Construction method of special-shaped floor formwork without scaffold

A construction method and a scaffolding technology, which are applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, and on-site preparation of building components, which can solve the problems of increasing wood usage, rising construction costs, Problems such as difficulty in connection, to achieve the effect of reducing the output of construction waste, eliminating the use of scaffolding, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following will further explain how the present invention is implemented in conjunction with the accompanying drawings and specific implementation methods.

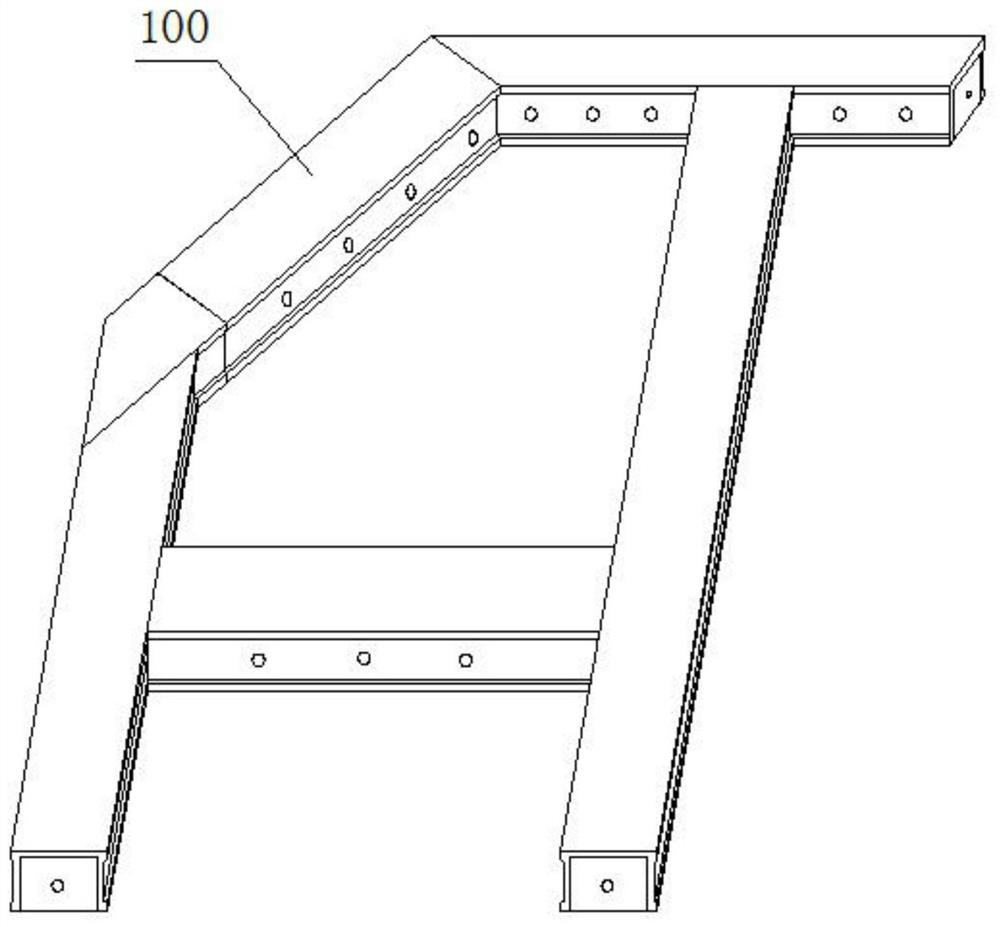

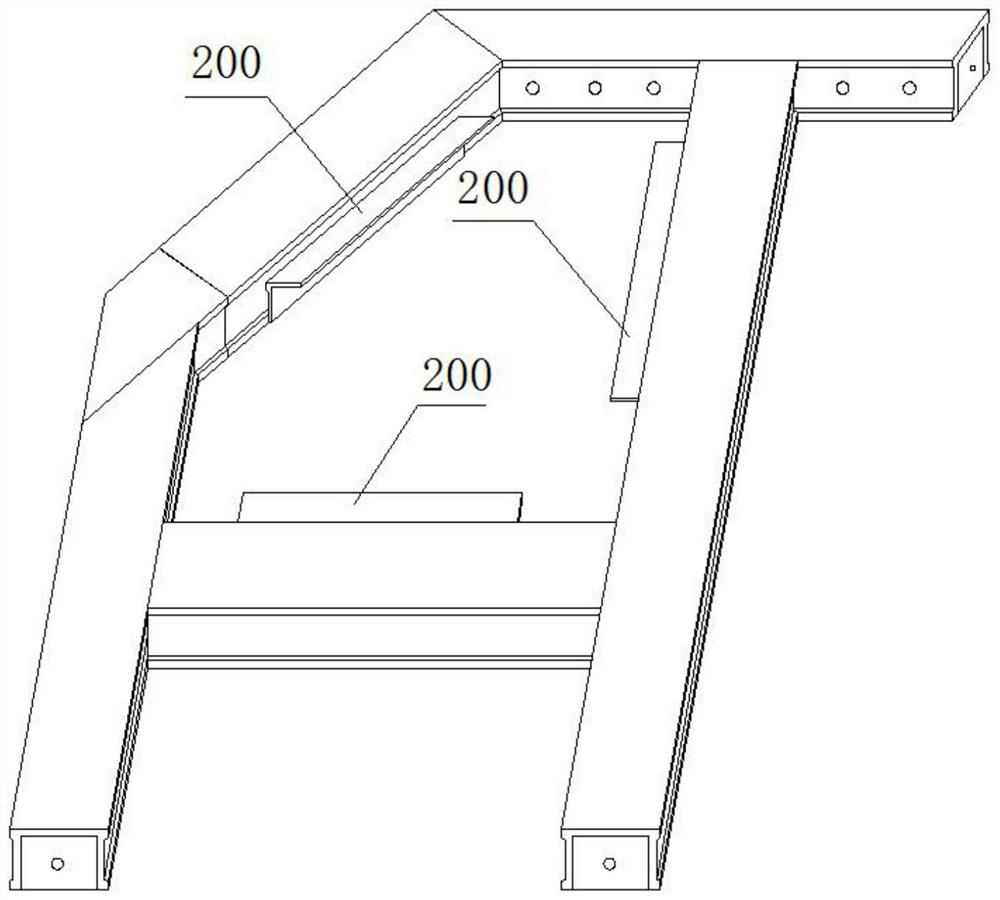

