Construction method for bonding polymer water-proof coiled material

A technology for polymer waterproofing and construction methods, applied in building thermal insulation materials, building components, etc., can solve problems such as easy contamination of the environment, difficult to remove air bubbles, and inability to cure immediately, to expand the scope of application, reduce engineering costs, and improve construction methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

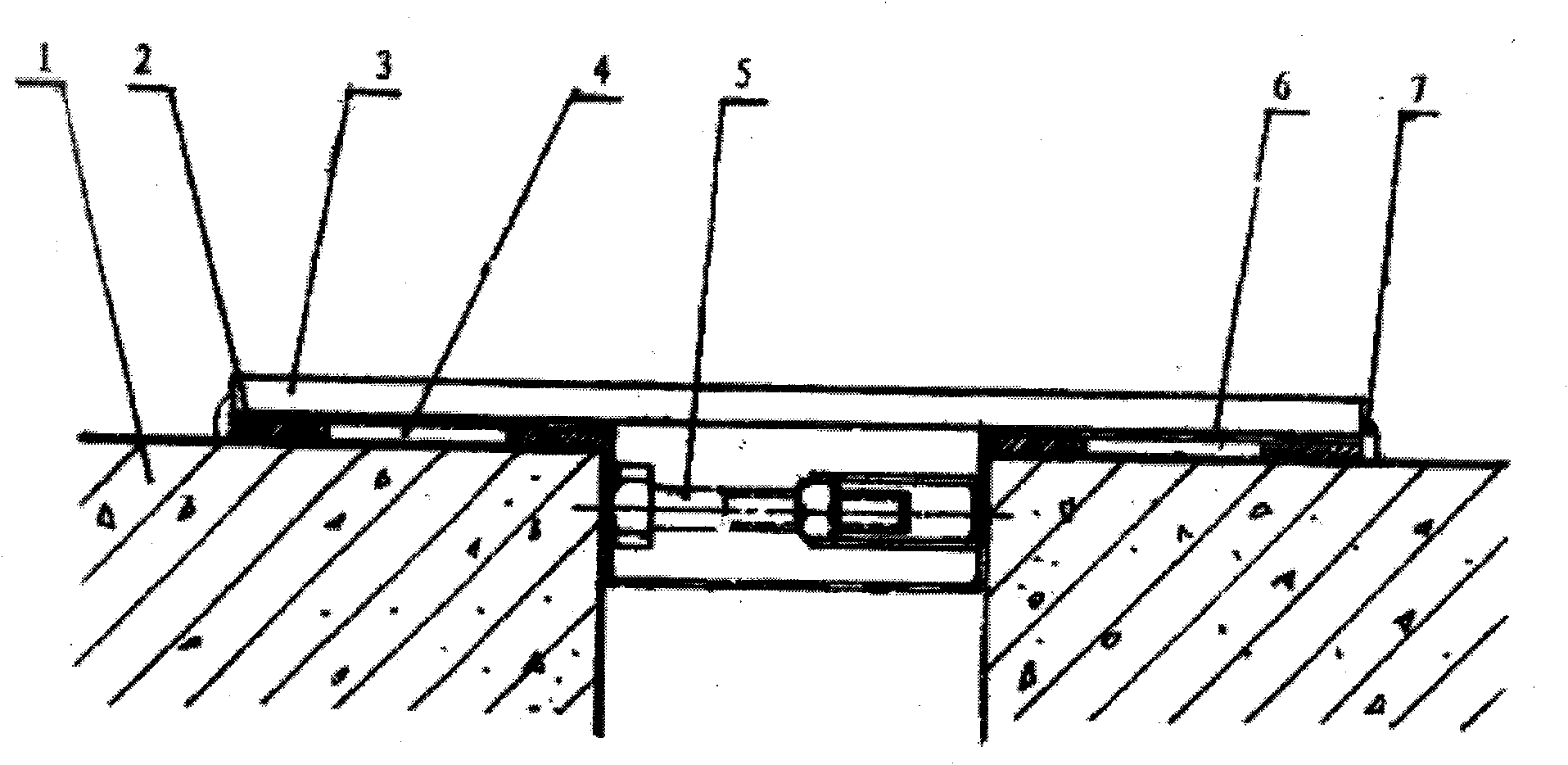

[0031] Example 1: See figure 2 as shown,

[0032] 1. Clean the surface to be glued.

[0033] For concrete 1, the release agent, oil and scum and dust should be removed, and the surface should be repaired and kept dry.

[0034] For metal surfaces, oil stains, paint films and rust scales should be removed.

[0035] To clean the surface of the polymer waterproof membrane, firstly, the dirty surface is scrubbed with water with detergent, then rinsed with clean water and dried. Then use a wool brush dipped in methyl ethyl ketone to brush on the adhered surface, and then dry it with clean cotton gauze. In addition, prepare a bottle of acetone for cleaning the wool brush. After brushing for a while, the wool brush is sticky with grease, which should be washed off in time. Wipe it with a dry cotton cloth before bonding to ensure that the surface of the waterproof membrane is dry.

[0036] 2. Treat the wet base surface.

[0037] In underground engineering, we often encounter the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com