Working method of triangular drawing machine with cleaning function and used for stator punching machining

A stator punching and working method technology, applied in metal processing equipment, manufacturing stator/rotor body, manufacturing tools, etc., can solve the problem that wire drawing accuracy and wire drawing efficiency cannot be guaranteed at the same time, and it is difficult to process workpieces wider than abrasive belts, Harm the life and health of staff and other problems, achieve good cooling effect, improve wire drawing efficiency, and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

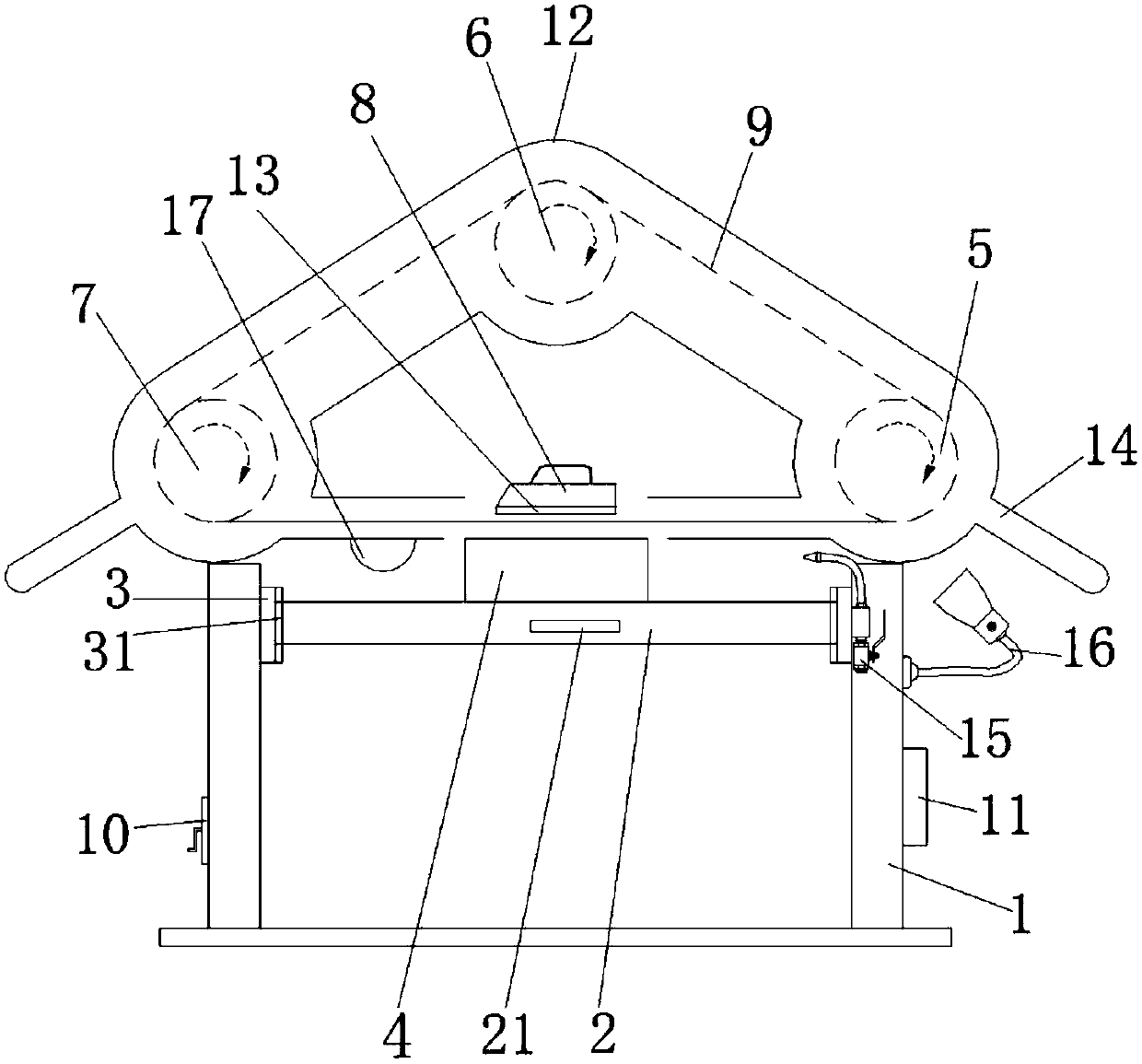

[0033] Such as figure 1 As shown, a working method of a triangular wire drawing machine with a cleaning function for stator punching processing in this embodiment, the specific working steps are as follows:

[0034] (1), first place the workpiece 4 in the middle of the workbench 2;

[0035](2) Start the power supply, and the staff sets the corresponding drum speed on the control panel 11 according to the material and size of the workpiece 4, and turns on the motor;

[0036] (3), the first drum 5, the second drum 6 and the third drum 7 drive the sandpaper belt 9 to run under the drive of the motor;

[0037] (4) The staff manually adjusts the height of the workbench 2 to an appropriate position by manually turning the handle 10, or electrically adjusting the height of the workbench 2 through the control panel 11;

[0038] (5) The staff performs wire drawing on the surface of the workpiece 4 by pressing the hand plate 8 .

[0039] When working, the buffer pad 13 provided at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com