Polystyrene foam particle heat insulation mortar

A technology of polystyrene foam and thermal insulation mortar, which is applied in the field of construction mortar, which can solve the problems of high price of composite thermal insulation mortar, failure to meet performance requirements, difficulty in cracking, hollowing, etc., and achieve light bulk density, long service life, and reduced The effect of cement dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

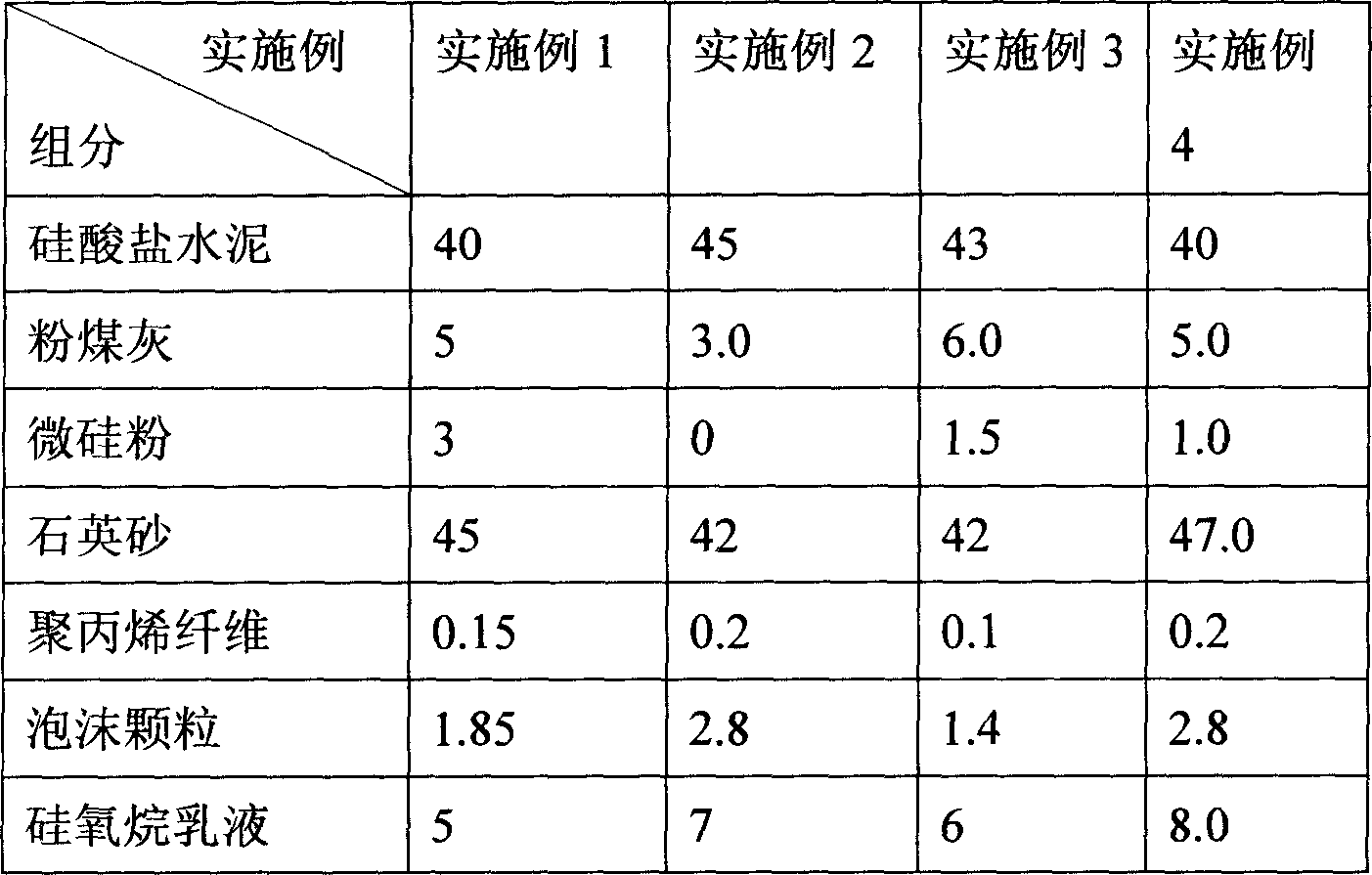

[0017] Provide following embodiment below in conjunction with content of the present invention:

[0018] Polystyrene foam particle insulation mortar, weigh various raw materials according to the formula ratio, first add siloxane emulsion to polystyrene foam particles, stir evenly, dry the mixture, then add micro silica fume, Portland cement, Fly ash, quartz sand and polypropylene fiber are fully stirred and evenly formed into a product, which is then bagged. According to the needs of engineering applications, the required properties can be obtained by adjusting the inventive formula. In specific implementation process, each component weight percent is:

[0019]

[0020] The above components are prepared according to the aforementioned process to obtain dry powder of polystyrene foam particle insulation mortar, add appropriate amount of water to make the consistency of the mortar mixture reach 80mm, and form samples according to the standard requirements. The consistency, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com