Connectors and Methods of Construction for a Precast Special Concrete Moment Resisting Shear Wall and Precast Special Concrete Moment Resisting Frame Building Panel System

a technology of special concrete and connection method, which is applied in the direction of walls, surface layering apparatus, manufacturing tools, etc., can solve the problems of plastic hinge region, lack of ductile connection of beams, shear walls or columns within the building, and the difficulty of conventional methods of constructing prefabricated concrete buildings and particularly prefabricated concrete foundations in seismically active areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

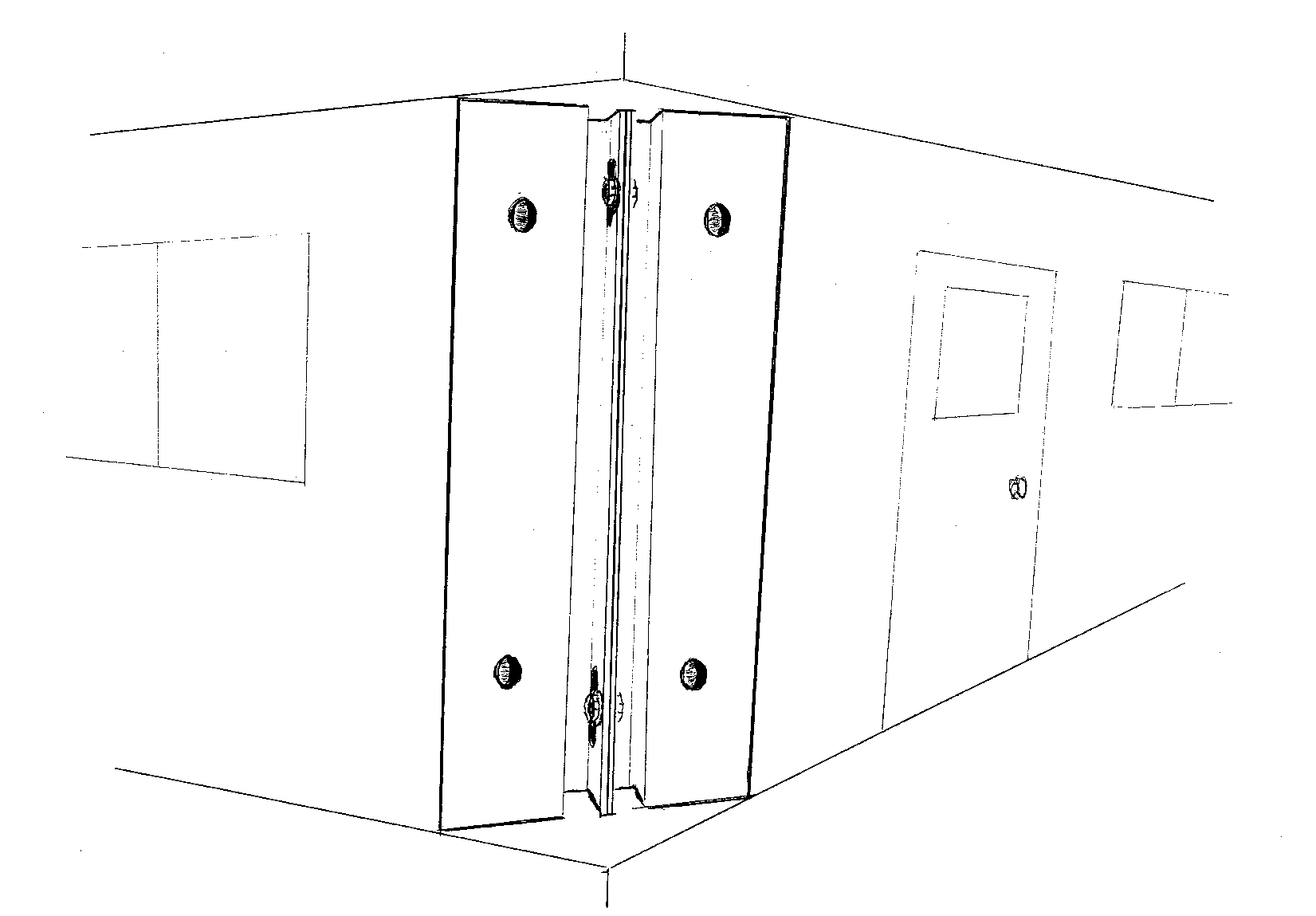

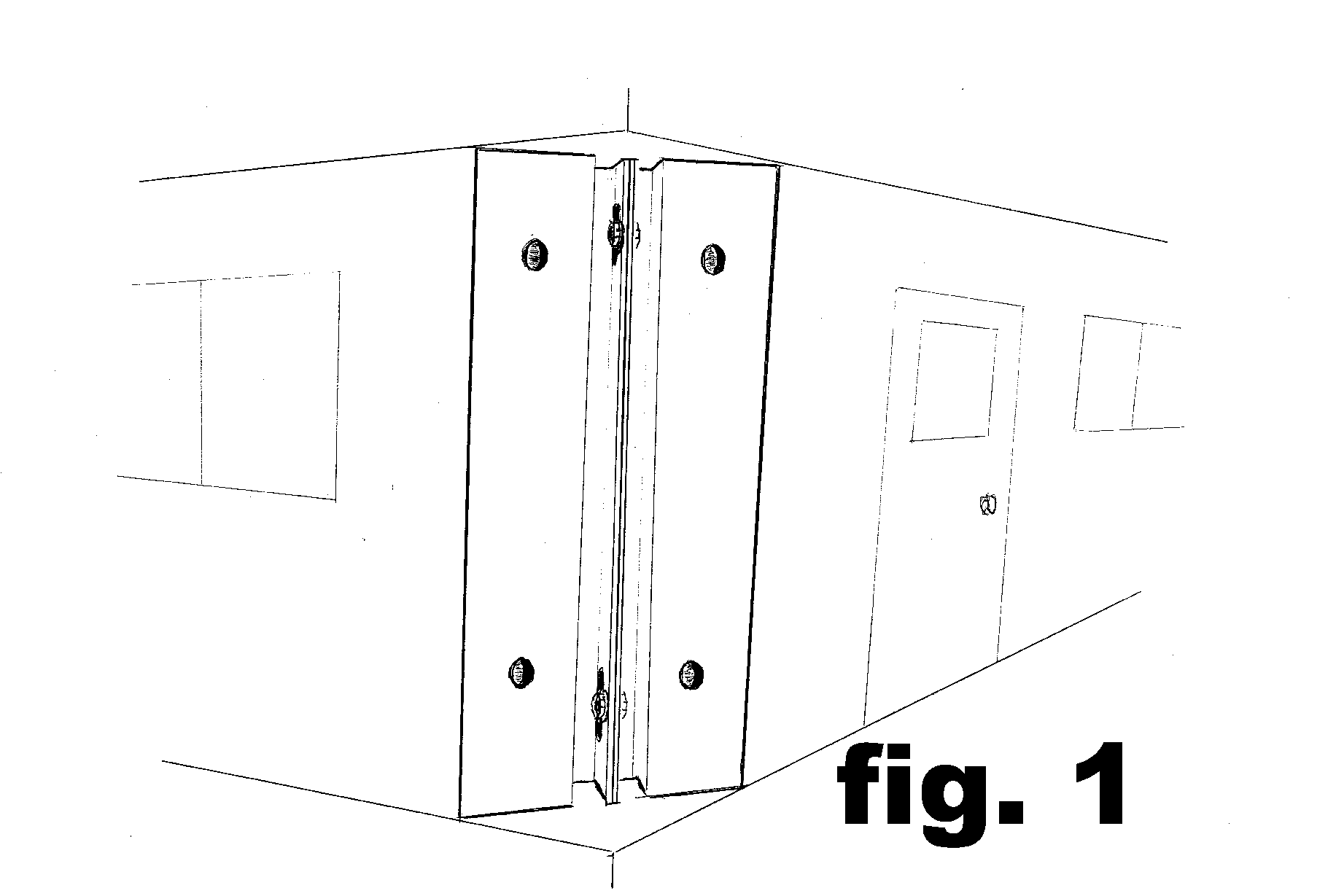

[0064]Conventional architectural building plans are prepared for a prospective building owner or developer by an architect or engineer. Soil, geo-technical, civil, and any other engineering studies required by the code and local building officials are prepared. The plans are submitted to a licensed panel manufacturer for evaluation of engineering requirements by an authorized engineer.

