Patents

Literature

105 results about "Framing (construction)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Framing, in construction, is the fitting together of pieces to give a structure support and shape. Framing materials are usually wood, engineered wood, or structural steel. The alternative to framed construction is generally called mass wall construction, where horizontal layers of stacked materials such as log building, masonry, rammed earth, adobe, etc. are used without framing.

Connectors and Methods of Construction for a Precast Special Concrete Moment Resisting Shear Wall and Precast Special Concrete Moment Resisting Frame Building Panel System

InactiveUS20080098676A1Saving environment protectionThermally efficientMoulding surfacesBuilding roofsComposite constructionInternational Building Code

A precast concrete wall panel molding system for fabricating a wall shell and a plurality of ribs and beams. A precast concrete wall panel molding system with facilities for incorporating door and window frames. A ductile panel end connector for attaching panels one to another whether in parallel or angled as in inside or outside corners. A ductile panel end connector for attaching panels to columns. A wall anchor / shear plate with post-tensioning brace plate. A hybrid precast / cast-in-place special moment resisting shear wall / special moment resisting frame reinforced concrete building system for regions of potential seismic activity. A prescriptive method building system for composite structural building assemblies with conventional wood and light-gauge steel framing, structural steel, and other building code approved and tested building systems, building components, building panel systems, building roofing systems, modular and manufactured buildings, and building electrical, mechanical, and plumbing systems. A precast concrete wall panel system conforming to industry practices and standards as published by the Precast / Prestressed Concrete Institute, (PCI) in it's “PCI Design Handbook” (fifth edition, 1999), the American Concrete Institute “Building Code Requirements for Structural Concrete” (ACI 318-05), The “International Building Code 2006” and the “Uniform Building Code”.

Owner:HUTCHENS JOHN FRANCIS

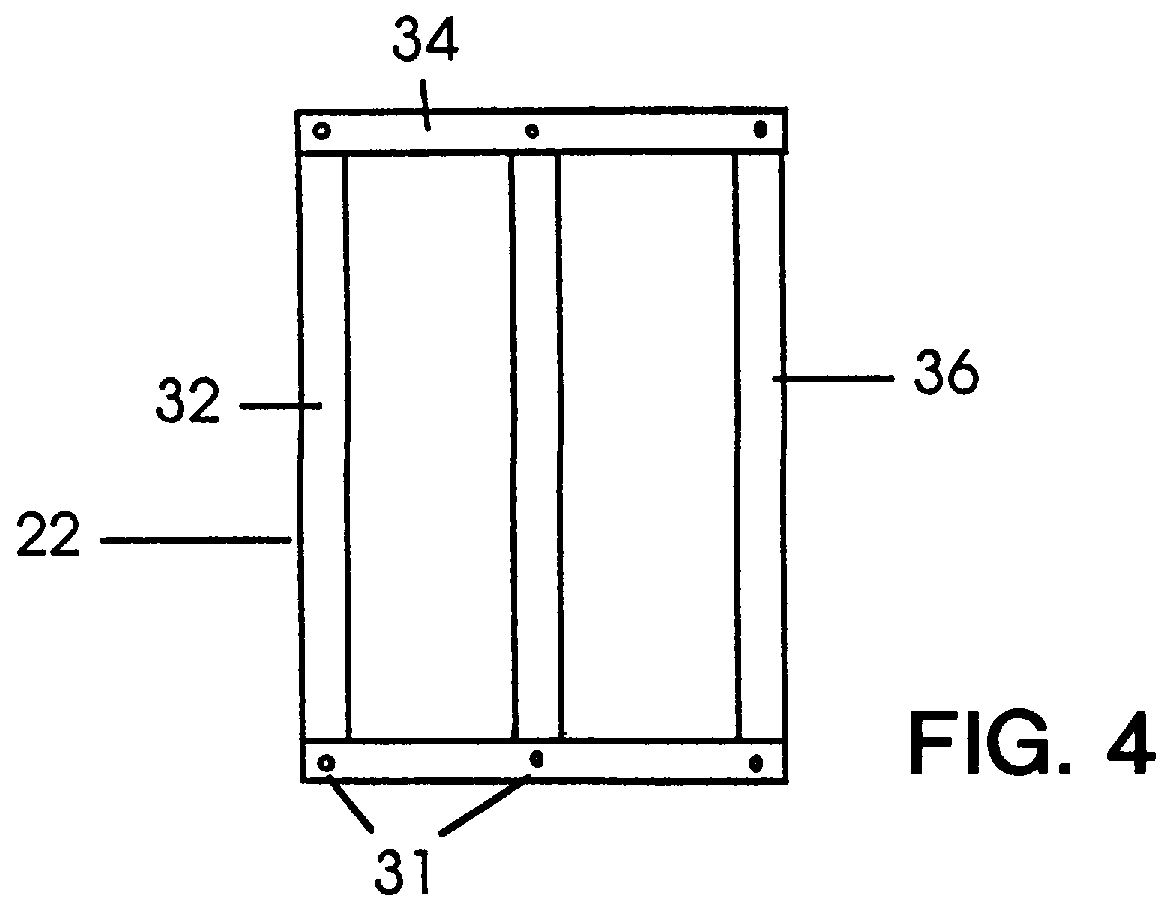

Construction system using interlocking panels

InactiveUS20120247038A1Avoid utilizationConstruction materialWallsConstruction engineeringPolystyrene

A system for constructing a structure, such as a wall, by assembling a plurality of interlocking panels together, is provided. Each of the panels includes a core made of an insulating material, preferably, an expanded polystyrene (EPS). Importantly, the panels include stiffeners (studs) on the outer surfaces; each spaced, preferably, about 24 inches on center (OC), to form a rigid exoskeleton. Unlike in conventional wood framing, the studs do not extend from the exterior surface to the interior surface. Instead, the studs are each structured as C-shaped supports wherein each stud is inserted into a grove pair cut into the core. Accordingly, conduction across the studs from the exterior to the interior, and vice versa, does not occur because the studs do not extend through the panels.

Owner:SYNTHEON

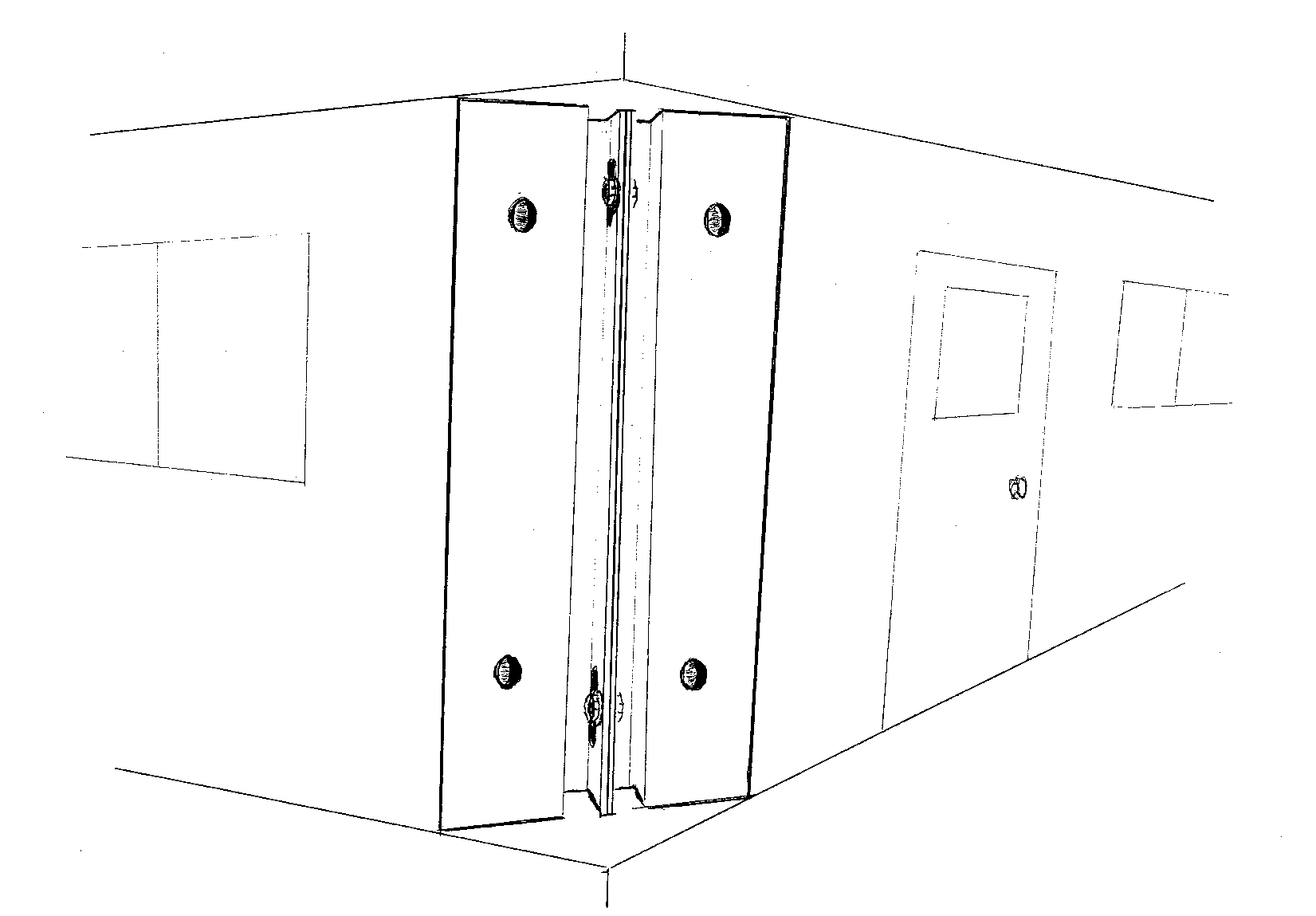

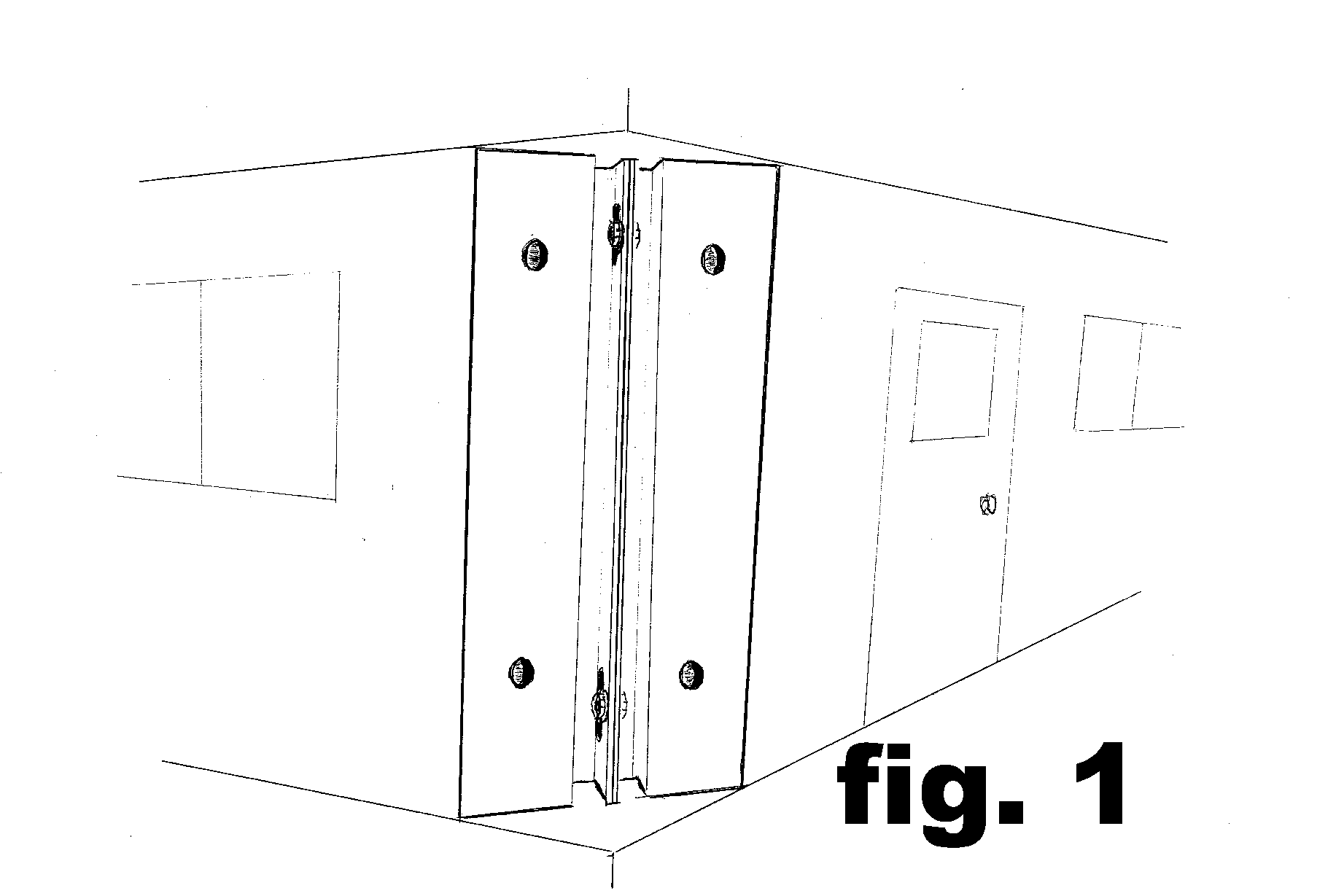

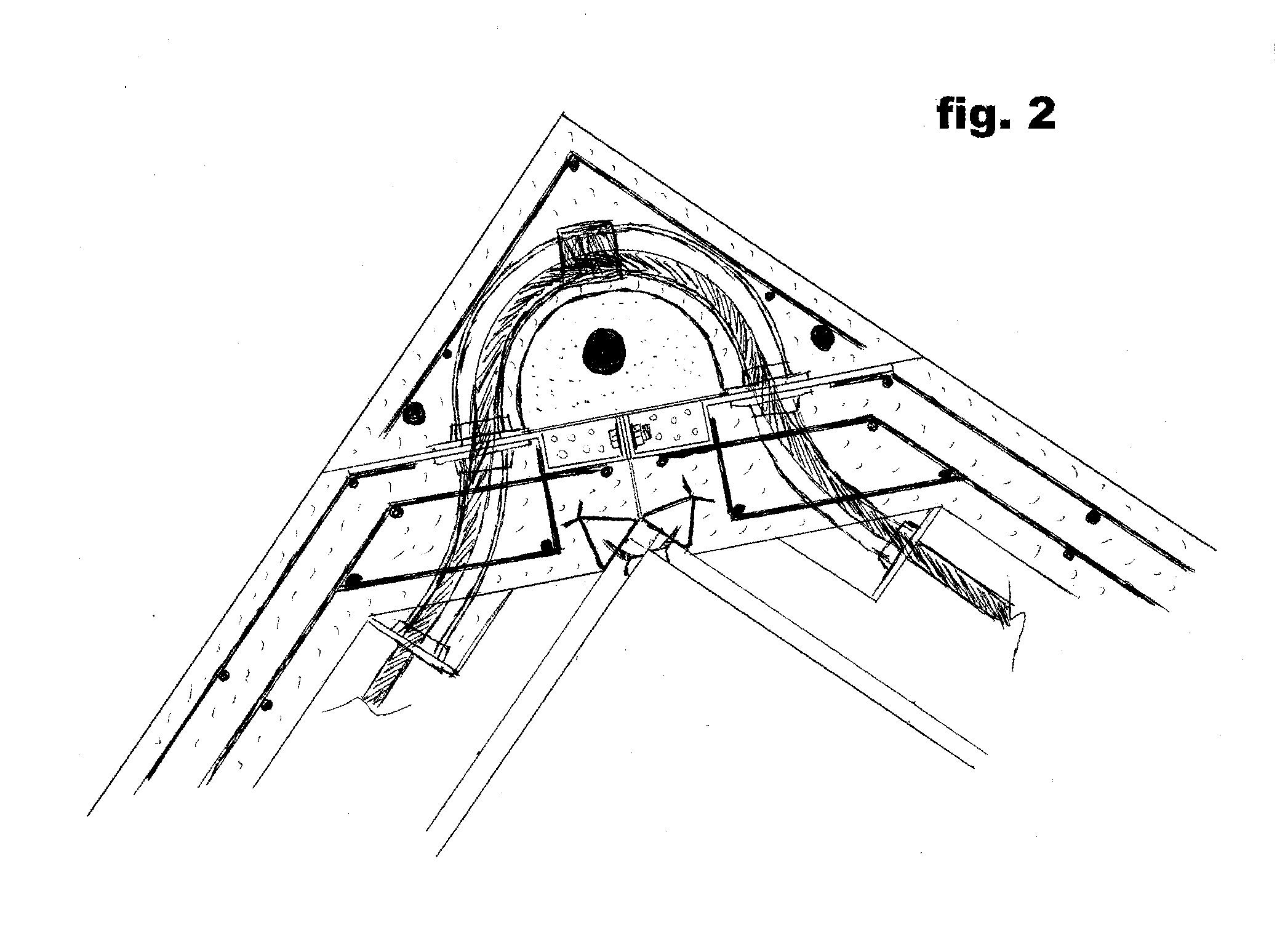

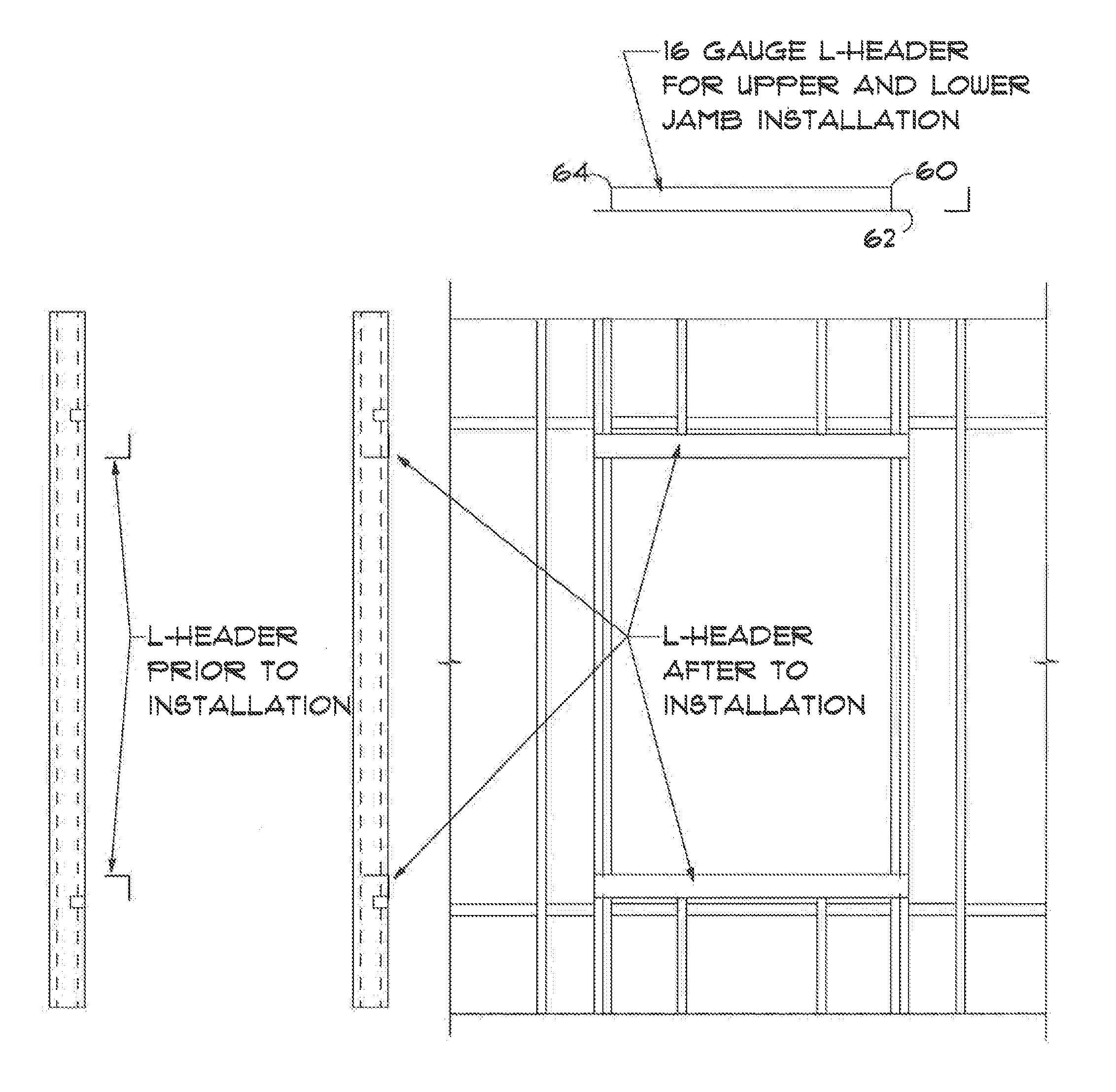

Framing system for building construction

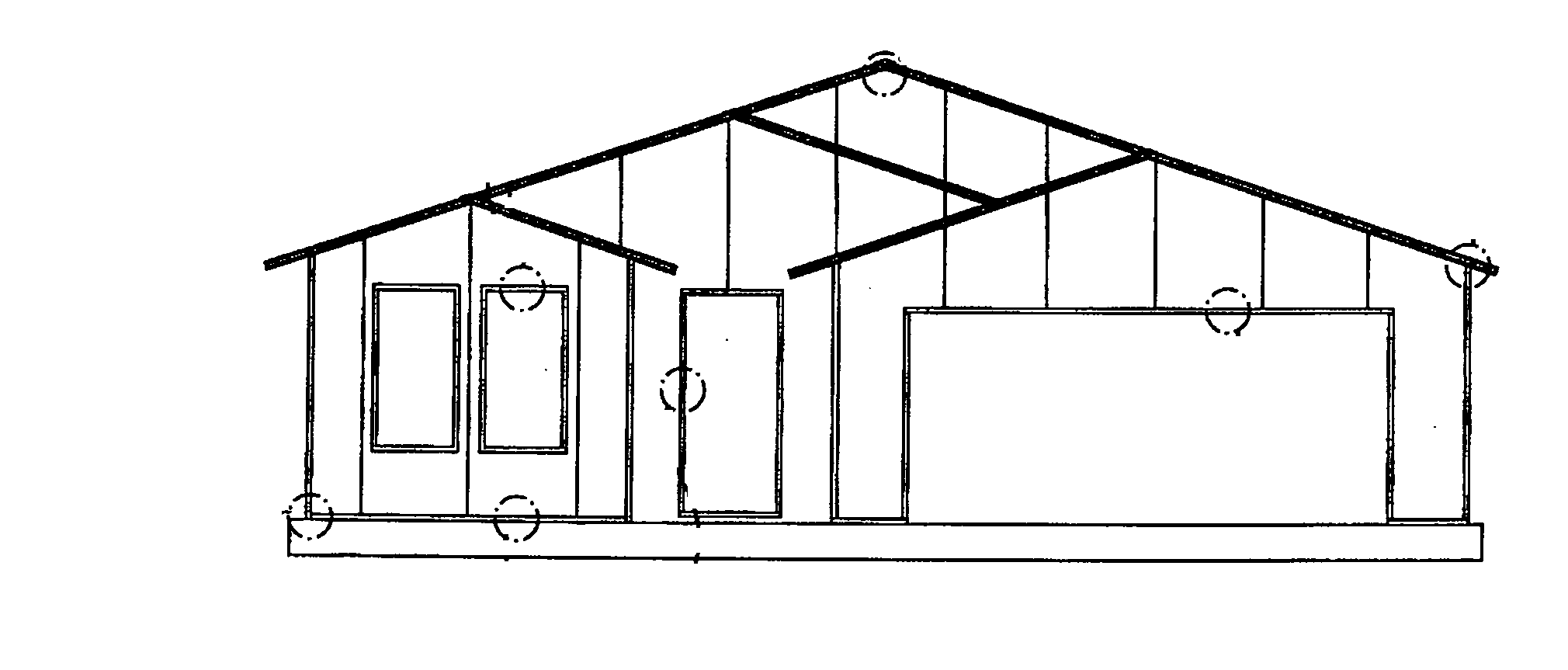

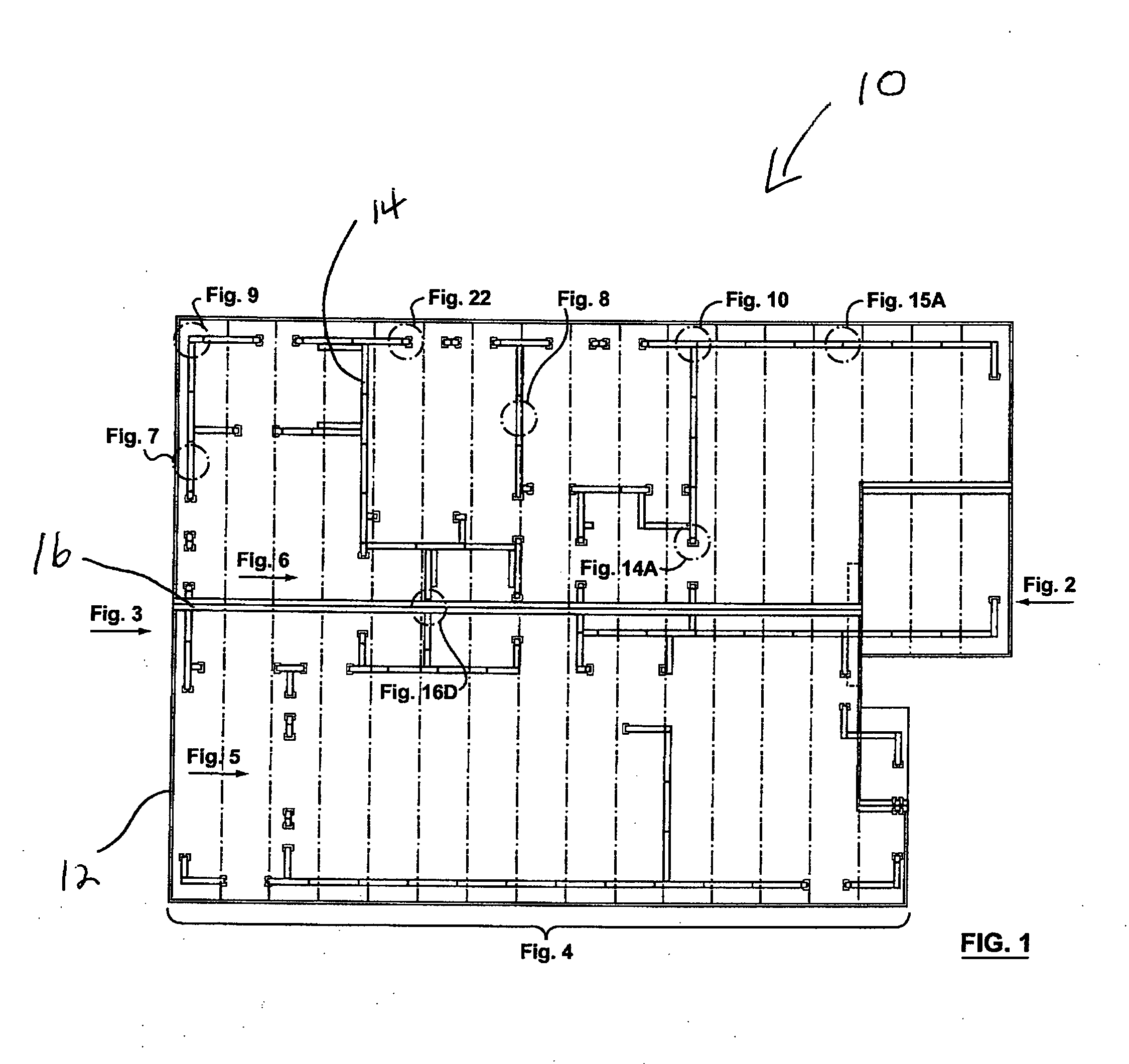

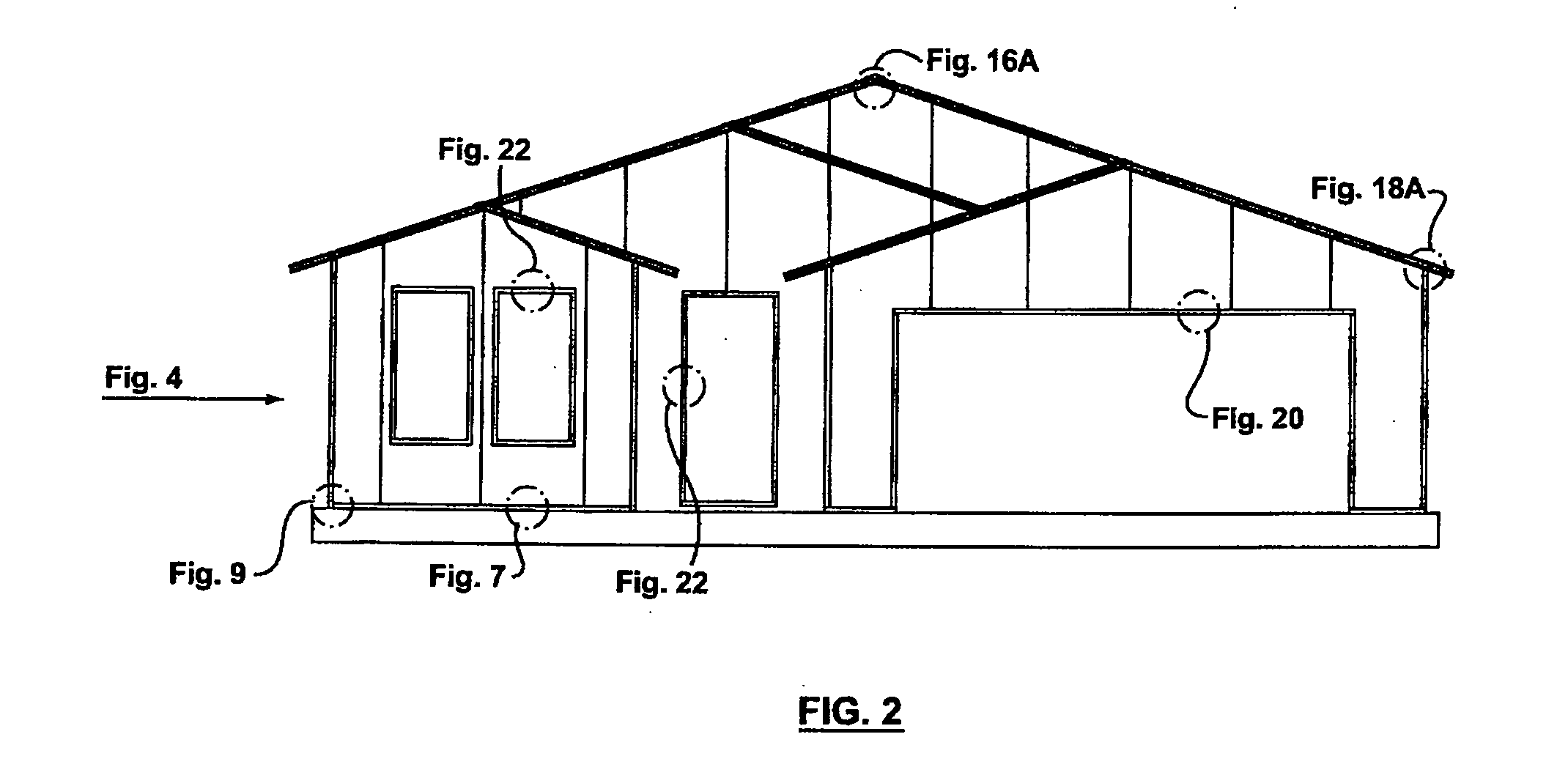

A system for framing houses or other buildings which uses pre fabricated steel framing and which is quick and easy to construct. A prefabricated system is provided for framing complete building, on a foundation. Folding telescopic framing units are used for vertical partitions and horizontal floor panels. A prefabricated system of framing units is provided for constructing a building comprising: a) providing a foundation; b) securing vertical beams having open upper ends to the foundation at spaced locations; c) securing horizontal beams between the upper ends of the vertical beams; d) erecting and securing folding, telescopic floor joists on the foundation; and e) erecting and securing folding, telescopic roof trusts at spaced locations on the horizontal beams. Also provided is a framed building comprising: a) a foundation; b) vertical beams having open upper ends secured to the foundation at spaced locations; c) horizontal beams secured between the upper ends of the vertical beams; d) erected folding, telescopic floor joists secured on the foundation; and e) erected folding, telescopic roof trusts secured at spaced locations on the horizontal beams.

