Framing demounting supporting structure of spandrelless arch bridge of over crossing operation highway and construction method

A supporting structure and arch bridge technology, which is applied in building structure, building maintenance, construction, etc., can solve the problems of poor economy, difficult construction, and affecting the normal traffic of the road under the bridge, so as to achieve cost saving and high construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In this embodiment, the welding process of the steel structure, the erection process of the bowl-shaped full hall support, and the concrete pouring construction process will not be repeated in this embodiment, and the embodiments of the structure related to the present invention will be focused on.

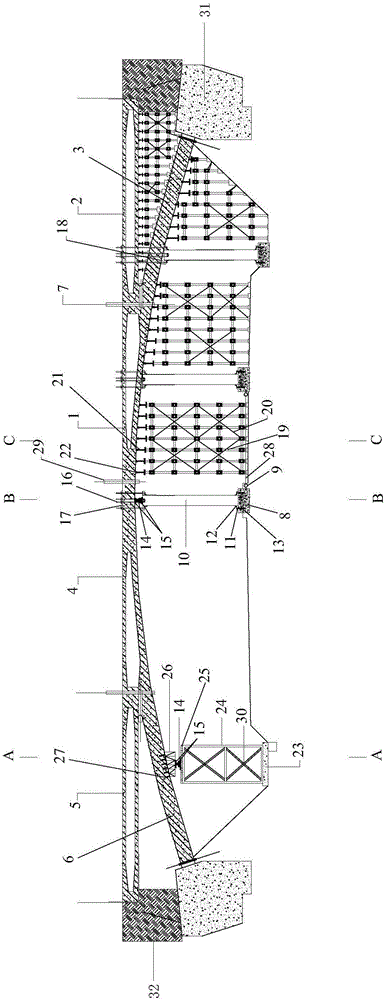

[0035] figure 1 It is a schematic diagram of the supporting structure of the webless arch bridge spanning the operating highway by framing and dismantling in the present invention. refer to figure 1 As shown, the supporting structure of the webbed-free arch bridge spanning the operating road in the present invention mainly includes the middle support, the bowl button type full hall support, the spiral steel pipe support and the frame support at the full hall support.

