Rotary folding type hydraulic channeling machine

A kind of rolling groove machine and folding technology, applied in the field of hydraulic rolling groove machine, can solve the problems of low work efficiency, large difference in pipe size, and inability to adjust the height and height, so as to achieve the effect of labor saving, convenience and ease, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

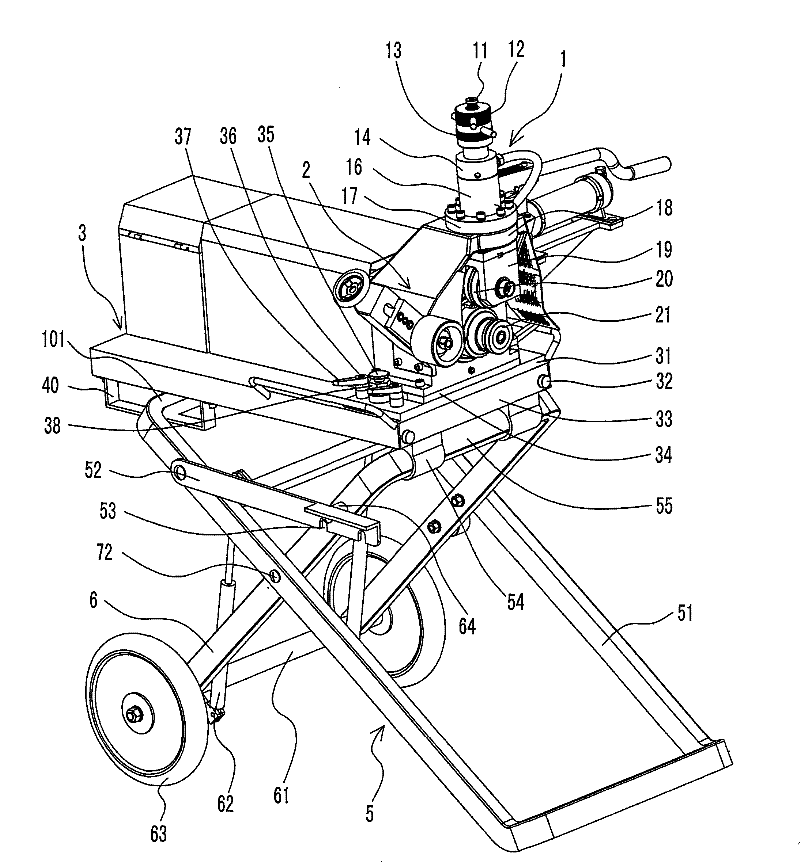

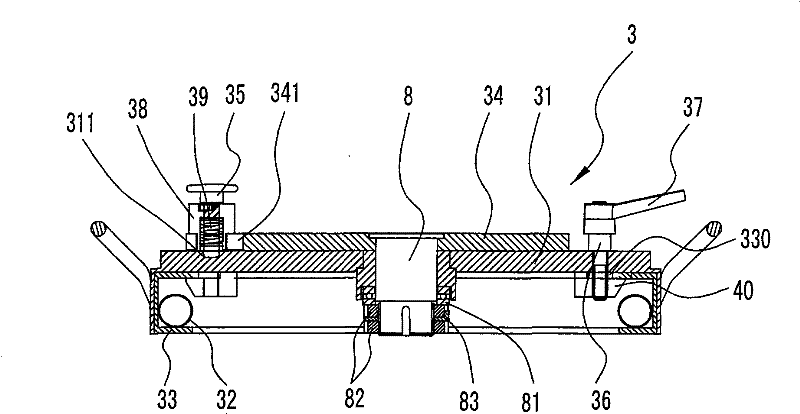

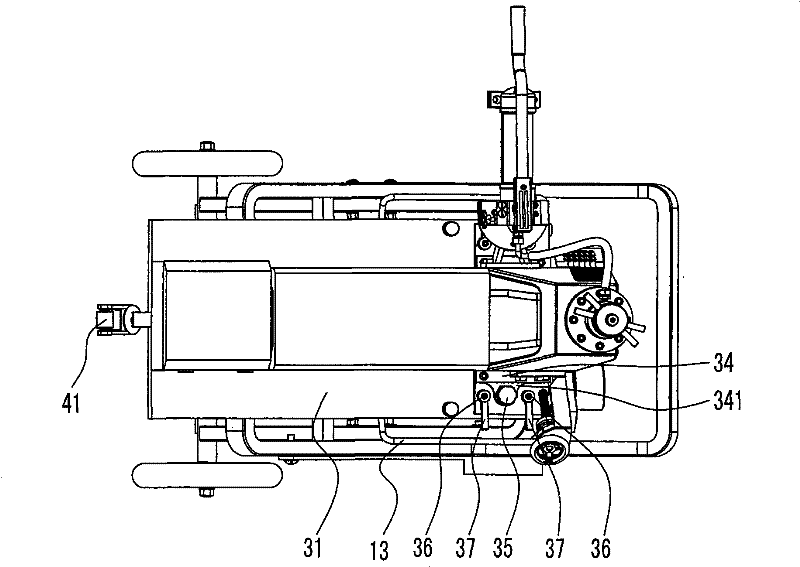

[0013] The invention relates to a rotating and folding hydraulic grooving machine, such as Figure 1-Figure 6As shown, it includes a main body and a frame. The main body includes a power head 2 and a rolling mechanism 1. The power head includes a main shaft driven by power, and the main shaft drives a knurled shaft 21. The rolling mechanism 1 described above comprises an oil cylinder body 16, the oil cylinder body is connected with an oil cylinder cover 14 and a bottom plate 17 of the oil cylinder, a piston 15 and a piston rod 11 are installed in the oil cylinder body, the lower end of the piston rod is connected with a movable block 18, and the movable block is connected with a pressure wheel Frame 19, the pressure roller 20 is installed in the pressure wheel frame, the main body is installed on the flat panel assembly 3, and the flat panel assembly 3 is connected to the frame 5. It is characterized in that there is a rotating device in the flat panel assembly 3, and the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com