Owner:CAMPBELL RONALD W

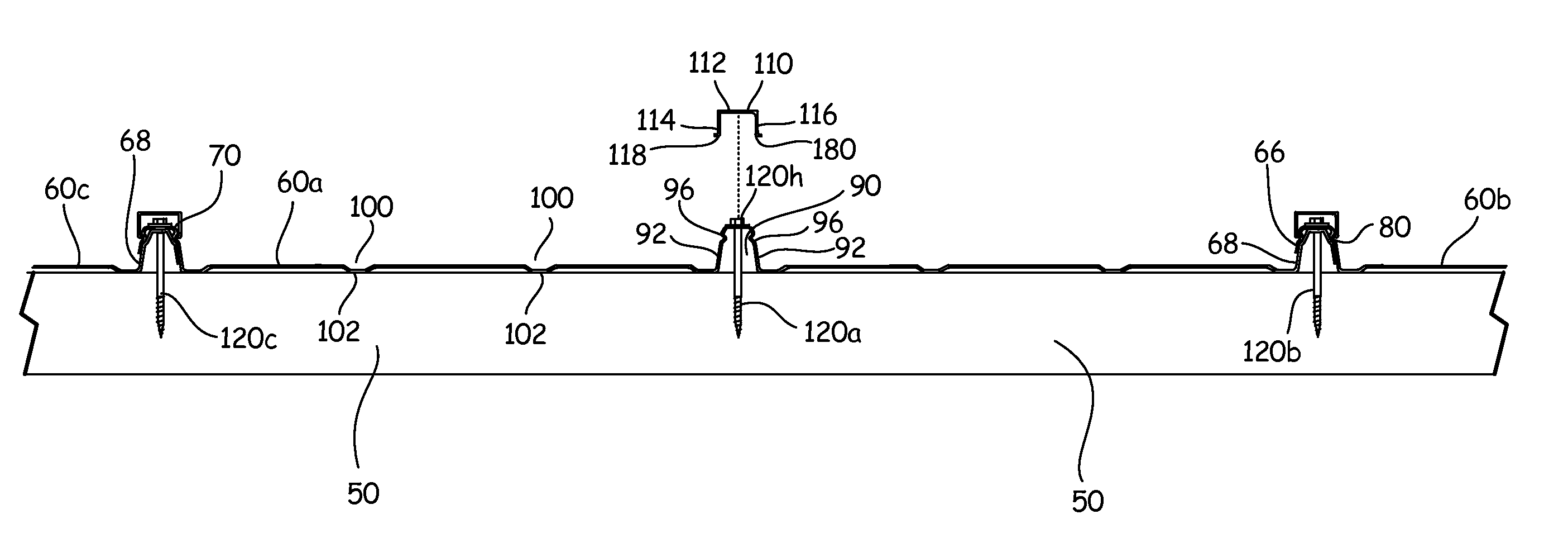

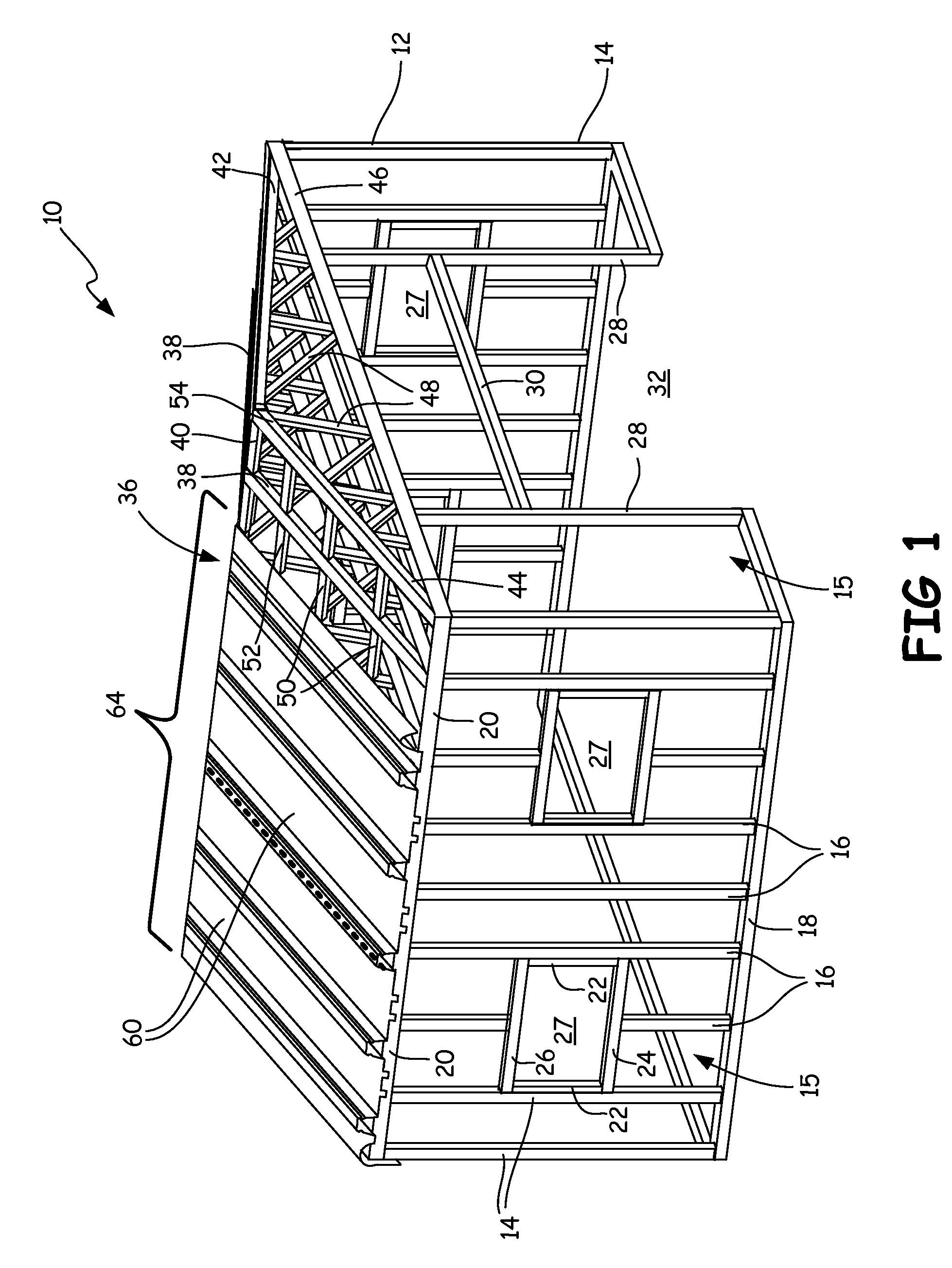

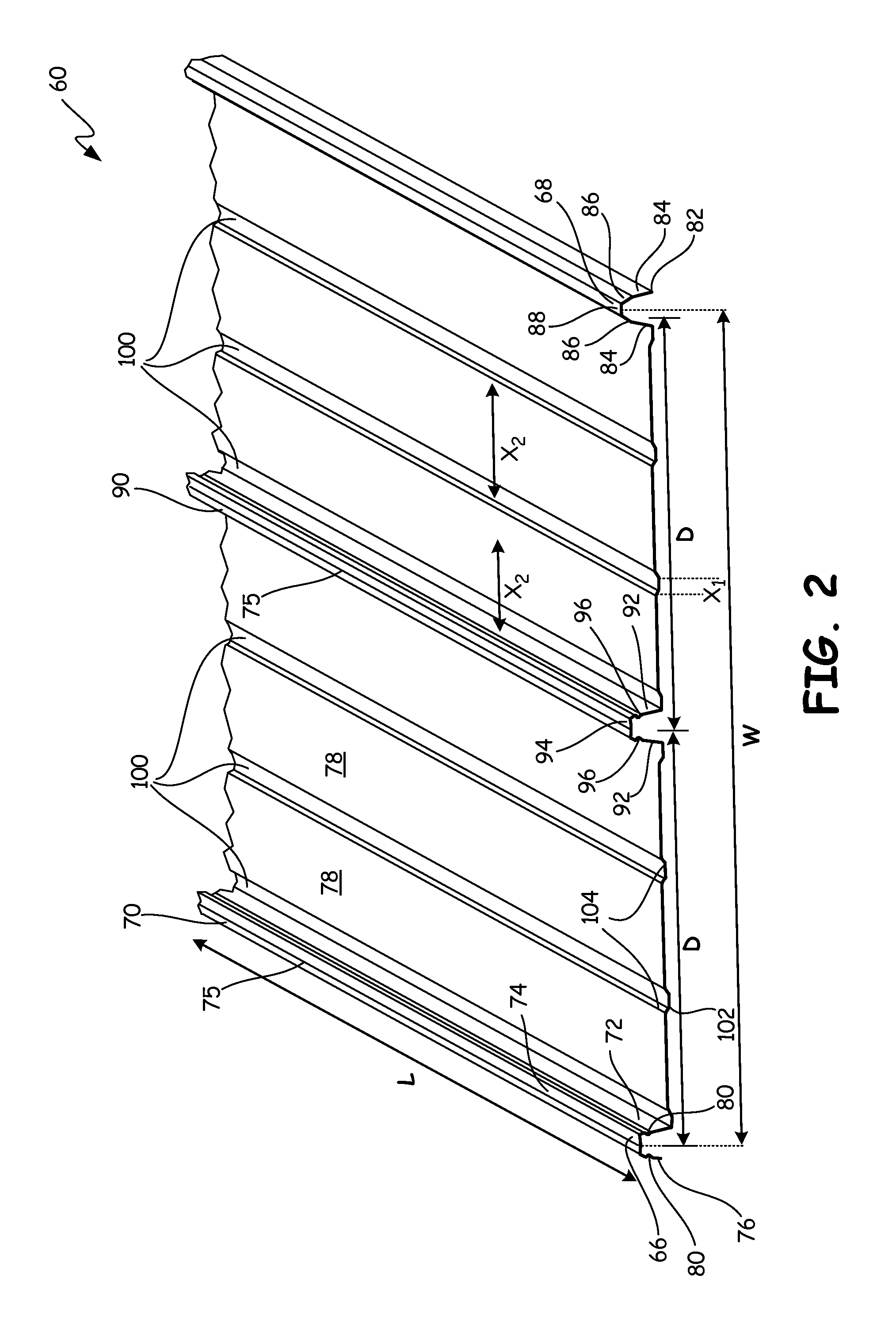

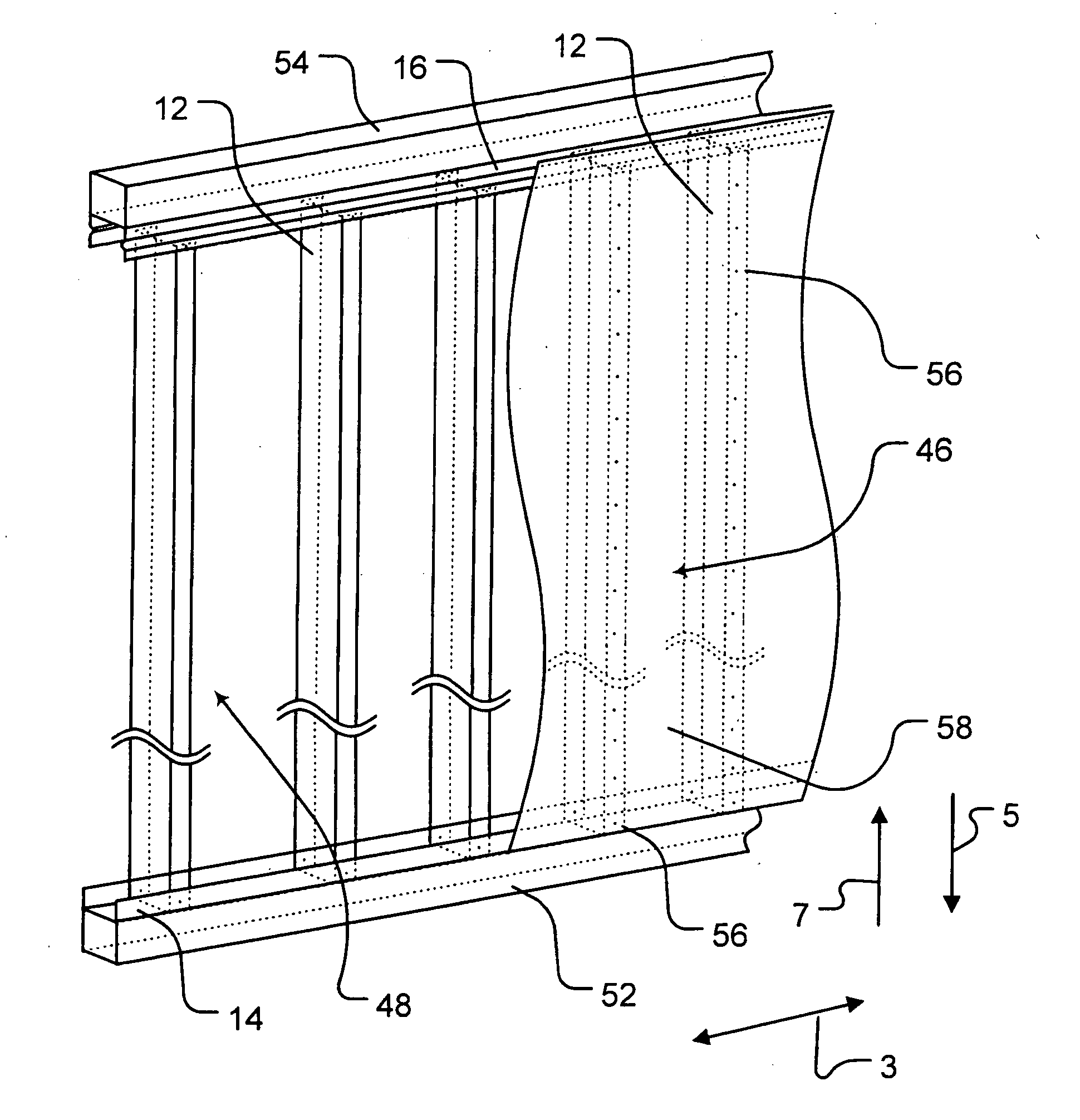

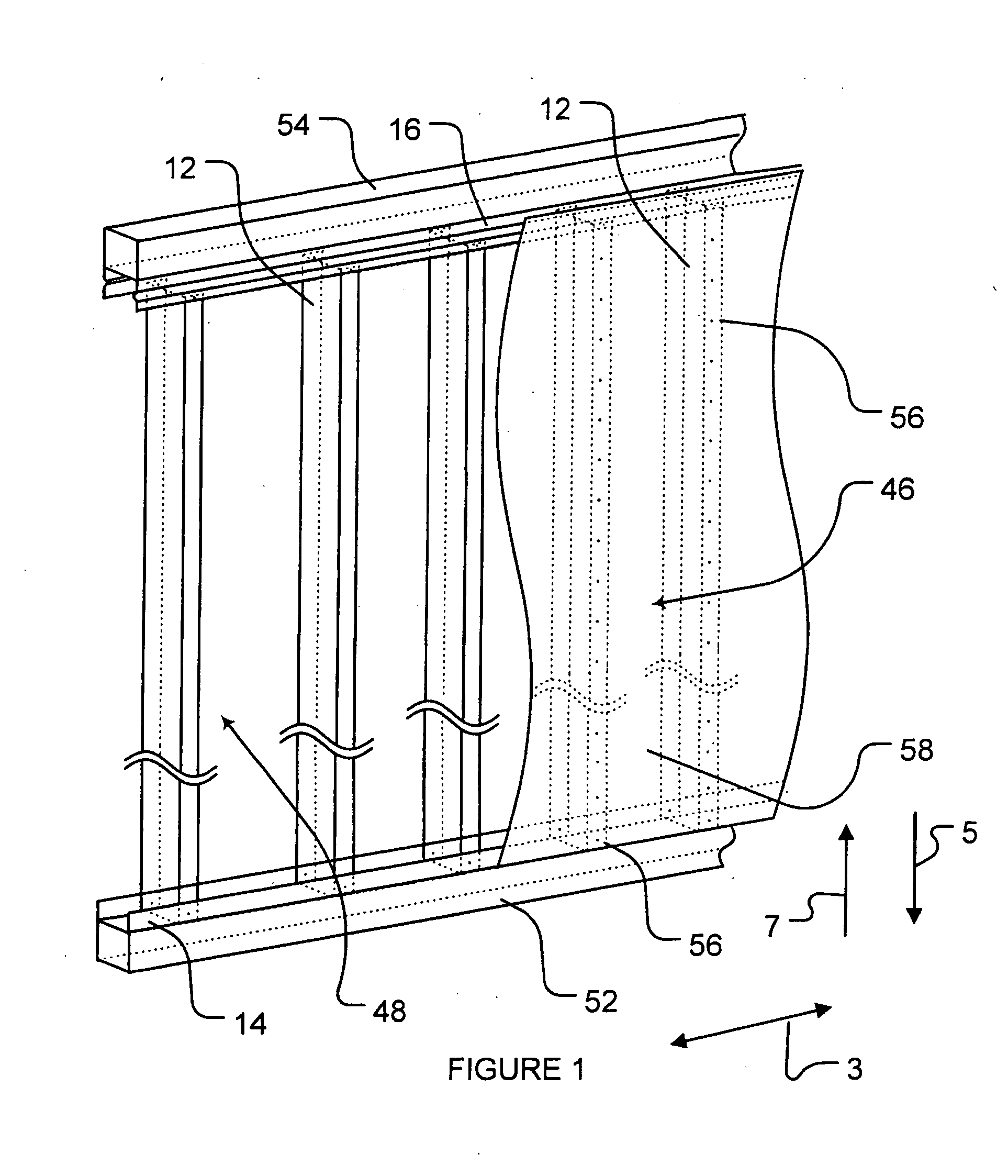

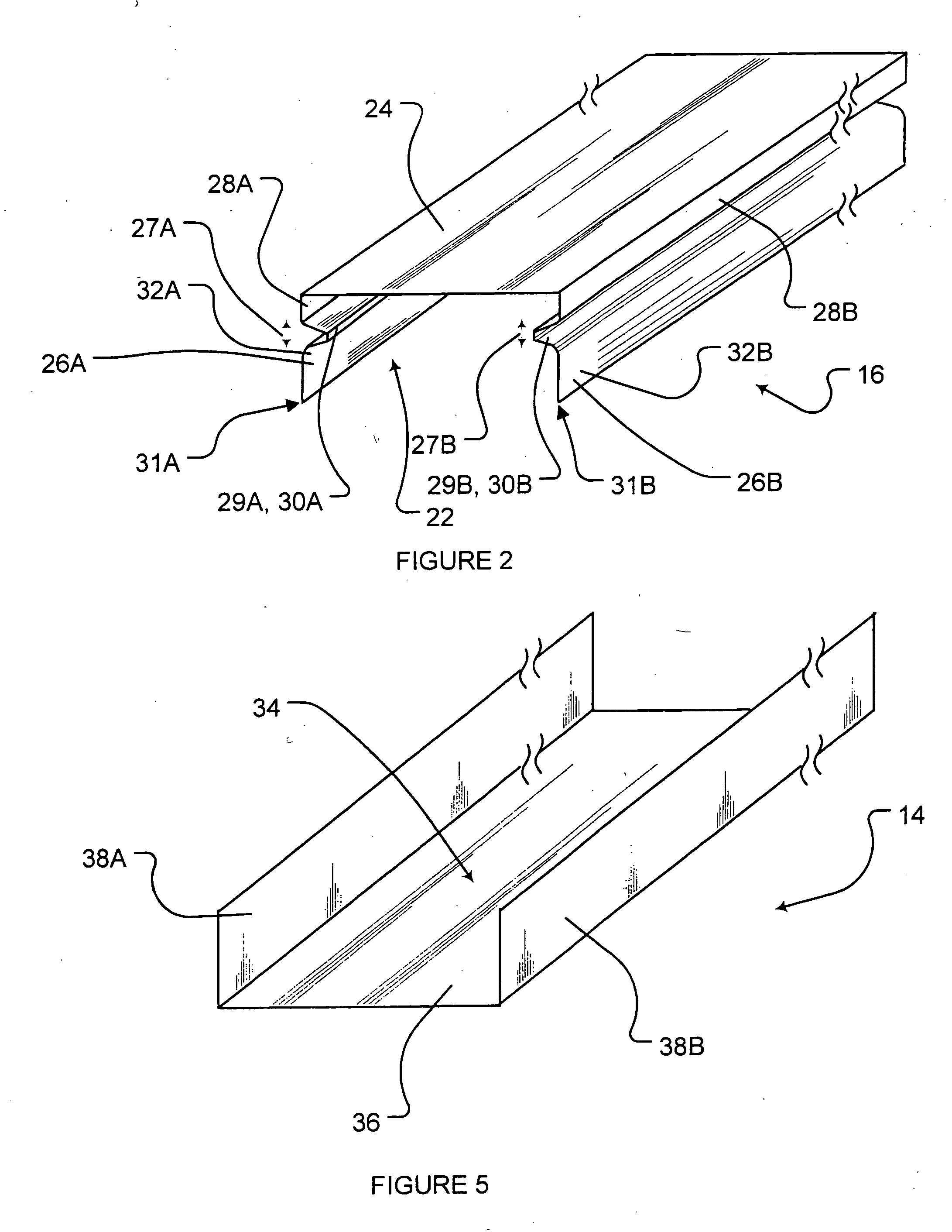

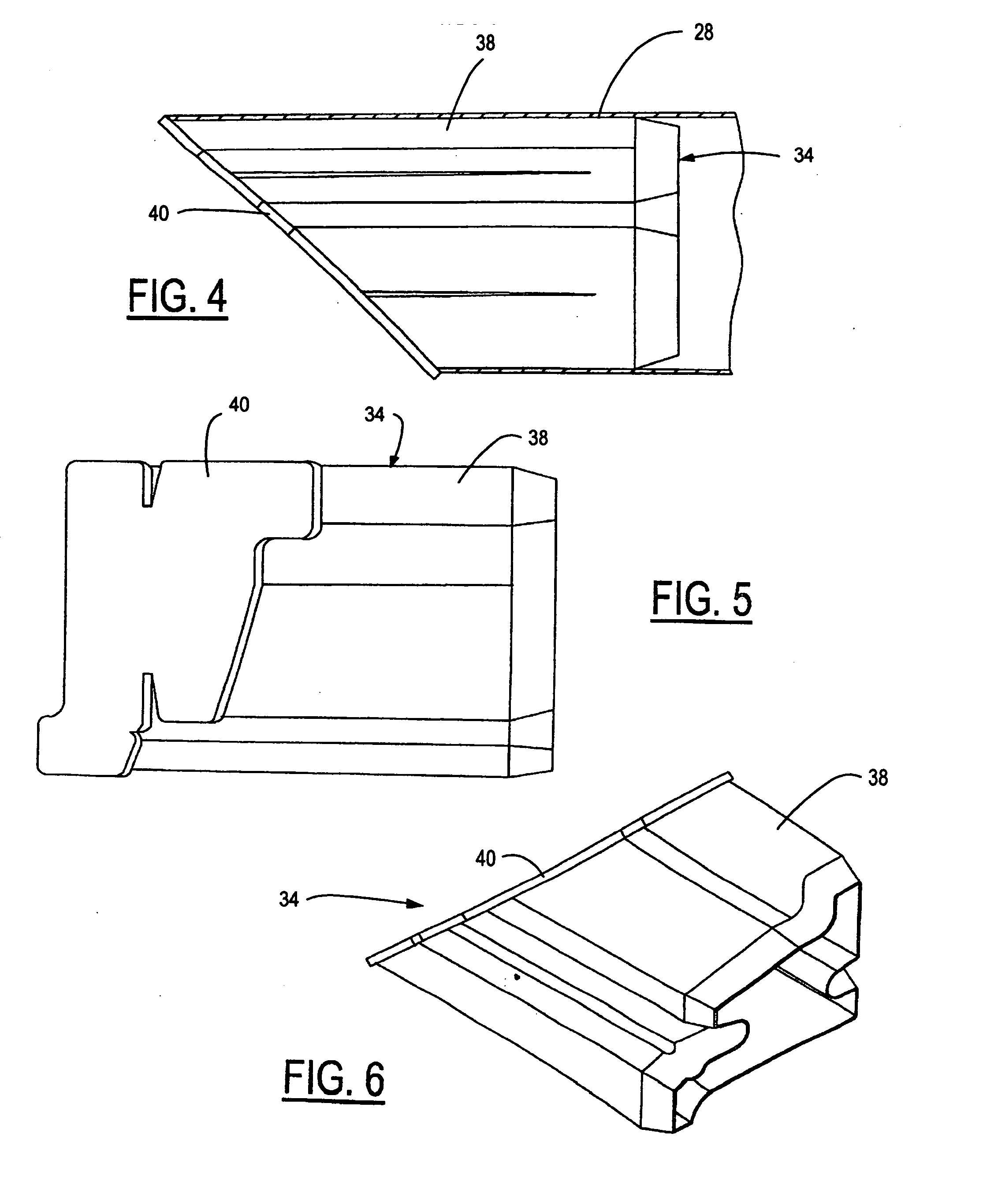

Concealed-fastener exterior cladding panels for building construction

ActiveUS9127451B1Improves Structural IntegrityLow costRoof covering using slabs/sheetsConstruction materialEngineeringInverted u

An exterior cladding panel assembly for covering an outside surface of a framed building is provided by the invention. A unique rib and batten system with overlapping raised female and male edge ribs on the adjacent installed panels, and raised interior ribs allow through fastening of the panels on the order of 32 inches or wider to the building's underlying framing structure with complete concealment of the fasteners, and without the need for special fastener clips. The ribs have an inverted U-shaped end profile that creates an open cavity between the rib top wall and the underlying framing member. The fastener can be driven through the rib top walls into the framing member without the need for a solid filler cleating strip.

