Cast-in-place construction method for large-span diamond-shaped bent cap of high pier

A construction method and large-span technology, applied to bridges, bridge parts, bridge materials, etc., can solve problems such as high risk, high cost, and many hidden dangers, and achieve the effect of avoiding difficult construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the present invention, the present invention will be further clearly and completely described below in conjunction with reference to the accompanying drawings and in conjunction with embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

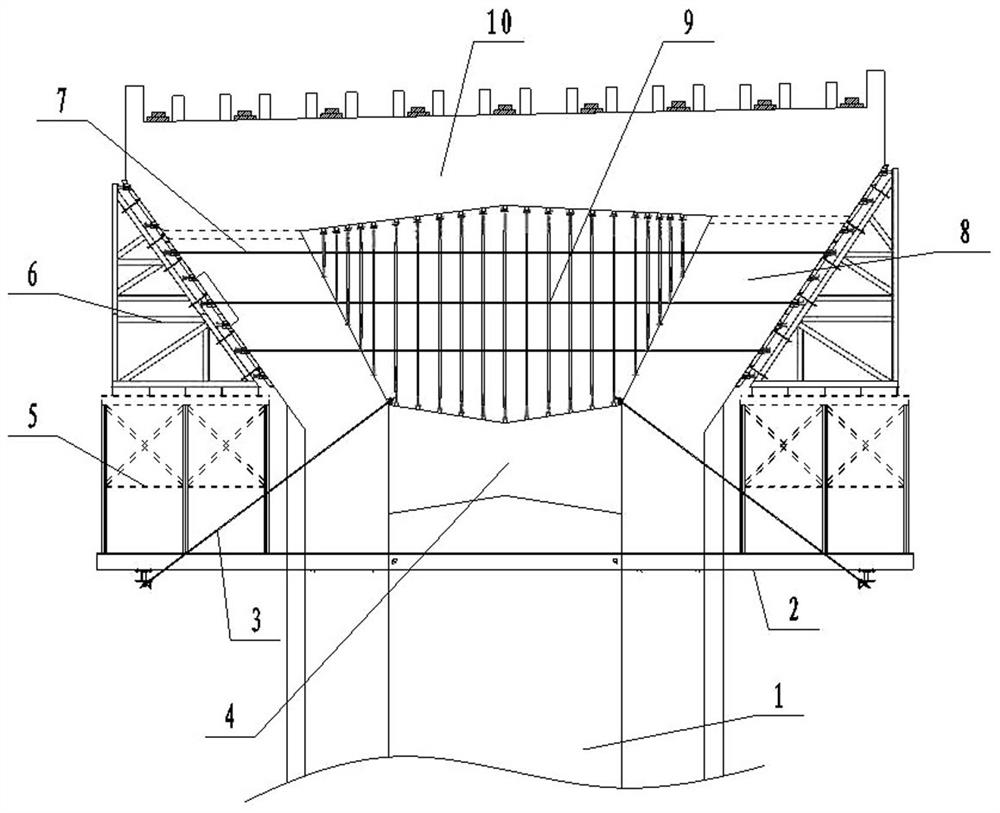

[0020] Such as figure 1 Shown, a kind of cast-in-place construction method of large-span diamond shaped cover beam for high bridge pier comprises the following steps:

[0021] 1) Cantilever support structure construction: Reserve holes on the standard section of straight pier 1 that has been built. The reserved holes are made of steel pipes with a diameter of 16cm. Steel rods are inserted in the reserved holes, and erected on the steel rods. 45a double I-beam 2 with a length of 24m, and the two ends of the 45a double I-beam 2 are fixed by diagonal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com