Push sliding type disk lock support heavy lining trolley and method for constructing lining form

A technology for lining trolleys and buckles, which is applied in wellbore lining, tunnel lining, earth-moving drilling and mining, etc., can solve the problems of time-consuming and laborious processing and manufacturing cost, high installation difficulty and high cost, and achieves the goal of eliminating joints and improving pouring quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

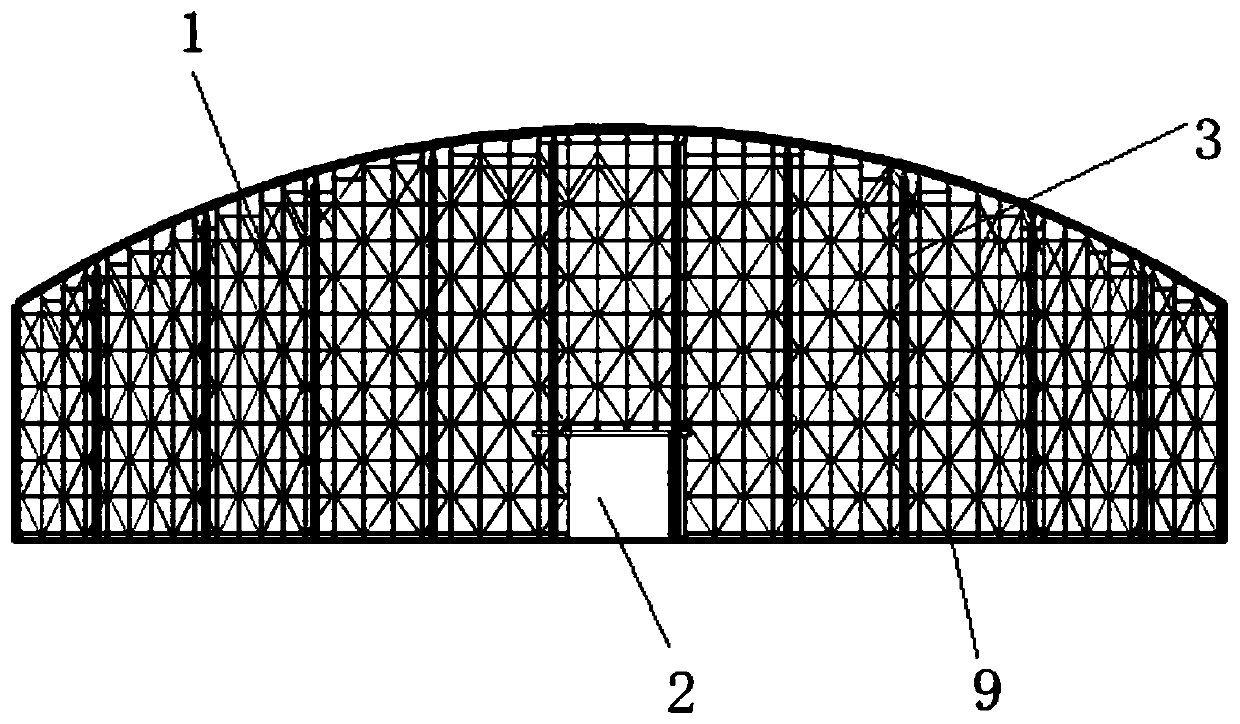

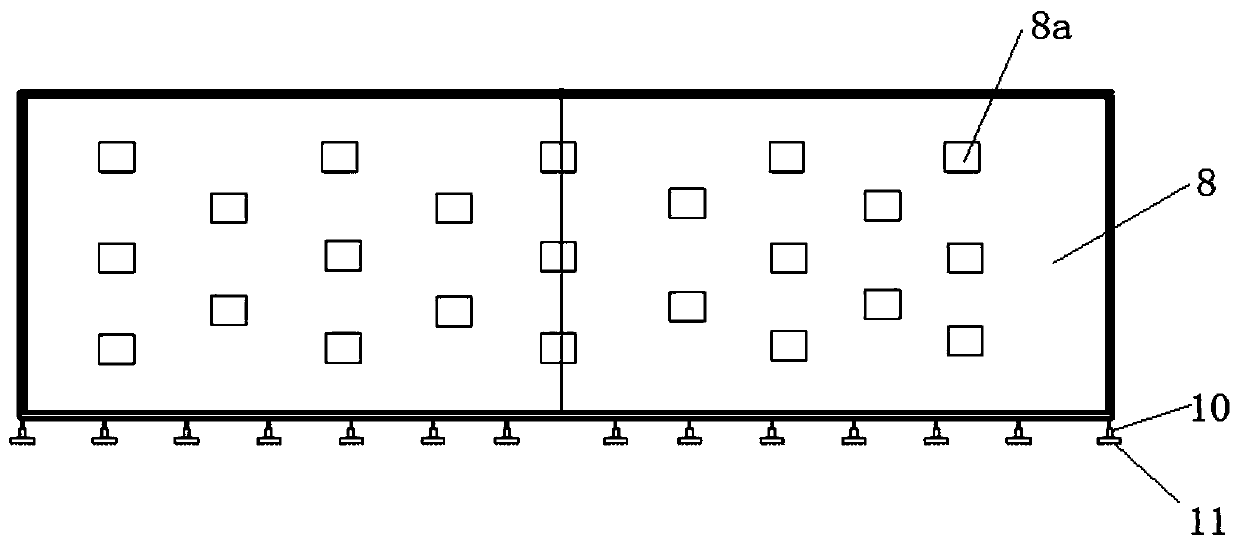

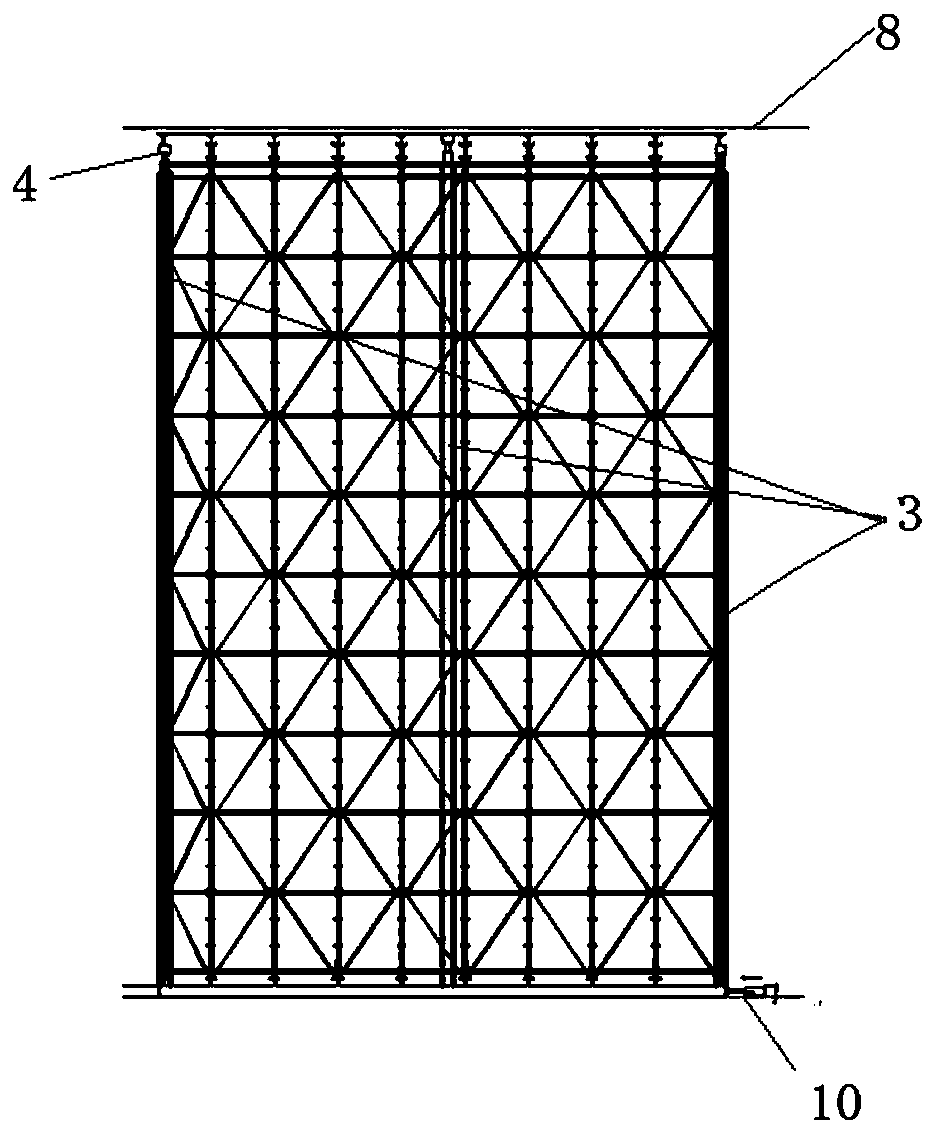

[0033] combine figure 1 — Figure 5 As shown in the figure, a heavy-duty lining trolley with a push-and-sliding disc buckle bracket is mainly composed of a lining formwork system, a pan buckle-type full hall support 1, a column 3, a screw jack 4, a longitudinal beam 5, and a chassis 9 of the trolley.

[0034] The buckle-type full hall support 1 has an adjustable top support 1a and an adjustable base 1b. The adjustable base 1b is used for the leveling of the buckle-type full hall support 1 itself, so as to ensure that the heavy-duty lining trolley will not tilt due to the unevenness of the tunnel floor.

[0035] A car door opening 2 is arranged in the bracket 1 of the buckle type full hall. When the lining trolley is constructed, the car door opening 2 is used as a logistics channel, which does not affect the normal construction in other places.

[0036...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com