Owner:LESTER BUILDING SYST

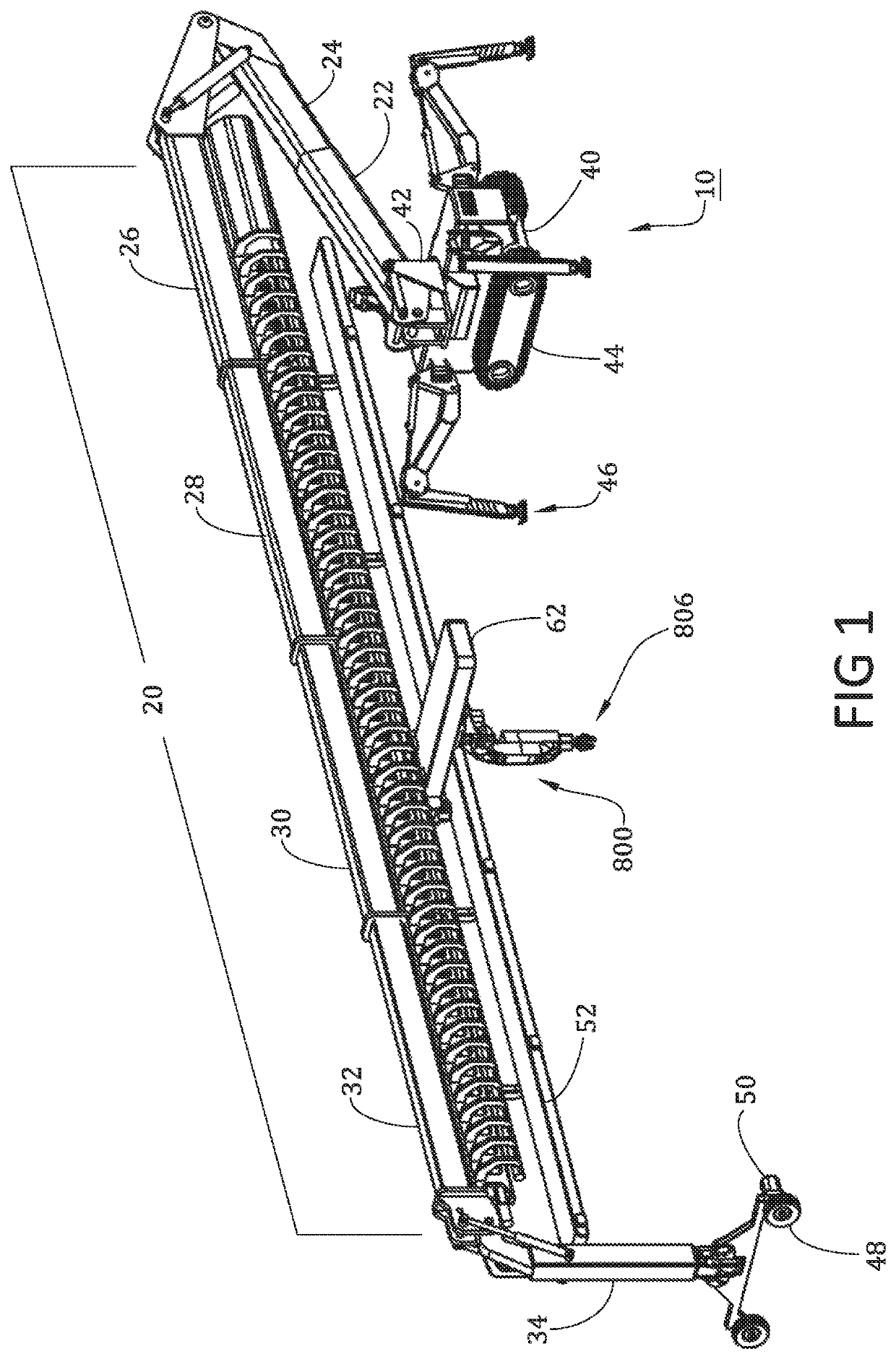

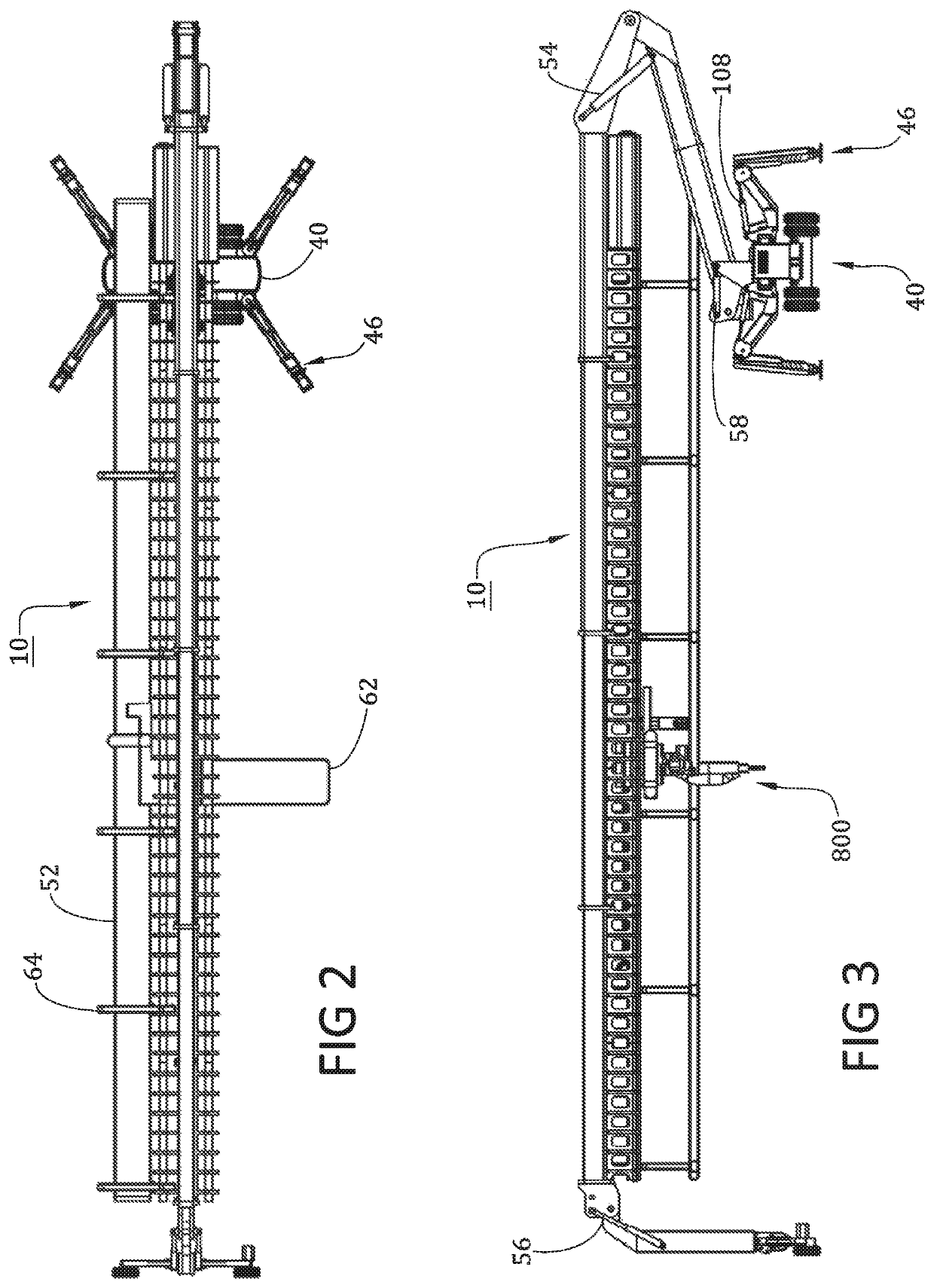

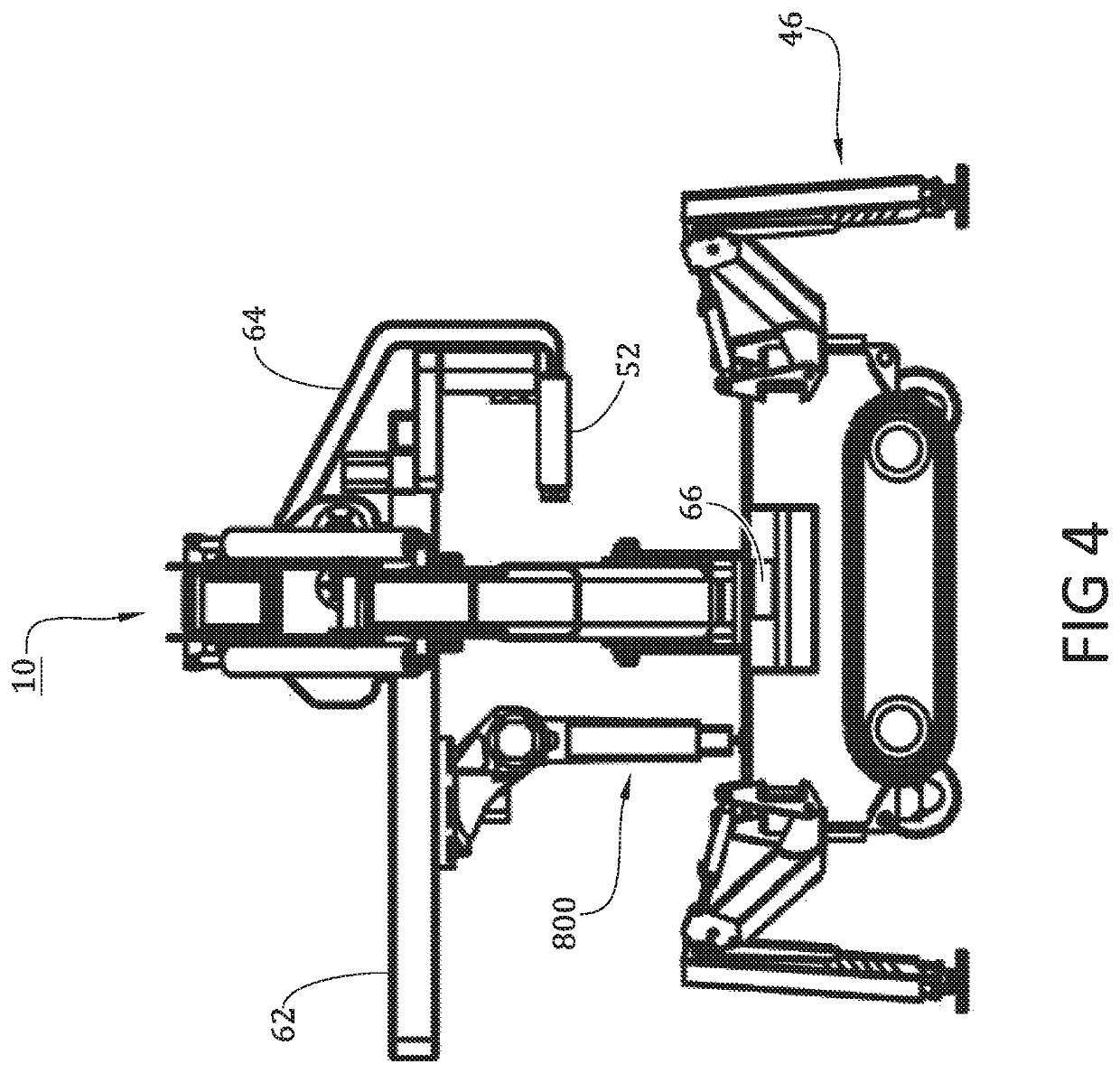

Portable robotic construction system

A robotic system having a movable gantry robot (10) for conducting construction operations. The gantry may have an expandable bridge (20) and articulated gantry support legs (34) as well as a support track system (60) holding a gantry robot (800) which may hold one or more implements and peripheral devices (806). The device can be moved by propulsion mechanisms, a controller, and one or more geo-positioned control devices to provide position information for the robotic gantry as it moves back and forth along a plurality of work sites (700). The robotic gantry is connected to a power supply system (236). The controller is automated, self-navigating, and activates, deactivates, and / or changes the operation of the propulsion mechanisms, and deploys, retracts, activates, deactivates, and / or changes the operation of one or more of the construction implements. The height of the frame may be adjusted by extending and rotating risers and booms to accommodate different building heights or sub-level heights at a worksite. A conveyor system is optimized for removing dirt from or delivering material to the robotic arm. This invention can be applied to automating construction jobs including surveying, land preparation, excavation, foundation, masonry, framing, and additive fabrication.

Owner:PEARSON JR KENT DOUGLAS

Wall construction method using injected urethane foam between the wall and autoclaved concrete (AAC) blocks

InactiveUS20150240483A1Limit waterLimit vapor infiltrationWallsHeat proofingArchitectural engineeringFraming (construction)

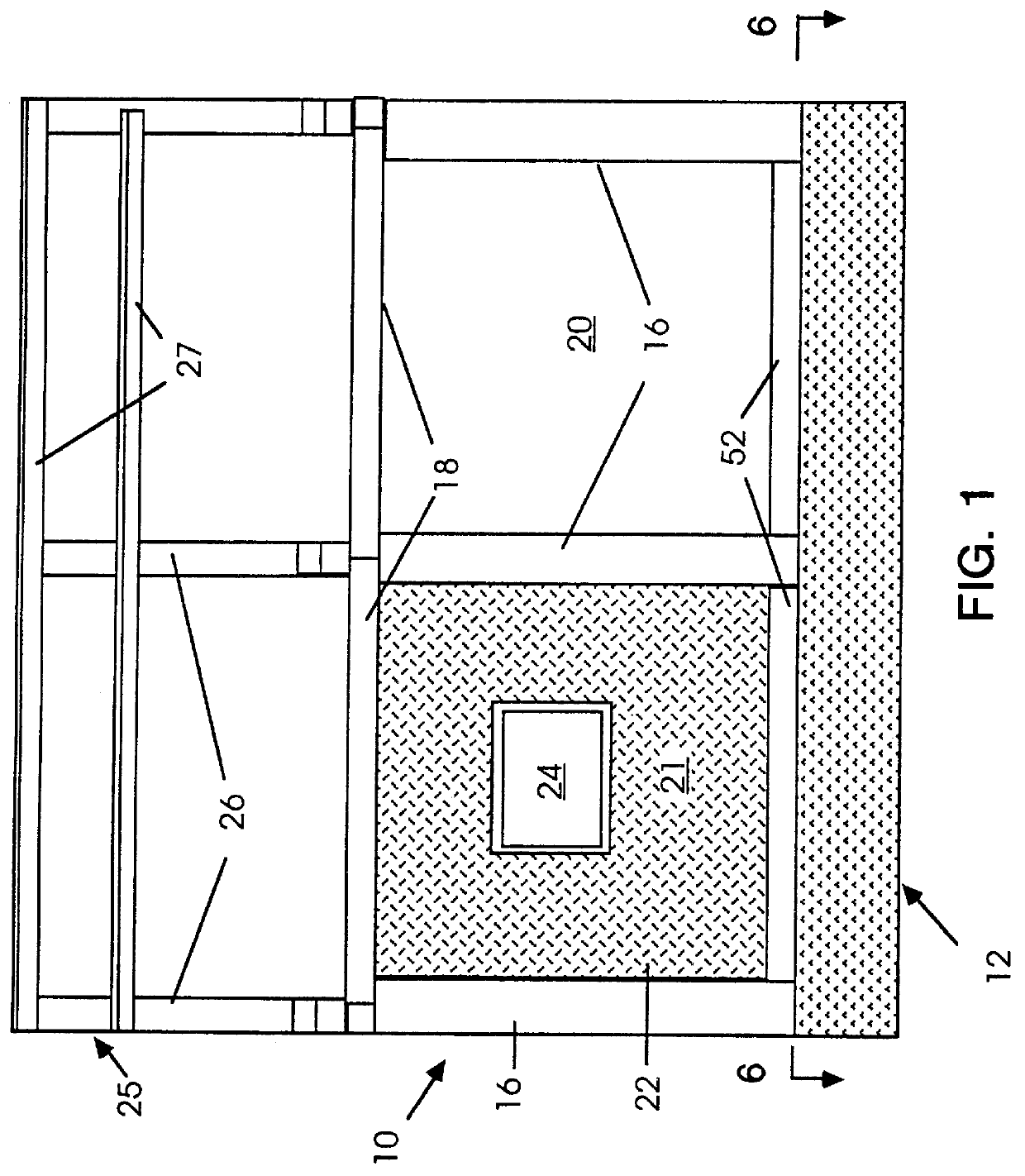

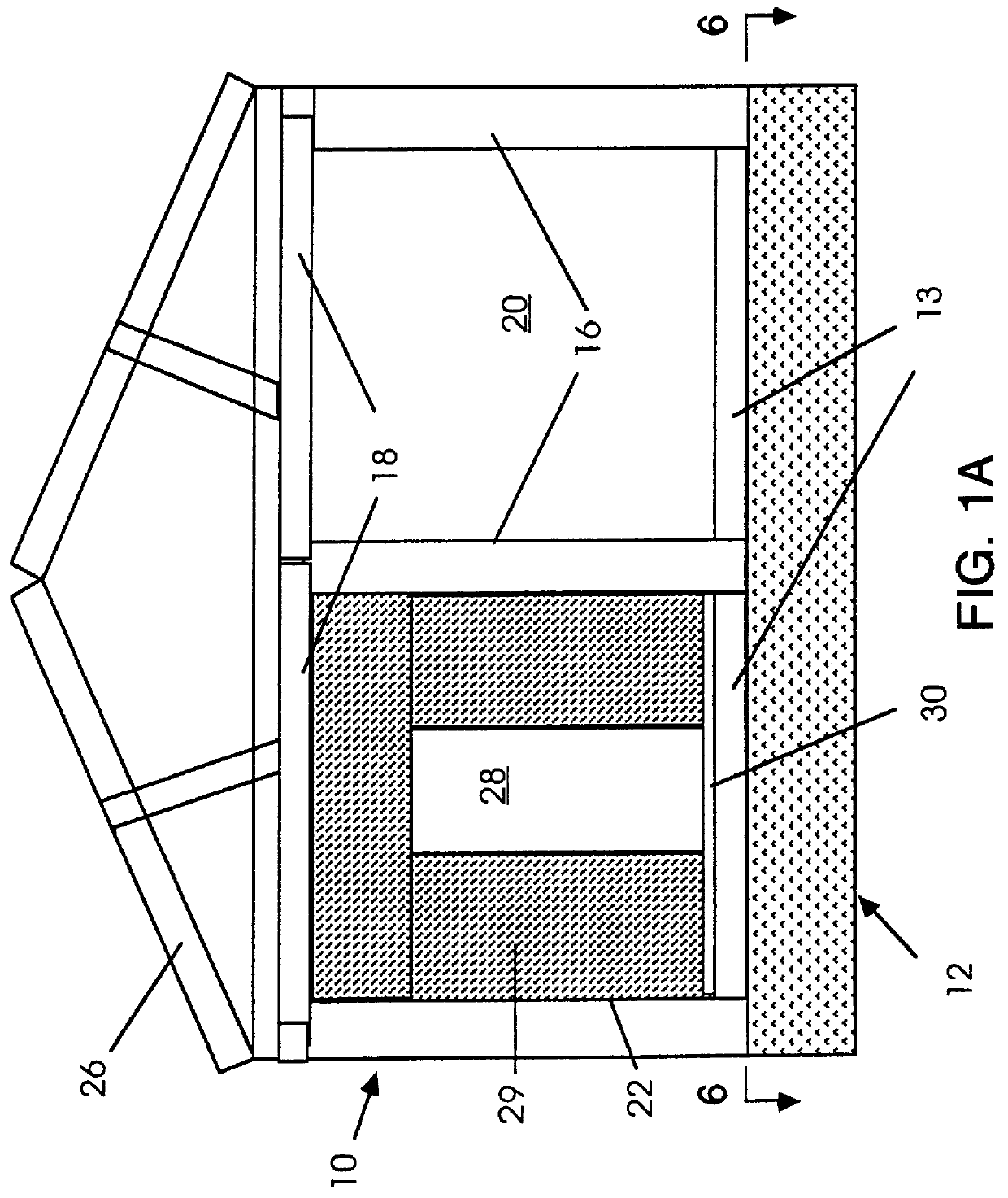

The present invention provides novel wall construction systems and materials for residential and commercial construction that incorporate grooved lightweight building material units (e.g., blocks, panels, and the like), a plurality of connection devices, a track system, and (injected) polyurethane structural foam. The wall construction system comprises building material units married to a building frame with a plurality of connection devices (e.g., clip fasteners) slidingly retained in a track system that is attached to the building's structural (e.g., load-bearing) framing. The building material units are joined to each other with a suitable binding agent. The cavity between the frame and the building material units is injected with an insulating structural polyurethane foam. The exterior of the wall is finished with a waterproof applied finish such as cementitious stucco. The interior of the wall is amenable to standard finish options.

Owner:BRETON SYST LLC

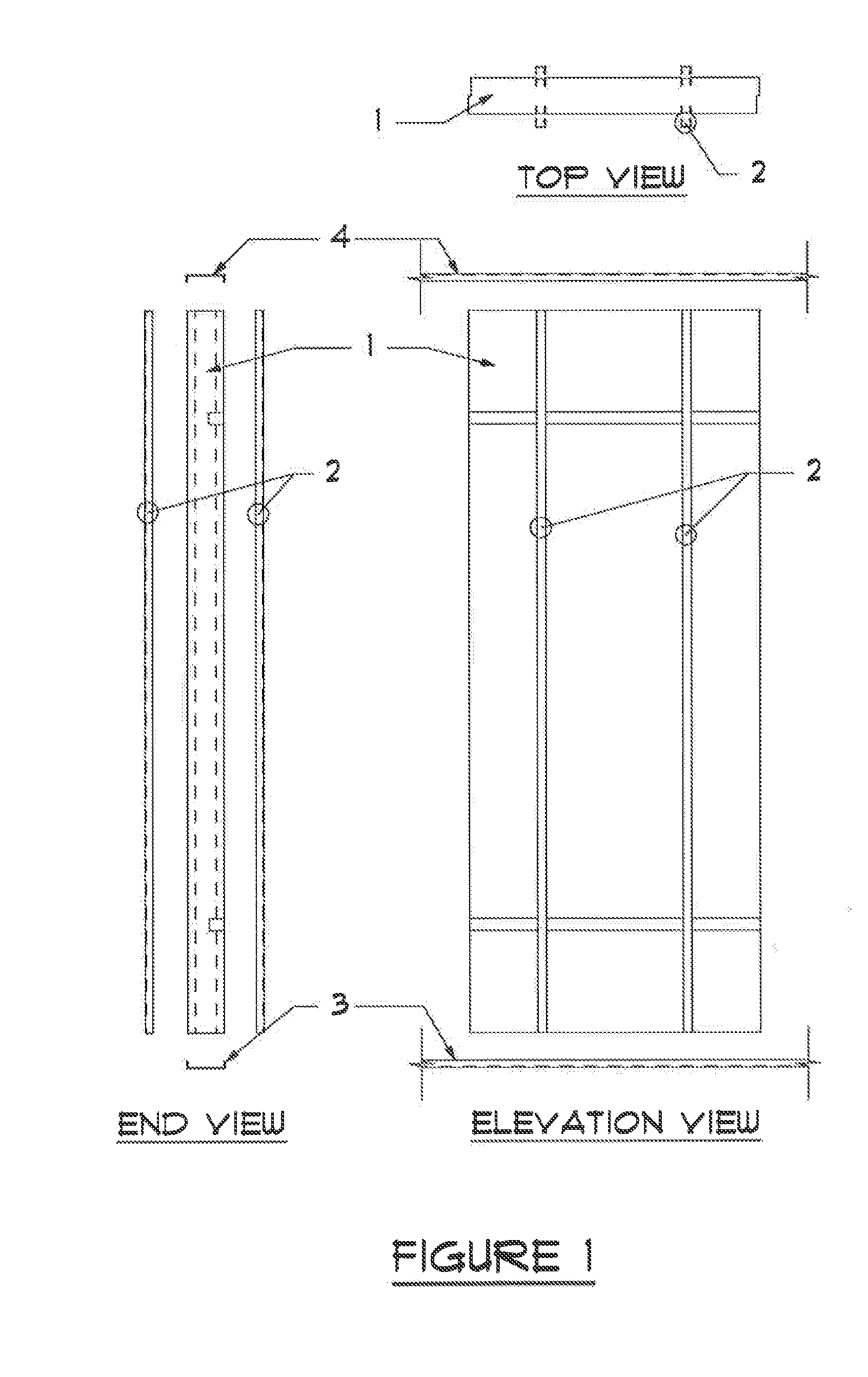

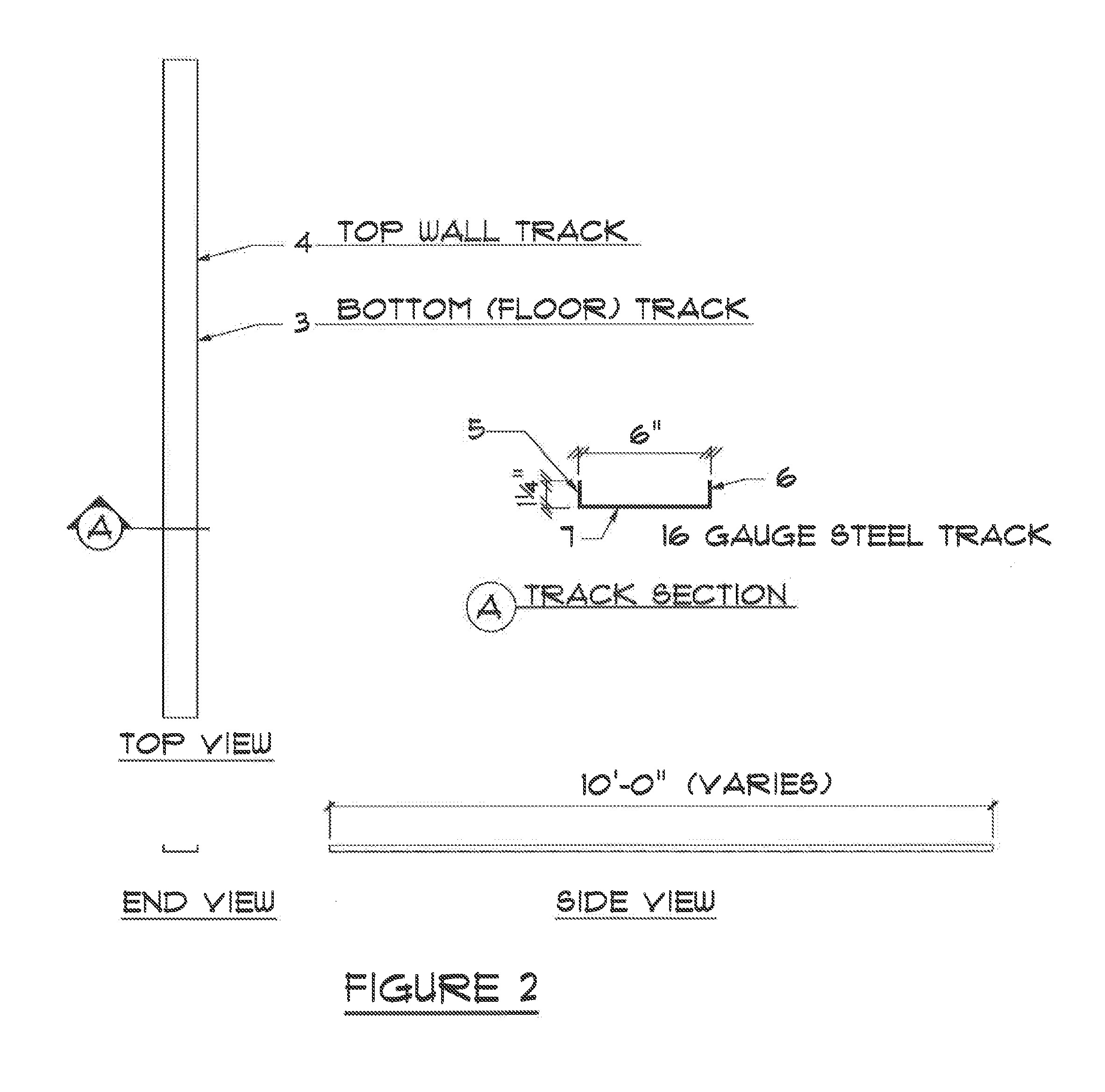

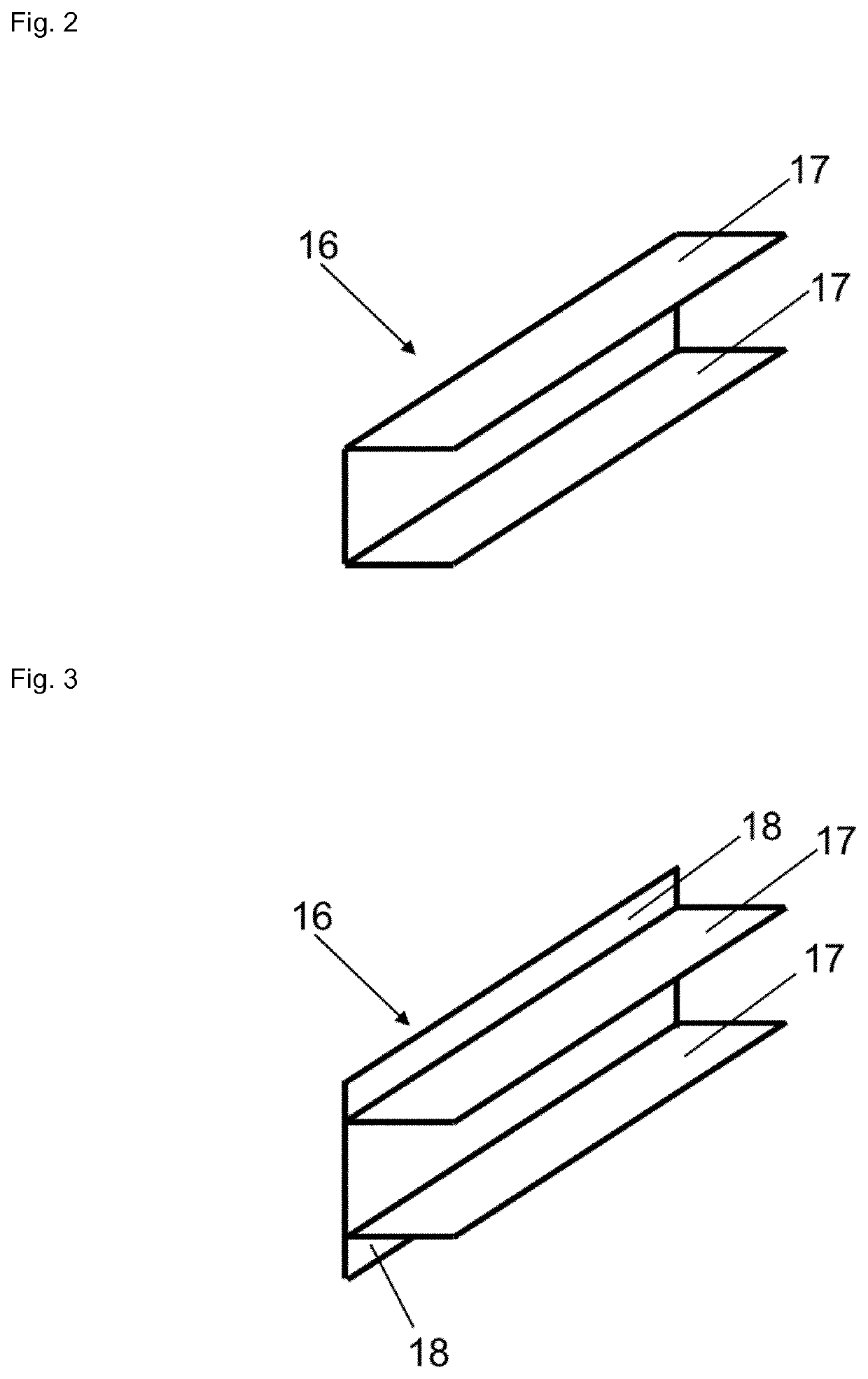

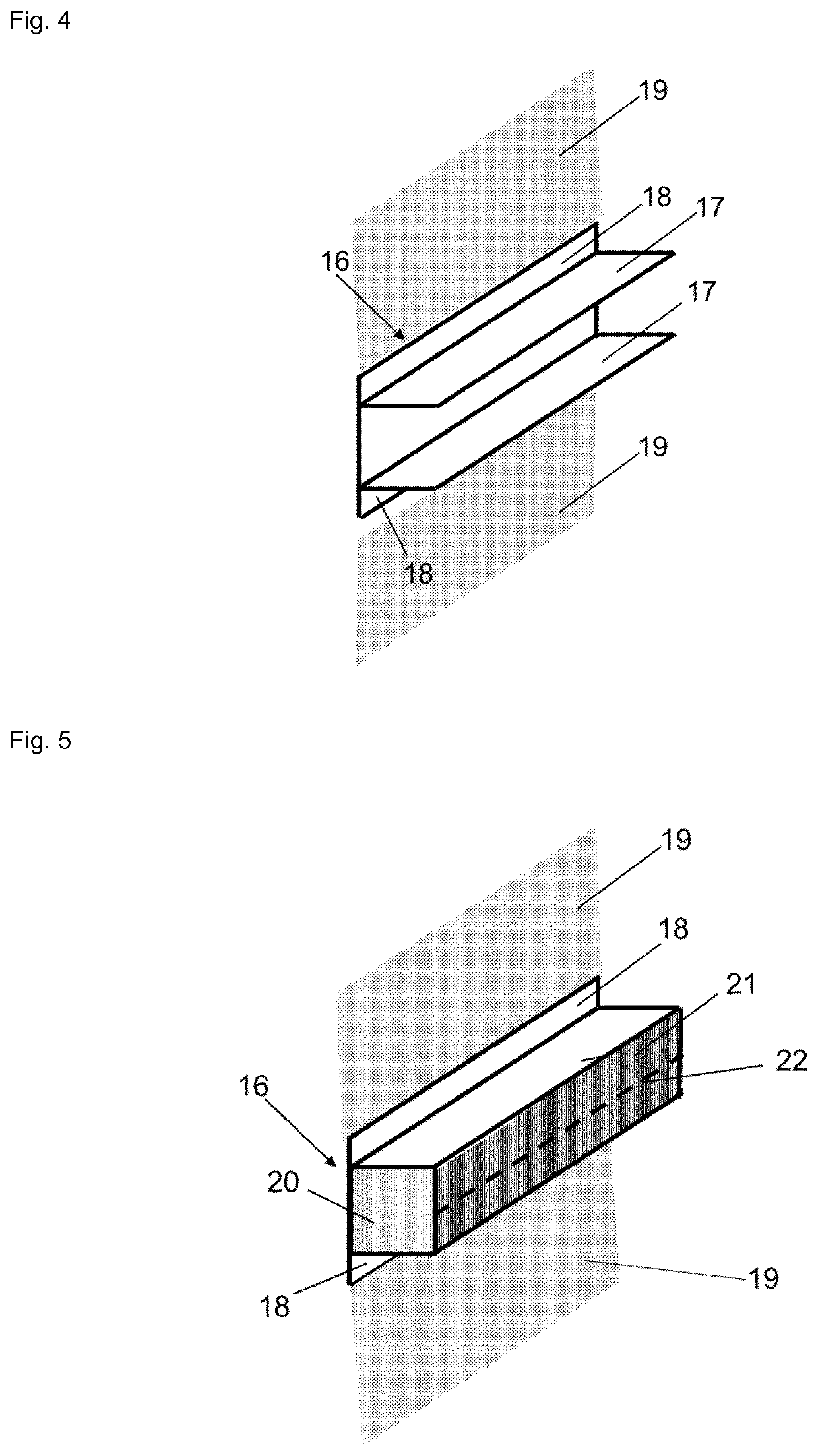

Construction framing system and track therefor

A framing system for use in a building structure includes a track having a longitudinally-extending web and a pair of spaced apart legs which extend from the web to form a channel between the web and the legs. One or more longitudinally-extending studs are coupleable to the legs of the track. Each leg of the track comprises a deformable portion, the deformation of which is accompanied by movement of the one or more studs toward or away from the web.

