Construction system using interlocking panels

a construction system and interlocking technology, applied in the direction of building components, walls, building repairs, etc., can solve the problems of high cost of steel, inability to fully embrace prefabricated building components using alternatives to wood, and use components made of steel rather than wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

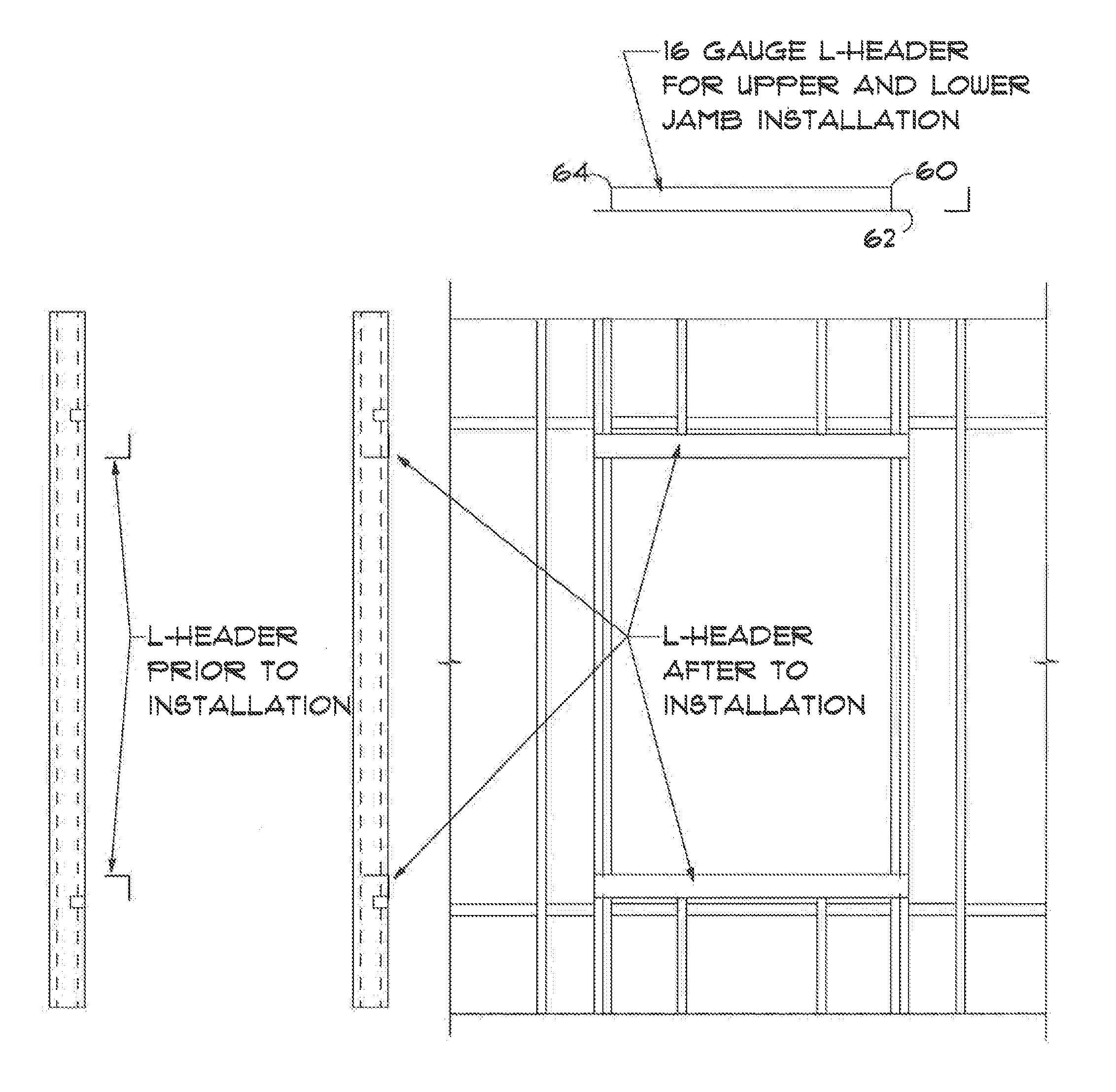

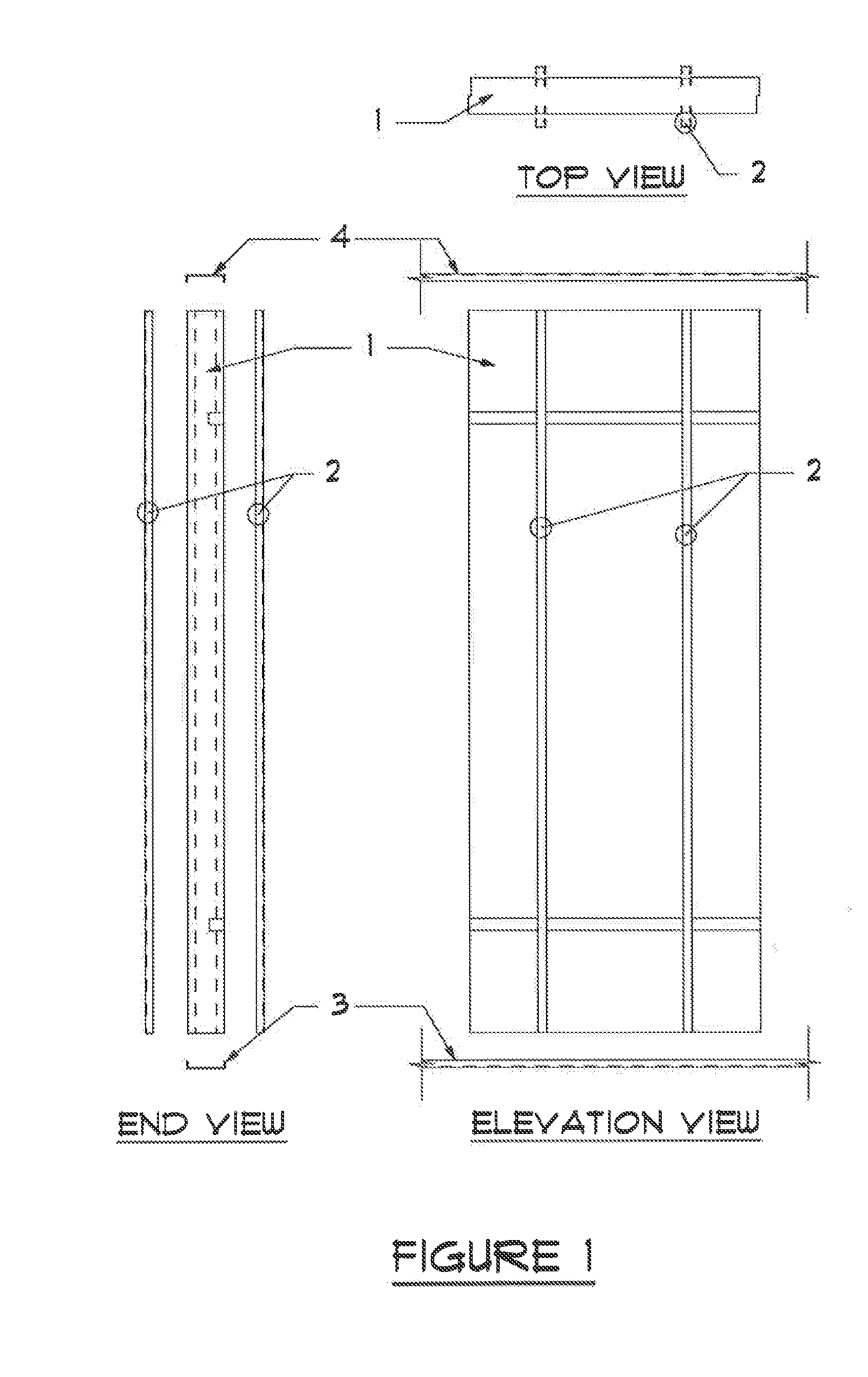

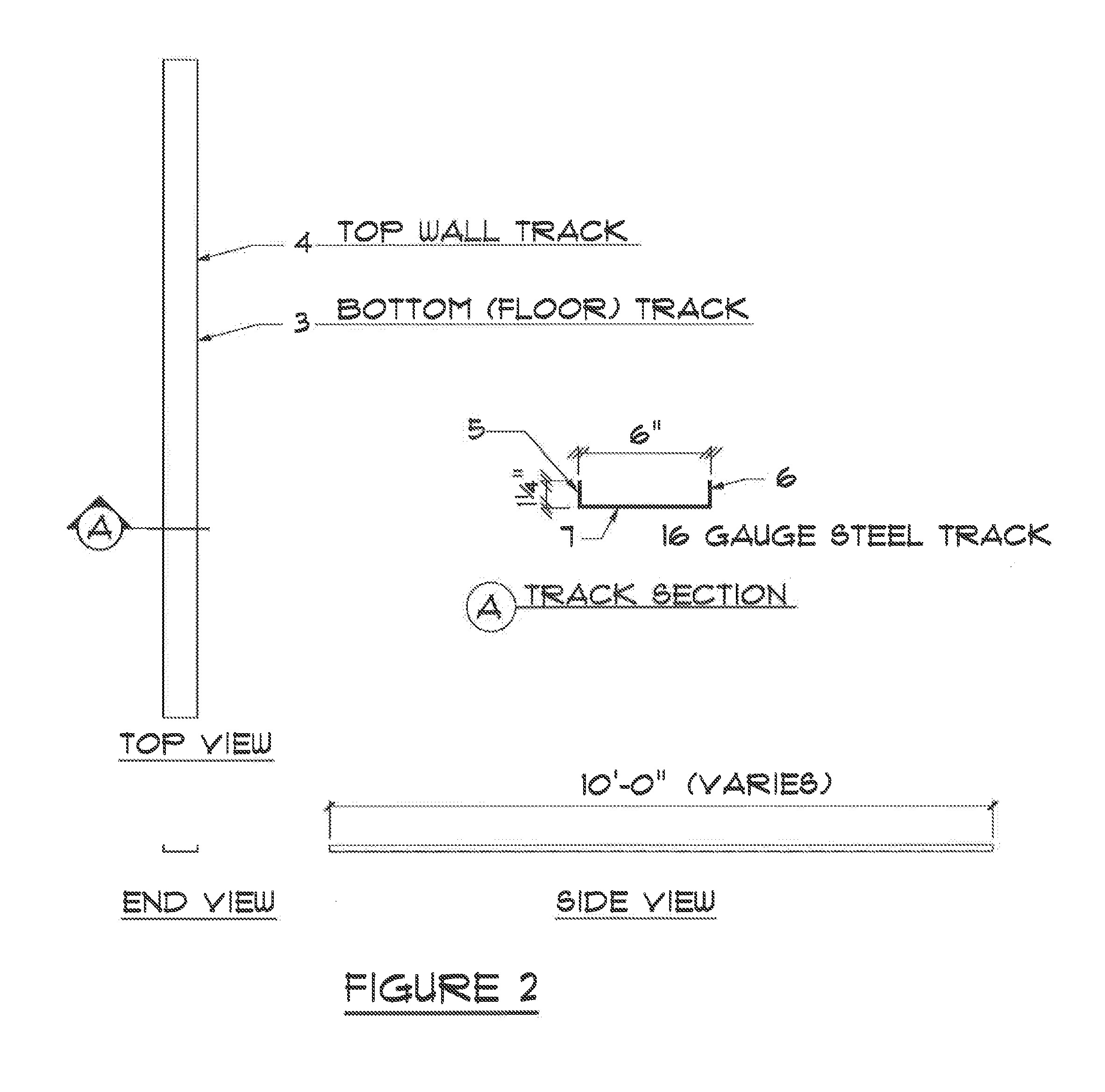

[0027]FIG. 1 shows an example of a panel 1 useable, in conjunction with other such panels 1, to construct a structure. As shown, the panel 1 includes a plurality of supports, referred to herein as studs 2, which are made from a rigid material, such as, for example, galvanized steel. The panel 1 preferably includes a bottom track 3 and a top track 4, as shown. As shown in FIG. 2, the bottom track 3 can be constructed of a C-shaped, sheet metal having leg members 5, 6 extending upward from a base member 7. Preferably, the top track 4 is identical to the bottom track 3. In a preferred embodiment, the bottom track 3 can be constructed from 16-gauge galvanized steel sheet metal However, it is to be understood that other structurally strong and relatively stiff materials can be used, depending on the desired structural specification of the completed wall. The base member 3 can be fastened to a concrete floor slab by any suitable means, such as, for example, using adhesive bonding, fastene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com