Construction method for breaking end socket tunnel portal retaining structure of shield section

A technology of enclosure structure and construction method, which is applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of low work efficiency, mud and block removal, water and sand gushing, etc. Risk, easy to handle, not easy to water and sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

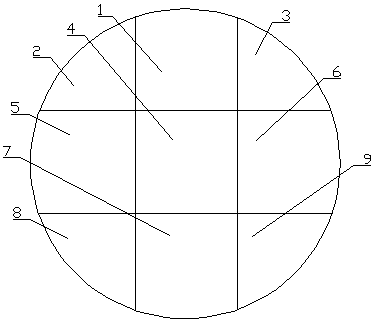

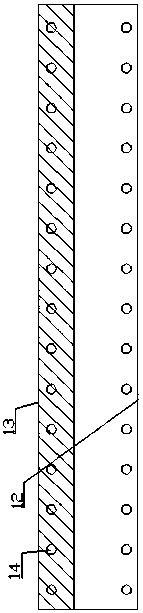

[0026] A construction method for destroying the enclosure structure of an end portal of a shield section, comprising the following steps in sequence:

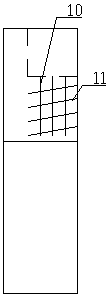

[0027] 1) Drill holes on the circular opening of the enclosure structure: drill vertical holes 10 downward along the direction vertical to the horizontal plane; drill longitudinal holes 11 along the direction of 10° downward from the inclined horizontal plane, such as figure 2 shown.

[0028] Wherein, the diameters of the vertical holes 10 and the longitudinal holes 11 are both 40 mm, the hole spacing is 300 mm, the row spacing is 400 mm, and the hole depth is 0.95 times the thickness of the circular door. By drilling the vertical holes 10 and the longitudinal holes 11, the effective pre-cracking of the circular door can be realized, and the work efficiency is high; the aperture, hole spacing, row spacing and hole depth of the vertical holes 10 and the longitudinal holes 11 are limited to effectively ensure construction safet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com