Owner:674249 B C

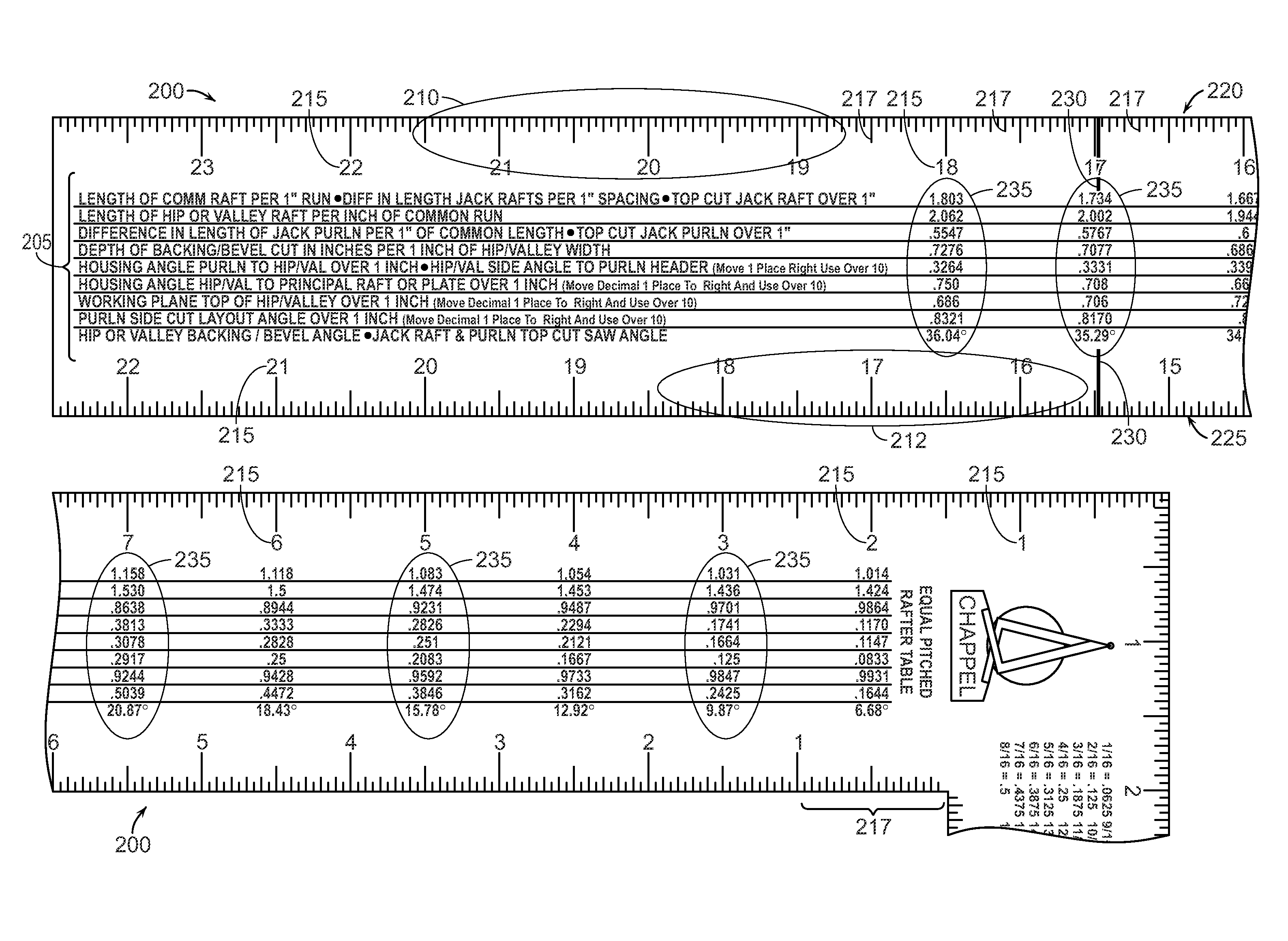

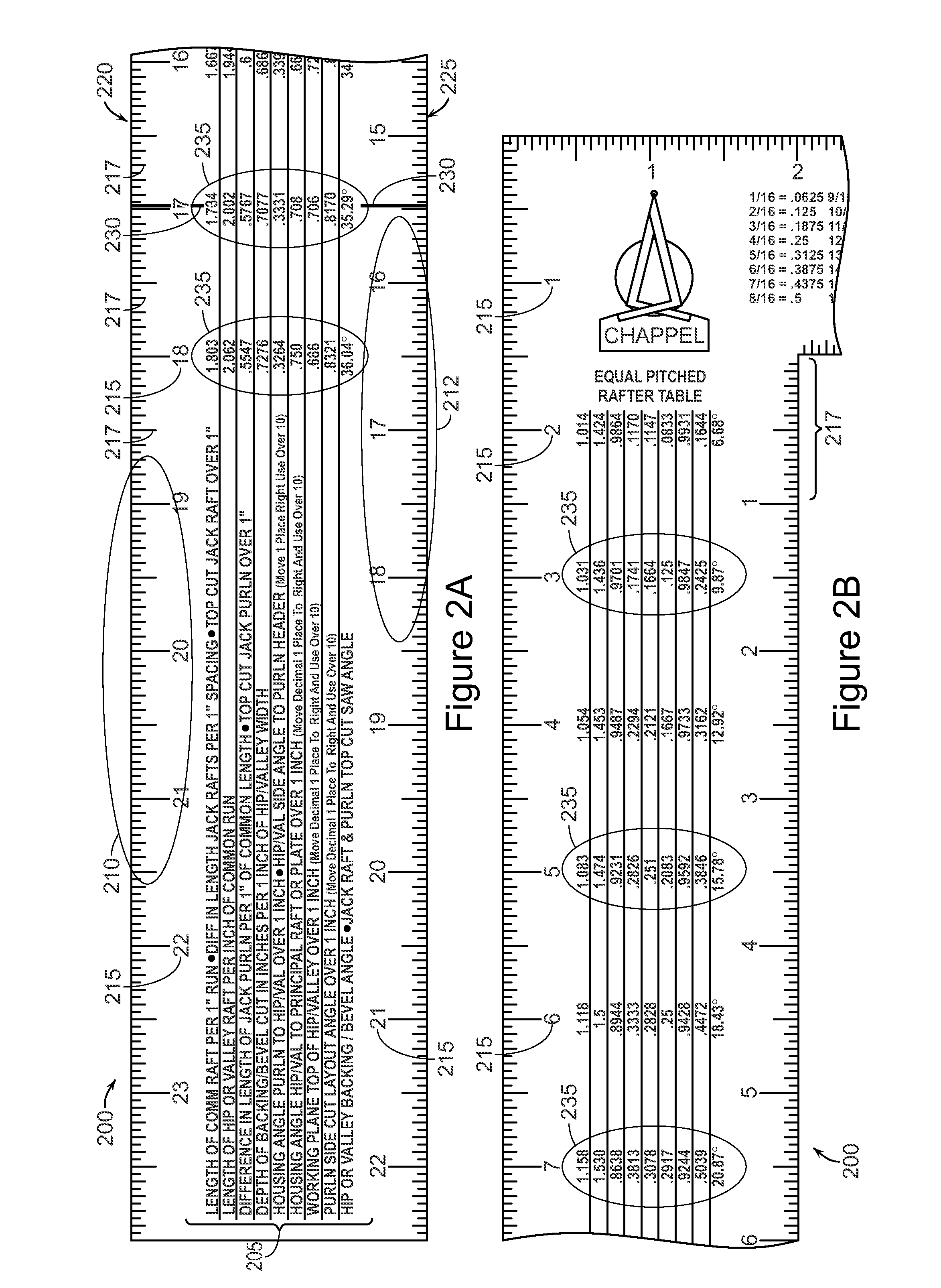

Universal framing square

The Chappell Universal Square™ solves the problems associated with standard framing squares and provides a dynamic framing square bearing novel indicia and a novel arrangement of same for direct application to framing members during construction of complicated framing systems of equal and / or unequal pitched members. Typically, squares are limited to use with a single base unit of measurement, e.g. inches or millimeters, and provide limited tabulated information for use in calculating lengths, distances, and angles at which to cut framing members. The present invention is a tool that provides universal applicability for use in building both simple and complex structures according to metric and standard / imperial measurement systems. The present invention provides tabulated calculations aligned with indicia that enable construction of equal and complex unequal pitch framing members without necessitating the execution of complex trigonometric calculations.

Owner:CHAPPELL STEVE K

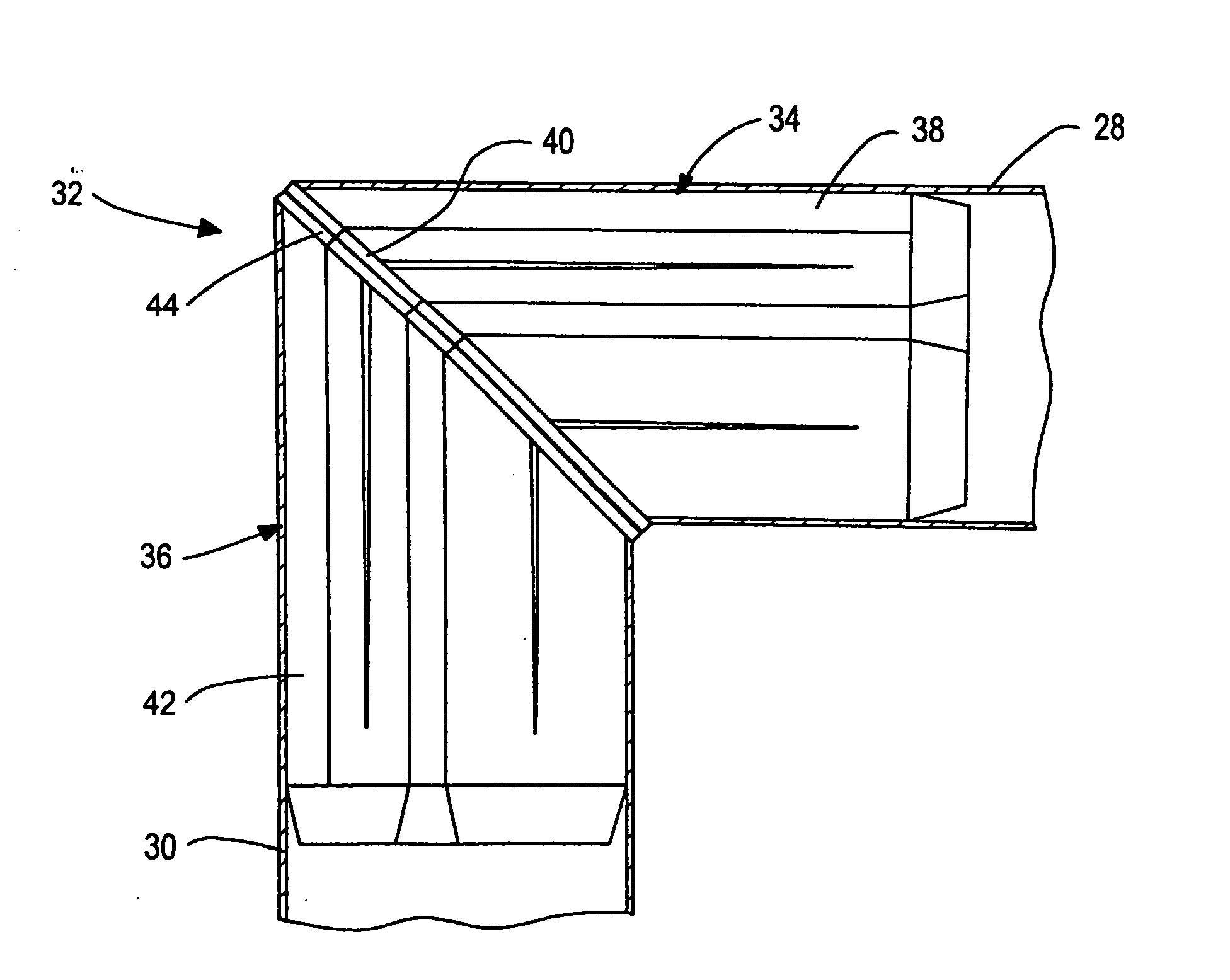

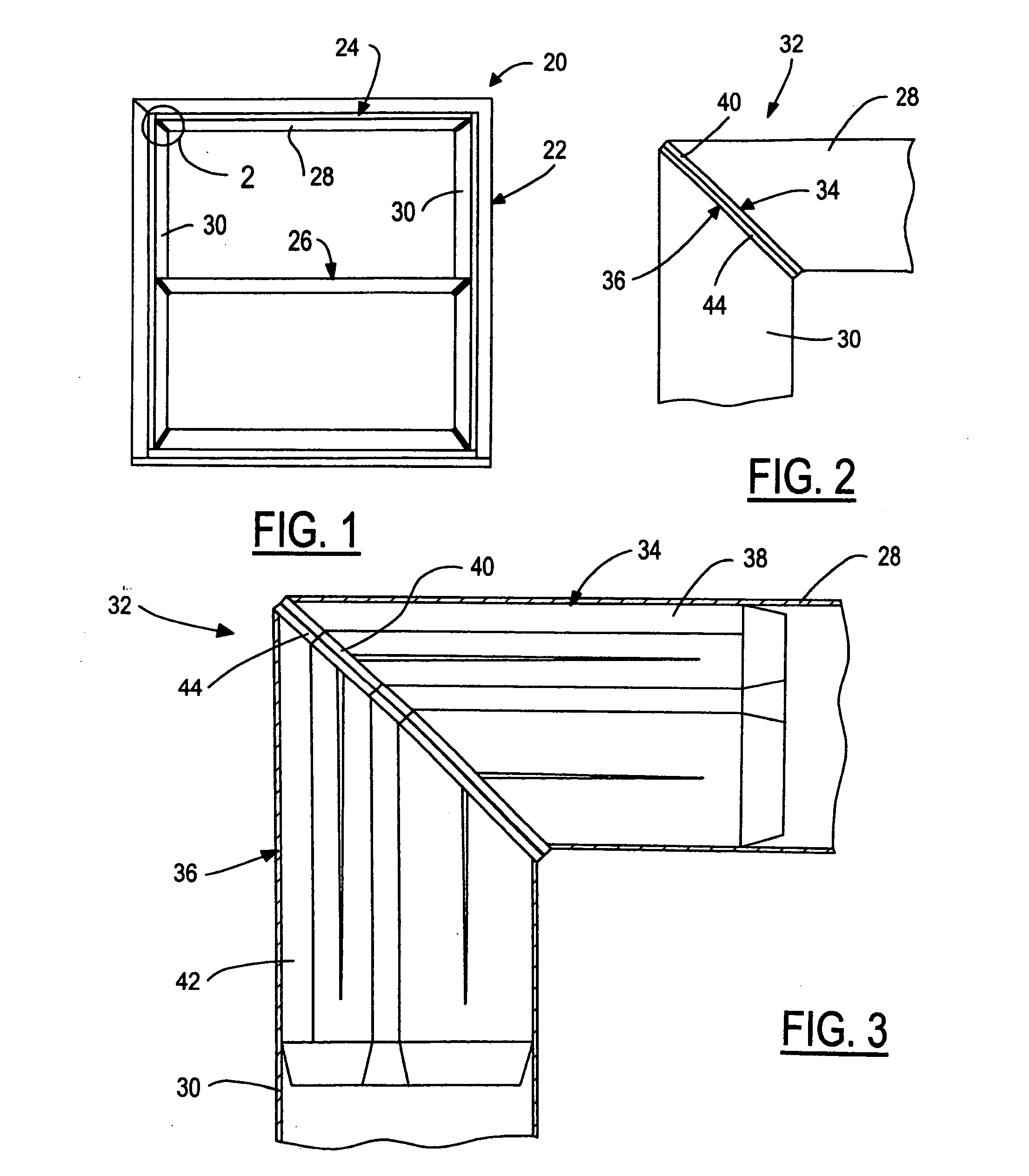

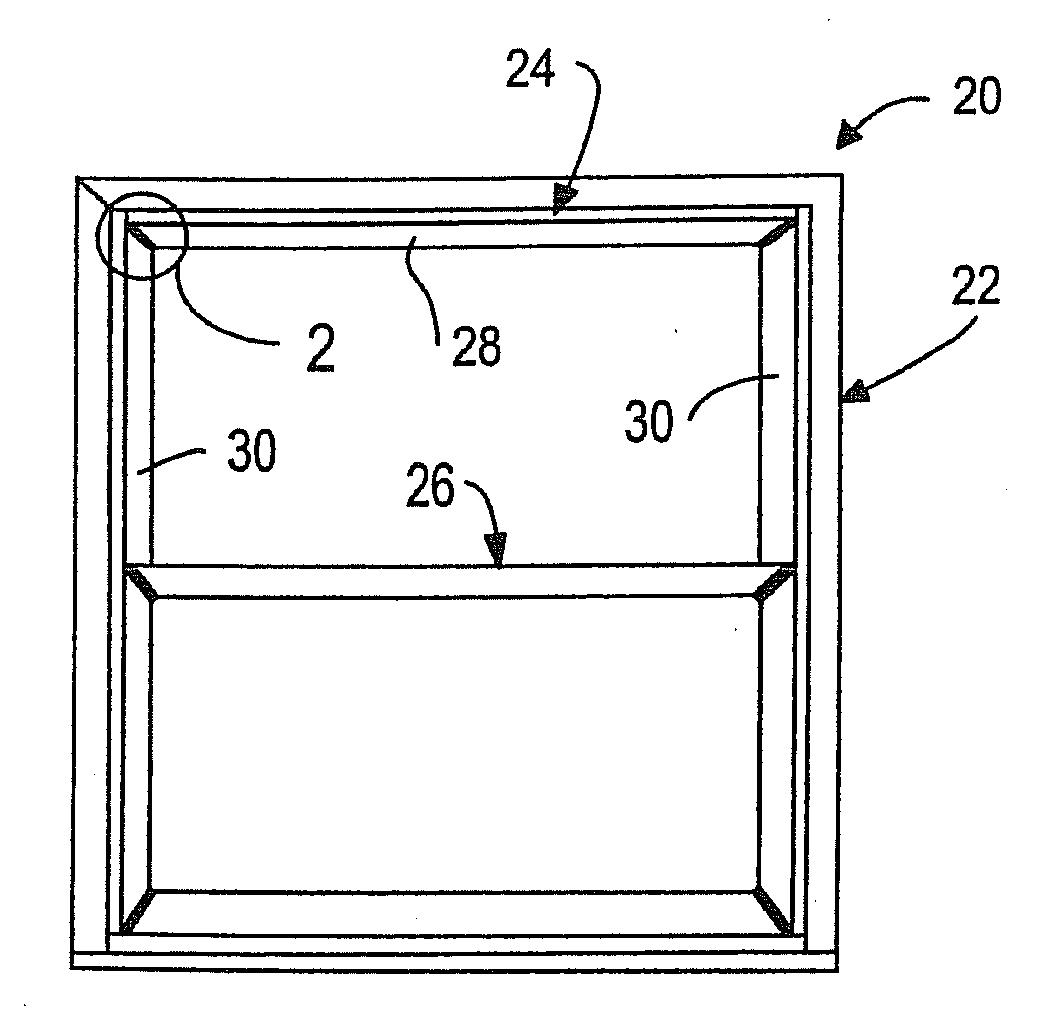

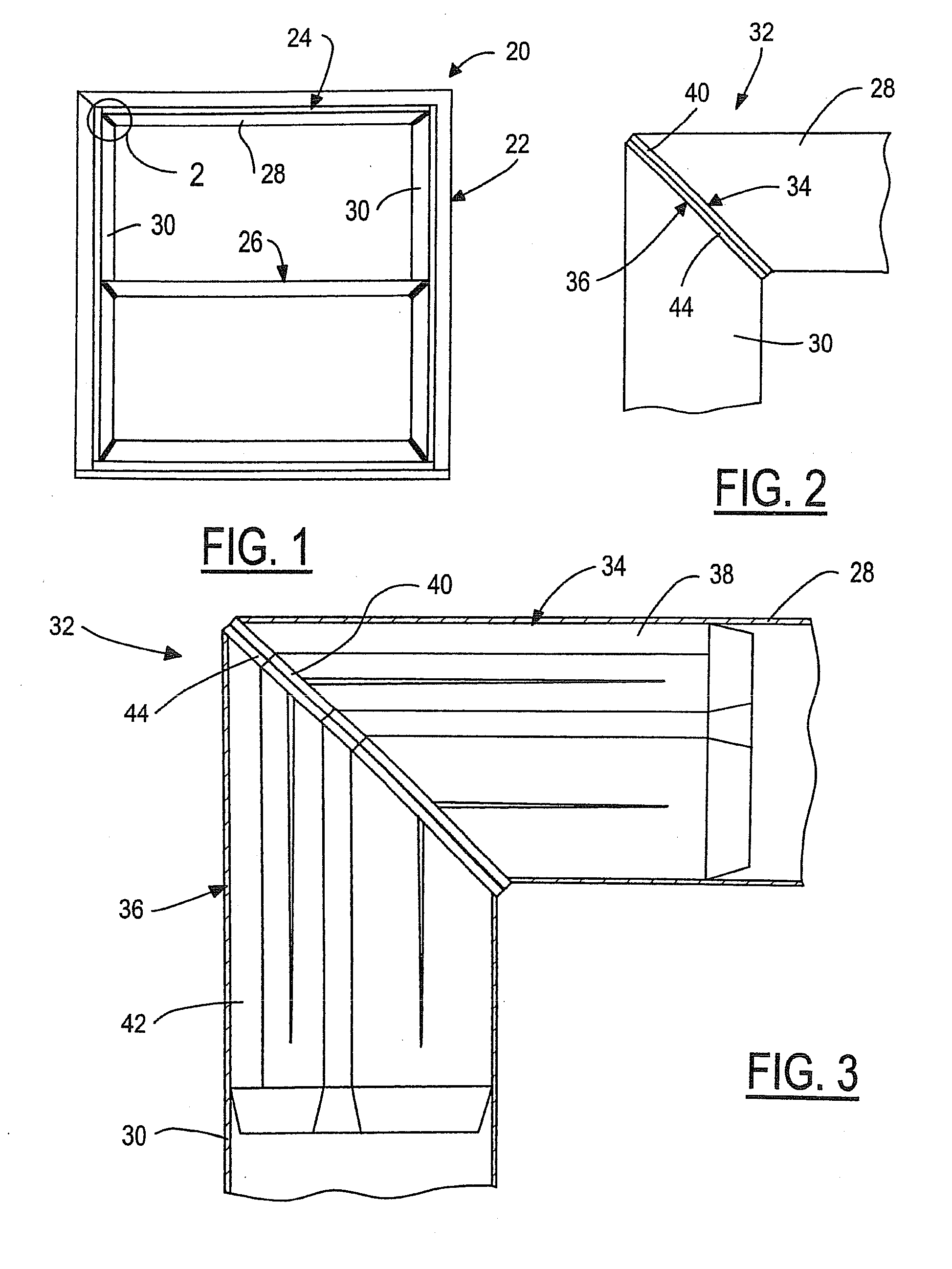

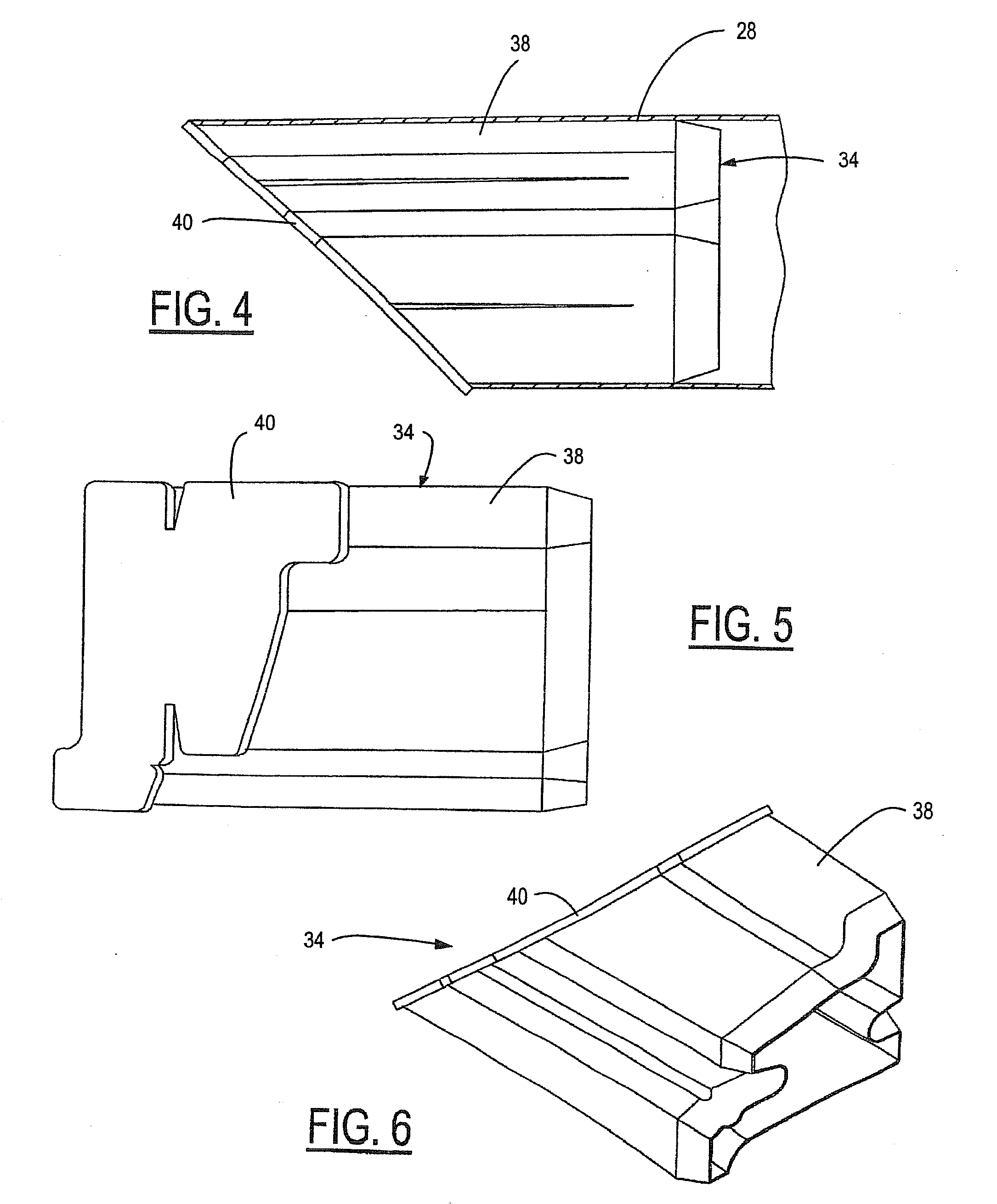

Framing corner joint and method of manufacture

InactiveUS20070245650A1Readily be welded to each otherIncrease costDoors/windowsPublic buildingsGlass fiberThermoplastic

A framing corner joint includes first and second framing rails of fiberglass-reinforced resin construction. The first and second framing rails have hollow mitered ends. A pair of thermoplastic plugs are received in the mitered ends of the respective framing rails. Each of the plugs includes a body inserted into the hollow interior of an associated framing rail and a flat plug flange at an angle of 45° to the body. The plug flanges extend outwardly from the peripheries of the bodies between the rail ends and have flat end faces that are bonded to each other. The bodies of the plugs preferably are hollow, and preferably are received by interference press-fit within the ends of the rails. The plug flanges of the plugs preferably are welded to each other.

Owner:MILGARD MFG INC

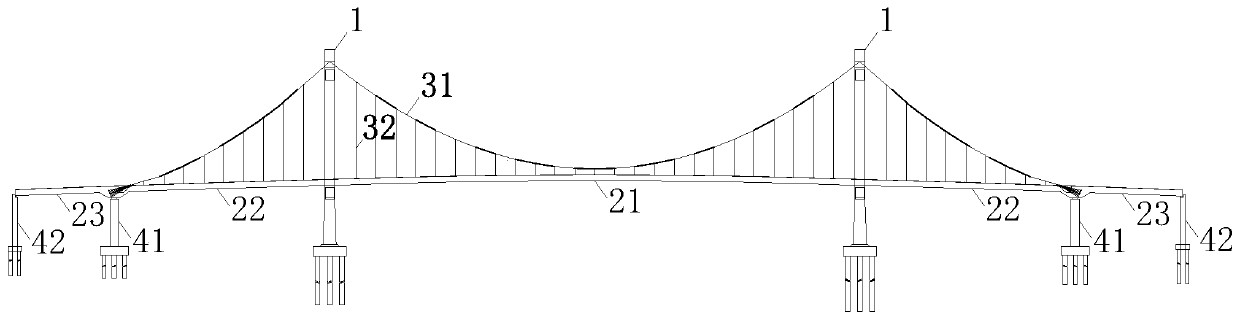

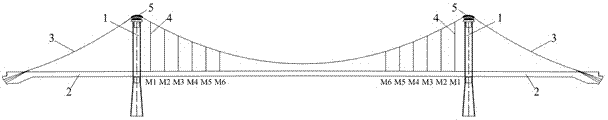

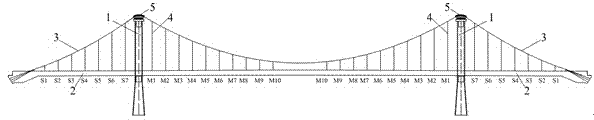

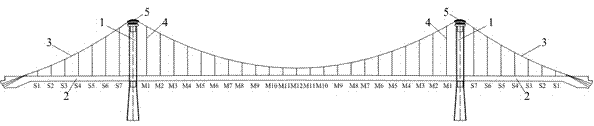

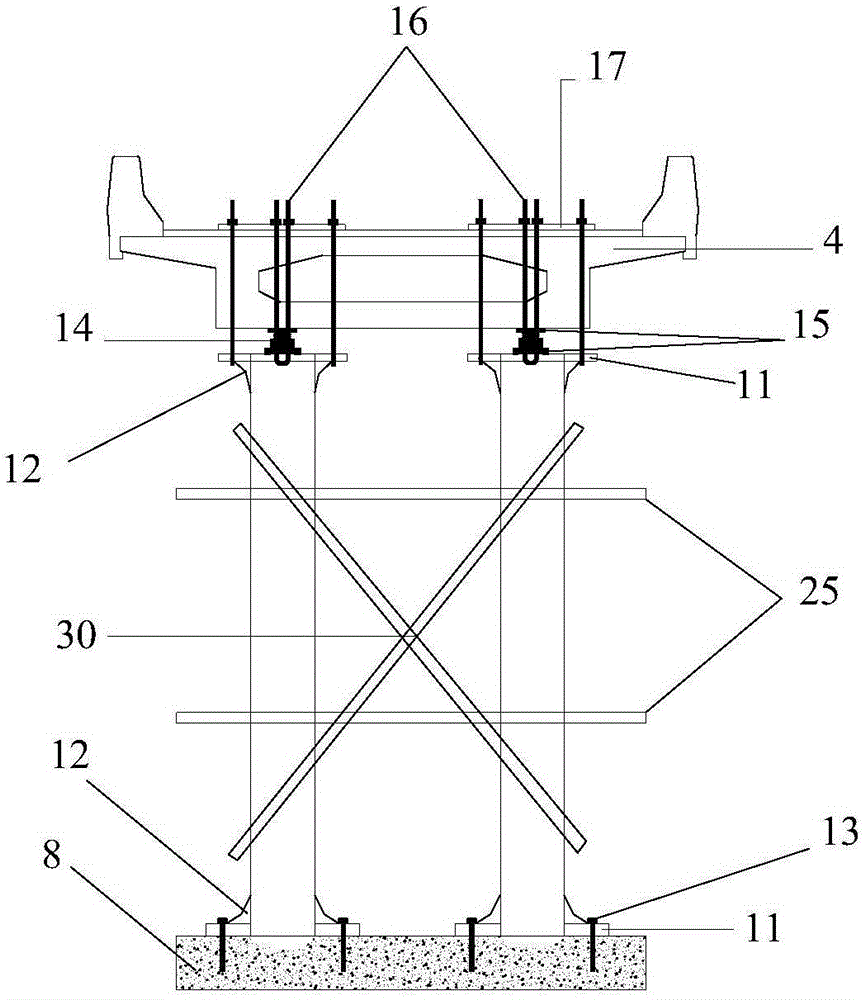

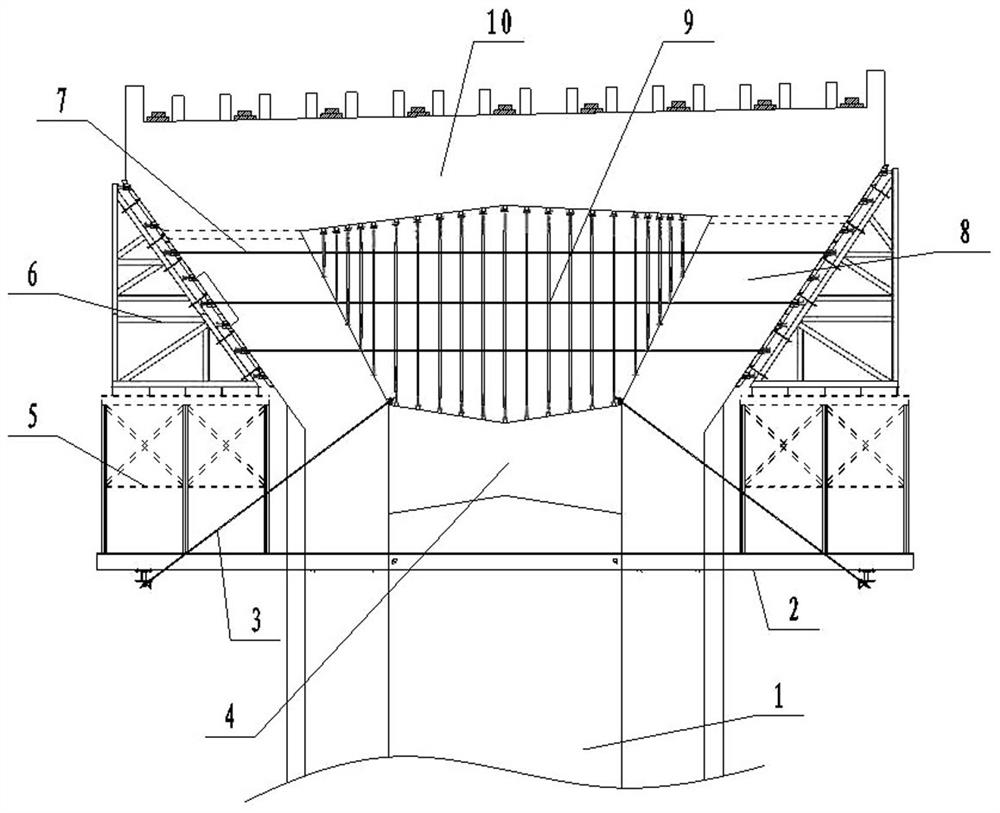

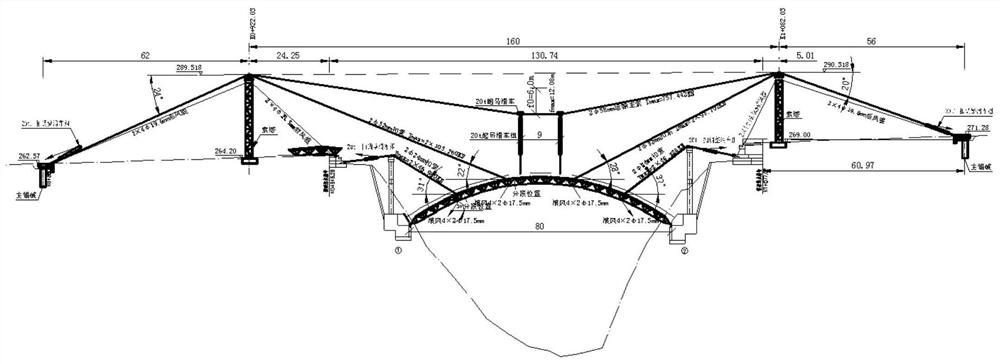

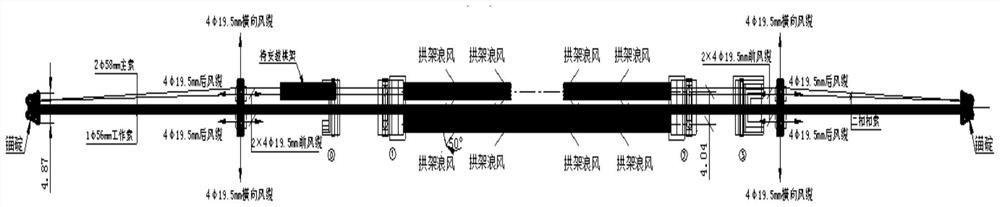

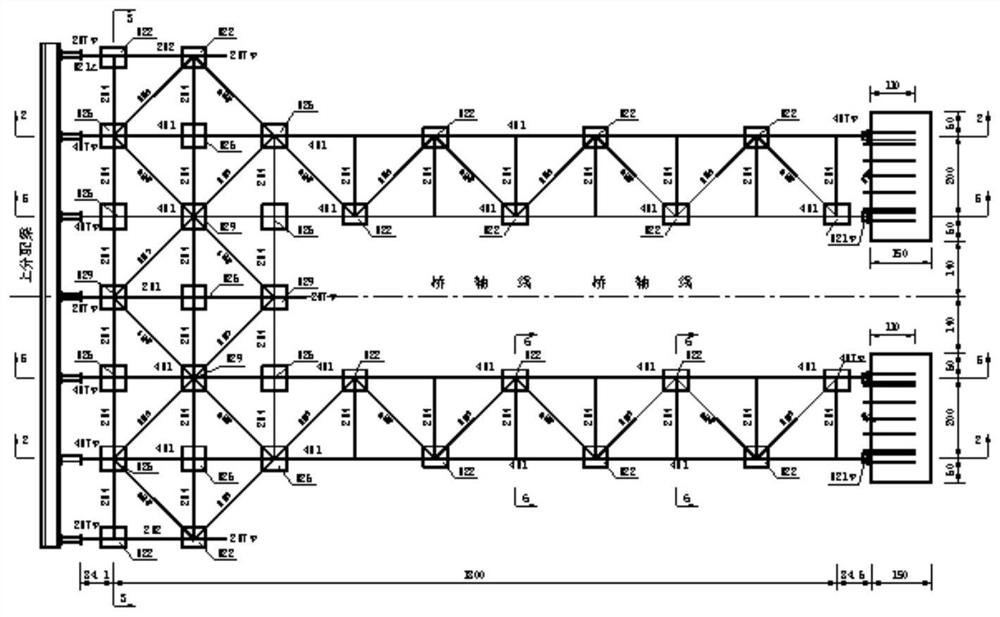

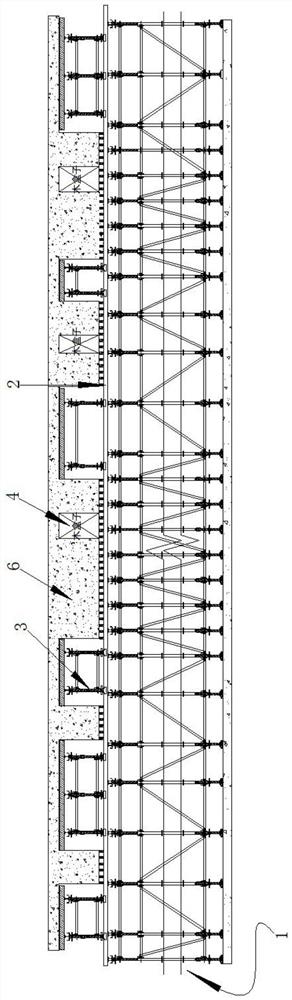

Self-anchorage type suspension bridge design and construction method adopting first cable later beam dynasty

