Modular structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

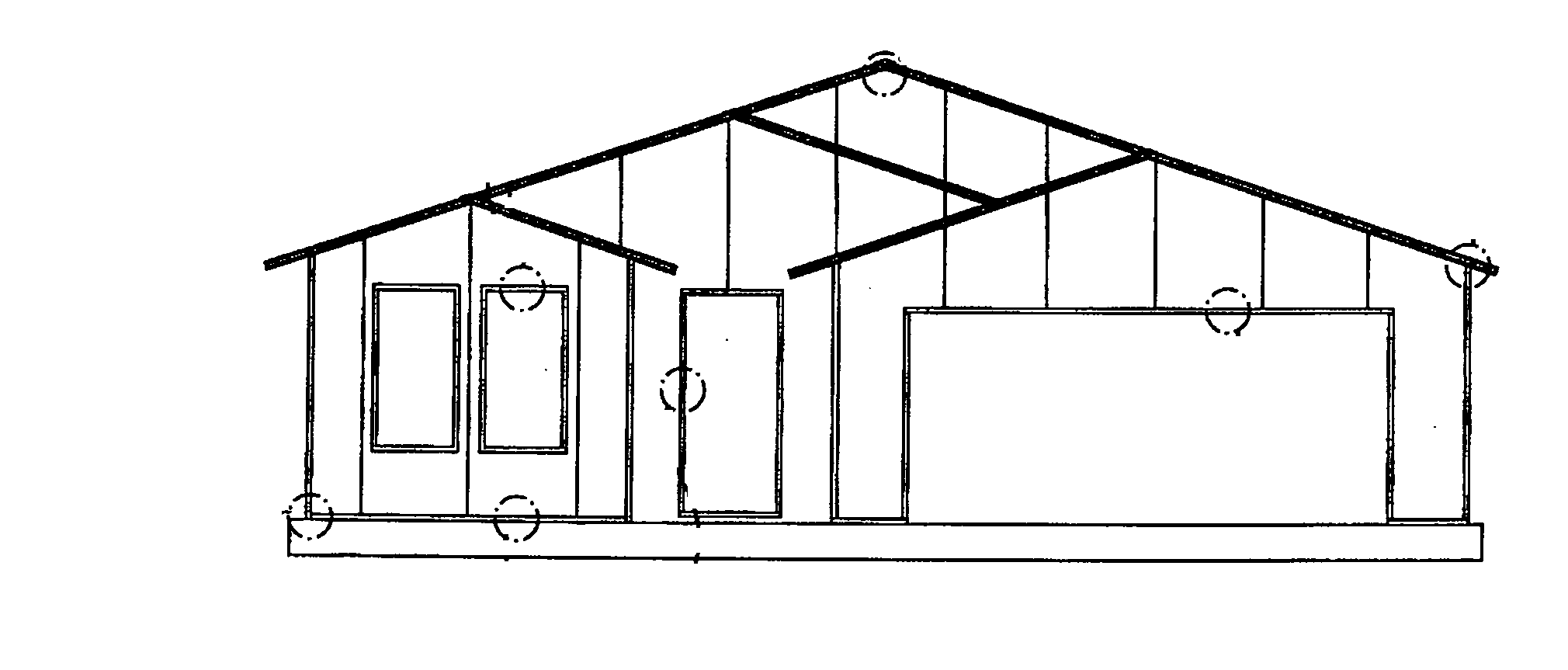

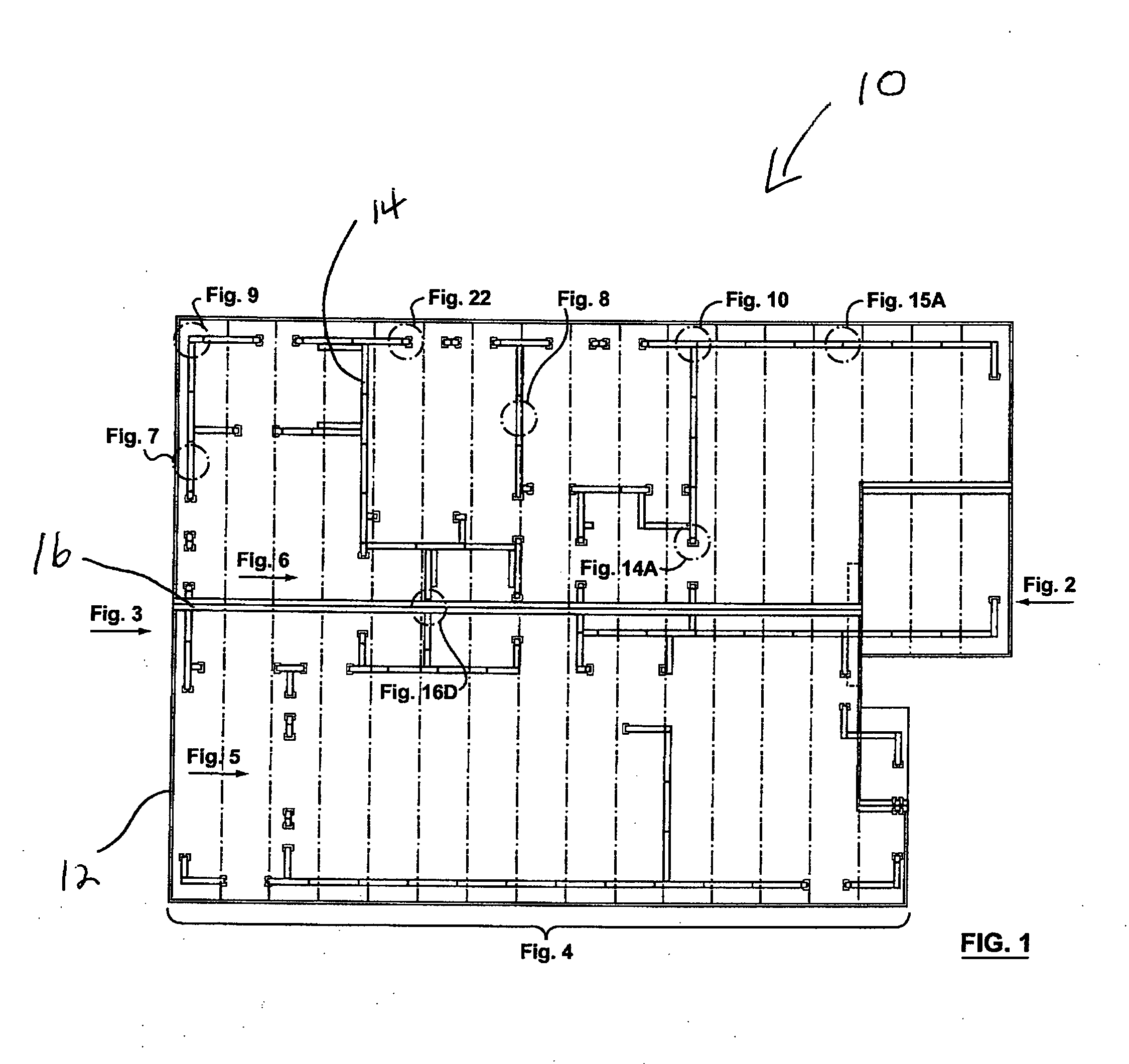

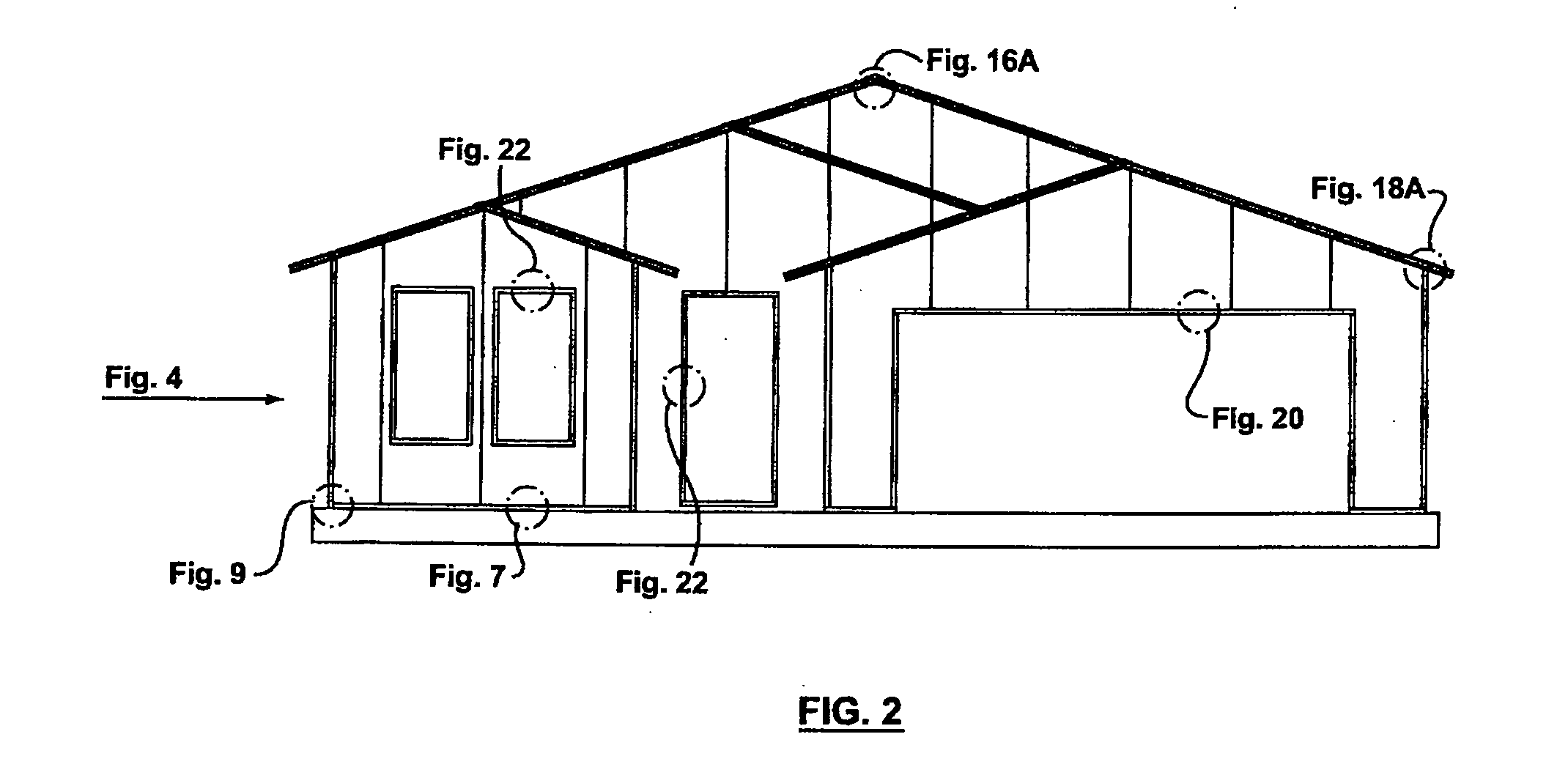

Construction of Modular House

[0071]Phase 1 involves the foundation & channel layout. The steps are as follows:[0072]Step 1: Foundation is constructed—concrete slab, basement, wood slab

[0073]Step 2: Exterior Perimeter and internal wall c-channels Bolted to foundation.

Phase 2 is the erection of the exterior walls according to the following steps.[0074]Step 1: First panel slides into c-channel into starting position. Starting position is in a corner.[0075]Step 2: Slide opposing corner piece, along the c-channel, to meet the first panel to create squared corner.[0076]Step 3: Screw ‘L’ bracket on interior of corner to each panel Step 4: Screw ‘L’ Bracket on exterior of each corner.[0077]Step 5: Apply adhesive to exposed panel side (tongue & grove).[0078]Step 6: Slide next exterior wall panel along the c-channel into position-tongue and grove—adhere to previous panel.[0079]Step 7: repeat step 5 & 6 till the first interior wall c-channel.[0080]Step 8: Insert interior wall panel into interi...

example 2

Insulation of a Thermo Break

[0103]1. Base bottom channel running around the perimeter of the house. The base channel must be flashed. The flashing cavity is to be 1½″ deep and must be insulated to minimum R-19. Flash per detail drawings.[0104]2. Eave channel / sidewalls to Roof. This area must be flashed as well, leaving a cavity of at least 1½″ (one and one half inch) and insulated minimum R19.[0105]3. The exterior gable channel, this area also must be flashed using the same procedure and insulated to minimum of R-19.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com