Overload small-clear-distance beam adjustable disc buckle formwork supporting frame and construction method thereof

A formwork support and construction method technology, applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connector, housing structure support, etc., can solve complex main structure, affect formwork installation quality, side formwork Reinforcing problems such as insufficient operating space to achieve the effects of convenient use, simple structure, and scientific and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings. Obviously, the described embodiments are only some, but not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

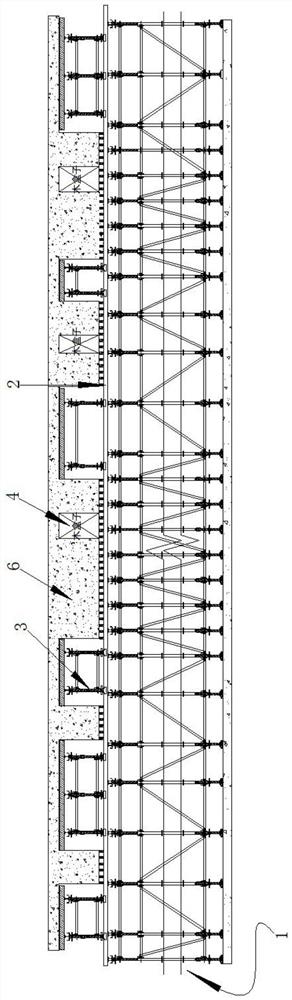

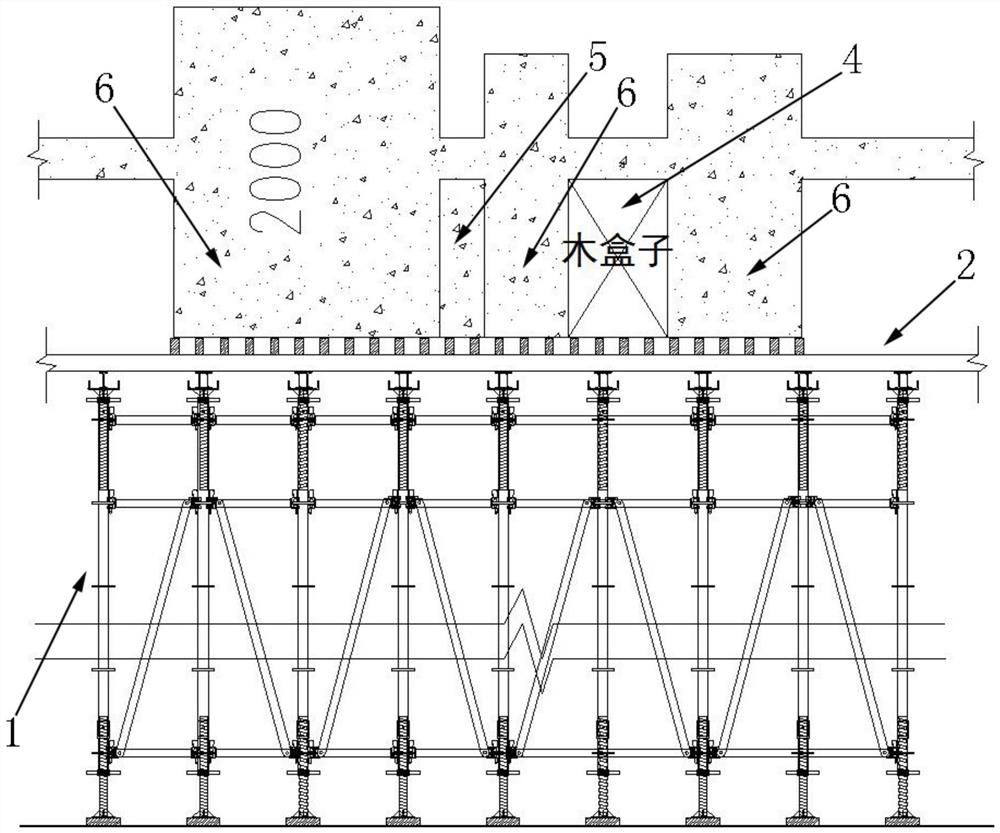

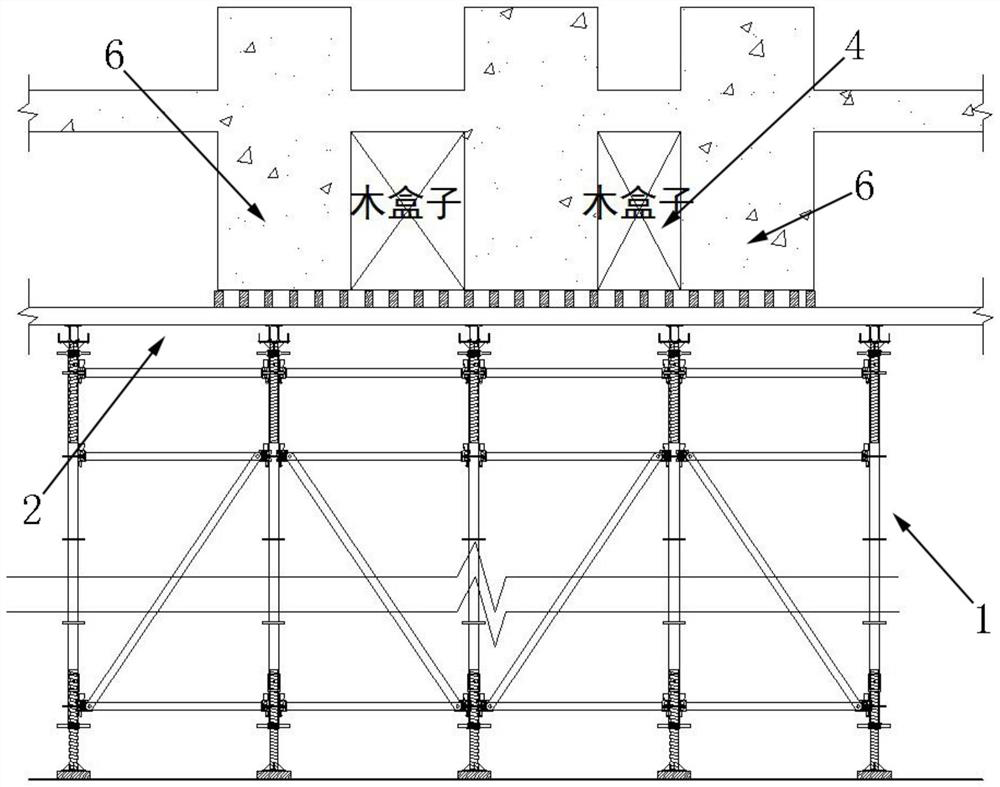

[0061] like Figure 1-14As shown in the figure, the adjustable disk-buckle formwork support frame provided by the present invention includes a disk-buckle type scaffold 1, a full-floor bracket 2 arranged on the disk-buckle-type scaffold 1, and a full-floor bracket 2 that is opposite to the beam body. 6. The adjustable top bracket 3 and the wooden box 4 for supporting, as well as the concrete pouring body 5 poured between adjacent beam bodies, the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com