InactiveCN110761168ASolve construction problemsClear forceSuspension bridgeBridge erection/assemblyArchitectural engineeringRiver bed

The invention discloses a self-anchorage type suspension bridge design and construction method adopting a first cable later beam dynasty. The method includes the steps that (1), bridge towers and piers are constructed, and main beam anchoring sections are constructed; (2), temporary anchors are constructed, and temporary pintle cables are mounted; (3), main cables are erected, and the temporary pintle cables are tensioned synchronously; (4), main beam sections are hoisted, main cable saddles on the tops of the bridge towers are pushed, and the temporary pintle cables are tensioned; and (5), the main beams are formed into a whole, the temporary pintle cables are detached, and system conversion is completed. The method has the beneficial effects that force bearing is clear, monitoring is facilitated, and navigation below a bridge is not interrupted, the construction method is simple and convenient, and design and monitoring are facilitated. Compared with a construction method adopting afirst beam later cable construction method, the requirements of navigation below the bridge can be guaranteed, the temporary measures that full framing and temporary piers are erected in a riverway with a deep riverbed are avoided, the construction problems of a self-anchorage type suspension bridge which has high requirements on navigation below the bridge and is located at the deep position of the riverbed can be solved, and the competitiveness of the large-span self-anchorage type suspension bridge is further improved.

Owner:ZHEJIANG PROVINCIAL INST OF COMM PLANNING DESIGN & RES CO LTD

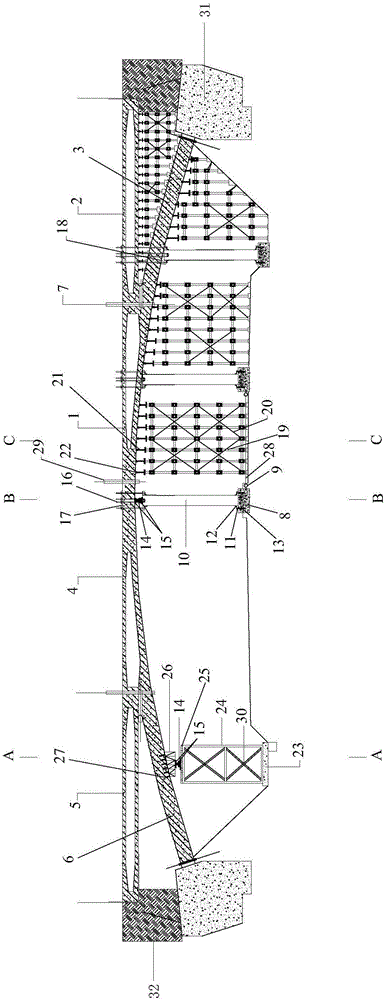

Self-anchored suspension bridge boom tensioning technology based on self-equilibrium system

InactiveCN104846747AEliminate the effect of bendingAvoid breakingBridge erection/assemblyArchitectural engineeringTower

The invention relates to the field of bridge construction, in particular to a self-anchored suspension bridge boom tensioning technology based on a self-equilibrium system. The technology includes: after the full framing cast-in-place of the main tower and the main beam reaches the design strength, building the main cable, installing the tensioning boom to complete the replacement of the structural system, and detach the full framing. The self-anchored suspension bridge boom tensioning technology based on the self-equilibrium system is short in duration of the boom tensioning construction technology, low in construction cost, less in adopted boom lengthening rods, tensioning times and position exchanging times of the jack, accurate in structural stress, better in fitness between the boom tensioning and the main cable displacement double control during tensioning, free of weather influence on the measurement during tensioning, higher in measuring precision, wider in applicable range of the boom tensioning construction technology, and not only applicable to the self-anchored concrete suspension bridge, but also applicable to the steel box beam self-anchored suspension bridge.

Owner:CHANGAN UNIV

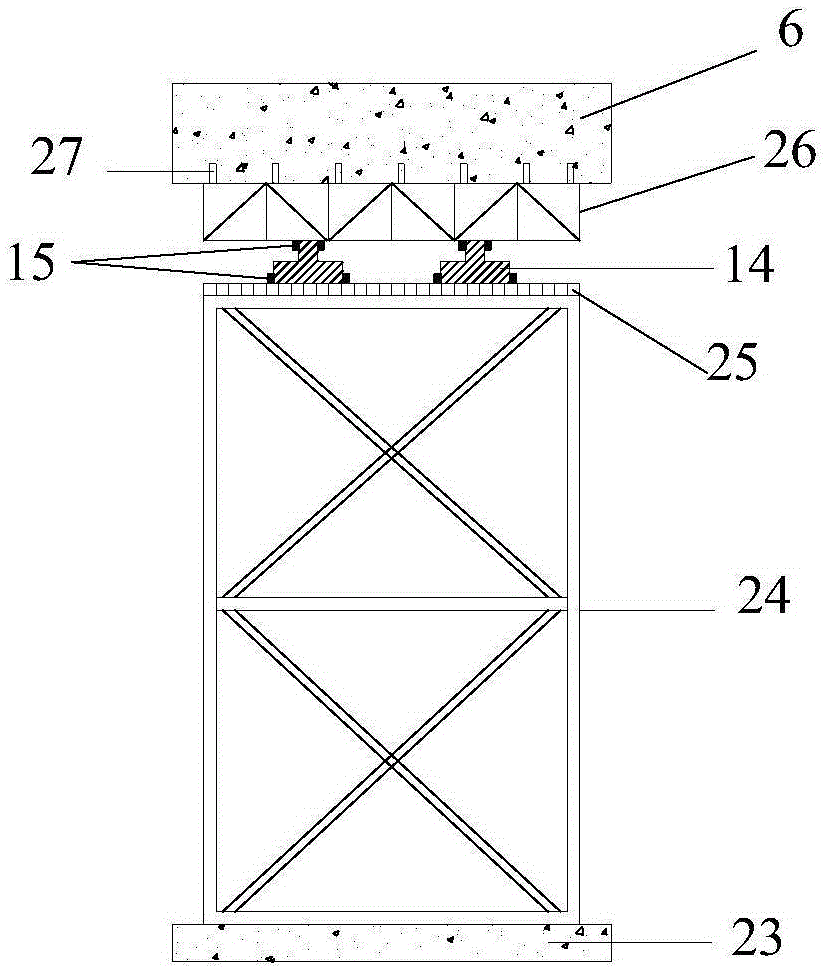

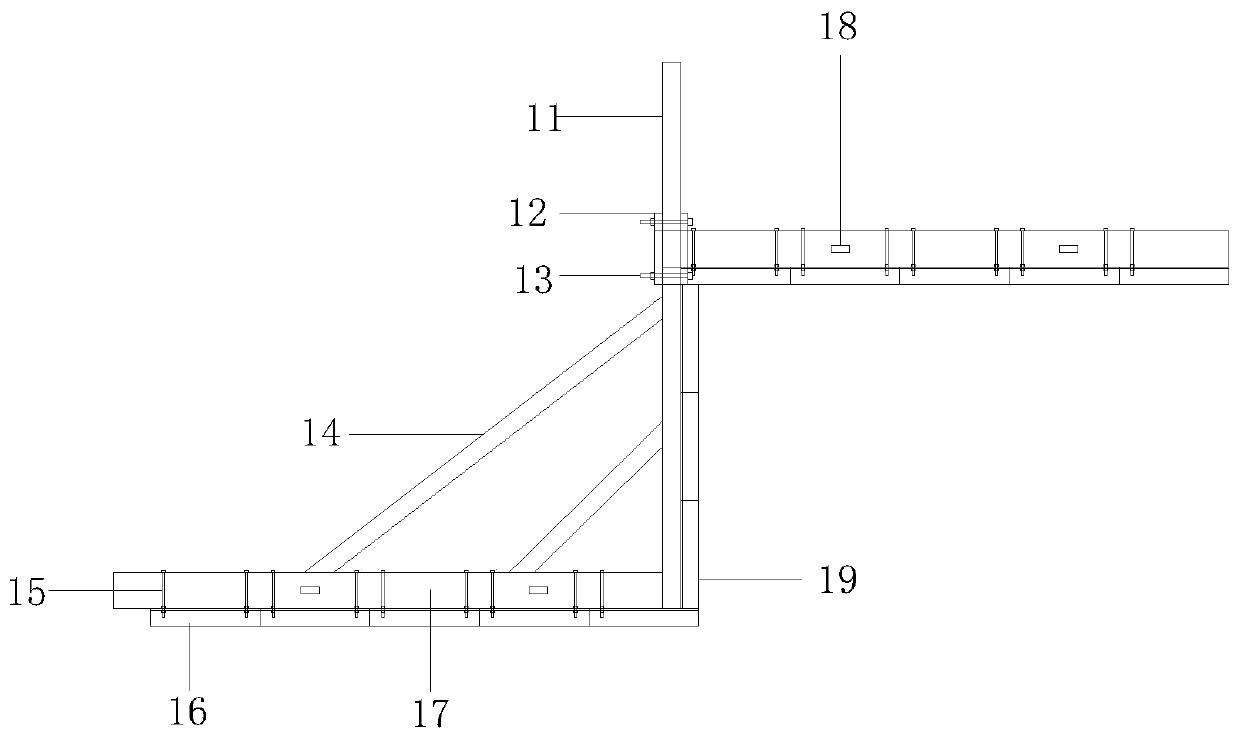

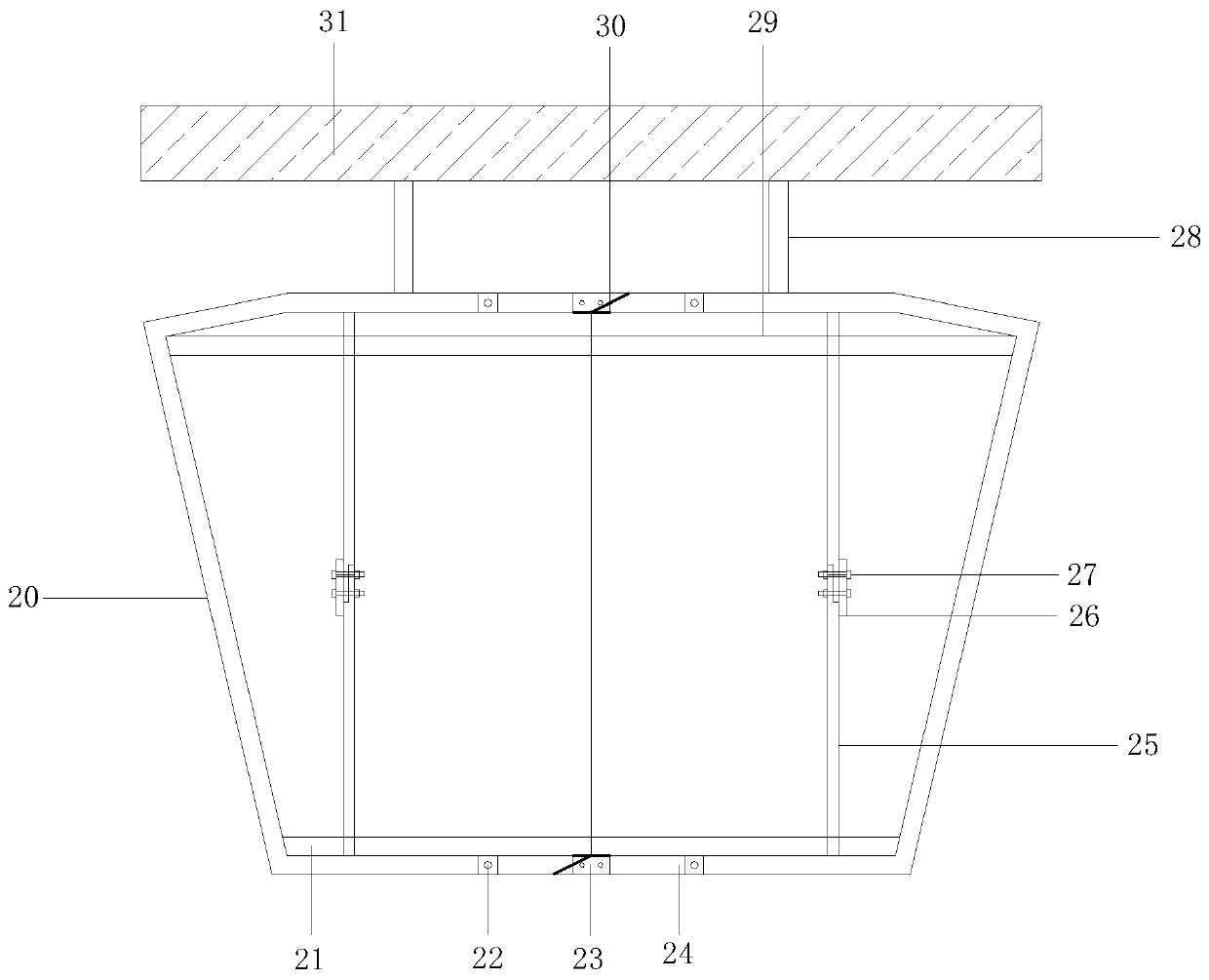

Framing demounting supporting structure of spandrelless arch bridge of over crossing operation highway and construction method

ActiveCN105113434AAvoid getting stuckEffective consolidationBuilding repairsBraced frameArchitectural engineering

The invention relates to a framing demounting supporting structure of a spandrelless arch bridge of an over crossing operation highway. The supporting structure is characterized by being mainly composed of an intermediate support, a bowl-button full support, a full support spiral steel pipe support and a frame support; the intermediate support comprises two spiral steel pipes, a transverse rod and a shearing force support are welded between the spiral steel pipes, the bottoms of the spiral steel pipes and a strip foundation are anchored, and the tops of the spiral steel pipes and a bridge body are anchored through a U-shaped screw; the bowl-button full support is provided with a shearing force support, a top support and a small wood wedge block, and the small wood wedge block is plugged between the top support and the bridge body; the spiral steel pipe support is additionally arranged at the bowl-button full support; and the frame support is formed by box iron in a welded manner, a shearing force support is arranged inside the frame support, an arc-shaped top support is arranged at the top of the frame support, and a shearing force key of the arc-shaped top support is inserted into an arch bridge arch ring. The supporting structure has the beneficial effects of being safe and reliable in construction and high in stability, having no influences on normal traffic, and having the good economic and technological benefits.

Owner:西安市市政建设(集团)有限公司

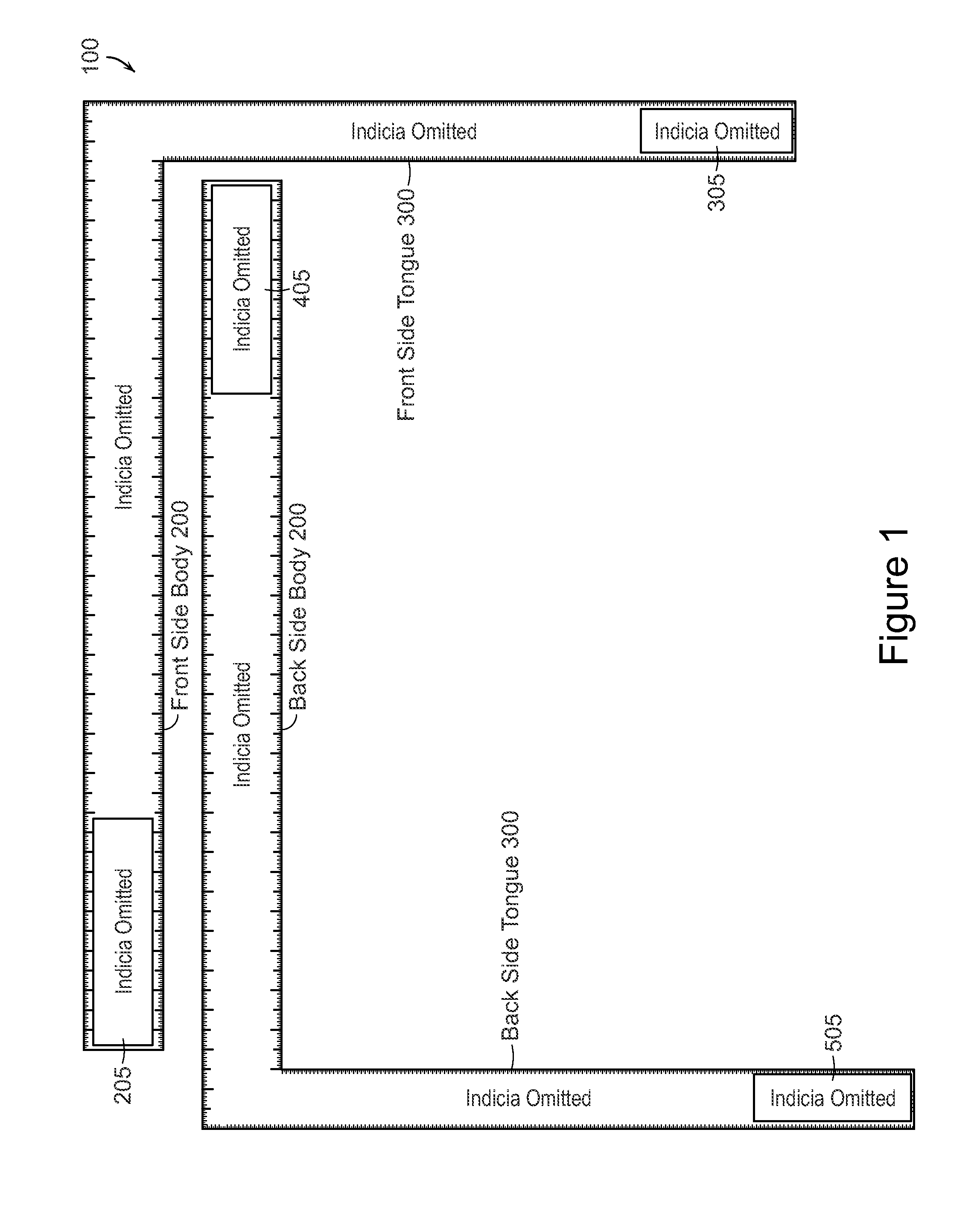

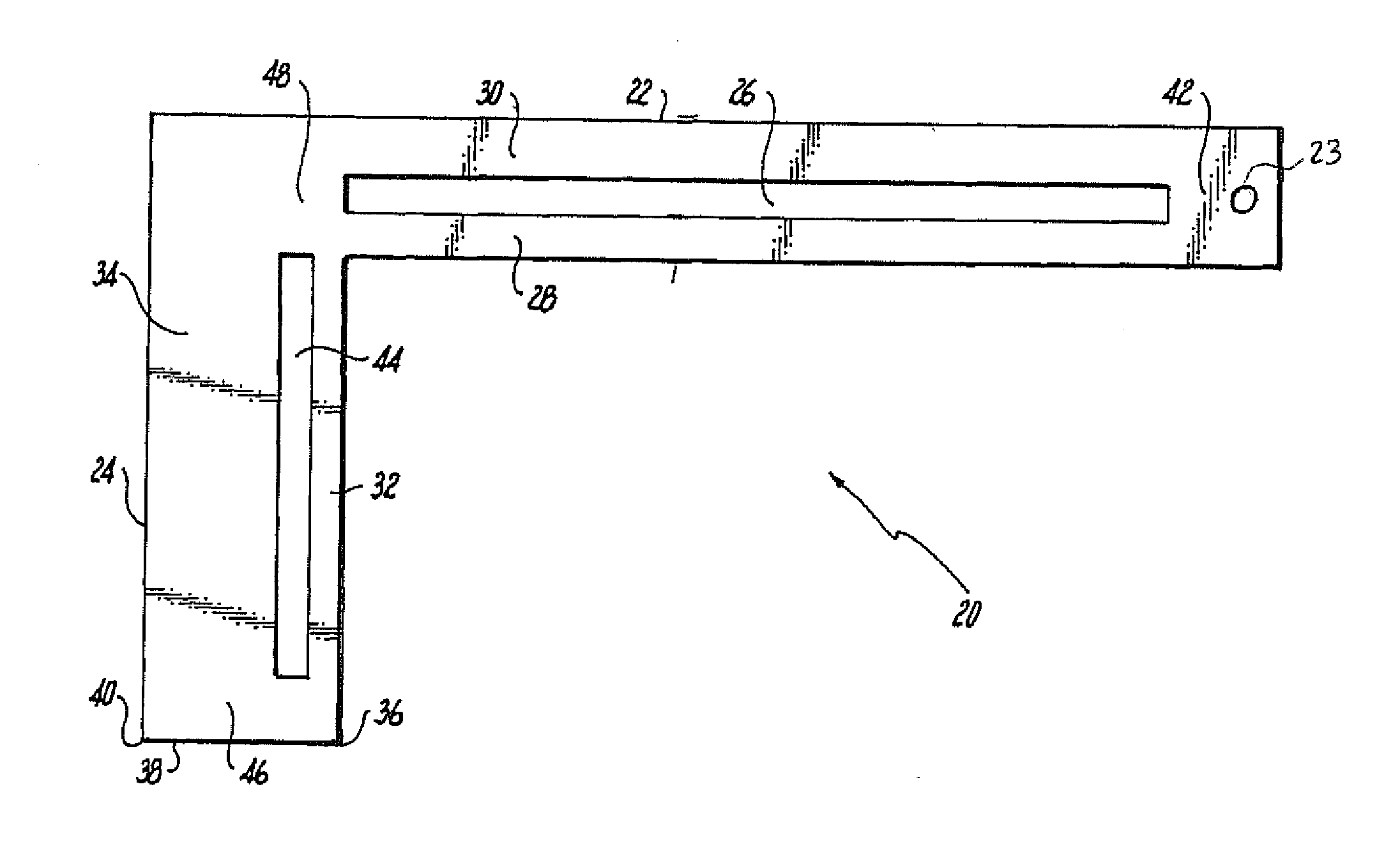

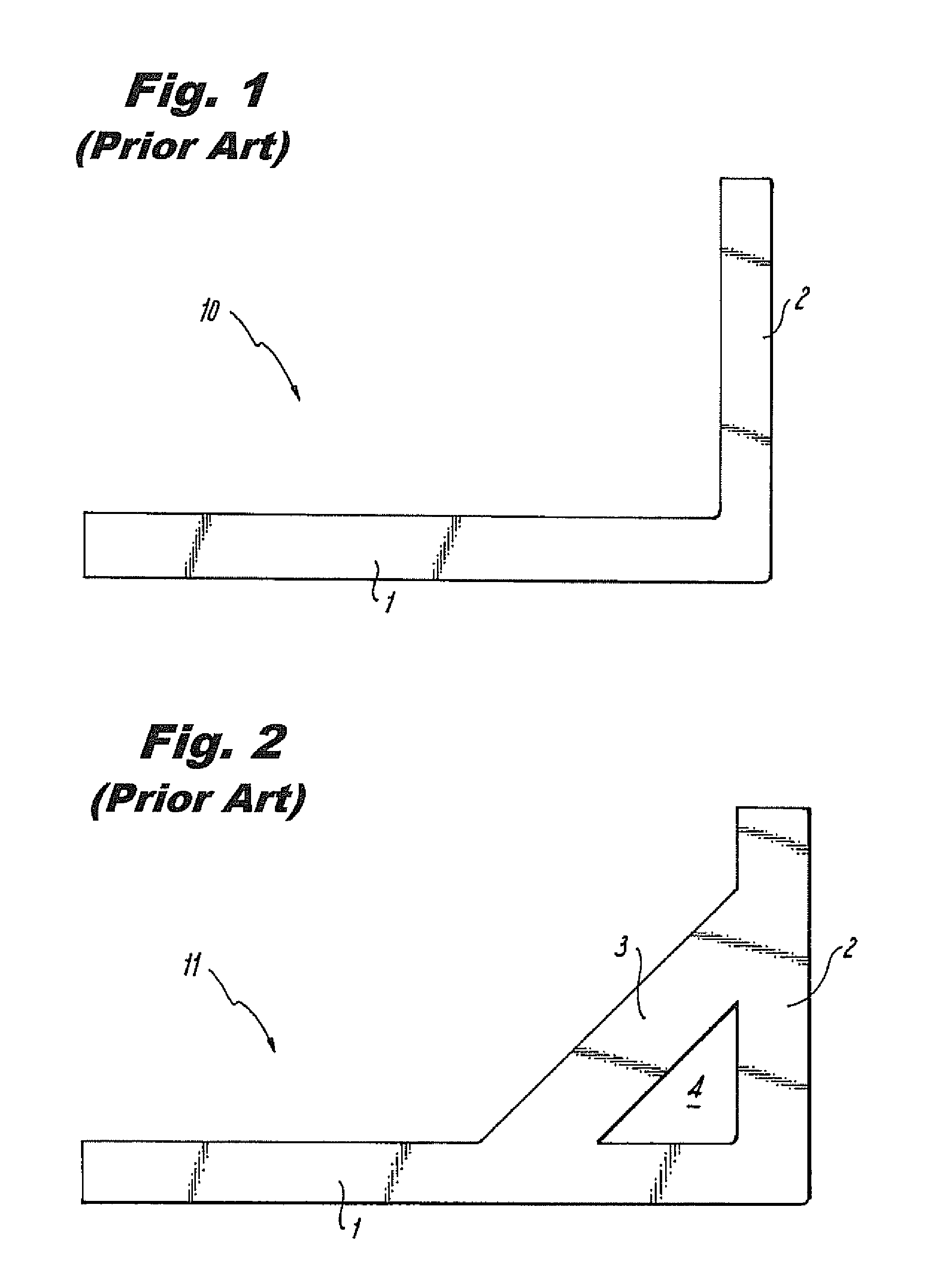

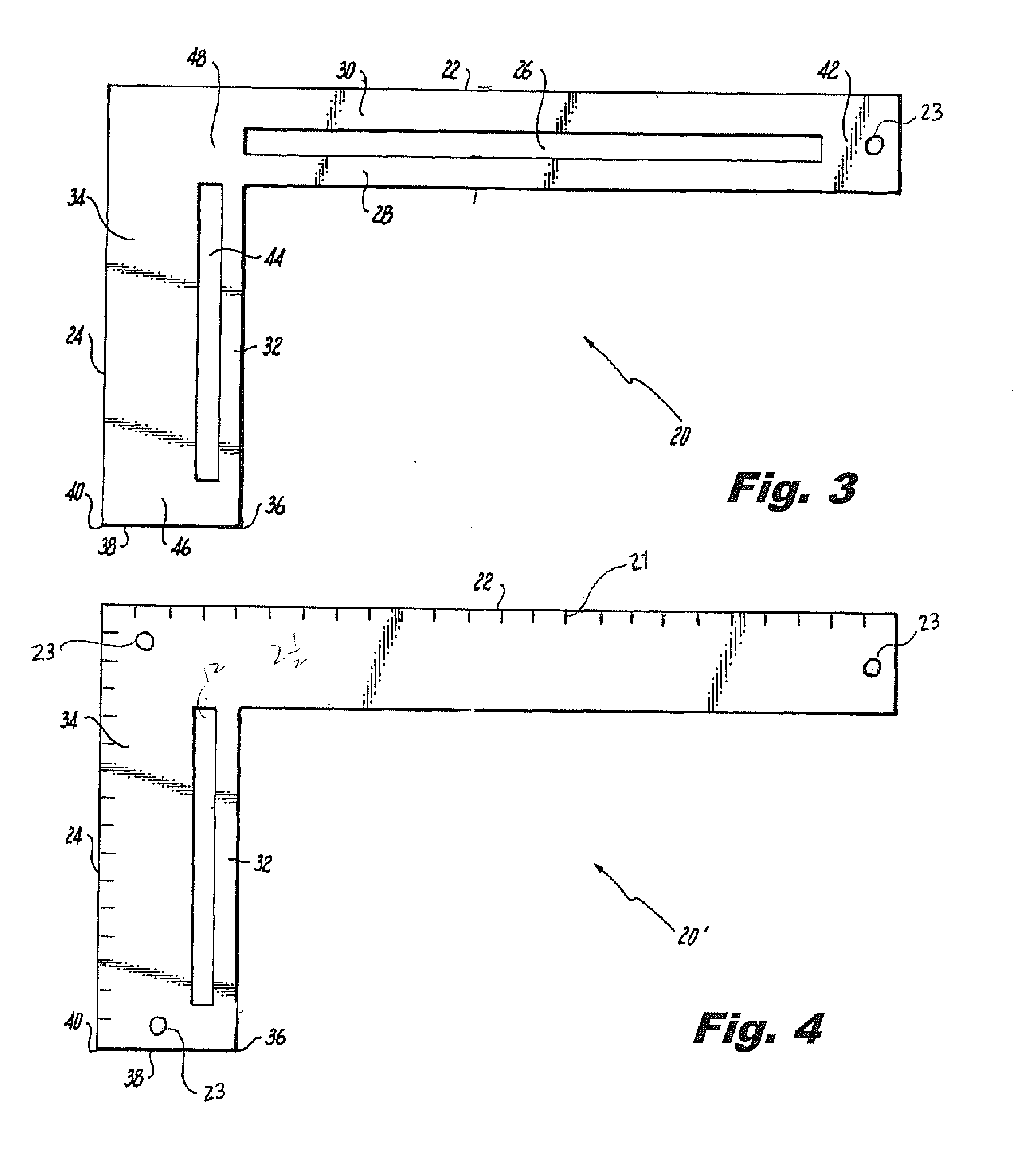

Metal framing layout square and a method of using same

InactiveUS20150276367A1Simple and cost-effective and efficientLow costWriting aidsOther workshop equipmentEngineeringMetal

A metal framing layout square of substantially flat unitary construction and a method for using the same is provided. The square preferably includes an elongated blade, an elongated slot defined in the blade and parallel to the edges of the blade to provide two additional edges for the marking of measurement scales. The tool provides a tongue joined at a right angle to the blade. The metal framing layout square is preferably used with the layout phase of interior metal framed walls, and is directed to a metal framing layout square for use in constructing compound metal framing systems comprising a plurality of predetermined lengths and widths, and has slots which are to allow a user to readily mark a series of layout marks from a starting point to efficiently complete a set of markings for an entire framing structure with minimal need for secondary measuring devices.

