Precise pressure attachment mechanism

A technology of precision pressure and clamping mechanism, applied in the field of precision pressure fitting mechanism, can solve the problems of waste of resources, unintuitive pressure, limited scope of application, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

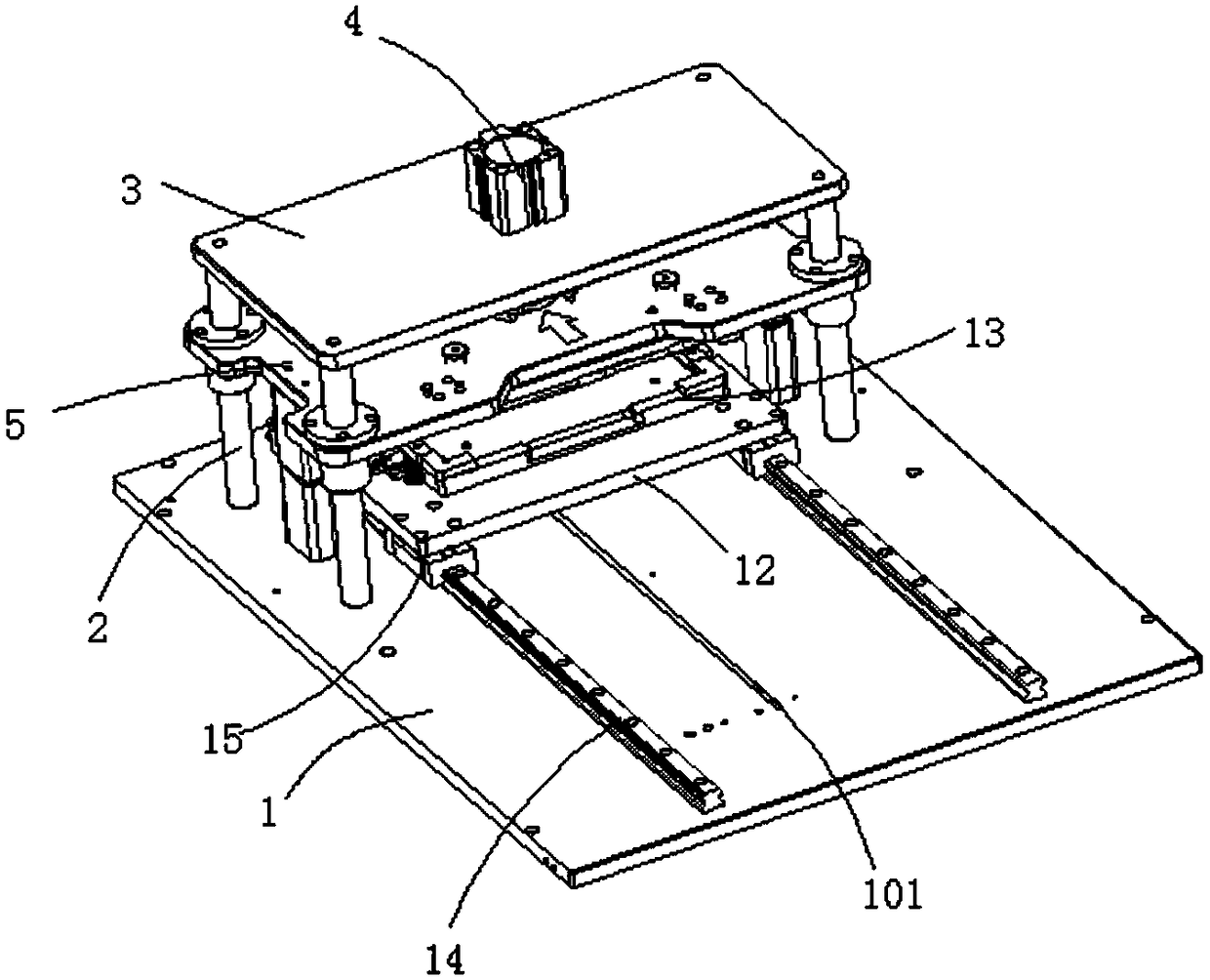

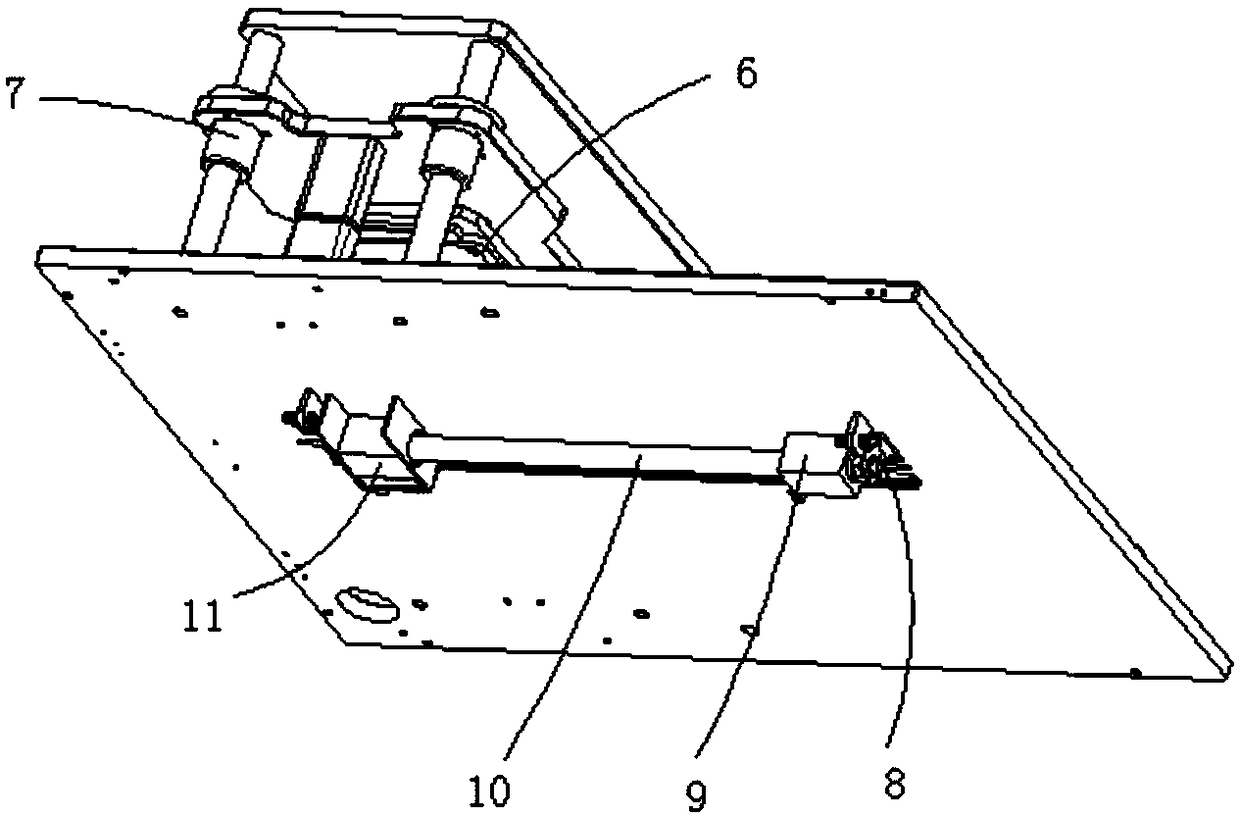

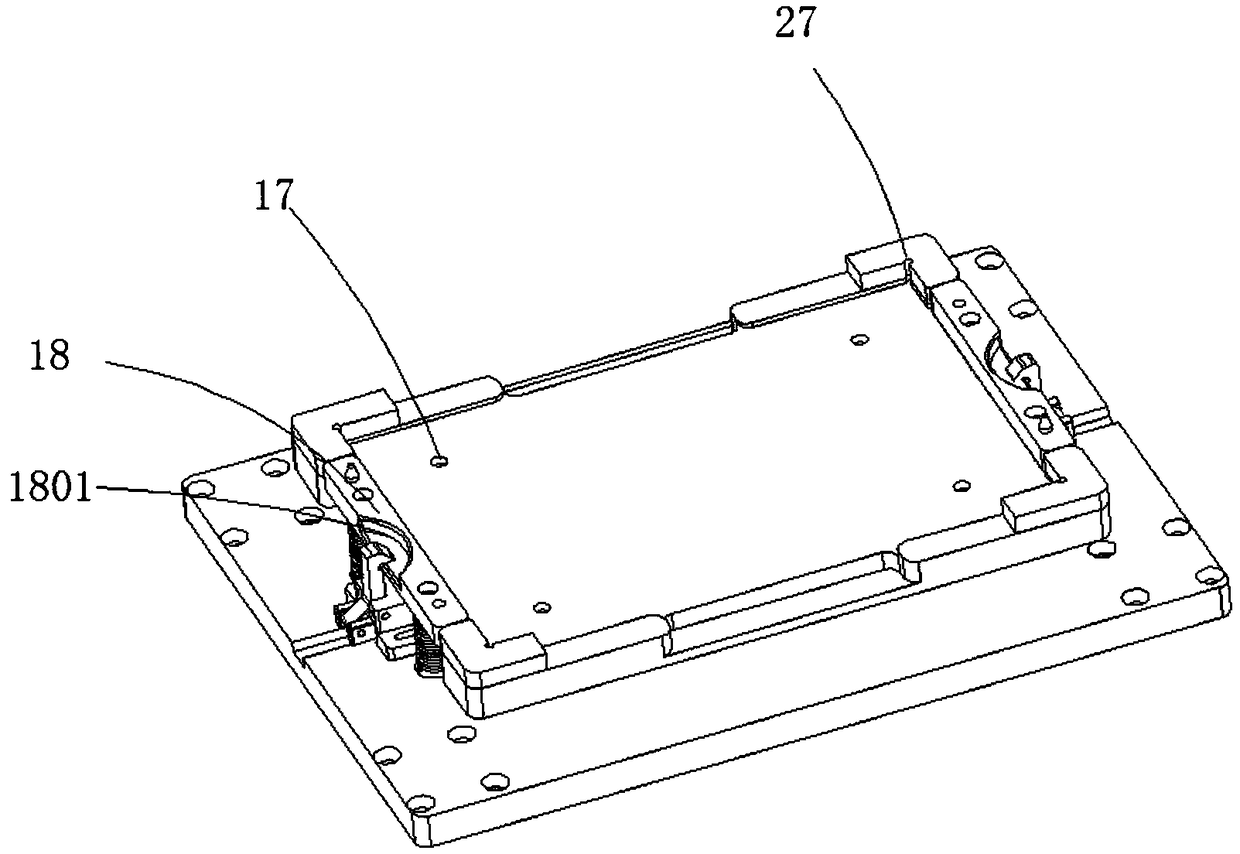

[0027] Examples, see attached Figure 1~5 , a precision pressure bonding mechanism, including a base plate 1, the base plate is a flat plate structure, a pressing assembly is installed behind the upper part of the base plate, and the pressing assembly includes four sets of support columns 2 installed on the base plate and four sets of support columns installed on the base plate The four groups of support columns have the same structure as the lower pressure cylinder fixing plate 3 on the column, and are all cylindrical structures. The four groups of support columns are symmetrically installed under the lower pressure cylinder fixing plate 3, and the lower pressure cylinder fixing plate 3 is also a flat structure. A down-pressing cylinder 4 is installed on the fixed plate of the said down-pressing cylinder, the piston rod of the said down-pressing cylinder passes through the down-pressing cylinder fixed plate, and the lower end of the piston rod of the down-pressing cylinder is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com