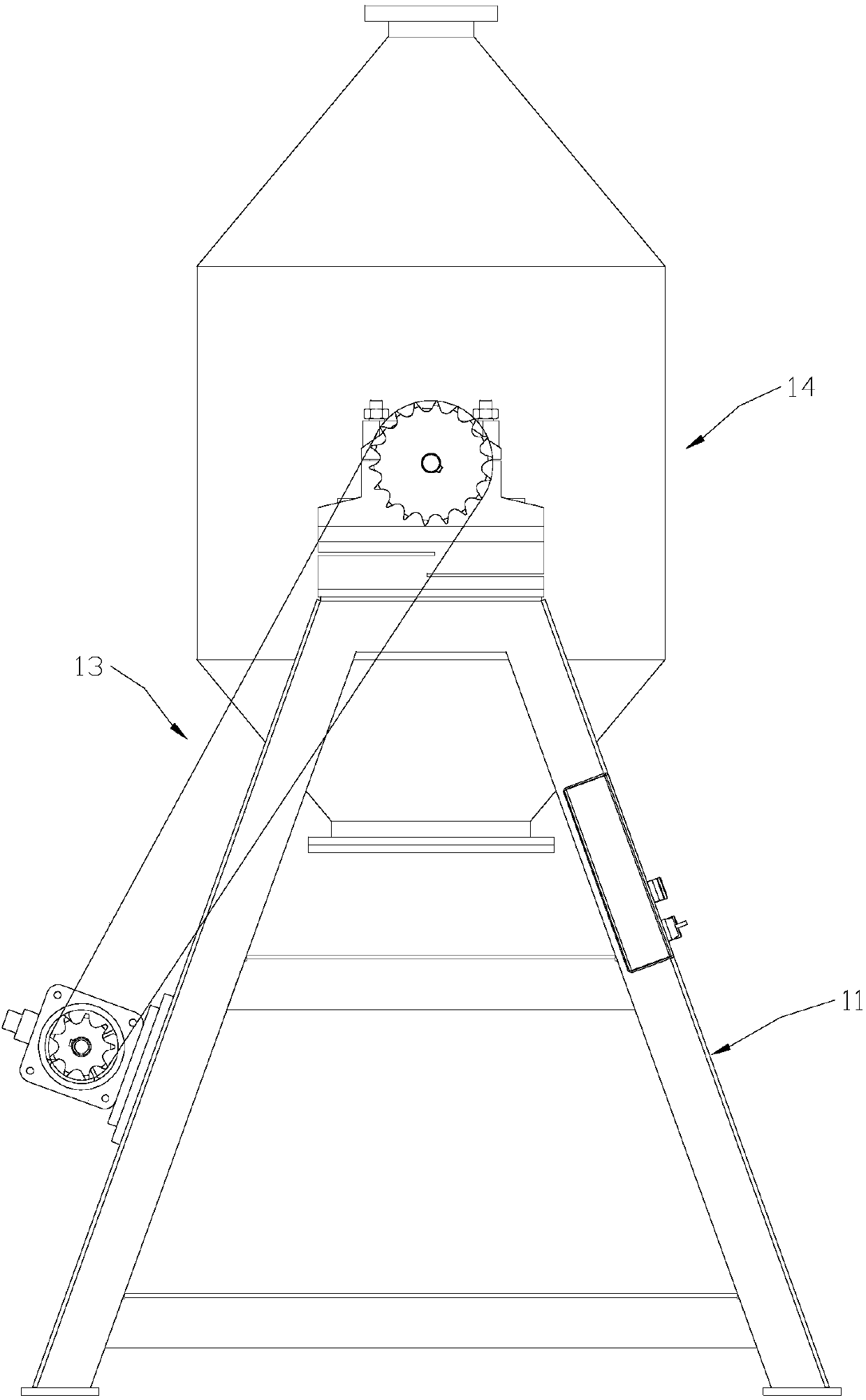

[0024] Figures 1 to 5 A preferred embodiment of the stirred tank of the present invention is shown.

[0025] The stirring tank can stir the metal powder in the process of powder metallurgy processing, which can realize intelligent unmanned stirring, improve the efficiency of stirring, and reduce the labor cost of stirring. In addition, the stirring tank adjusts the position of the stirring blade And the width and then adjust the angle of the stirring blade, so as to achieve the effect of full stirring.

[0026] Such as figure 1 and figure 2 As shown, the stirring tank can be used to stir the fine metal powder, and it includes a support frame 11, a stirring tank body 14 arranged on the support frame 11, and a drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com