Prefabricated downcast pipe pile in building foundation pit and use method thereof

A technology of downwater pipes and foundation pits, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of waste of resources, heavy rainfall construction workload, discarded well point pipes, etc., to reduce the impact on the environment and improve Anti-floating performance and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described in conjunction with the following examples.

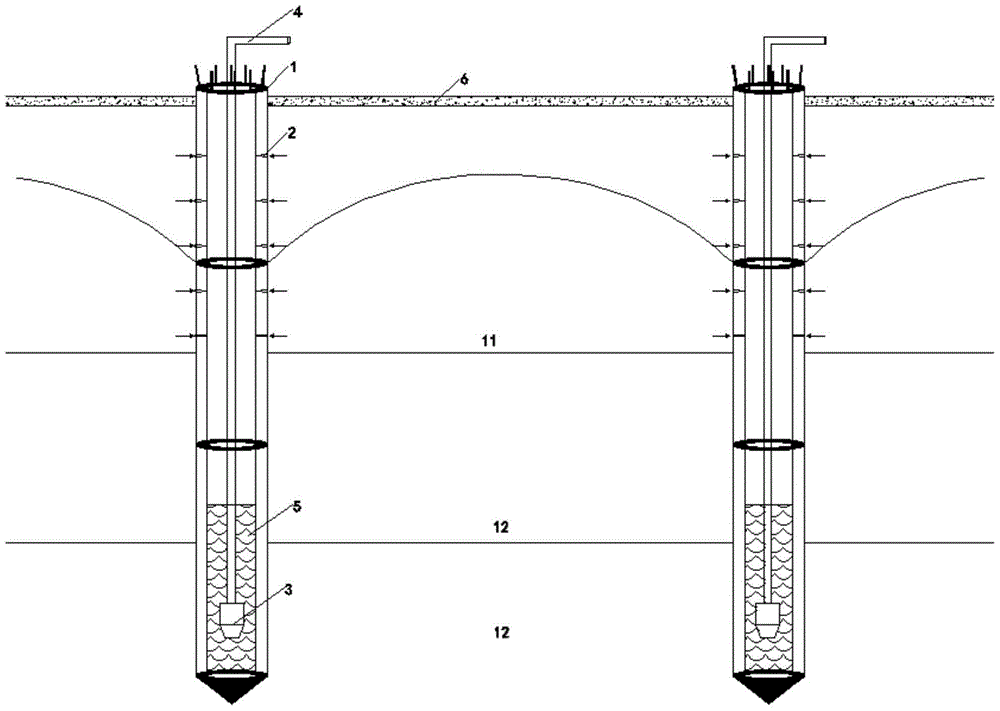

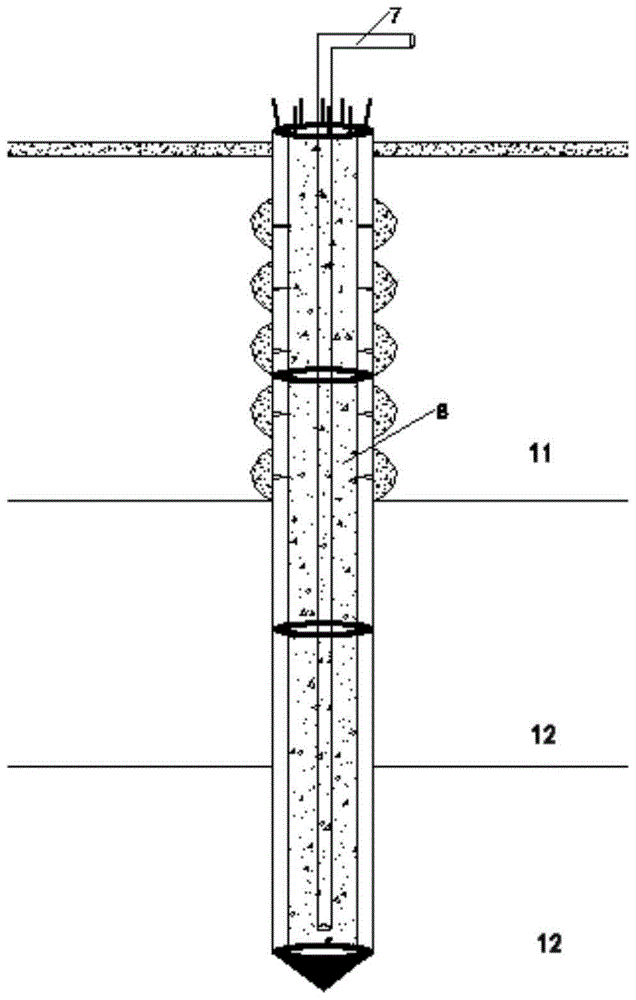

[0021] Prefabricated downwater pipe piles in building foundation pits, such as figure 1 As shown, the prefabricated downwater pipe pile 1 is hollow and cylindrical, including a pipe wall and a tapered pile tip. A plurality of permeable holes 2 are arranged at intervals on the upper part of the pipe wall. In this embodiment, the cross-section of the permeable hole 2 is trumpet-shaped, and the diameter of the cross-section gradually decreases along the direction from the outer surface to the inner surface of the pipe wall. The outer diameter of the permeable hole 2 is 20 mm, and the inner diameter is 8 mm. , to facilitate the rapid discharge of groundwater 5 into the prefabricated downfall pipe pile 1.

[0022] The general soil layer is divided into a permeable layer 11 and an impermeable layer 12. The groundwater 5 is mainly concentrated in the aquifer layer 11. After the prefabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com