Owner:LAMANNA MICHAEL +1

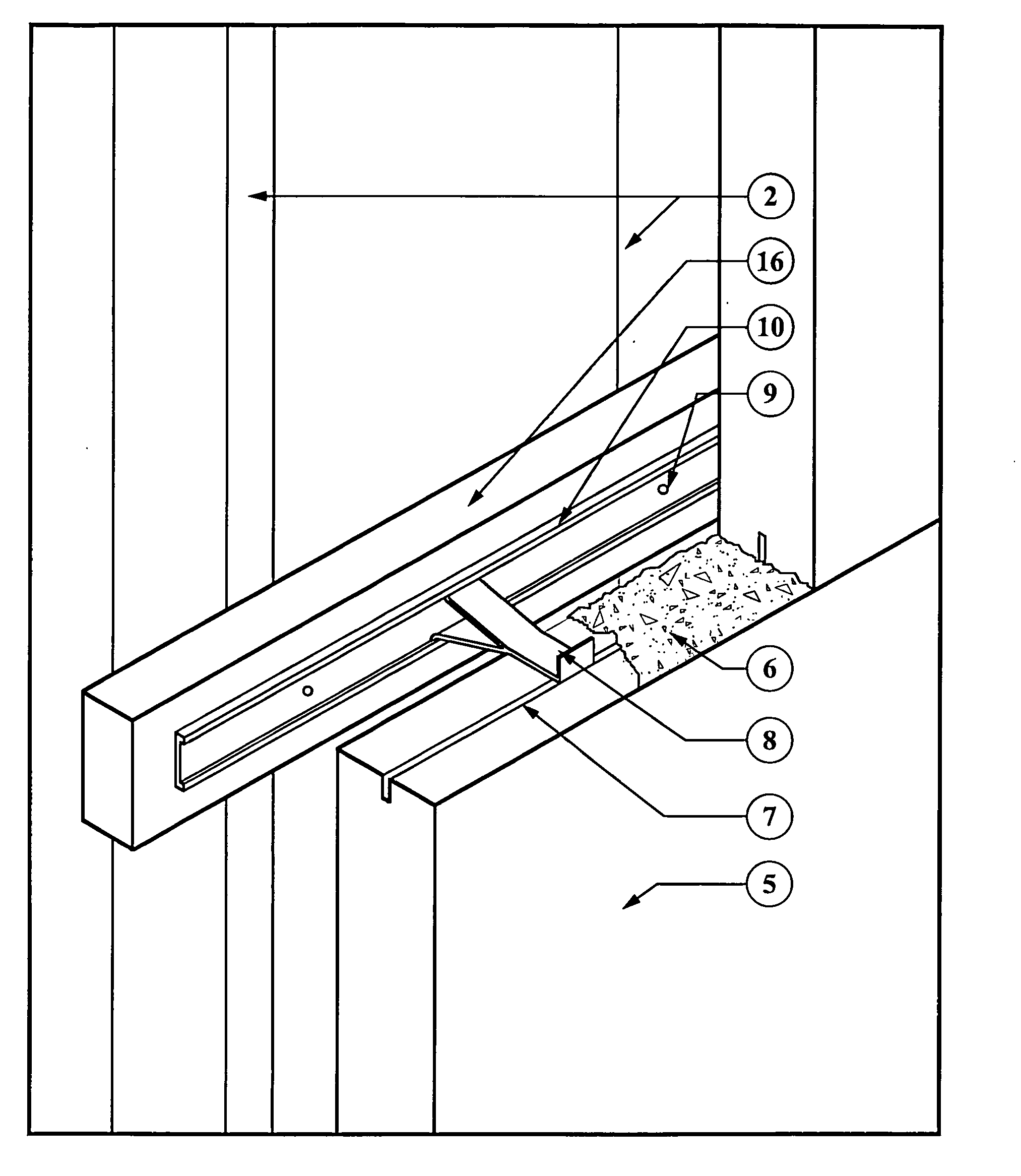

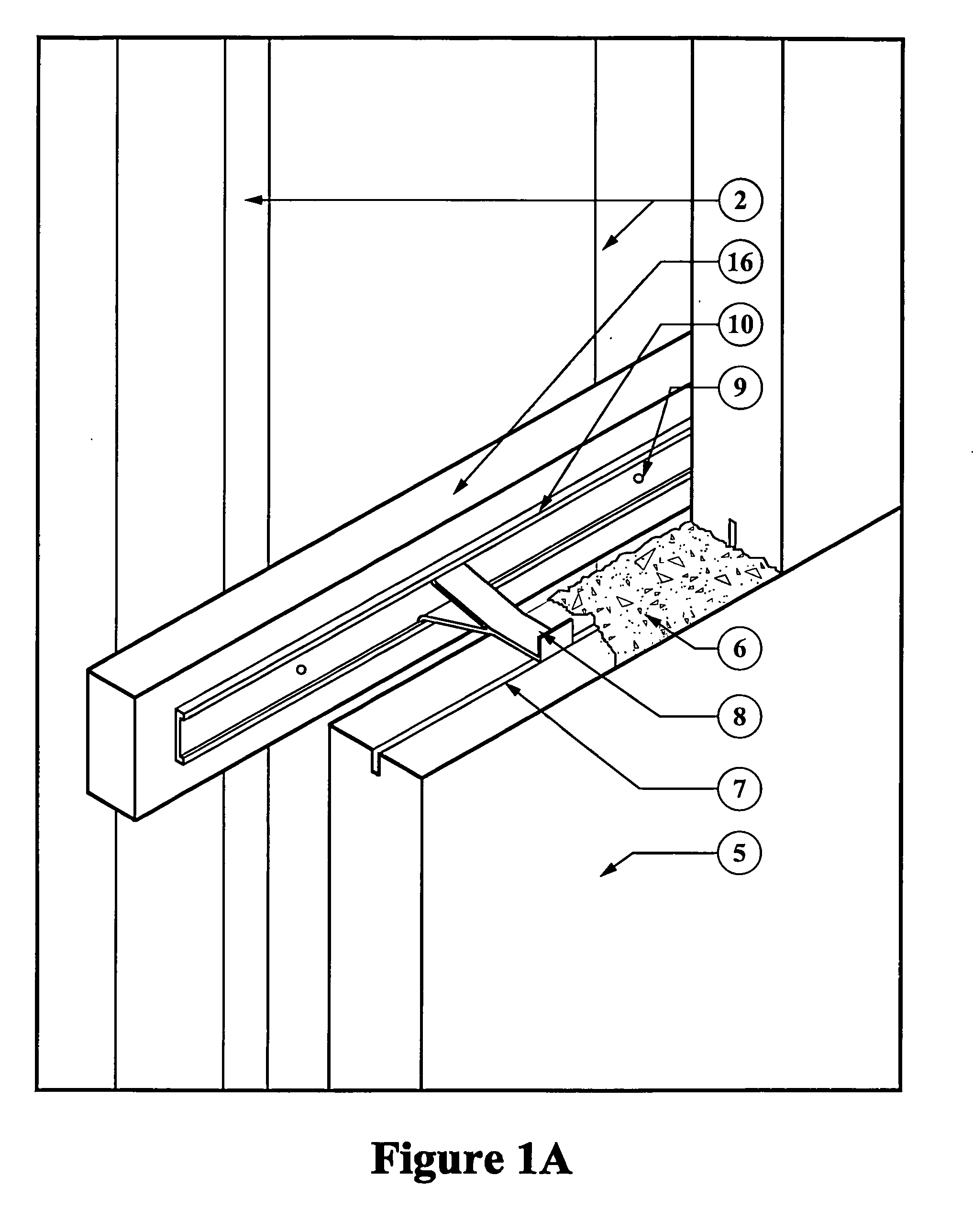

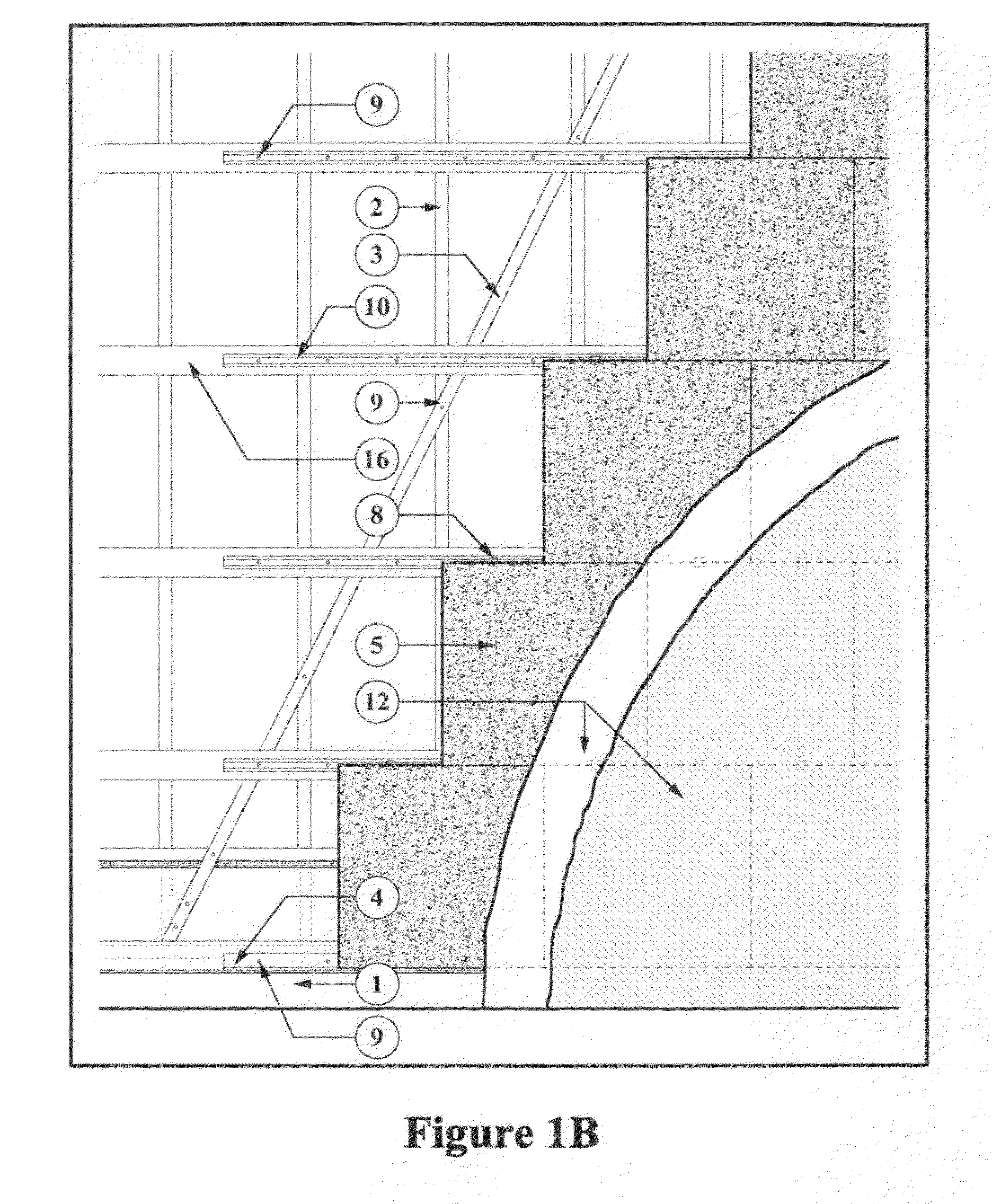

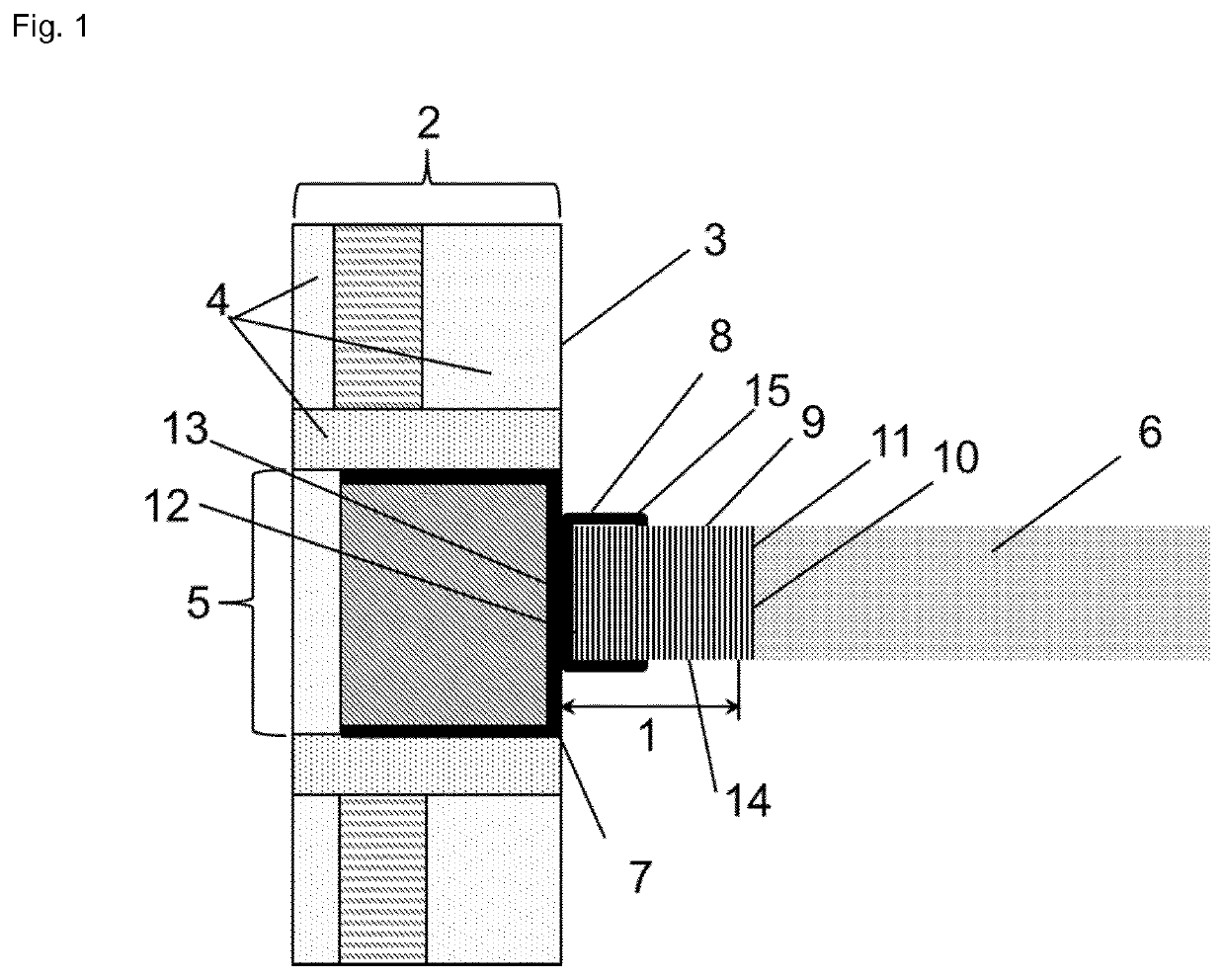

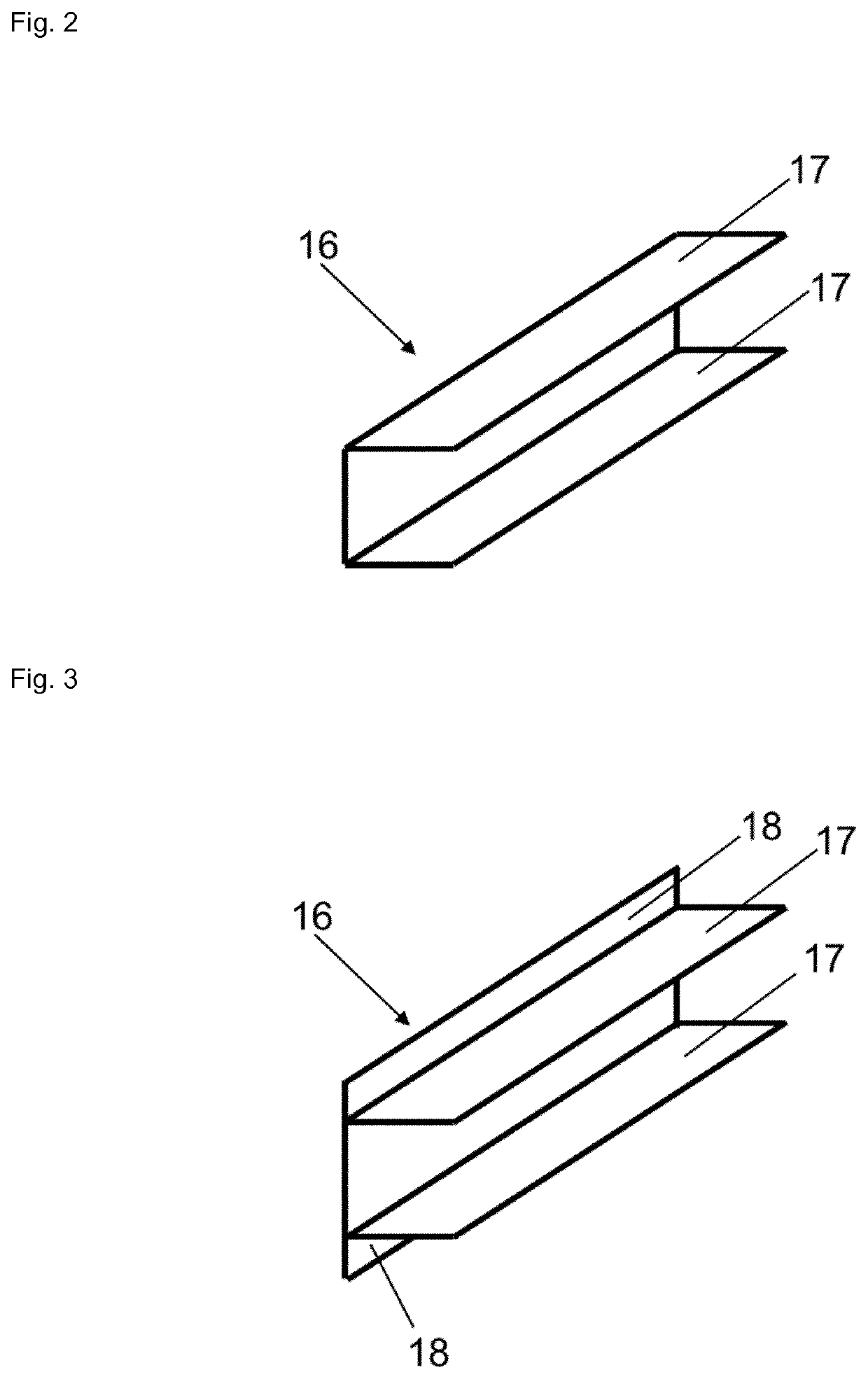

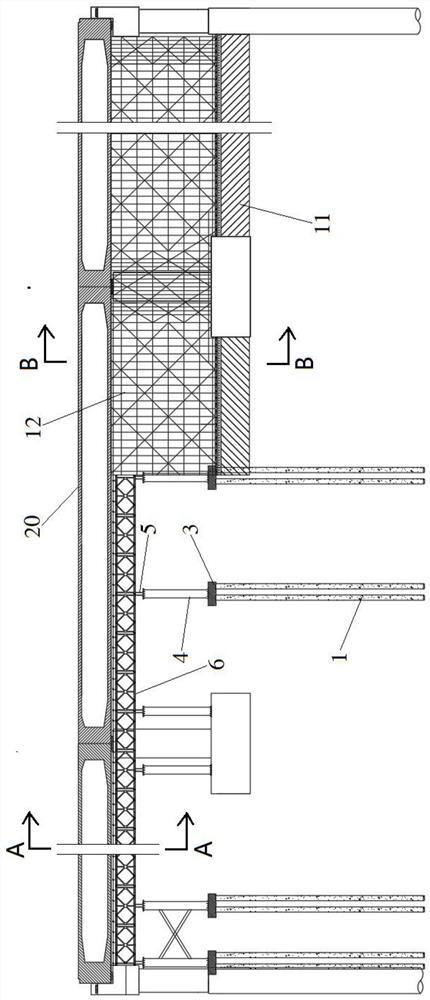

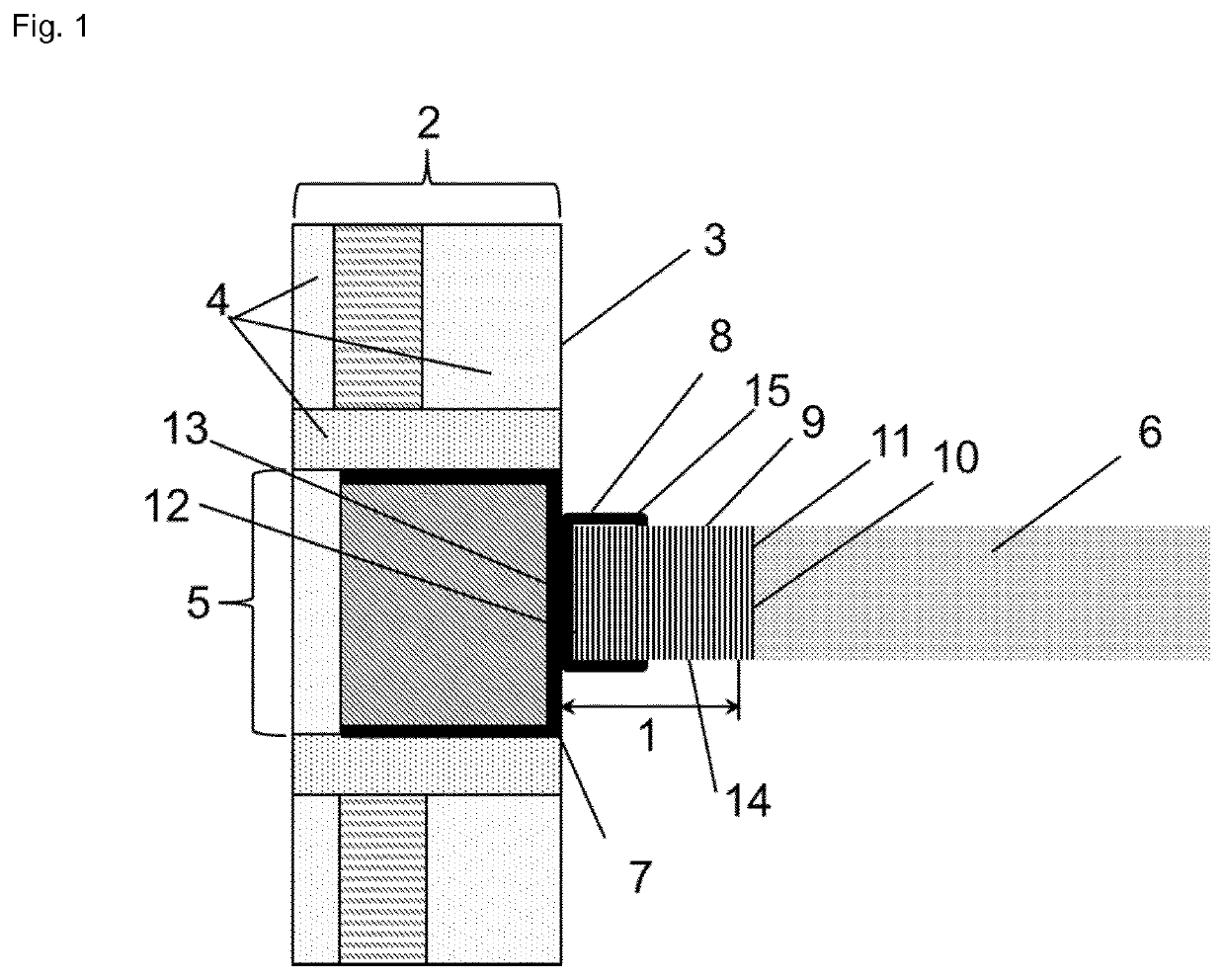

Thermal and acoustic insulating and sealing system for a safing slot in a curtain wall

Described is a construction and parts of the construction for effectively thermally and acoustically insulating and sealing of a safing slot (1) between a floor (6) of a building and an exterior wall construction wherein the exterior wall construction comprises a curtain wall configuration (2) utilizing an interior panel module design. In particular, the thermal insulating and sealing system comprises a first element (7) comprising a top framing component (8) having an interior wall surface (13) and an opening, positioned substantially in the height of the floor (6), wherein the top framing component (8) is located on top of the interior wall surface (3) of the spandrel panel (7), and a second element (9) comprised of a thermally resistant and / or air tight material for insulating, positioned at least partially in the top framing component (8) of the first element (7), wherein the second element (9) includes an inner end surface (10) positionable in abutment with respect to the outer edge (11) of the floor (6) for sealing thereadjacent, outer end surface (12) positionable in abutment with respect the interior wall surface (13) of the top framing component (8), a lower facing surface (14) extending between the inner end surface (10) and the outer end surface (12) and facing downwardly therebetween, and an upper facing surface (15) extending between the inner end surface (10) and the outer end surface (12) and facing upwardly therebetween.

Owner:HILTI AG

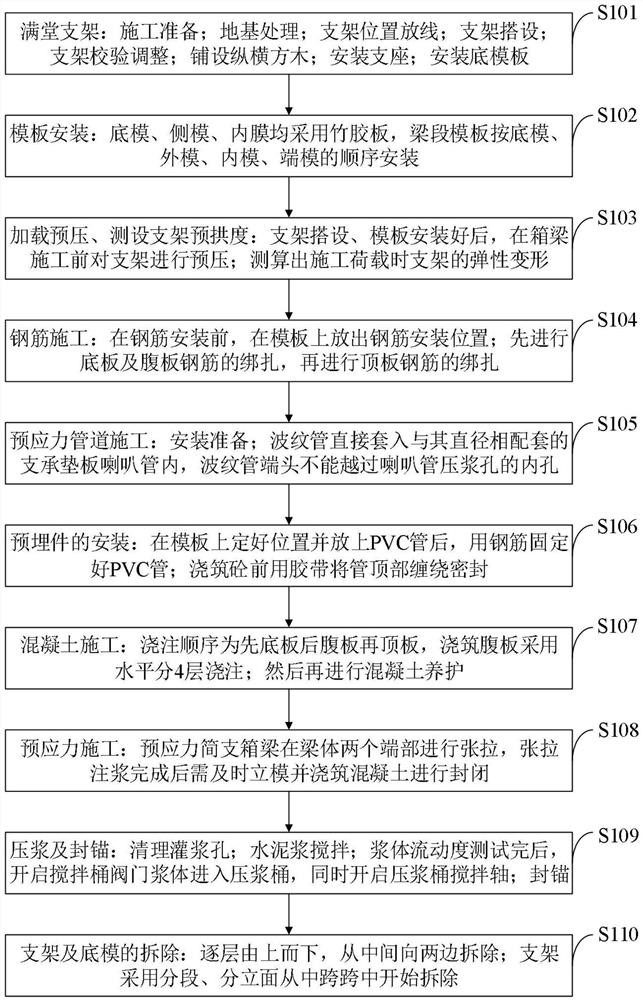

Construction method applied to template supporting frame body based on BIM template integral installation technology

PendingCN113158295AEnsure construction safetyReduce construction costsGeometric CADSpecial data processing applicationsTemplate matchingTemplate based

The invention discloses a construction method applied to a template supporting frame body based on a BIM template integral installation technology. The construction method comprises the following steps: S1, creating a BIM model; s2, outputting an automatic safety calculation book; s3, optimizing the BIM model; s4, performing one-key output on the construction drawing; s5, accurately calculating the quantity and generating a template matching list; s6, centralized processing and template numbering; s7, performing positioning and paying off; s8, erecting a full framing; s9, the formwork is hoisted; s10, carrying out vertical component steel bar installation and template supporting; s11, carrying out vertical component concrete pouring; s12, carrying out full framing inspection and acceptance; s13, installing a beam plate template; s14, binding beam steel bars; s15, carrying out checking and accepting; s16, carrying out horizontal component pouring; s17, carrying out concrete curing; and S18, removing the template. According to the method, BIM software is combined with related specifications to establish a template supporting frame body BIM model, mechanical calculation is conducted on a template supporting frame body, a template supporting frame body erecting plane graph, a large sample graph and the steel pipe and template material amount are output, a perfect template engineering planning scheme is compiled accordingly, and the management level and construction quality of template engineering are improved.

Owner:贵州建工集团第四建筑工程有限责任公司

Modular structure

InactiveUS20090120021A1Cost savingEase of constructionBuilding roofsFloorsModularityModular structure

A modular building system including methods and kits is provided. The system comprises C-channels anchored to a base. Structural insulated panels are slid into the channels to form walls. Adaptors are provided to provide channels at an angle for the insertion of roof panels. The building system provides for the rapis construction of a building without the need for framing or the use of roof trusses.

Owner:HILL DON A

Cast-in-place box girder construction system and construction method for excavation section of existing in-service line modified bridge

PendingCN111827129AShorten the construction periodFoundation testingForms/shuttering/falseworksArchitectural engineeringFraming (construction)

The invention provides a cast-in-place box girder construction system and construction method for an excavation section of an existing in-service line modified bridge. Stand columns of a stand columnpre-isolation structure are pre-buried in backfill soil of a foundation; a foam light soil pipe is positioned and sleeved on each stand column; tie beam side dies and tie beam bottom dies of a tie beam supporting structure are positioned on the outer side of a tie beam; the tie beam side dies are arranged between the stand columns, and two ends are respectively connected with the stand columns; the tie beam bottom dies are positioned and supported through low brackets and are used for realizing the positioning arrangement of tie beams; the lower portion of a box girder outer side die of a boxgirder formwork structure is located on a box girder bottom die through a supporting frame, and the upper portion is located through a pull rod assembly; and a box girder inner side die is positionedin the box girder outer side die. By arranging the stand column pre-isolation structure, the tie beam supporting structure and the box girder formwork structure, full framing and corresponding construction support formwork dismounting are not needed, more time and labor are saved, the construction period is greatly shortened, and the system is economical, practical and suitable for wide popularization.

Owner:ANHUI ROAD & BRIDGE GRP

Framing Corner Joint and Method of Manufacture

ActiveUS20110123755A1Readily be welded to each otherDoors/windowsLaminationThermoplasticFraming (construction)

A framing corner joint includes first and second framing rails of fiberglass-reinforced resin construction. The first and second framing rails have hollow mitered ends. A pair of thermoplastic plugs are received in the mitered ends of the respective framing rails. Each of the plugs includes a body inserted into the hollow interior of an associated framing rail and a flat plug flange at an angle of 45° to the body. The plug flanges extend outwardly from the peripheries of the bodies between the rail ends and have flat end faces that are bonded to each other. The bodies of the plugs preferably are hollow, and preferably are received by interference press-fit within the ends of the rails. The plug flanges of the plugs preferably are welded to each other.

