Combined cast-in-place box girder support structure and construction method thereof

A support structure and combined technology, which is applied in the direction of infrastructure engineering, bridges, bridge construction, etc., can solve the problems of increased volume of sludge cleaning, increased volume of replacement materials, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

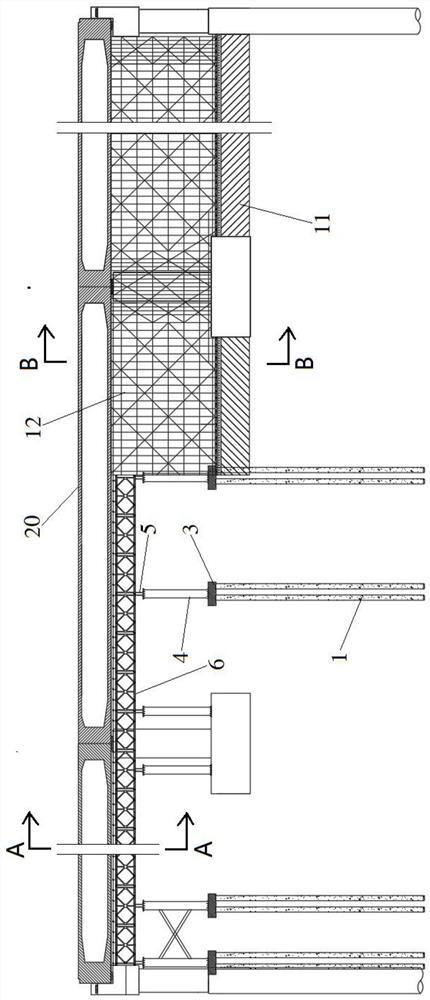

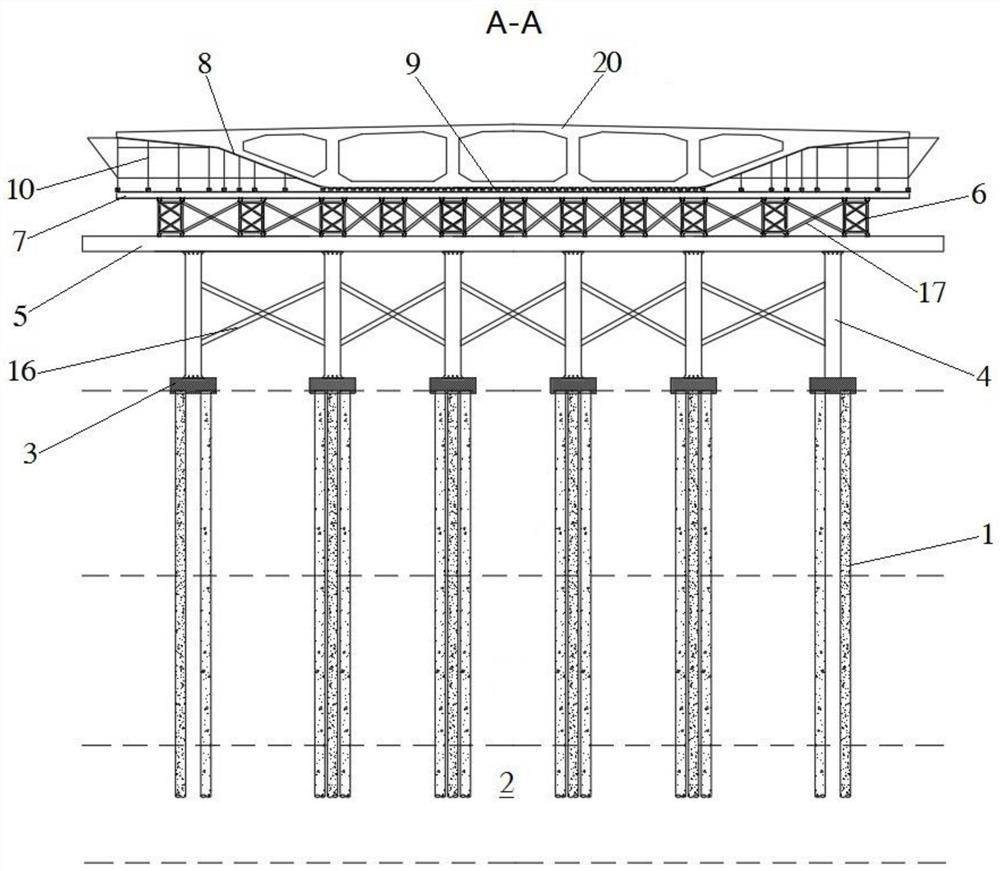

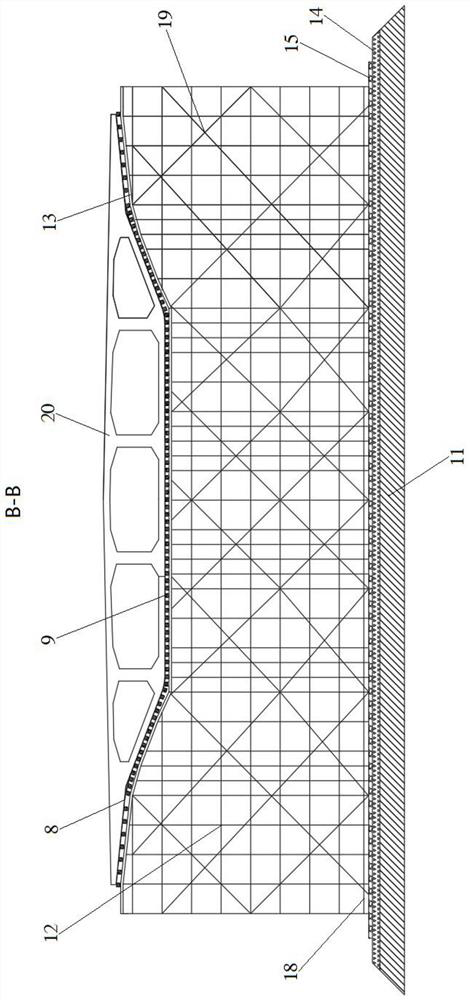

[0037] refer to figure 1 , figure 2 and image 3 , the embodiment of the present invention proposes a combined cast-in-place box girder support structure, which is used to cast-in-place box girder 20 for a large bridge. One section of the bridge spans a weak foundation, and the other section spans a hard ground. The pouring box girder support structure includes: multiple sets of prestressed pipe pile foundations 1, multiple steel pipe columns 4, formwork 8 and roadbed 11; multiple sets of prestressed pipe pile foundations 1 are distributed in the weak foundation along the bridge direction, and the The lower end goes deep into the fully weathered granite layer 2, and the upper end of each group of prestressed pipe pile foundations 1 is respectively provided with a concrete cap 3; each of the steel pipe columns 4 is respectively fixed on one of the concrete caps 3, and each row A load-bearing beam 5 is respectively fixed on the steel pipe column 4; a plurality of the Bailey f...

Embodiment 2

[0043] refer to figure 2 and image 3 A gravel layer 14 is laid on the road bed 11, and a concrete layer 15 is laid on the gravel layer 14.

[0044] The degree of compaction of the road bed 11 reaches more than 90%, the thickness of the gravel layer 14 is 30cm, the degree of compaction reaches more than 95%, and the concrete layer 15 is C15 concrete with a thickness of 15cm.

Embodiment 3

[0046] refer to figure 2 , on the basis of Embodiment 2, a first scissor brace 16 is connected between every two horizontally adjacent steel pipe columns 4 .

[0047]The first scissors braces 16 are arranged in the transverse bridge direction of the steel pipe piles 4 to laterally reinforce the steel pipe columns 4, and the first scissors braces 16 are made of I20a engineering steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com