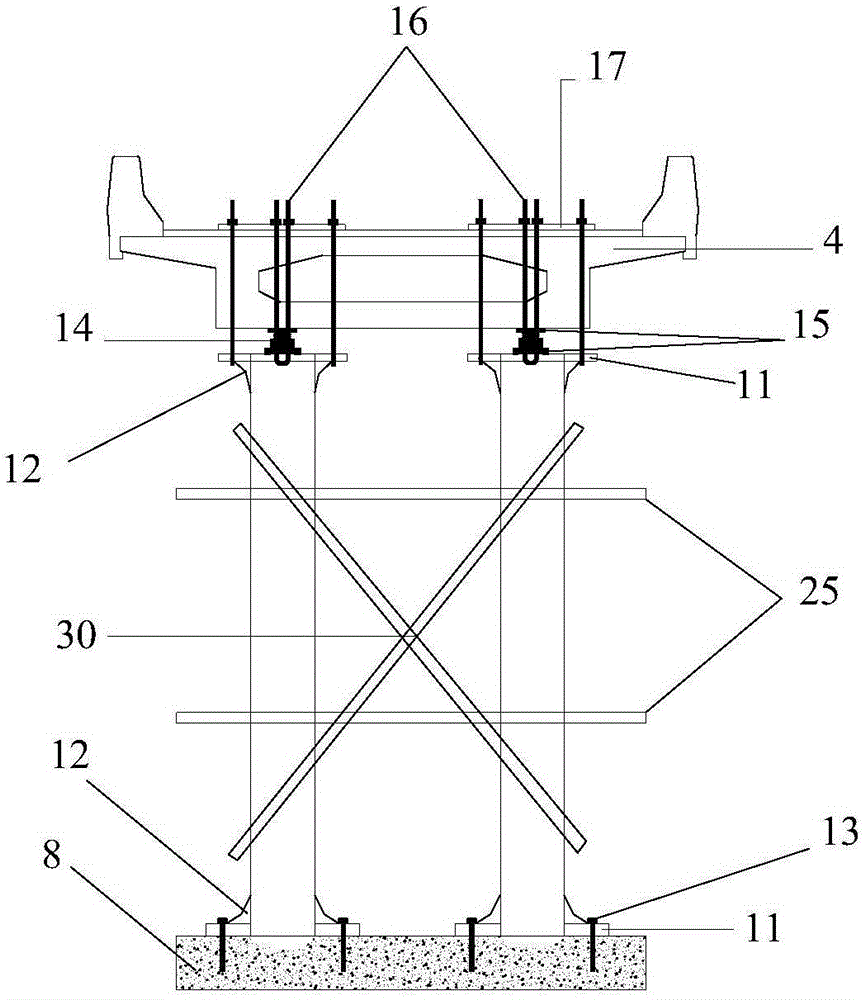

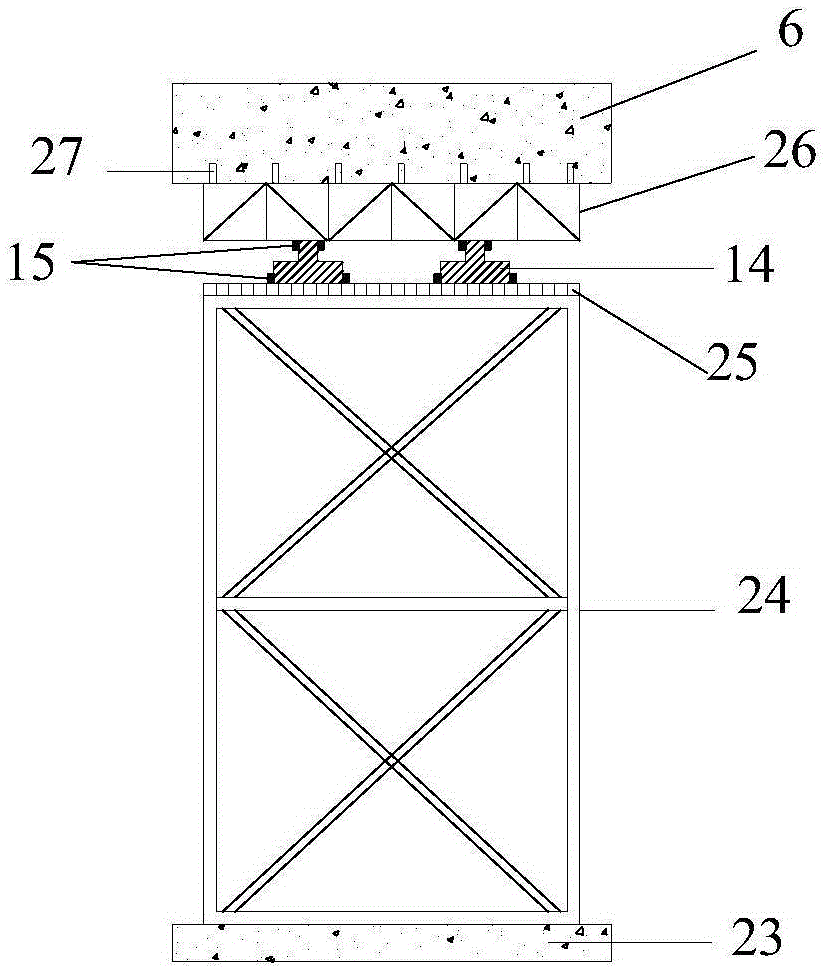

[0036] refer to figure 2 As shown, the intermediate support structure is composed of two spiral steel pipes 10, the spiral steel pipes 10 are anchored on the strip foundation 8 through flanges 11 and threa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Vertical spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com