Rapid repair grouting mortar for high-speed rail ballastless track mortar layer

A technology of ballastless track and mortar layer, which is applied in the field of rapid repair grouting mortar for high-speed rail ballastless track mortar layer, which can solve the problem of poor corrosion resistance and freeze-thaw resistance of cement emulsified asphalt mortar, and no rapid repair of high-speed rail ballastless track mortar layer Materials, low bonding strength of quick-drying cement, etc., to achieve the effect of strong filling, civilized construction, and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment relates to the rapid repair grouting mortar and its preparation method for the mortar layer of the ballastless track of the high-speed railway:

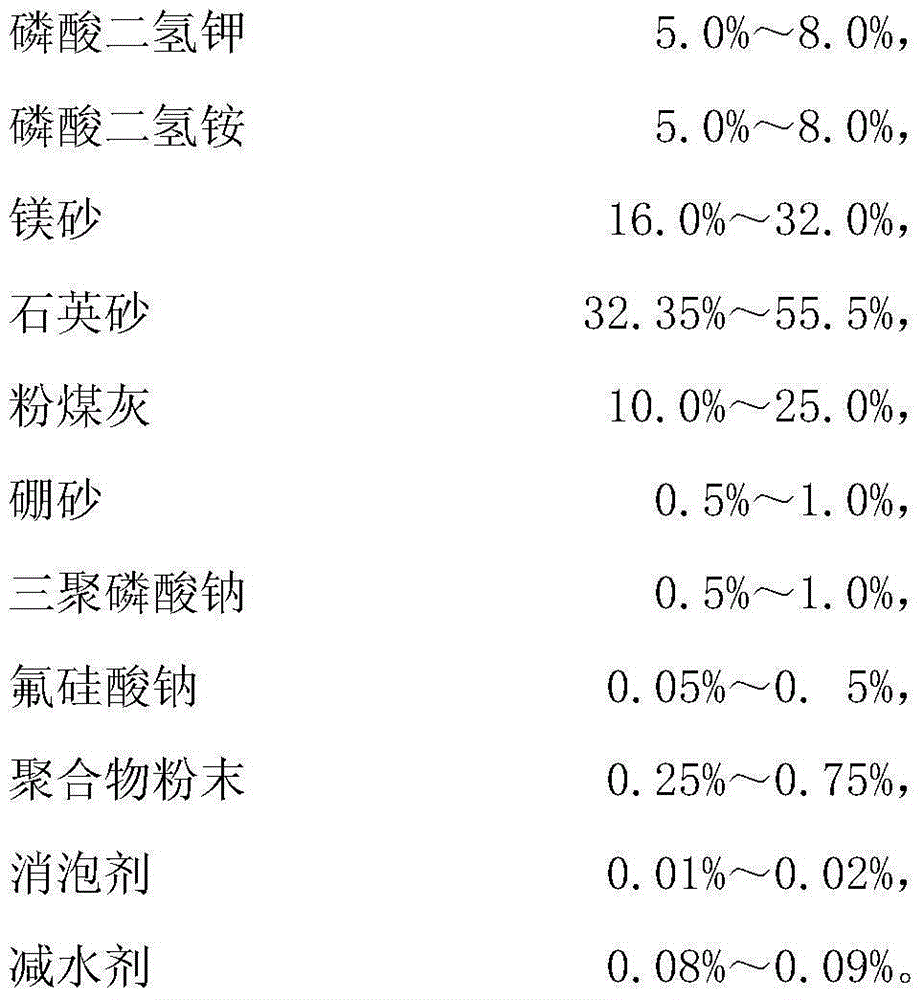

[0028] Described each component and its weight percent are:

[0029]

[0030]

[0031] The above-mentioned components are prepared according to the above-mentioned process to prepare a fast repairing material, which is mixed with water according to the following ratio to prepare mortar. The repairing material: water is 1:0.08 (mass ratio), and the measured fluidity is 240mm, and the setting time is 10 minutes. Injection repair was performed on a damaged high-speed rail slag-free track mortar layer, and samples were made for testing at the same time. The repaired road section was opened to traffic 1 hour later, and after 1 month of observation, no damage occurred in the repaired mortar-free layer.

[0032] Implementation effect: the test results of the sample produced in this embodiment are as follows: i...

Embodiment 2

[0034] This embodiment relates to the rapid repair grouting mortar and its preparation method for the mortar layer of the ballastless track of the high-speed railway:

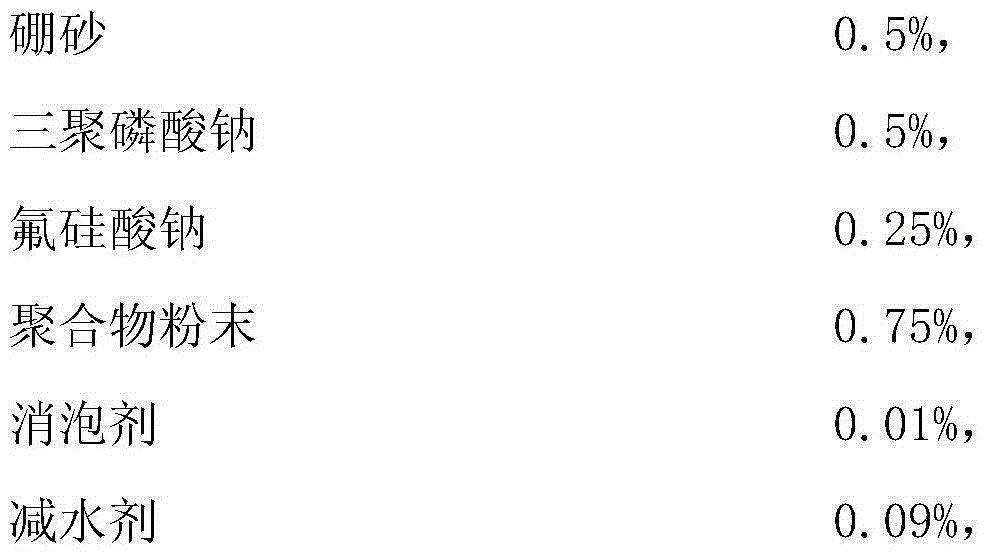

[0035] Described each component and its weight percent are:

[0036]

[0037] The above components are prepared according to the aforementioned process to prepare quick repair materials, and they are mixed with water according to the following ratio to prepare mortar. 15 minutes. Injection repair was performed on a damaged high-speed rail slag-free track mortar layer, and samples were made for testing at the same time. The repaired road section was opened to traffic 1 hour later, and after 1 month of observation, no damage occurred in the repaired mortar-free layer.

[0038] Implementation effect: the test results of the sample produced in this embodiment are as follows: it has been solidified in 15 minutes, the compressive strength after 1 hour is 30 MPa, and the compressive strength is 60 MPa after 28 da...

Embodiment 3

[0040] This embodiment relates to the rapid repair grouting mortar and its preparation method for the mortar layer of the ballastless track of the high-speed railway:

[0041] Described each component and its weight percent are:

[0042]

[0043] The above-mentioned components are prepared according to the above-mentioned process to prepare a fast repairing material, which is mixed with water according to the following ratio to prepare mortar. The repairing material: water is 1:0.10 (mass ratio), and the measured fluidity is 260mm, and the setting time is 20 minutes. Injection repair was performed on a damaged high-speed rail slag-free track mortar layer, and samples were made for testing at the same time. The repaired road section was opened to traffic 4 hours later, and after 3 months of observation, there was no damage to the repaired mortar-free layer.

[0044] Implementation effect: the test results of the sample produced in this embodiment are as follows: it has bee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com