Paperboard pasting mechanism

A technology of cardboard pasting and top plate, applied in rigid containers, lamination devices, lamination auxiliary operations, etc., can solve the problems of affecting the effect of pasting, loss of viscosity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

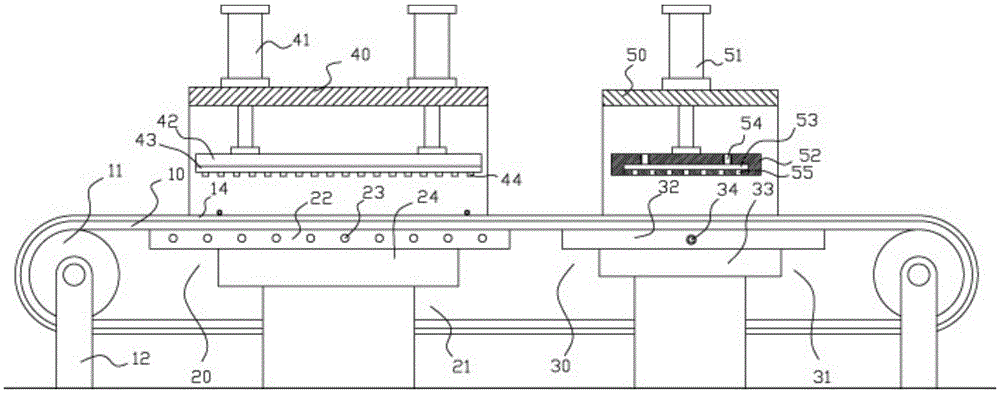

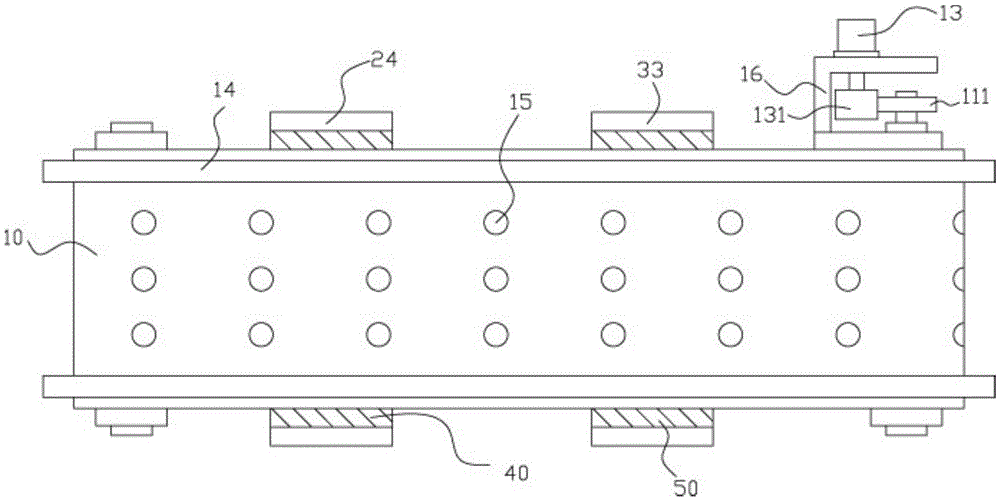

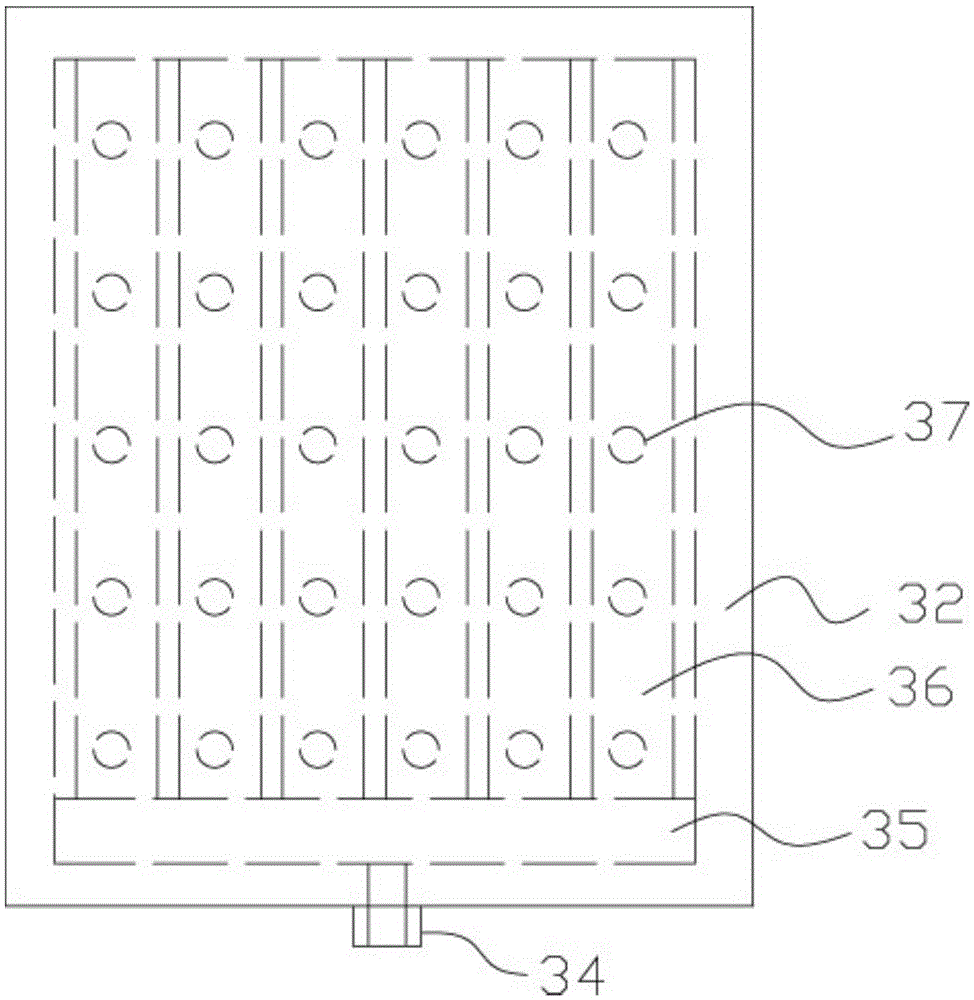

[0018] Example: see Figure 1 to Figure 3 As shown, a cardboard pasting mechanism includes a conveyor belt 10, and the conveyor belt 10 is stretched on two transmission rollers 11, and the two ends of the transmission rollers 11 are hinged with supporting legs 12, and the supporting legs 12 are fixed on the ground, wherein A driving motor 13 is fixed on a support leg 12, and the output shaft of the driving motor 13 drives one of the drive rollers 11 to rotate. Limiting edges 14 are fixed on the walls on both sides of the conveyor belt 10, and the middle part of the conveyor belt 10 is evenly distributed with multiple Vent 15, heating device 20 is fixed on the first support 21, and blowing device 30 is fixed on the second support 31, and heating device 20 and blowing device 30 are in the space before the upper conveyer belt portion of conveyor belt 10 and the lower conveyer belt portion. In the cavity, the heating device 20 and the blowing device 30 are arranged around;

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com