High efficiency construction method of cast-in-situ hollow core floor slab

A construction method and technology for hollow-core slabs, which are applied to slabs, building components, buildings, etc., can solve problems such as application limitations of cast-in-place hollow slabs with dark ribs, poor economic and technical indicators, and difficult positioning of formwork.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

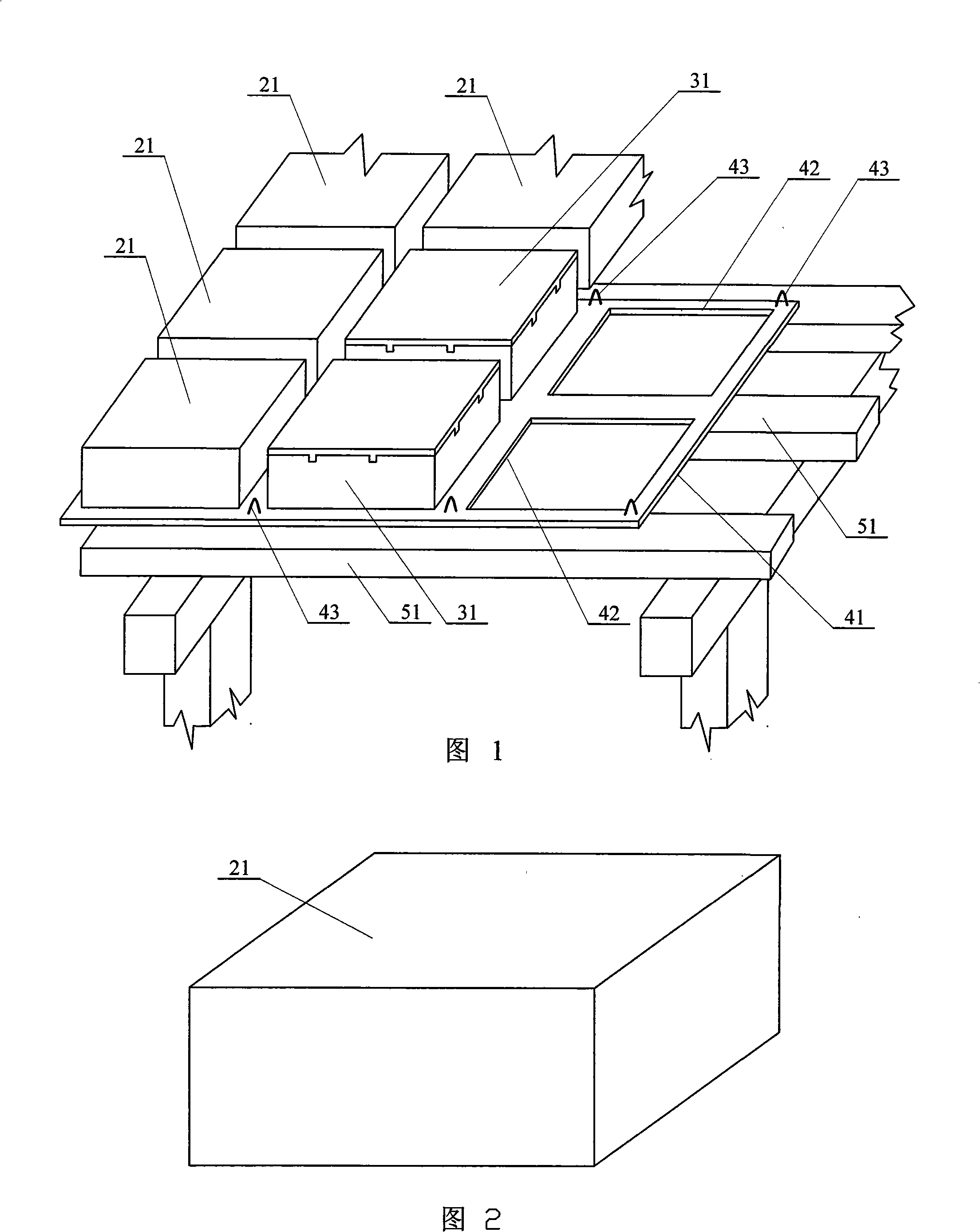

[0005] Specific embodiment one: (referring to Fig. 1) the construction method of this embodiment is realized by following steps: one, set up temporary support beam 51; Line 42, the ceiling 41 of concave-convex line 42 periphery is provided with suspension hook 43; Three, above temporary support beam 51, be covered with ceiling 41 without gap; Block 21 or the assembled hollow box 31 of magnesite material, the assembled hollow box 31 of the aerated block 21 of magnesite material or magnesite material all cooperates with the concave-convex line 42 of ceiling 41; five, in the magnesite material In the gap between the aerated block 21 or the assembled hollow box 31 of magnesite material, put steel bars and bind the steel bars; six, pour concrete.

