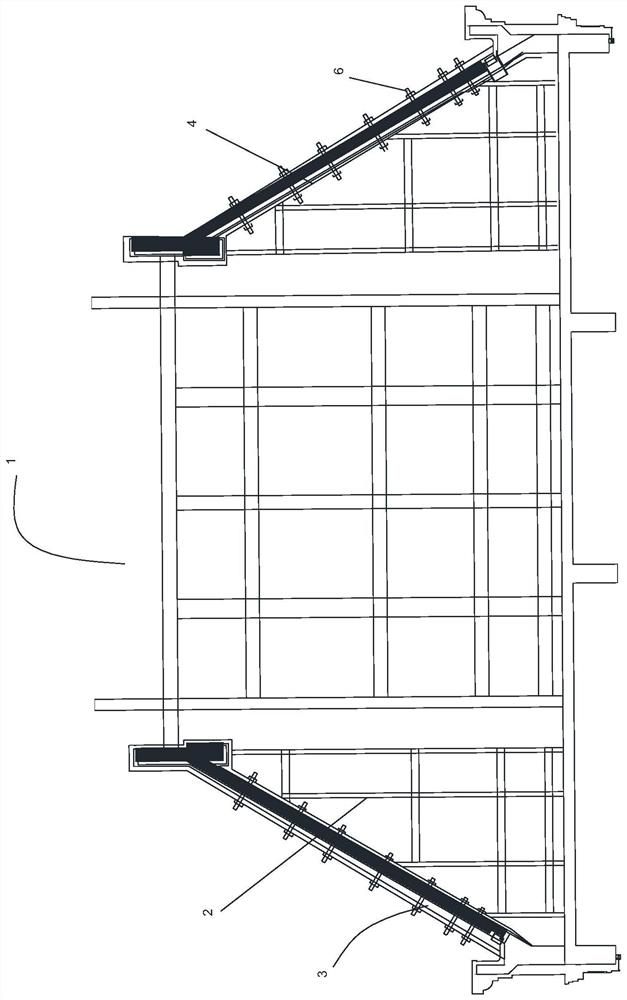

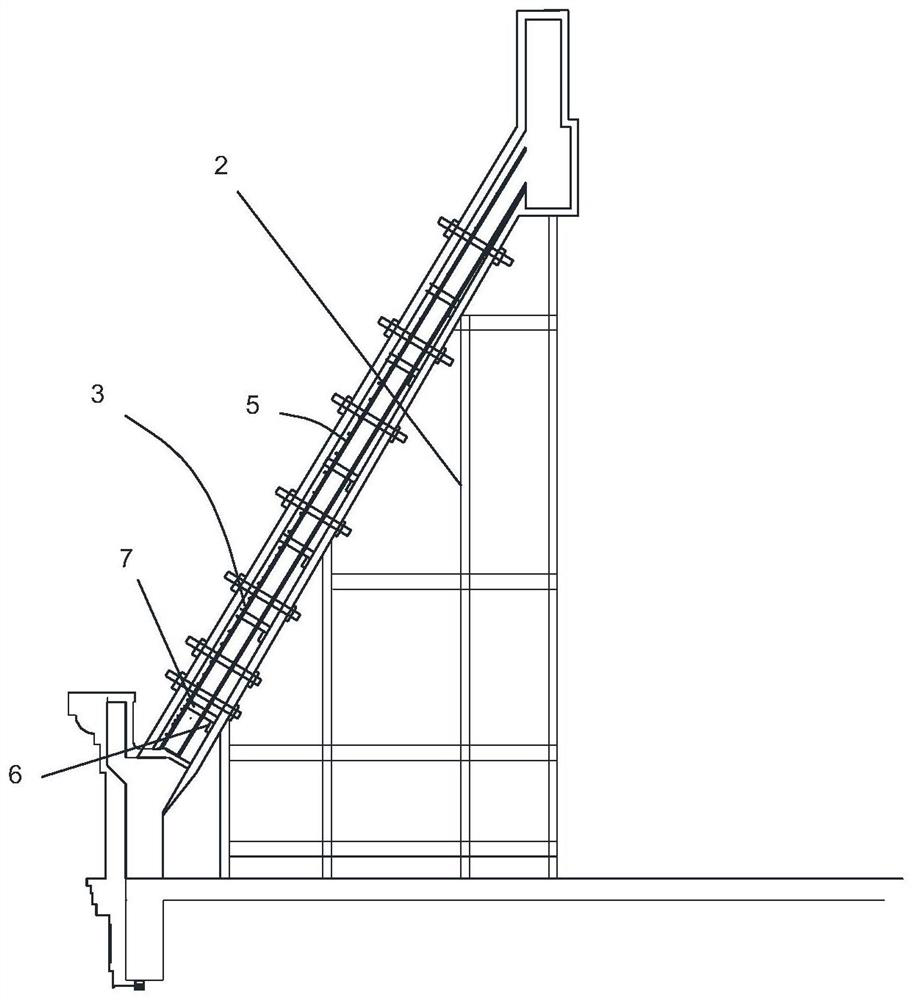

Large-gradient special-shaped sloping roof concrete construction system and construction method thereof

A construction method and technology of sloping roof, applied in the direction of roof, formwork/formwork/work frame, building components, etc., can solve the problems of difficult construction joints, inconvenient operation, limited operating space for sloping roofs, etc., and achieve convenient placement and fine-tuning. , easy to set effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] According to the calculation formula f cu,O ≥f cu,k +1.645σ (σ=5.0MPa), calculate the preparation strength: f cu,o =20+1.645×5.0=28.2MPa.

[0074] According to the calculation formula W / C=(a a × f ce )÷(f cu,o +a a ×a b × f ce ), calculate the water-cement ratio: W / C=(0.46×42.5)÷(28.2+0.46×0.07×42.5)=0.66;

[0075] According to the requirements of concrete slump, particle size distribution of aggregates and water-reducing effect of admixtures, the unit water consumption W is determined to be 175kg / m 3 Among them, the amount of water reducing agent is 1.0% of the amount of gelling material, the amount of accelerator is 3.5% of the amount of gelling material, and the benchmark water-binder ratio for trial matching is 0.43.

[0076] According to the calculation formula, the calculated benchmark cementitious material consumption is 407kg / m 3 ; and its benchmark cement consumption is 407kg / m 3 .

[0077] Calculate the amount of coarse and fine aggregates using th...

Embodiment 2

[0081] According to the benchmark water-binder ratio, reduce the water-binder ratio by 0.03, and calculate the concrete mix ratio.

