Premixing device for cement blended with concrete early-strength water reducing agent

A technology of early-strength water-reducing agent and concrete, which is applied in the field of premixing equipment for mixing cement with early-strength water-reducing agent. problem, achieve the effect of saving manpower, preventing reunion and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

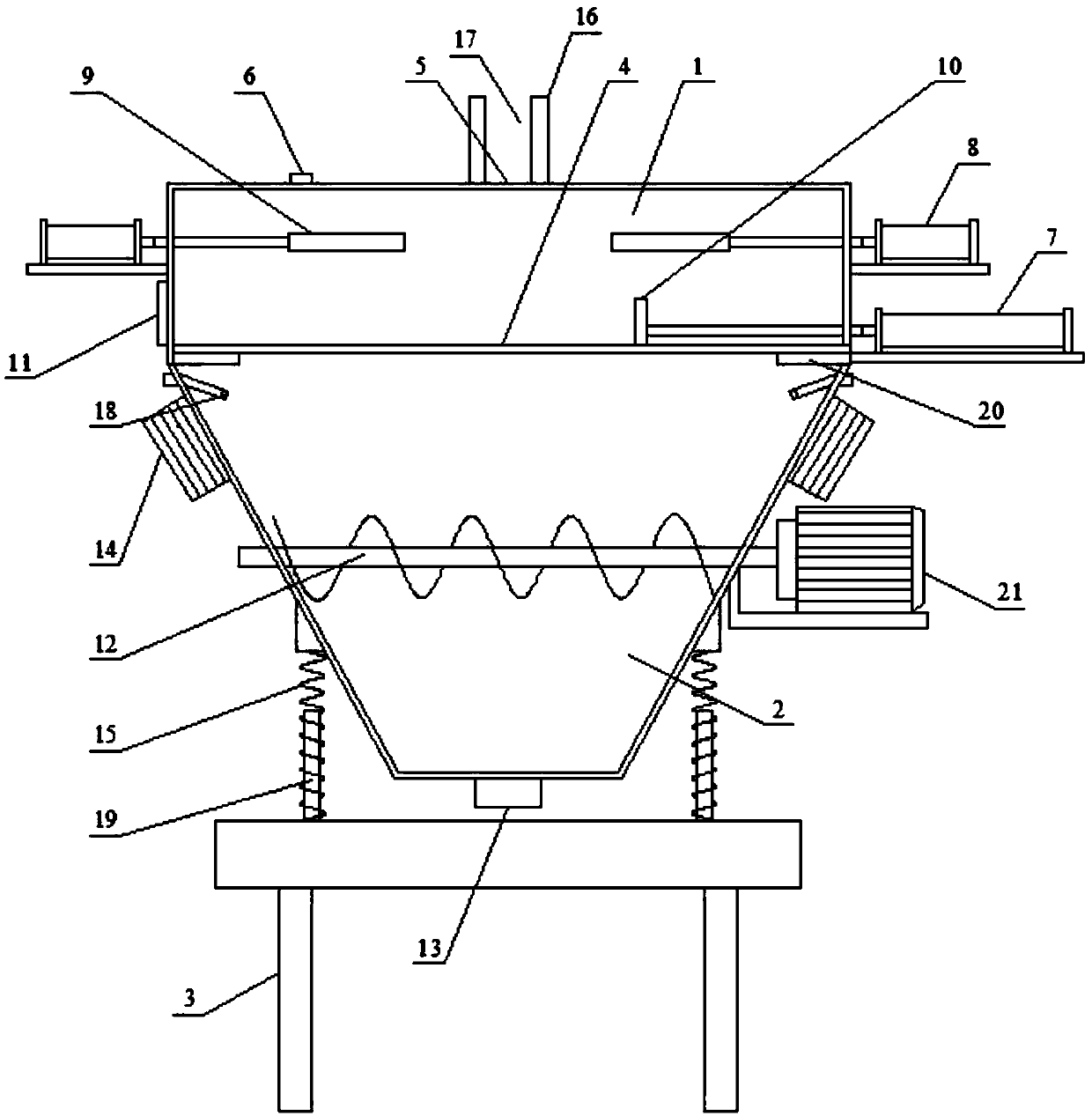

[0032] like figure 1 and figure 2 As shown, a premixing device for mixing cement with early-strength water reducer for concrete includes a mixing tank composed of a feeding chamber 1 and a mixing chamber 2 and a tank support platform 3, and the feeding chamber and the mixing chamber There is a feeding screen 4 horizontally between them, a bagged cement inlet 5 and an early-strength superplasticizer inlet 6 are arranged on the top of the feeding chamber, and a slag discharge cylinder 7 and two Relatively symmetrical bag cutting cylinder 8, the guide rod of the bag cutting cylinder vertically penetrates into the feeding chamber and the front end is provided with a matching semi-circular bag cutting blade 9, the guide rod of the slag discharge cylinder vertically penetrates into the feeding chamber and the front end There is a slag discharge plate 10 vertically attached to the material passing screen, a slag discharge door 11 is provided on the side wall of the feed chamber fac...

Embodiment 2

[0035] likefigure 1 and figure 2 As shown, a premixing device for mixing cement with early-strength water reducer for concrete includes a mixing tank composed of a feeding chamber 1 and a mixing chamber 2 and a tank support platform 3, and the feeding chamber and the mixing chamber There is a feeding screen 4 horizontally between them, a bagged cement inlet 5 and an early-strength superplasticizer inlet 6 are arranged on the top of the feeding chamber, and a slag discharge cylinder 7 and two Relatively symmetrical bag cutting cylinder 8, the guide rod of the bag cutting cylinder vertically penetrates into the feeding chamber and the front end is provided with a matching semi-circular bag cutting blade 9, the guide rod of the slag discharge cylinder vertically penetrates into the feeding chamber and the front end There is a slag discharge plate 10 vertically attached to the material passing screen, a slag discharge door 11 is provided on the side wall of the feed chamber facin...

Embodiment 3

[0043] Such as figure 1 and figure 2 As shown, a premixing device for mixing cement with early-strength water reducer for concrete includes a mixing tank composed of a feeding chamber 1 and a mixing chamber 2 and a tank support platform 3, and the feeding chamber and the mixing chamber There is a feeding screen 4 horizontally between them, a bagged cement inlet 5 and an early-strength superplasticizer inlet 6 are arranged on the top of the feeding chamber, and a slag discharge cylinder 7 and two Relatively symmetrical bag cutting cylinder 8, the guide rod of the bag cutting cylinder vertically penetrates into the feeding chamber and the front end is provided with a matching semi-circular bag cutting blade 9, the guide rod of the slag discharge cylinder vertically penetrates into the feeding chamber and the front end There is a slag discharge plate 10 vertically attached to the material passing screen, a slag discharge door 11 is provided on the side wall of the feed chamber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com