Owner:MILGARD MFG LLC

Cast-in-place construction method for large-span diamond-shaped bent cap of high pier

InactiveCN112211113ABridge structural detailsBridge erection/assemblySupporting systemArchitectural engineering

According to the cast-in-place construction method for the large-span diamond-shaped bent cap of the high pier, cast-in-place construction of inclined legs and the bent cap is achieved through a two-part supporting system, in the first part, a combined supporting system is formed through 45a double-spliced I-shaped steel, a channel steel bracket and a slope bracket, and cast-in-place constructionof an inclined leg supporting bent cap structure is achieved; and in the second part, a fastener type steel pipe full framing is erected at the hollow structure on the tie beam which is poured and solidified, square timbers and formworks are laid, and cast-in-place construction of the cross beam is achieved. The construction method is a very simple, effective, safe, reliable, rapid and economicalconstruction scheme for viaducts and municipal bridges constructed under the complex conditions of high piers crossing rivers, valleys crossing, soft soil foundations crossing and the like. By the adoption of the construction technology, the defects that a traditional bracket is difficult to construct, long in construction period, high in cost, large in risk, multiple in potential safety hazard and the like are overcome.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

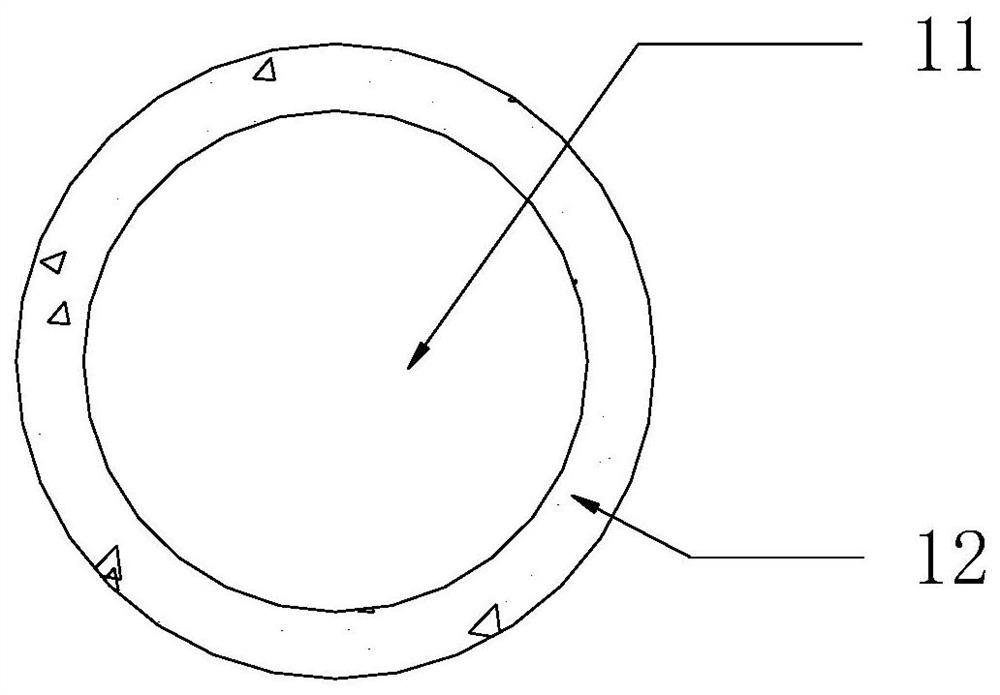

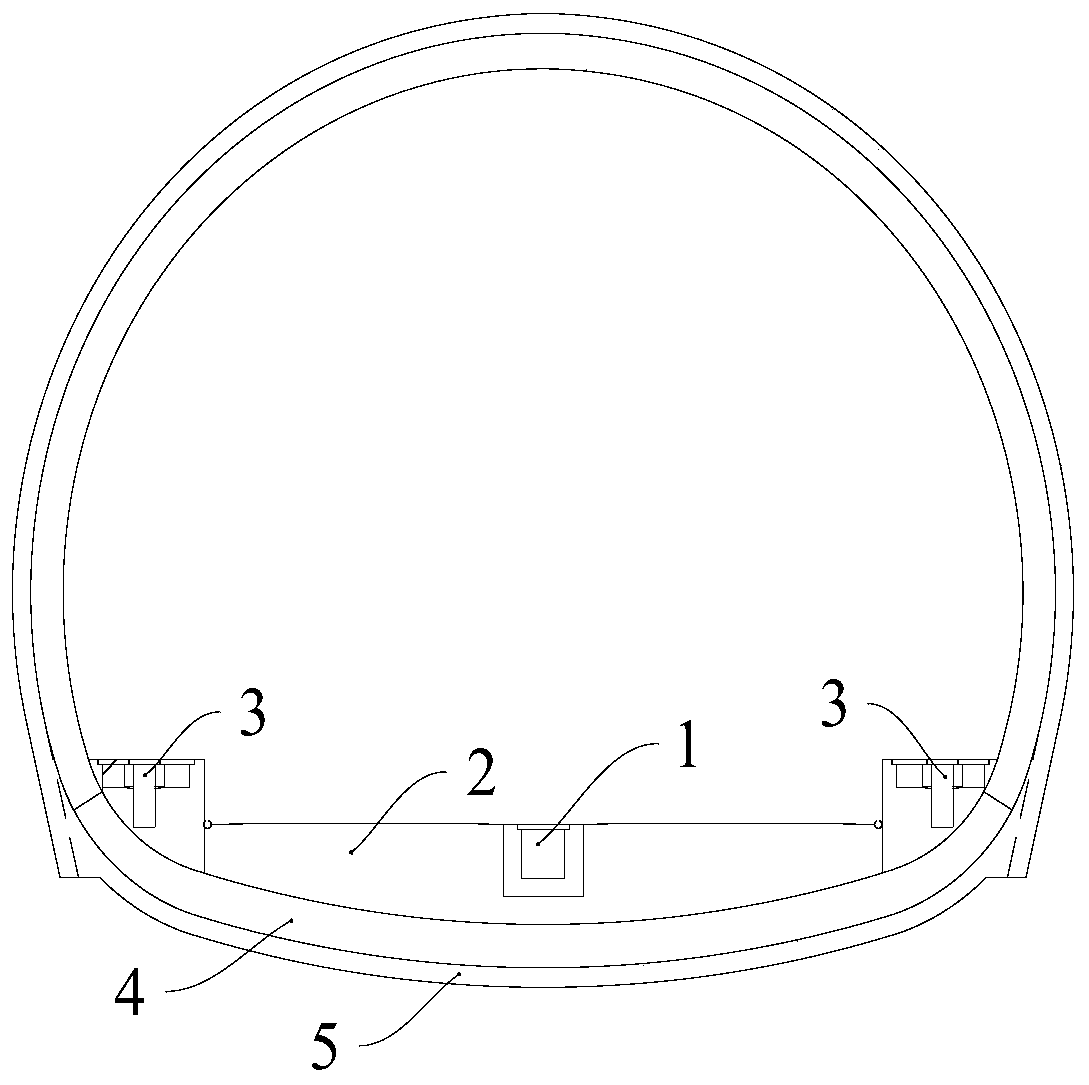

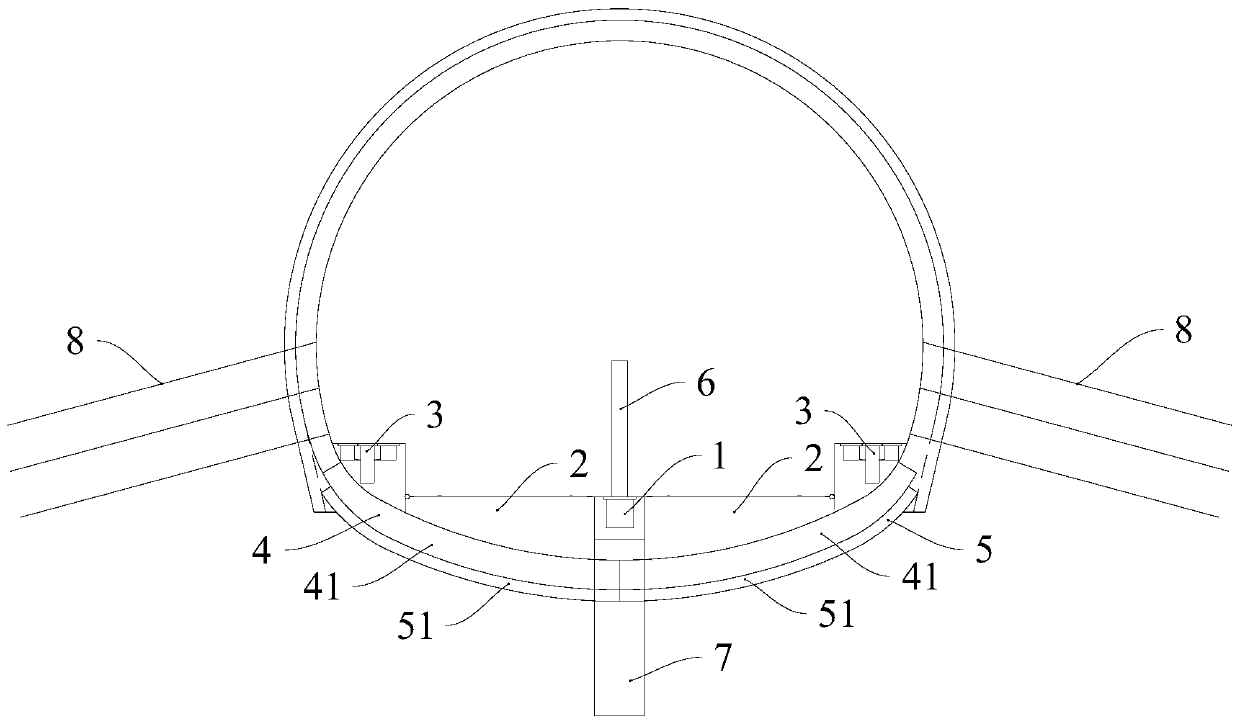

Lining supporting system for tunnel framing reconstruction tunnel bottom structure and construction method thereof

PendingCN111271079AEnsure safetyReduce riskMining devicesUnderground chambersSupporting systemTrackway

The invention discloses a lining supporting system for a tunnel framing reconstruction tunnel bottom structure and a construction method thereof. The supporting system comprises an inverted arch lining, a primary support, steel flower tube lock feet, a blocking isolation wall and a pre-reinforcing pile, wherein the inverted arch lining and the primary support are arranged at the tunnel bottom, thesteel flower tube lock feet are driven into surrounding rock from side walls on the two sides, and the blocking isolation wall and the pre-reinforcing pile are positioned above and below a central ditch correspondingly; the inverted arch lining comprises two half-range inverted arch linings which are symmetrically arranged in the transverse direction of a tunnel; the primary support comprises twohalf-range primary supports which are symmetrically arranged in the transverse direction of the tunnel; and the pre-reinforcing pile is fixedly connected with the two half-range inverted arch liningsand the two half-range primary supports. According to the lining supporting system for the tunnel framing reconstruction tunnel bottom structure and the construction method thereof, the risk of framing reconstruction of the tunnel bottom structure in the operating state of the tunnel is reduced in the form of framing excavation and framing support, the operation time of reconstruction of the tunnel bottom structure can be not limited, the overhead reinforcing procedure of a steel cushion beam is omitted, interference to a track structure is reduced, and the construction progress in the operating state can be greatly improved on the premise of ensuring safety.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Cable rope crane system and hoisting method

The invention relates to the technical field of bridge construction, in particular to a cable rope crane system and a hoisting method. The cable rope crane system crosses over the two sides of a riverand is composed of cable bent towers, cable ropes, an anchoring system, cable saddles, a hoisting car and a buckling and hanging system. The cable bent towers are mounted on the two opposite sides ofthe river through foundation embedded parts and are connected with the foundation embedded parts through bolts. The cable saddles are arranged on the cable bent towers. The anchoring system is composed of a rear anchor foundation of a reinforced concrete structure and anchor piles. According to the cable rope crane system and the hoisting method, the technical problem that due to the fact that the clearance of an arch bridge is high, full framing construction cannot be adopted is solved.

Owner:CHONGQING COMM CONSTR GRP +1

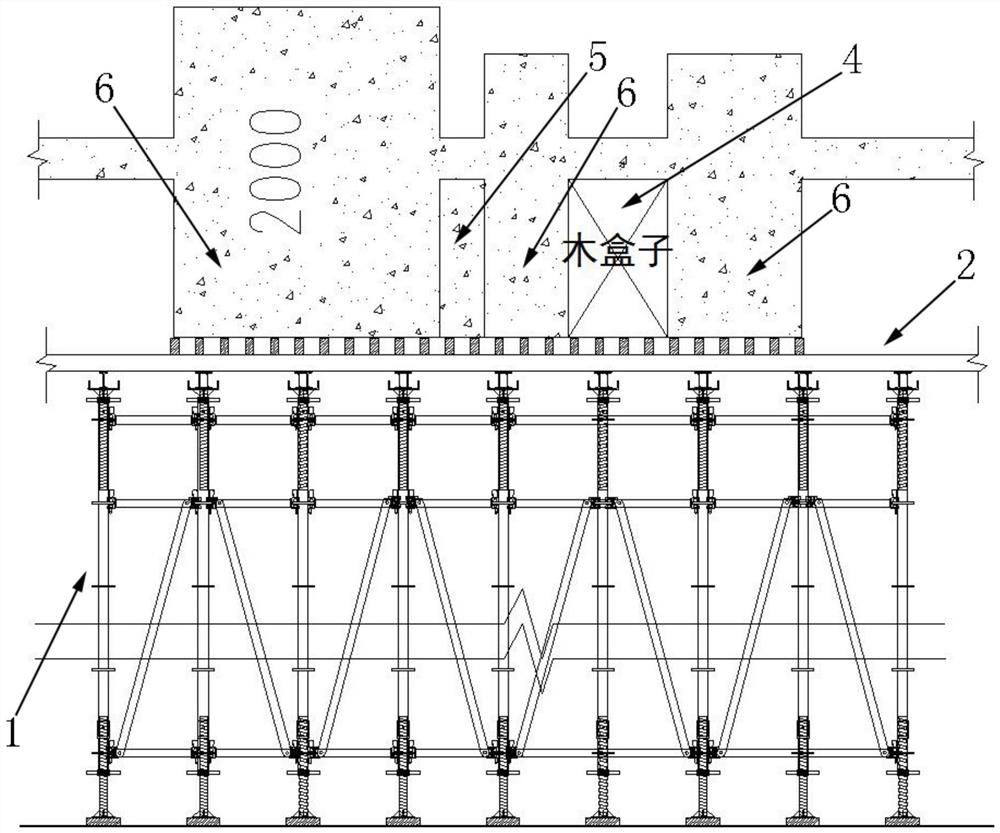

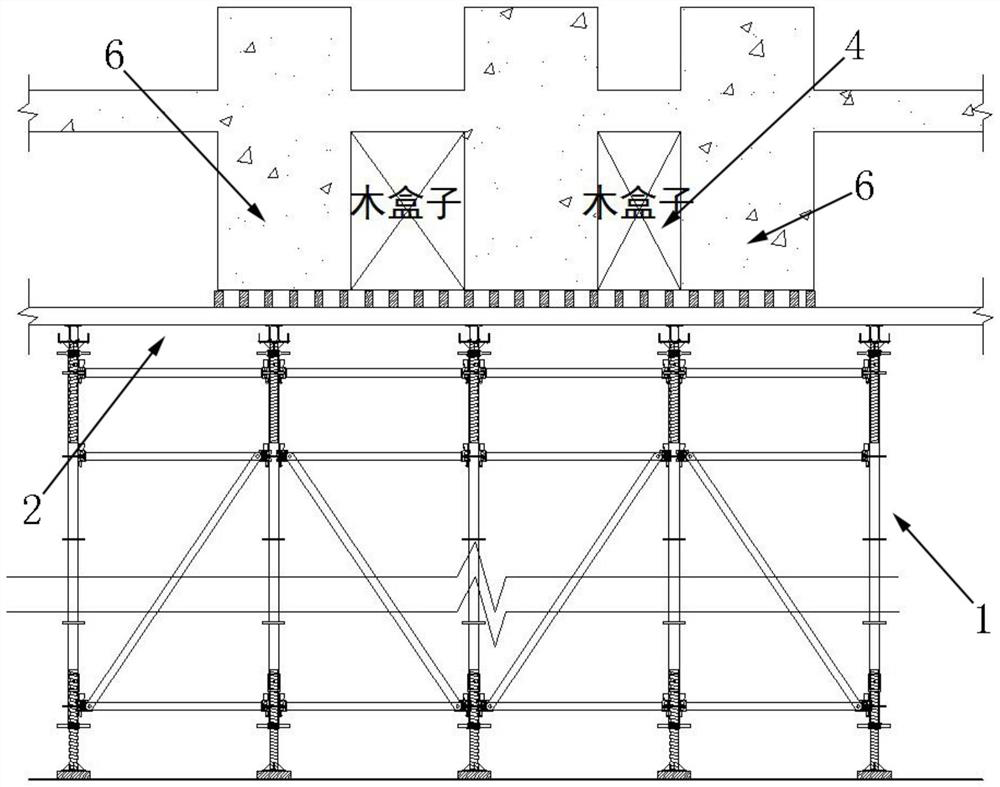

Overload small-clear-distance beam adjustable disc buckle formwork supporting frame and construction method thereof

PendingCN114575593ASimple structureScientific and reasonable designForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksArchitectural engineeringFraming (construction)

The invention discloses a super-load small-distance beam adjustable ring buckle formwork supporting frame and a construction method thereof.The super-load small-distance beam adjustable ring buckle formwork supporting frame comprises a ring buckle type scaffold, a full framing arranged on the ring buckle type scaffold, a full framing adjustable jacking and a wooden box, and the full framing adjustable jacking and the wooden box are arranged on the full framing and used for supporting a beam body; the concrete pouring bodies are poured between the adjacent beam bodies, and the bottoms of the concrete pouring bodies abut against the full framing. The construction method comprises the steps of erecting the ring-lock type scaffold, erecting the full framing and erecting the overload small-clear-distance inter-beam supporting structure. The technical problems that the erecting working condition of a beam body supporting frame cannot meet the modular space requirement of the ring-lock type scaffold, and the formwork mounting quality is affected due to insufficient side formwork reinforcing operation space caused by complex main body structures or large-density beam body distribution of a transfer layer are mainly solved.

Owner:CHINA MCC5 GROUP CORP

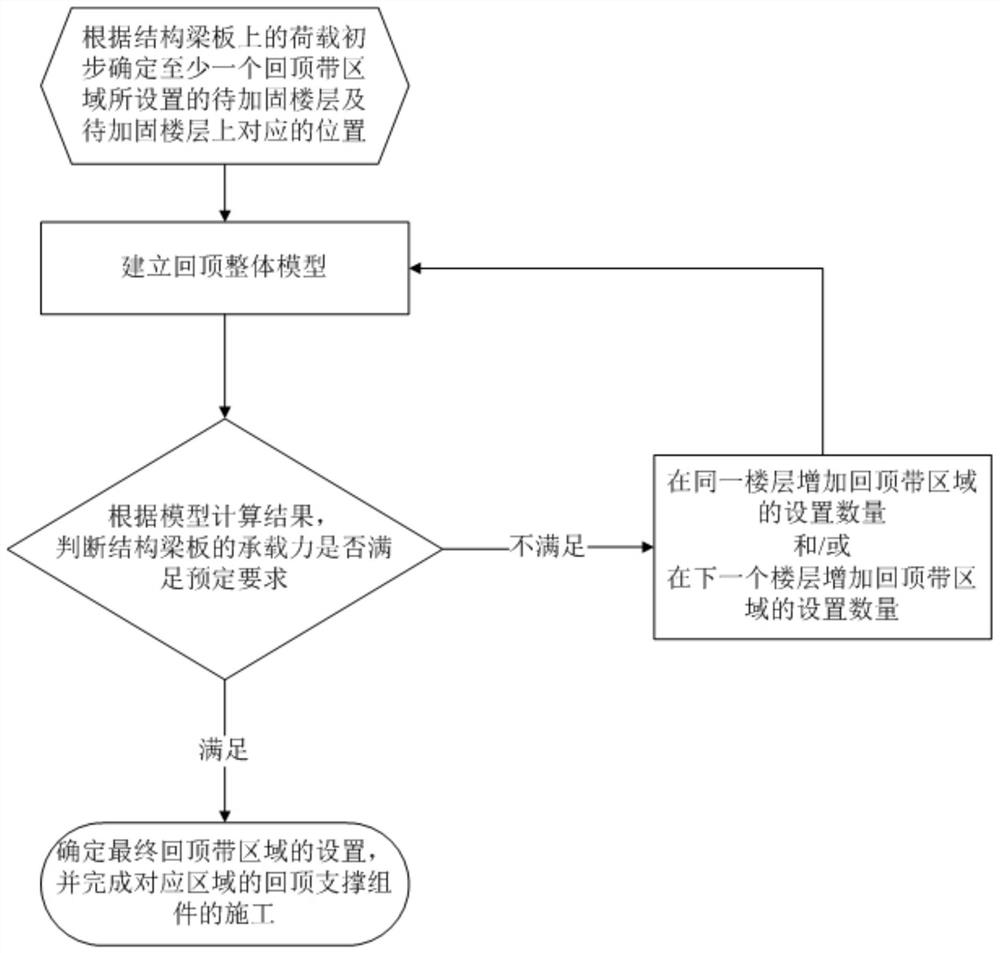

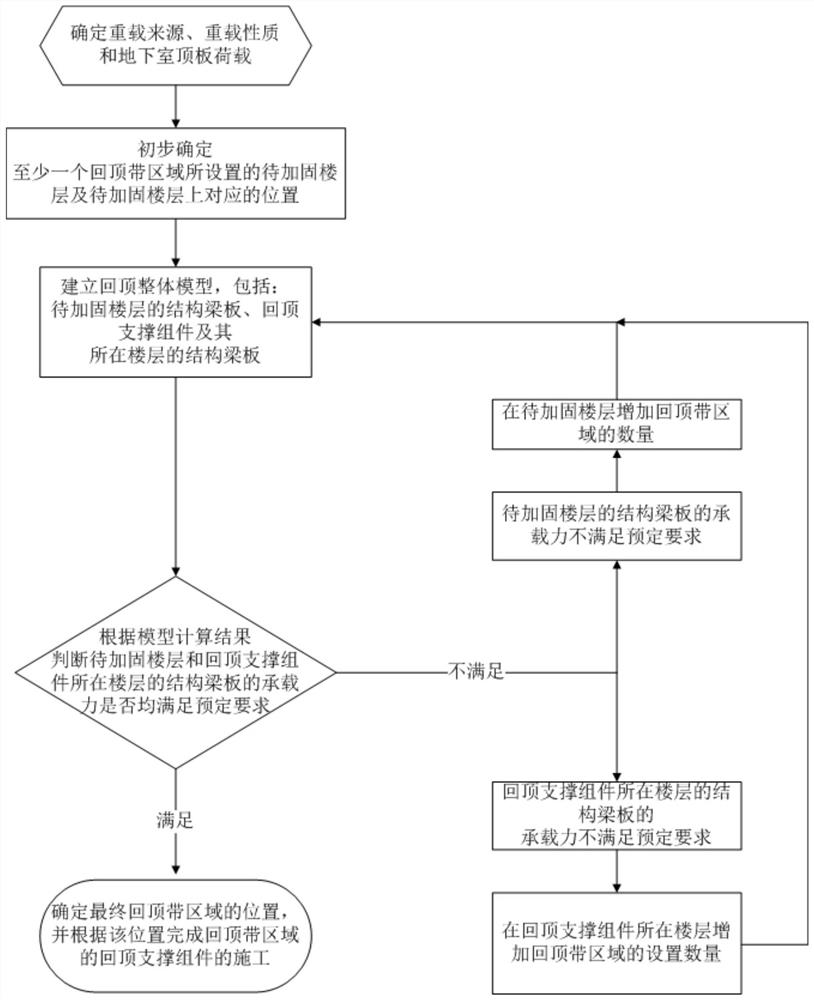

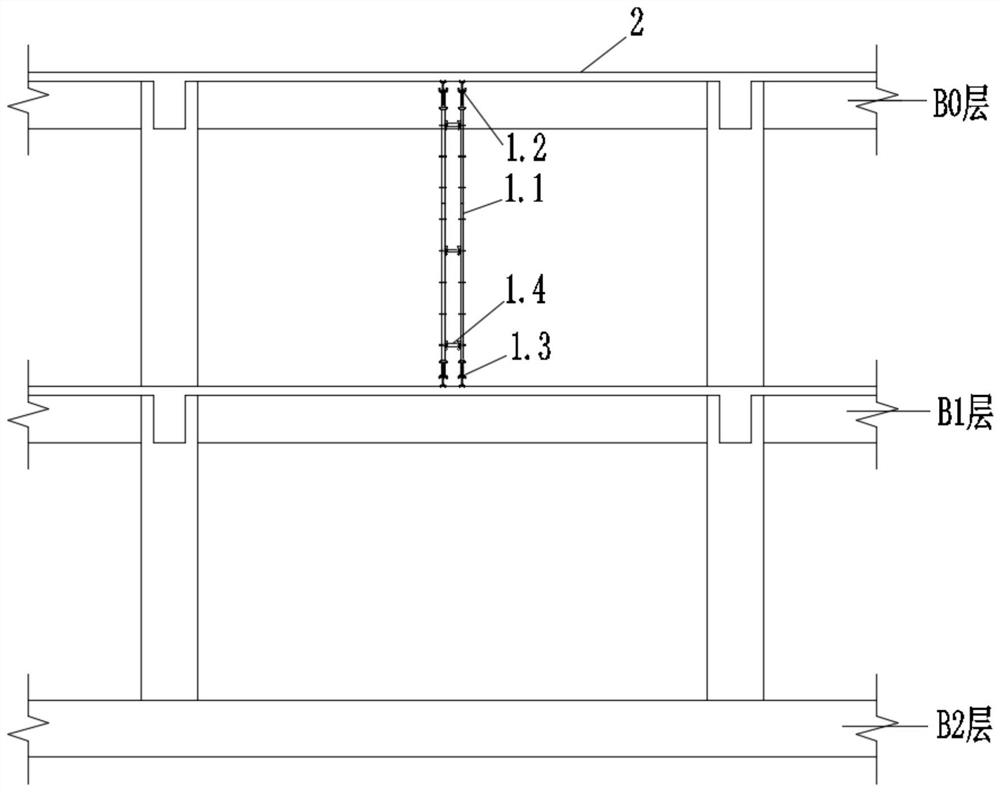

Structure beam plate back-to-top reinforcing method

PendingCN113482394ASolving Temporary Reinforcement IssuesSimple structureBuilding repairsBasementArchitectural engineering

The invention relates to the field of buildings, and provides a structural beam plate back-to-top reinforcing method. The structural beam plate back-to-top reinforcing method comprises the following steps that a to-be-reinforced floor arranged in a back-to-top zone area and a corresponding position on the to-be-reinforced floor are preliminarily determined according to a load on a structural beam plate, and a back-to-top supporting assembly is arranged below the back-to-top zone area; a back-to-top overall model is established; the bearing capacity of the structural beam plate is judged according to a model calculation result; if the bearing capacity is insufficient, the setting number of the back-to-top zone areas is continuously increased on the same floor and / or the setting number of the back-to-top zone areas is increased on the next floor, and then re-modeling is carried out until the bearing capacity meets the preset requirement; and setting of the final back-to-top zone area is determined, and construction of the back-to-top supporting assembly of the corresponding area is completed. A basement top plate is divided into a plurality of span plates by providing the back-to-top zone, the plate span of the basement top plate is reduced, the bearing capacity of the basement top plate is improved, a large number of full framing does not need to be erected, and therefore the construction cost is reduced, and the construction efficiency is improved.