[0082] Among them, W / C=0.40, the water-cement ratio is reduced by 0.03, and the sand rate is reduced by 1%. According to the mass ratio, the ratio of cement, fly ash, river sand, gravel, water, and water reducing agent is as follows: 309:103 :829:1013:165:4.12.

[0083] According to its specific ratio, try mixing 35L to check the performance of the mixture, wherein the cement, fly ash, river sand, gravel, water, and water reducing agent are respectively 10.82:3.61:29.02:35.46:5.78:0.144, And its unit is kg.

[0084] Through observation, the measured slump is 170mm, the gas content is 3.3%, the workability is good, and the measured density is 2430kg / m 3 , and according to the calculation, the density does not need to be adjusted.

Embodiment 3

[0086] Increase the water-binder ratio by 0.03 according to the benchmark water-binder ratio, and calculate the concrete mix ratio:

[0087] Wherein, W / C=0.46, the water-cement ratio increases by 0.03, and the sand rate increases by 1%. According to the mass ratio, the proportion of cement, fly ash, stone, water, and water reducing agent is as follows: 269:90:891 :1005:165:3.59.

[0088] According to its specific ratio, try mixing 35L to check the performance of the mixture, wherein the cement, fly ash, river sand, gravel, water, and water reducing agent are respectively 9.42, 3.15, 31.19, 35.18, 5.78, 0.126, And its unit is kg.

[0089] The measured slump is 170mm, the gas content is 3.3%, the workability is good, and the measured density is 2420kg / m 3 , and according to the calculation, the density does not need to be adjusted.

[0090] As shown in the table below, the three groups of mix ratios were tested for 7, 28, and 56 days of strength respectively. According to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com