Automatic packaging tape pasting mechanism for packaging box production

A technology for packing boxes and sticking tape, applied in the field of cardboard processing, can solve the problems of poor sticking effect, low efficiency, time-consuming and laborious manual tape sticking, etc., and achieve the effect of ensuring the sticking effect, improving production efficiency, and ensuring the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

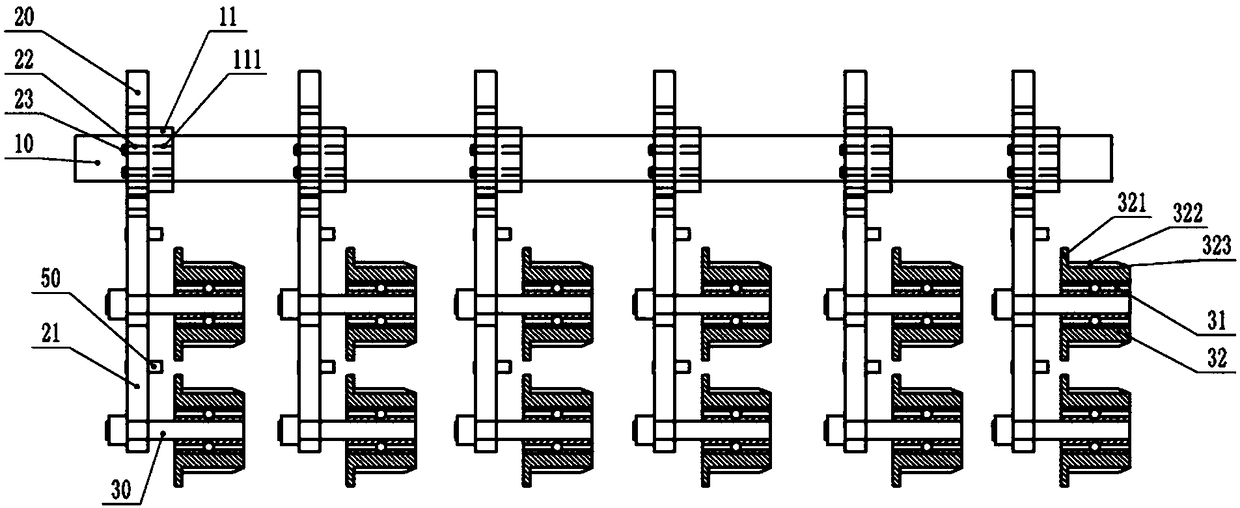

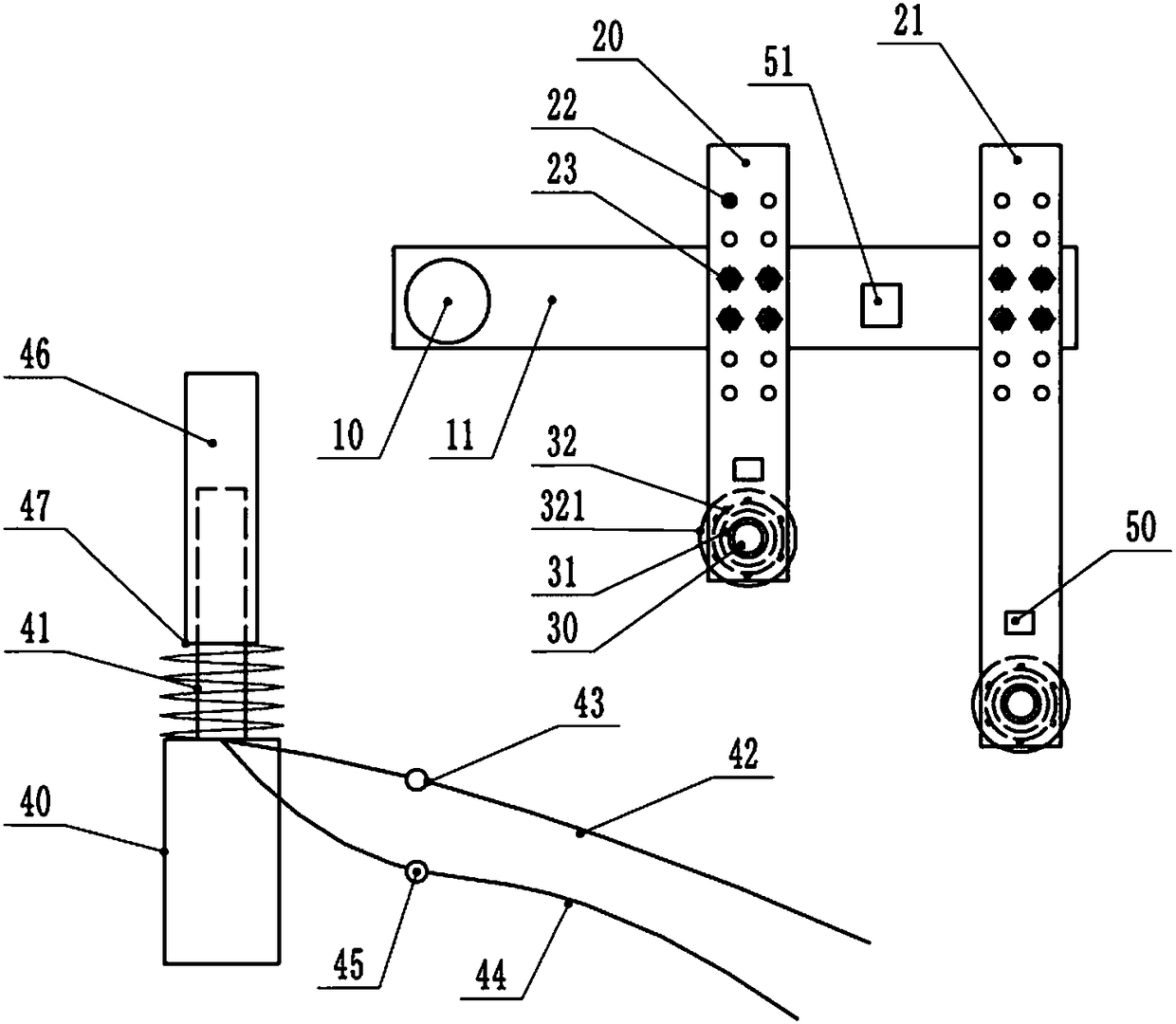

[0026] Such as figure 1 , figure 2 as shown, figure 1The middle cylinder is not shown, and the automatic tape sticking mechanism for packing box production includes a cross bar 10 fixed on the cutting device, a plurality of sticking units fixed on the cross bar 10 and corresponding to the positions of the cutting knives, and the number corresponds to the sticking unit The roll-changing unit; in order to make this mechanism more widely applicable, in this embodiment, there are preferably six pasting units and roll-changing units.

[0027] The pasting unit includes a support plate 11, a first vertical plate 20 and a second vertical plate 21, the support plate 11 is fixed on the cross bar 10 along the direction of corrugated cardboard transmission, and the first vertical