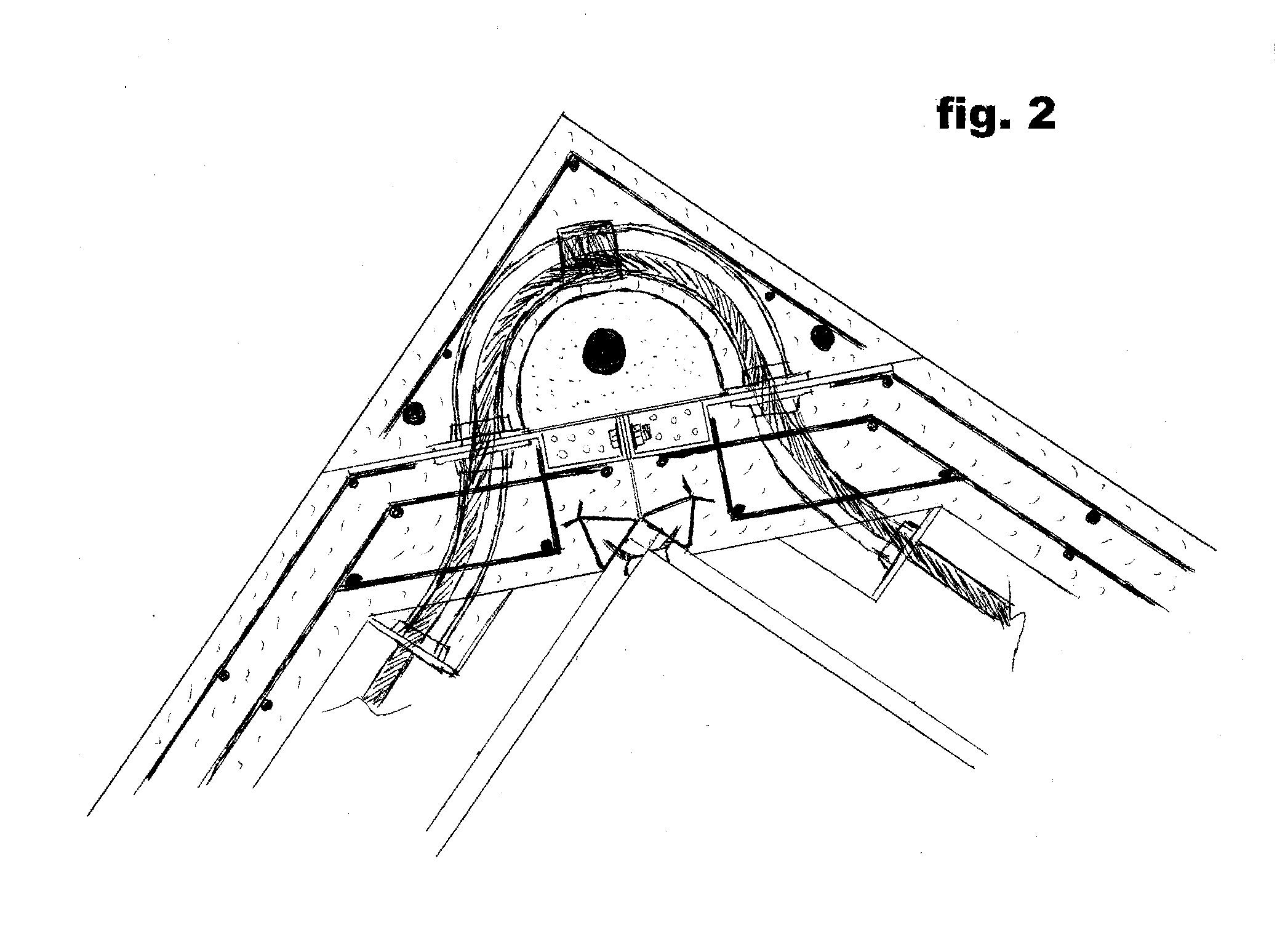

[0065]A feasibility study is performed and upon acceptance an estimate of the building and construction costs is prepared. When a contract to build is executed, the licensed panel manufacturer prepares the necessary plans and documentation for permit application, including engineering of the structural assembly components, structural walls, columns, beams, diaphragms, moment frames, trusses, reinforcement bar, wire, cable, anchors, inserts, plates, ductile connectors, channel, tubing, and any other embedded elements and any other structural members.

[0066]Engineering documentation of all loads, shear, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com