Solid-web arch bridge system spliced by UHPC prefabricated corrugated plate sections and construction method

A corrugated plate and solid-belly technology, applied in arch bridges, erection/assembly bridges, bridges, etc., can solve the problems of high foundation requirements, complex processes, and long construction periods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in detail below in conjunction with accompanying drawing.

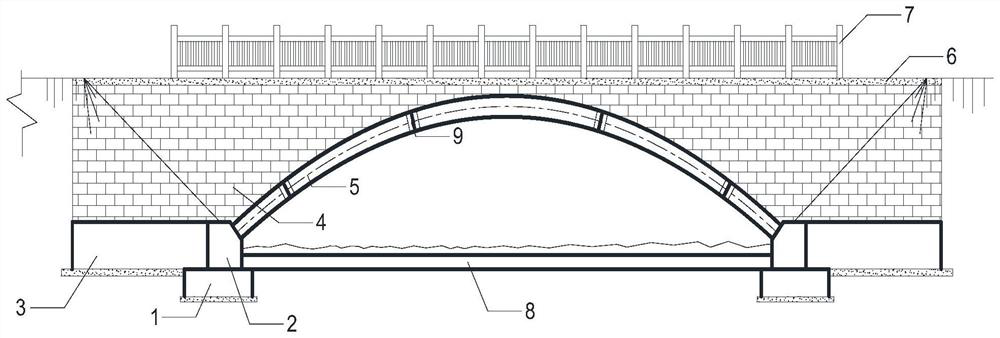

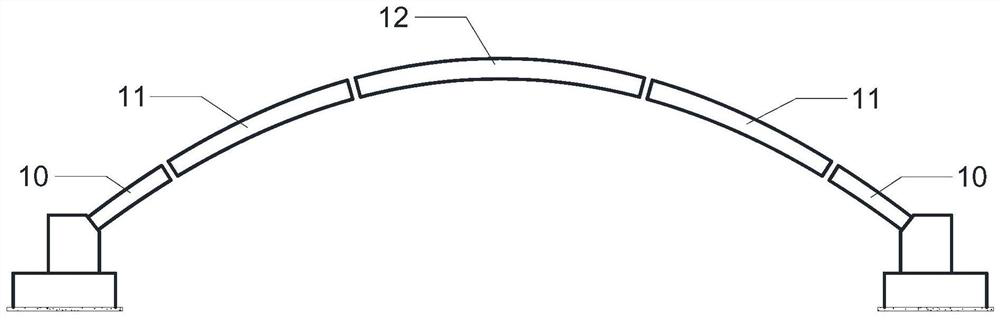

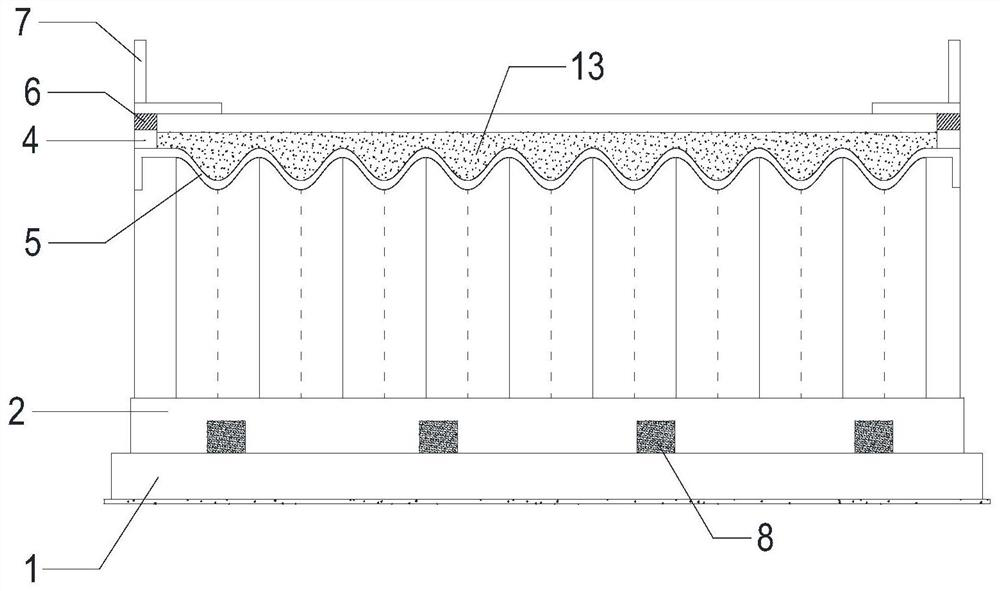

[0034] Such as figure 1 As shown, a solid web arch bridge system assembled by UHPC prefabricated corrugated plate segments, including two strip concrete foundations 1 set on the foundation soil, an abutment 2 is set on the strip concrete foundation 1, and UHPC corrugated plate arch The ring 5 is set on two abutments 2, and prefabricated RUHPC tie rods 8 are arranged horizontally between the two abutments 2. The abutment 2 is externally connected to the side wall foundation 3, and the side wall foundation 3 and the UHPC corrugated plate arch ring 5 are built by masonry Side wall 4, side wall top 6 is constructed on the top surface of side wall 4, and guardrail 7 is arranged on side wall top 6.

[0035] The UHPC corrugated plate arch ring 5 is prefabricated by ultra-high performance concrete UHPC material, and longitudinal steel bars 22 and transverse stirrups 23 are arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com