plate 20 and the second vertical plate 21 are fixed vertically On the support plate 11; on the support plate 11, four threaded holes 111 are provided at the positions in contact with the first vertical plate 2...

Embodiment 2

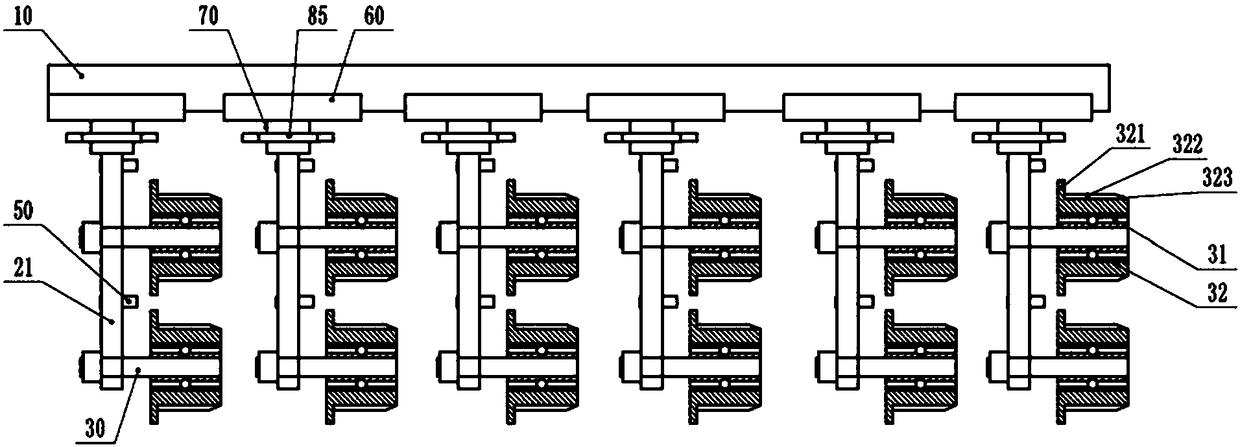

[0036] The difference between this embodiment and embodiment 1 is that, as image 3 , Figure 4 , Figure 5 as shown, image 3 The middle cylinder is not shown, and the lower end of the support plate 11 is fixed with a ring plate 60, and the lower end of the ring plate 60 is provided with a ring groove 61, and two second bearings 62 are slidably connected in the ring groove 61, and the second bearing 62 is fixed with a Two sliding seats 70; a sliding cavity 71 is provided inside the sliding seat 70, and the upper ends of the first vertical plate 20 and the second vertical plate 21 are slidably connected in the sliding cavity 71. The first vertical plate 20 and the top of the second vertical plate 21 are provided with a first magnetic block 72, and an end close to the cross bar 10 is provided with a second magnetic block 73 that is attracted to the first magnetic block 72 on the support block. A third magnetic block 74 repelling the first magnetic block 72 is provided at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com