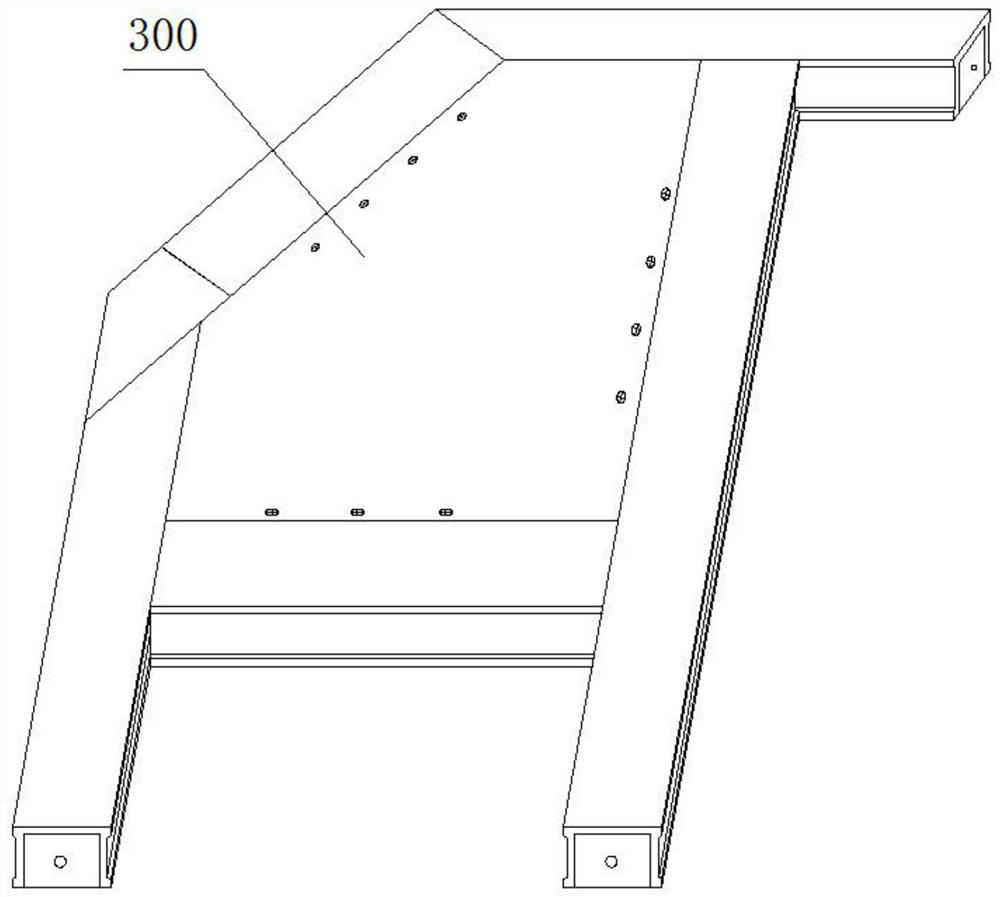

[0033] refer to Figure 1 to Figure 4 As shown, it is an application example of a special-shaped floor construction based on the construction method of the present invention free of scaffolding special-shaped floor formwork. Small and similar to a trapezoidal structure, based on this premise, the steps of construction processing using the scaffold-free special-shaped floor formwork construction method provided by the present invention are as follows:

[0034] Step 1. According to the part of the special-shaped floor to be constructed (ie figure 1 For the metal frame 100 size of the trapezoidal floor part shown in , customize the corresponding size and quantity of metal angle iron (or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com