Automatic resin mixing system

A mixing system, automatic technology, applied in the field of resin, can solve the problems of wasted labor, low degree of automation, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

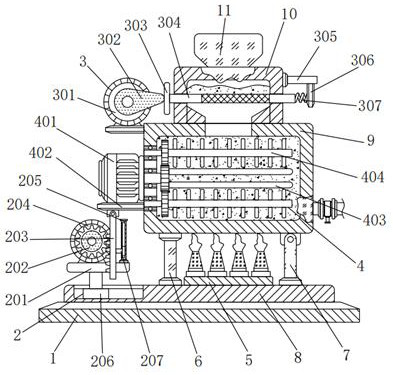

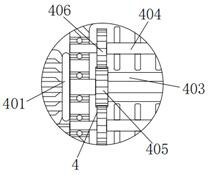

[0032] A resin automatic mixing system, comprising a base plate 1, a long plate 8 is fixed on the top of the base plate 1, and a spray gun 5 is fixed on the right side of the top of the long plate 8. The left side of the top is fixedly connected with a riser 6, the top right side of the long board 8 is fixedly connected with a vertical bar 7, and the top of the front end of the vertical bar 7 is rotatably connected with the bottom right bump of the box body 9 through a pin shaft, and the vertical plate 6 The top of the vertical plate fits the left side of the bottom of the box body 9, and the top of the riser 6 is fixed with a rubber pad, which can reduce the wear between the vertical plate 6 and the box body 9, and the top of the box body 9 is fixed with a square Case 10, the top of square case 10 is communicated with feed inlet 11, and the left side of casing 9 is provided with stirring device 4, and stirring device 4 comprises first motor 401, horizontal plate 402, long rod ...

Embodiment 2

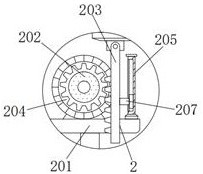

[0034] As an option, see figure 1 , 3And 4, the automatic resin mixing system, the top of the long plate 8 is provided with a moving device 2, and the moving device 2 includes a square plate 201, a third gear 202, a rack 203, a second motor 204, a groove plate 205, a slide block 206 and a short Block 207, the lower part of the outer wall of the slider 206 is slidingly engaged with the inner wall of the groove on the top left side of the long board 8. The slider 206 and the long board 8 form a sliding structure. When the slider 206 is stressed, it can be on the left side of the top of the long board 8 The groove slides left and right, the top of the slider 206 is provided with a square plate 201, the bottom of the square plate 201 is fixedly connected with the top of the slider 206, the top of the square plate 201 is provided with a second motor 204, and the model of the second motor 204 is SM80 -D601930, the bottom of the second motor 204 is fixedly connected to the top of th...

Embodiment 3

[0037] As an option, see figure 1 , 5 And 6, resin automatic mixing system, the top of casing 9 is provided with screening device 3, and screening device 3 comprises the 3rd motor 301, eccentric wheel 302, short plate 303, filter screen 304, straight plate 305, vertical block 306 and spring 307, the preset motor seat below the third motor 301 is fixedly connected to the upper left side of the box body 9, the model of the third motor 301 is ECMA-E11320RS, and the output end of the third motor 301 is fixedly connected with an eccentric wheel 302, eccentric The right end of wheel 302 fits with the left side of short plate 303, and the right side of short plate 303 is provided with filter screen 304, and the material of filter screen 304 and number of meshes are determined according to actual usage conditions, and the left end of filter screen 304 and short plate The right end of 303 is fixedly connected, and the left and right sides of outer wall of filter screen 304 cooperates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com