Owner:中建三局集团(深圳)有限公司

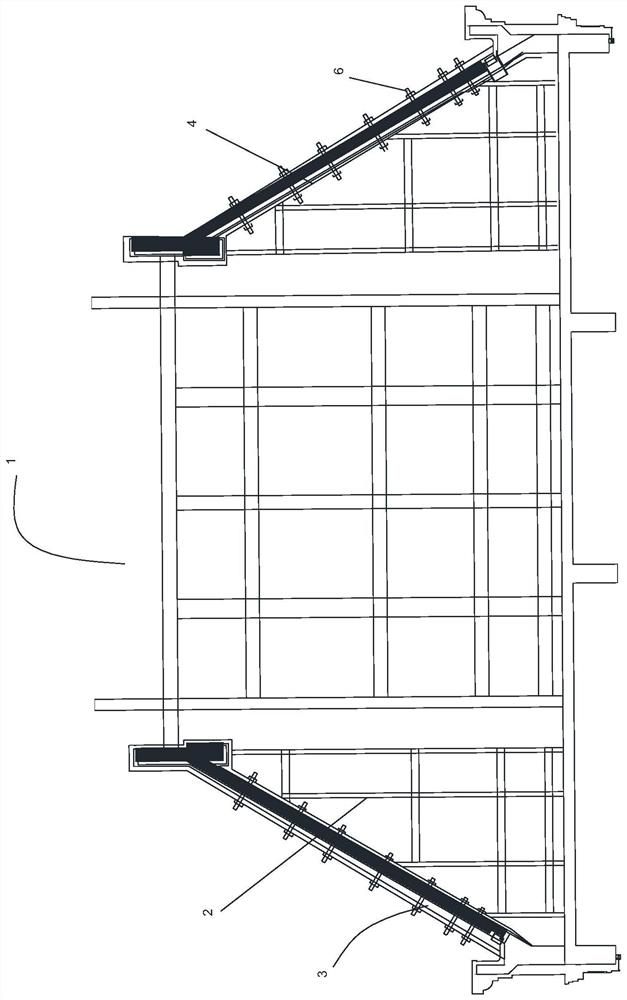

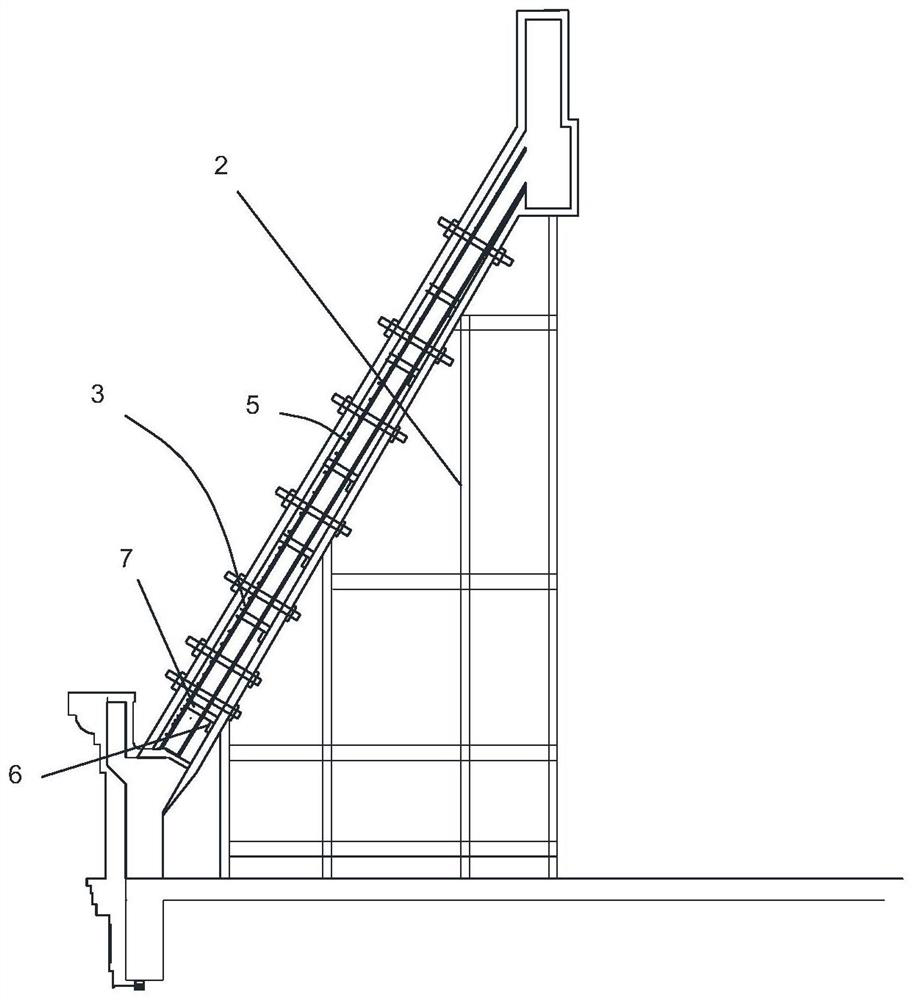

Large-gradient special-shaped sloping roof concrete construction system and construction method thereof

PendingCN113898104AEasy to set upEasy to placeBuilding roofsForms/shuttering/falseworksArchitectural engineeringHoneycomb

The invention provides a construction method of a large-gradient special-shaped sloping roof concrete construction system. The construction method of the large-gradient special-shaped sloping roof concrete construction system comprises the following steps that a full framing system is built firstly, then a bottom formwork and an outer formwork are erected, and the outer formwork is reinforced; a double-formwork structure is adopted, a vibration space facilitating vibration of a direct inserted type vibration rod is formed in a steel bar system, an inclined roof panel formed after casting is clamped between the bottom formwork and the outer formwork, the bottom formwork and the outer formwork can enable the surface flatness of the inclined roof panel to be good, the honeycomb and pitted surface phenomena do not exist, and the inclined roof panel is well connected with a connecting position. According to the large-gradient special-shaped sloping roof concrete construction system, the arrangement of pre-embedded supporting pieces particularly facilitates the arrangement of the steel bar system and the placement and fine adjustment of a whole top formwork; meanwhile, in order to ensure the vibration effect of the inserted type vibration rod, radians are intermittently arranged on transverse steel bars in the steel bar system.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

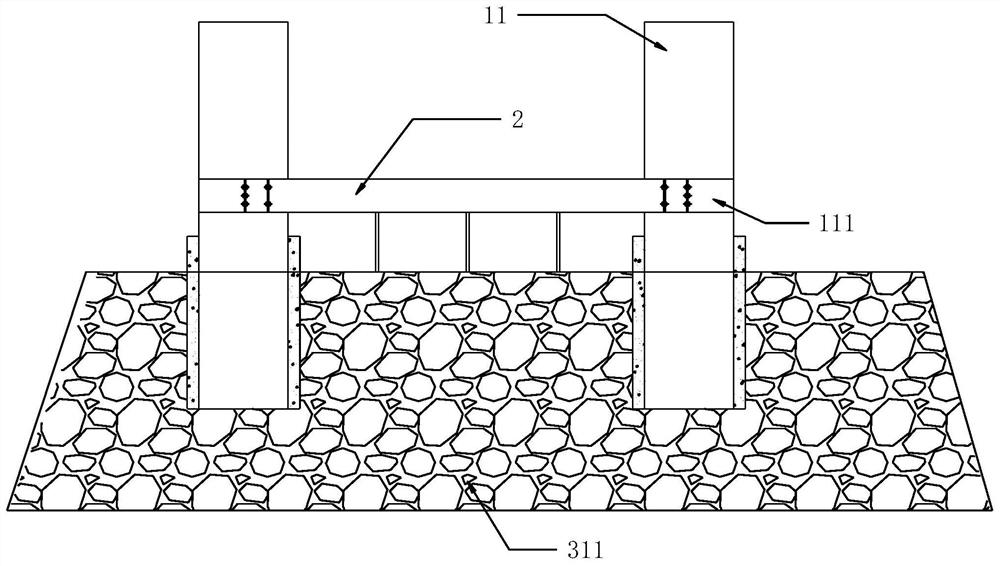

Combined cast-in-place box girder support structure and construction method thereof

PendingCN112779864AReduce processingReduce construction costsBridge erection/assemblyBulkheads/pilesPre stressArchitectural engineering

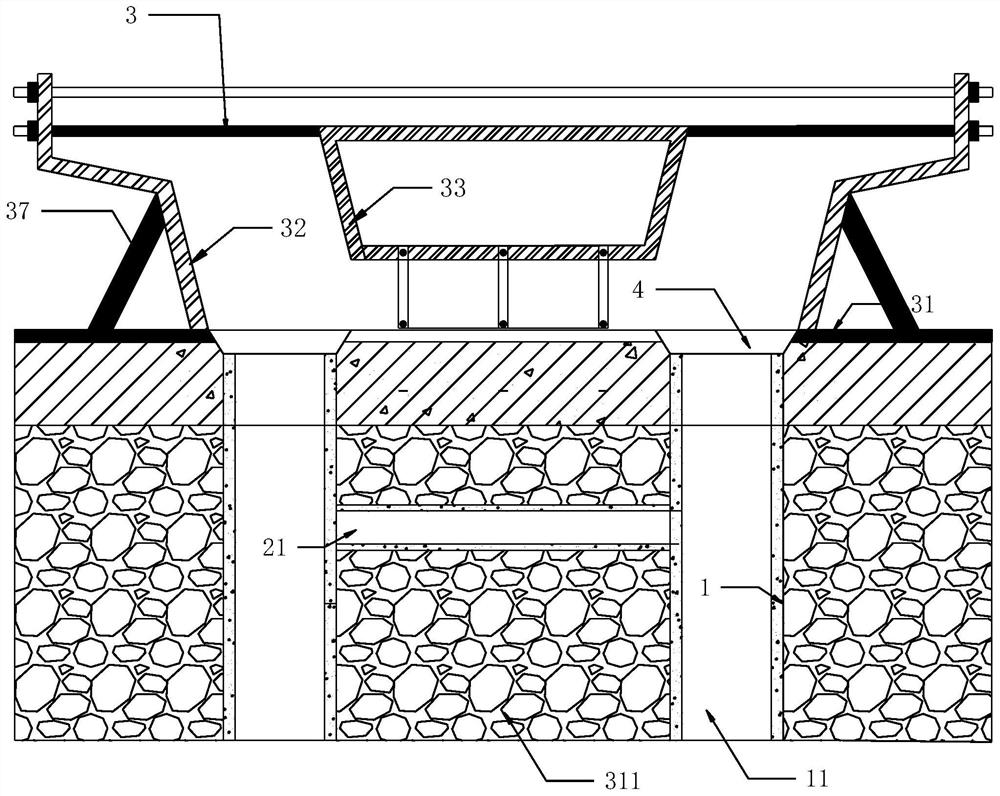

The invention provides a combined cast-in-place box girder support structure. The combined cast-in-place box girder support structure comprises a prestressed pipe pile foundation, a steel pipe column, a formwork and a roadbed, wherein multiple sets of prestressed pipe pile foundations are distributed in a soft foundation in an array mode, lower ends of the prestressed pipe pile foundations penetrate into a fully-weathered granite layer, and a concrete bearing platform is arranged at an upper end of each set of prestressed pipe pile foundation; each steel pipe column is fixed on one concrete bearing platform, and a bearing beam is fixed on each row of steel pipe columns; a plurality of bailey trusses are lapped on the bearing beams, and a plurality of distribution beams are transversely carried on the bailey trusses; the formwork comprises a bottom plate and side plates, a plurality of square timbers are arranged between the bottom plate and the distribution beams in the bridge direction, and side formwork supporting frames are arranged between the side plates and the distribution beams; the roadbed is located on the hard ground, a bowl-buckle-type full framing is built on the roadbed, a jacking plate is arranged on the upper portion of the bowl-buckle-type full framing, and a plurality of square timbers are arranged between the jacking plate and a bottom plate and a side plate of the formwork in the bridge direction. The invention further provides a construction method of the combined cast-in-place box girder support.

Owner:中交二公局第六工程有限公司

Thermal and acoustic insulating and sealing system for a safing slot in a curtain wall

Described is a construction and parts of the construction for effectively thermally and acoustically insulating and sealing of a safing slot (1) between a floor (6) of a building and an exterior wall construction wherein the exterior wall construction comprises a curtain wall configuration (2) utilizing an interior panel module design. In particular, the thermal insulating and sealing system comprises a first element (7) comprising a top framing component (8) having an interior wall surface (13) and an opening, positioned substantially in the height of the floor (6), wherein the top framing component (8) is located on top of the interior wall surface (3) of the spandrel panel (7), and a second element (9) comprised of a thermally resistant and / or air tight material for insulating, positioned at least partially in the top framing component (8) of the first element (7), wherein the second element (9) includes an inner end surface (10) positionable in abutment with respect to the outer edge (11) of the floor (6) for sealing thereadjacent, outer end surface (12) positionable in abutment with respect the interior wall surface (13) of the top framing component (8), a lower facing surface (14) extending between the inner end surface (10) and the outer end surface (12) and facing downwardly therebetween, and an upper facing surface (15) extending between the inner end surface (10) and the outer end surface (12) and facing upwardly therebetween.

Owner:HILTI AG

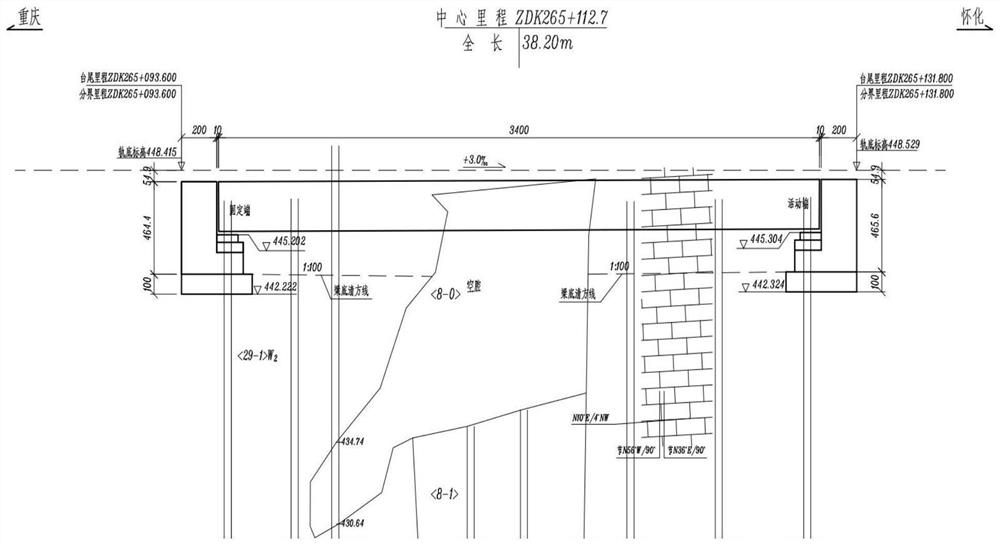

Cast-in-place box girder spanning cavern method for karst tunnel

PendingCN112502041ASimple structureEasy constructionBridge erection/assemblyStress concentrationArchitectural engineering

The invention belongs to the technical field of box girder spanning cavern construction, and discloses a cast-in-place box girder spanning cavern method for a karst tunnel, which comprises the following steps of treating a foundation; erecting a bracket; mounting an outer side mold; binding bottom and web steel bars; threading the steel strands; mounting an inner mold; binding top plate reinforcing steel bars; pouring concrete; carrying out surface finishing and maintenance; conducting pre-tensioning and initial tensioning; removing the template and the bracket; performing final tensioning andmud jacking; adopting a full framing method for construction; the bottom die, the outer die and the inner die are all wood dies, the inner supports are pulled outwards, and tie bars are arranged at the beam bottom and the beam top for reinforcement; concrete pouring adopts centralized stirring of a mixing station, a tank truck transports the concrete to a construction site, and a delivery pump truck pours the concrete; the full framing foundation is locally filled with tunnel hole slag, a water passing channel is reserved, and the foundation is hardened by C20 concrete by 30 cm. The method isconvenient to construct, durable, convenient to maintain, small in investment scale, good in universality and high in economic benefit; obvious stress concentration cannot be generated at the periphery, and a new fatigue risk source is prevented from being introduced.

Owner:中铁二十局集团第三工程有限公司

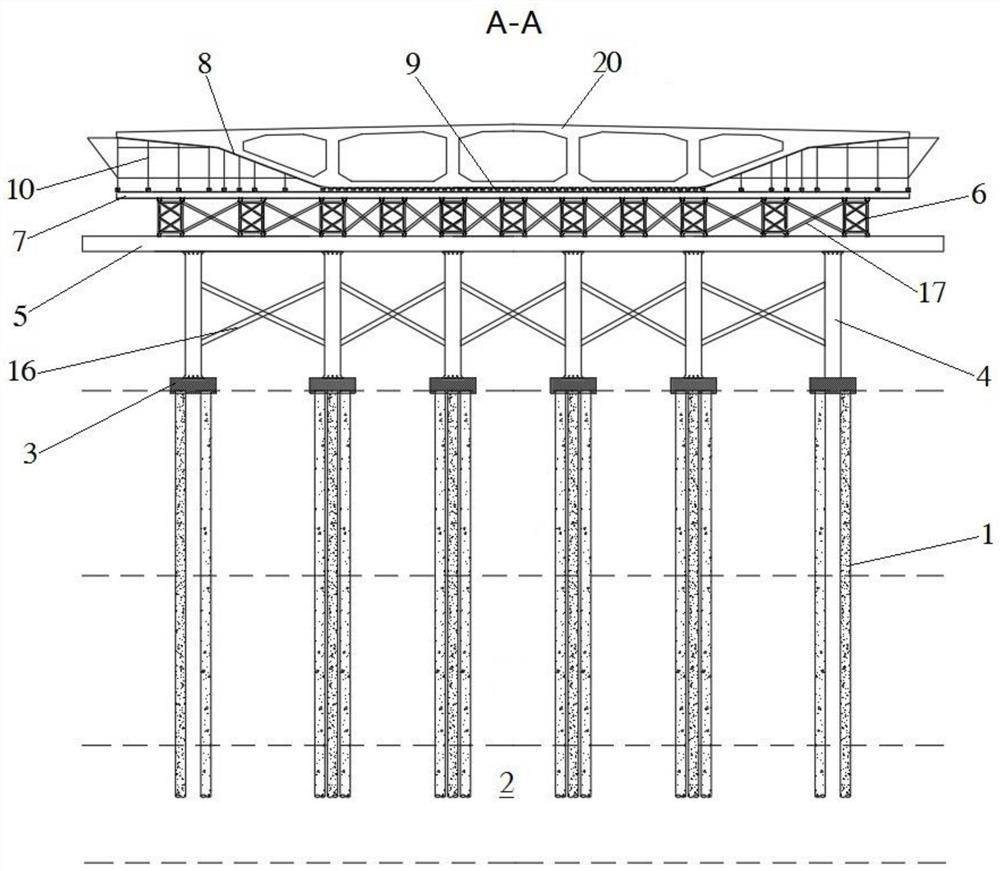

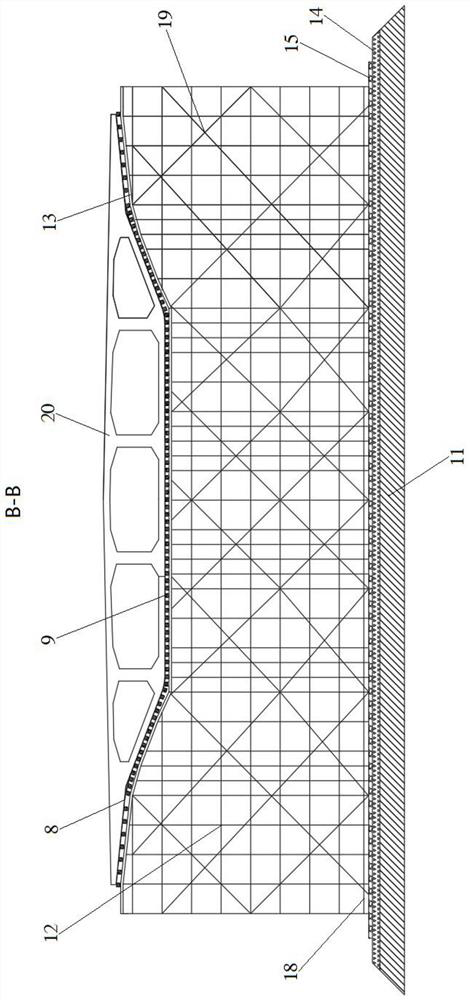

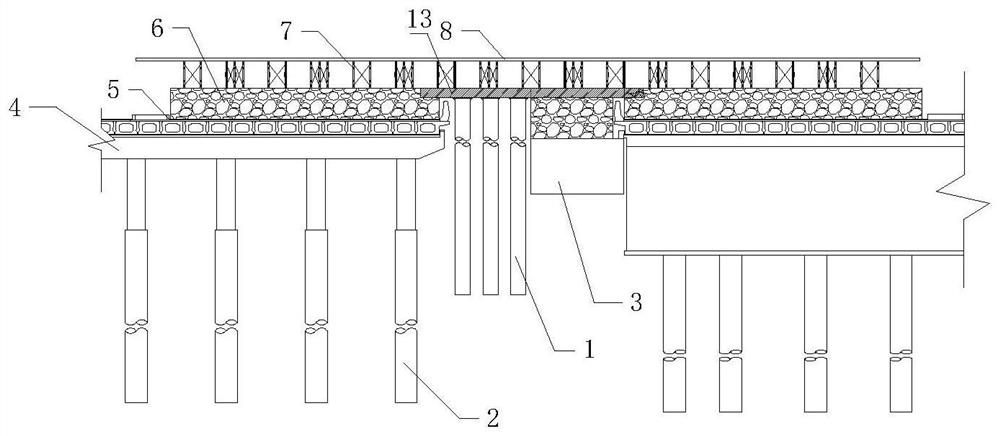

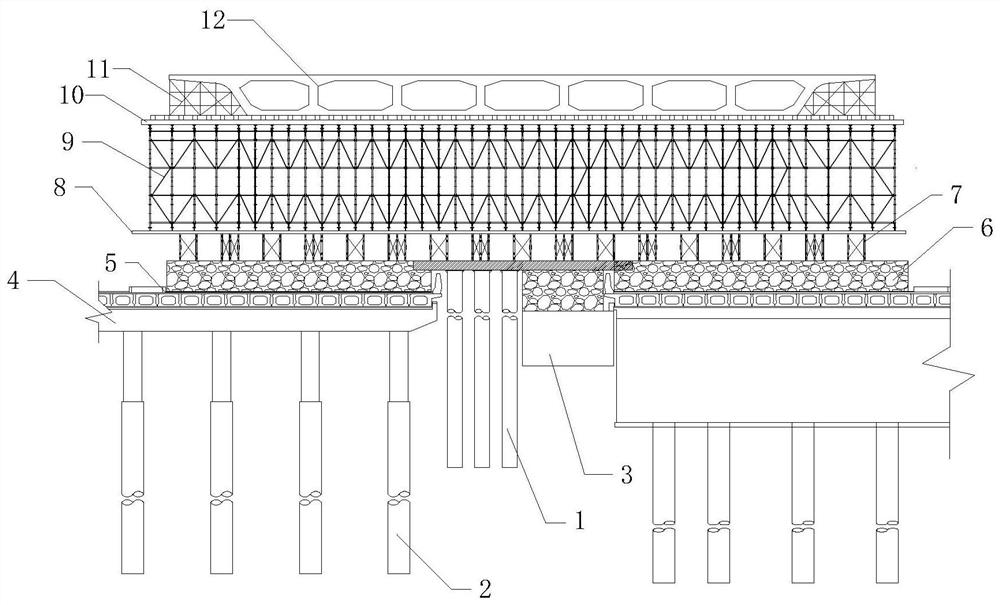

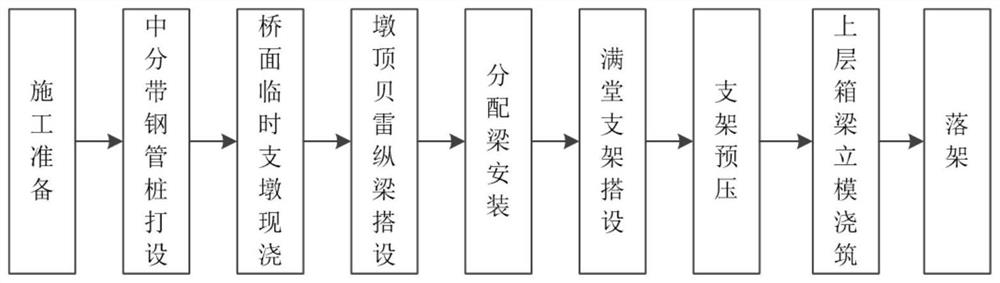

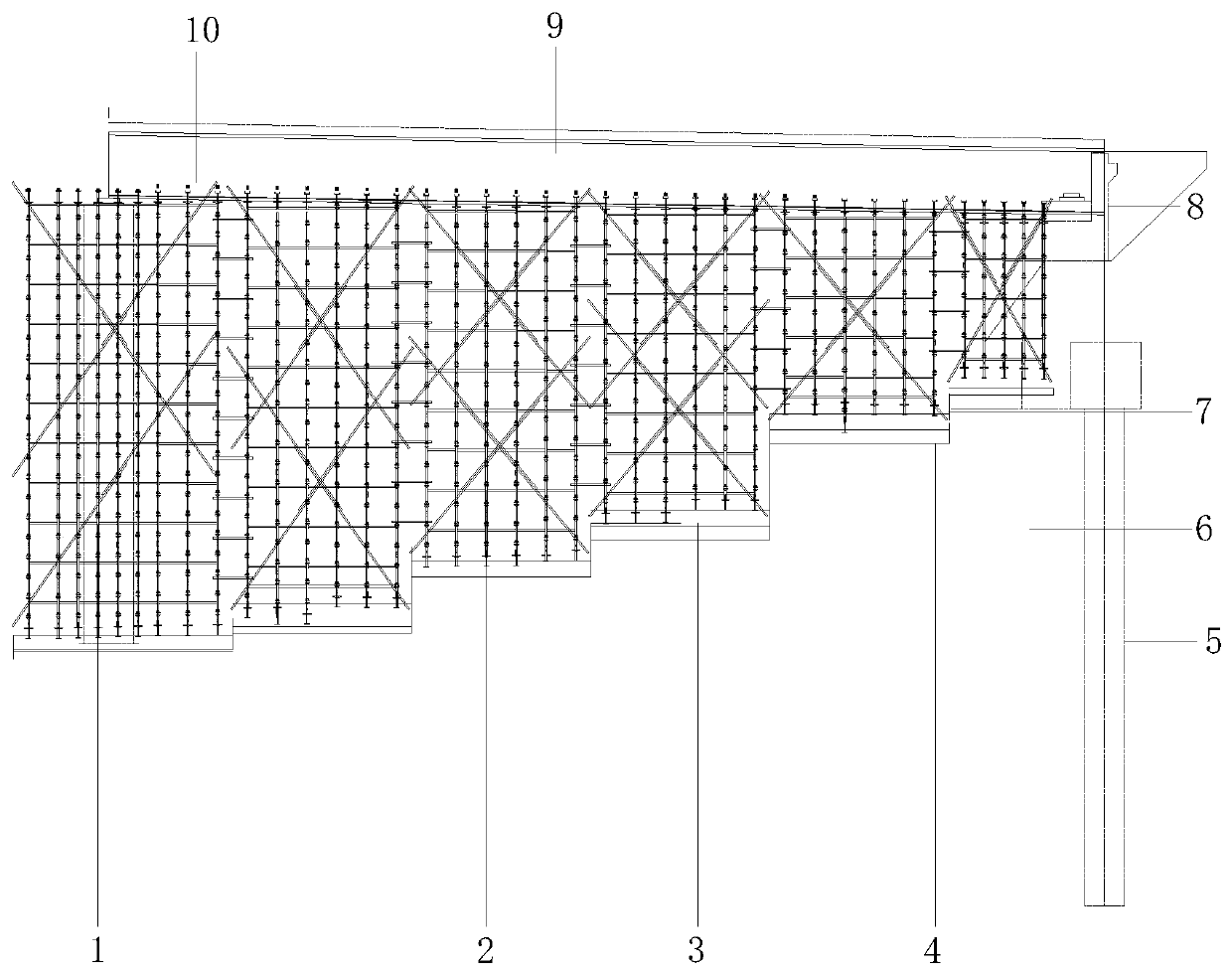

Viaduct cross-ground parallel bridge buttress full framing combined support and construction method thereof

ActiveCN112554059AEnsure safetyAvoid damageBridge structural detailsBridge erection/assemblyButtressSupporting system

The invention provides a construction method of a viaduct cross-ground parallel bridge buttress full framing combined support. The method comprises the steps of 1 conducting construction preparation;2 driving center parting strip steel pipe piles; 3casting bridge deck temporary buttresses in place; 4 erecting pier top longitudinal bailey beams and distributive girders; 5 erecting a full framing;6 pre-pressing the support; 7 conducting upper-layer box girder formwork erecting and pouring; and 8 dismounting a template and the support, namely erecting temporary supporting points on bridge decksright above bridge decks (buttresses) at the two ends of a ground bridge which is implemented in advance, erecting steel pipe pile foundation buttresses in the framing middle of the ground bridge, and erecting longitudinal Bailey longitudinal beams and profile steel distribution beams to form a combined support system for erecting the full framing. The problem of erecting of the cast-in-place boxgirder support of an overpass bridge is solved.

Owner:ZHEJIANG COMM CONSTR GRP CO LTD

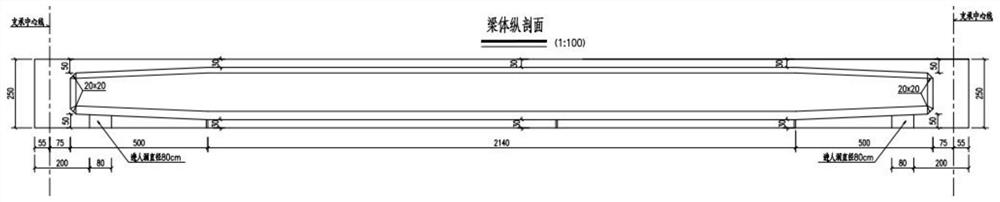

Porous large-section cast-in-situ box girder and construction method

ActiveCN110847052AImprove stabilityAvoid instabilityBridge erection/assemblyBridge materialsSupporting systemArchitectural engineering

The invention provides a porous large-section cast-in-situ box girder and a construction method. The method comprises the following steps that 1, foundation treatment is conducted, specifically, stepsare excavated on an original foundation, and mortar plastering construction is conducted by adopting a Z-shaped dragging sliding device for carrying out foundation construction; 2, a support is set,specifically, after the foundation reaches a certain strength, a support system is set up; 3, a bottom die is mounted, and specifically, the bottom die of the box girder is mounted; 4, the support ispre-pressed, and specifically, the support system is pre-pressed by using a water bag; 5, an inner die is mounted; 6, box girder construction is conducted; 7, a box girder formwork is removed; and 8,the support system is removed. Aimed at the porous large-section cast-in-situ box girder ultrahigh full framing system construction method, the engineering cost is effectively reduced, the construction speed is accelerated, and the good technical economic benefits can be achieved by applying the method to practical engineering.

Owner:湖北省路桥集团有限公司

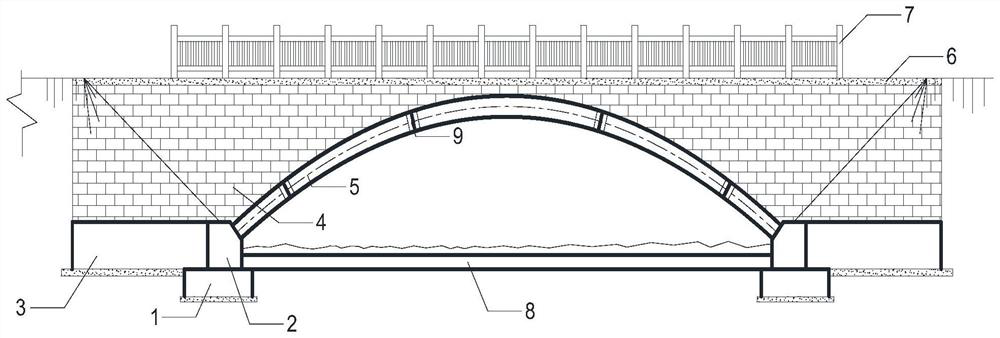

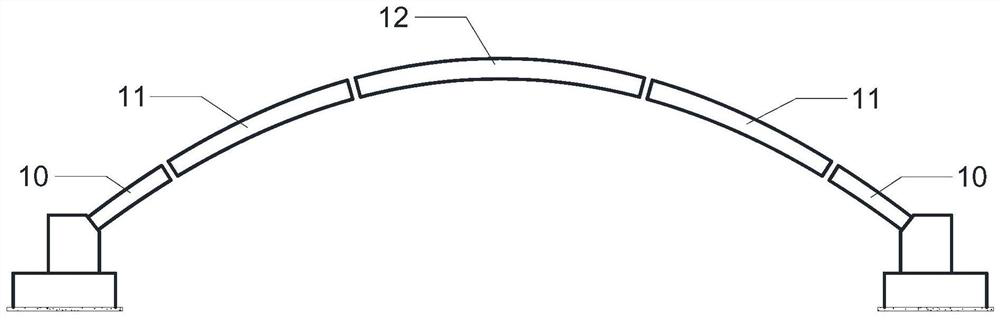

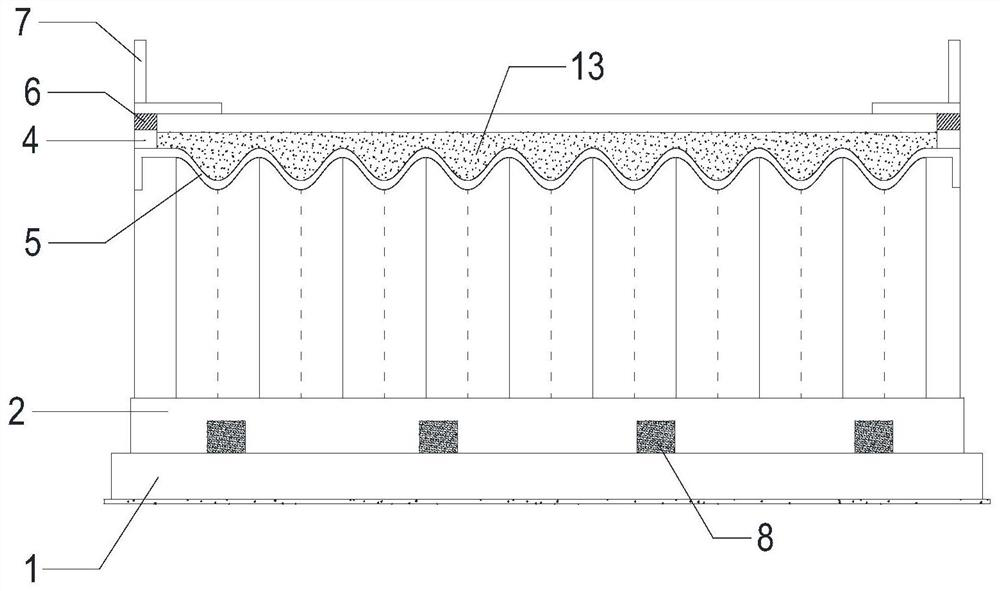

Solid-web arch bridge system spliced by UHPC prefabricated corrugated plate sections and construction method

PendingCN112813794AGive full play to high-strength tensile and compressive propertiesEven by forceBridge erection/assemblyArch-type bridgeEpoxyArchitectural engineering

The invention discloses a solid-web arch bridge system spliced by UHPC prefabricated corrugated plate sections and a construction method. The arch bridge system comprises a strip-shaped concrete foundation arranged on foundation soil, two arch seats provided with reinforced ultra-high performance concrete (RUHPC) tie bars, segment assembled UHPC corrugated plate arch rings arranged on the arch seats, side wall foundations, side walls built by concrete precast blocks, arch filler and concrete side wall coping. The UHPC corrugated plate arch ring is prefabricated in a segmented mode through UHPC, and all the prefabricated segments are spliced into a whole through finish rolling twisted steel and epoxy resin mortar. The UHPC corrugated plate main arch ring is firstly pre-assembled, hoisting construction is adopted after pre-assembly is qualified, and after the main arch ring is hoisted in place, main arch ring folding and on-arch building construction are conducted on the full framing. The prefabricated RUHPC tie bars and the strip-shaped concrete foundation are adopted, the arch foot thrust can be balanced, the work amount of the lower structure can be remarkably reduced, the damage of excavation to the environment is reduced, and the adaptability to the fragile ecological environment area is enhanced.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com