Self-anchorage type suspension bridge design and construction method adopting first cable later beam dynasty

A technology of self-anchored suspension bridge and construction method, applied in the direction of suspension bridge, bridge form, bridge construction, etc., can solve the problem of increasing the span of self-anchored suspension bridge, and achieve the effect of improving competitiveness, clear force and easy monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

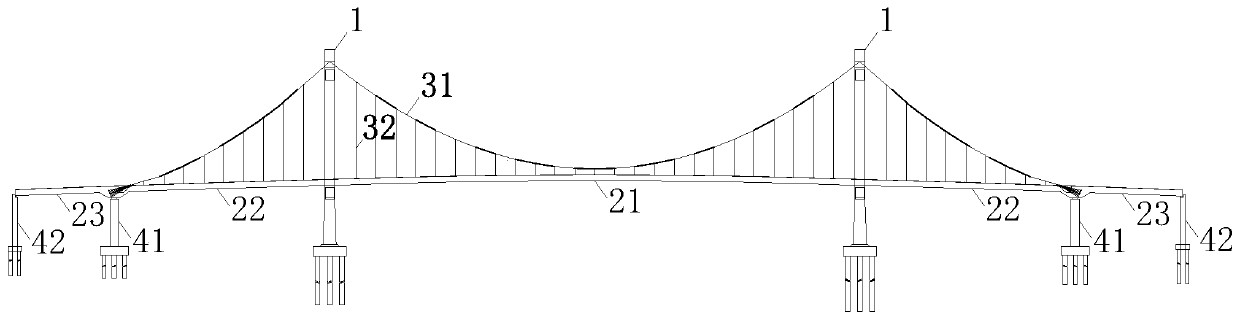

[0035] like figure 1 As shown, it is a typical self-anchored suspension bridge with two towers and five spans. 22 and anchor span girder 23), main cable 31 and sling 32 etc.

[0036] from figure 1 The self-anchored suspension bridge is in a reasonable bridge state. It can be seen that since the main cable 31 of the self-anchored suspension bridge is anchored on the main girder, when the main girder acts on the vertical load, the main cable 31 has a large horizontal component force. The component force will be borne by the main girder. The state of the structure during the construction process is not exactly the same as that of the completed bridge. During the construction process, the main girder is assembled in sections; It is also one of the design ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com