specific Embodiment approach 2

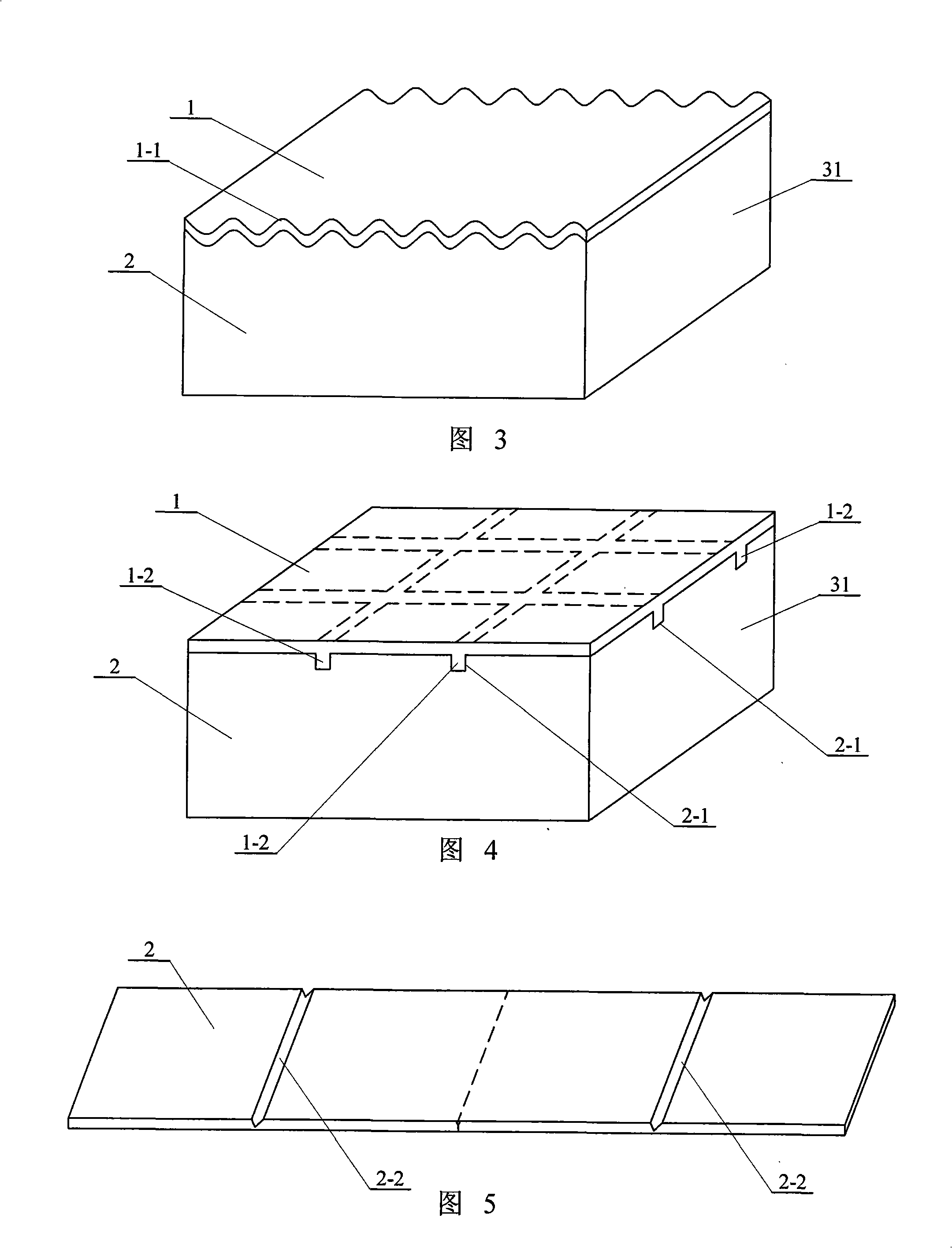

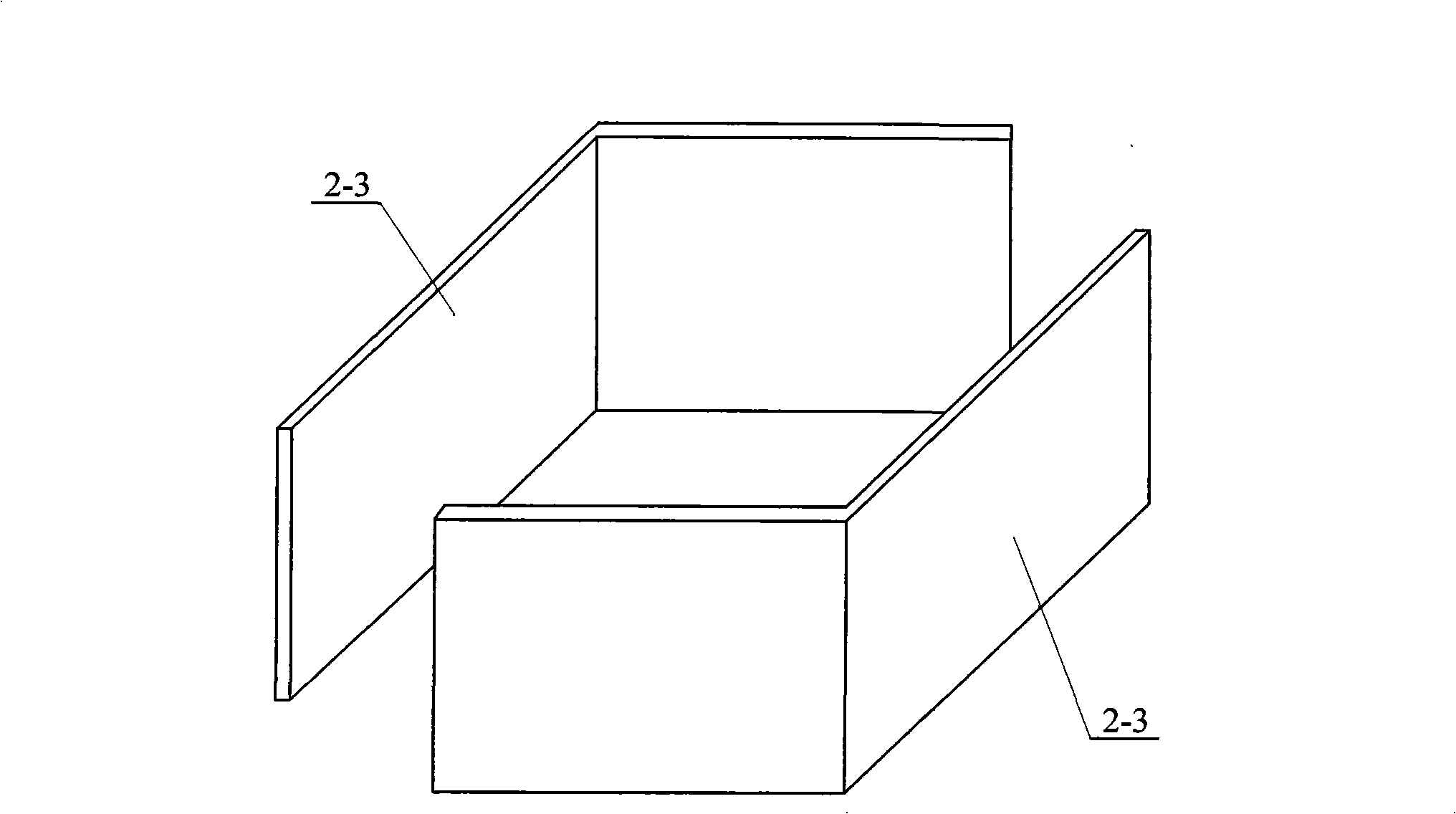

[0006] Embodiment 2: (see FIGS. 2 to 4 ) The assembled hollow box 31 in this embodiment includes an upper cover 1 and a rectangular tube 2 , and the lower side of the upper cover 1 fits with the upper end of the rectangular tube 2 .

specific Embodiment approach 3

[0007] Specific embodiment three: (see FIG. 3 ) The upper cover 1 of this embodiment is in a wave shape 1-1. The strength of the corrugated loam cake 1 can be greatly improved, and can meet the technical requirements of the construction load on the hollow member. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com