A detection device for coated glass

A technology of coated glass and detection device, which is applied to measurement devices, optical testing flaws/defects, instruments, etc., can solve the problems of inconvenient coating glass, affecting detection efficiency, and confusion of coated glass, etc. Detecting the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

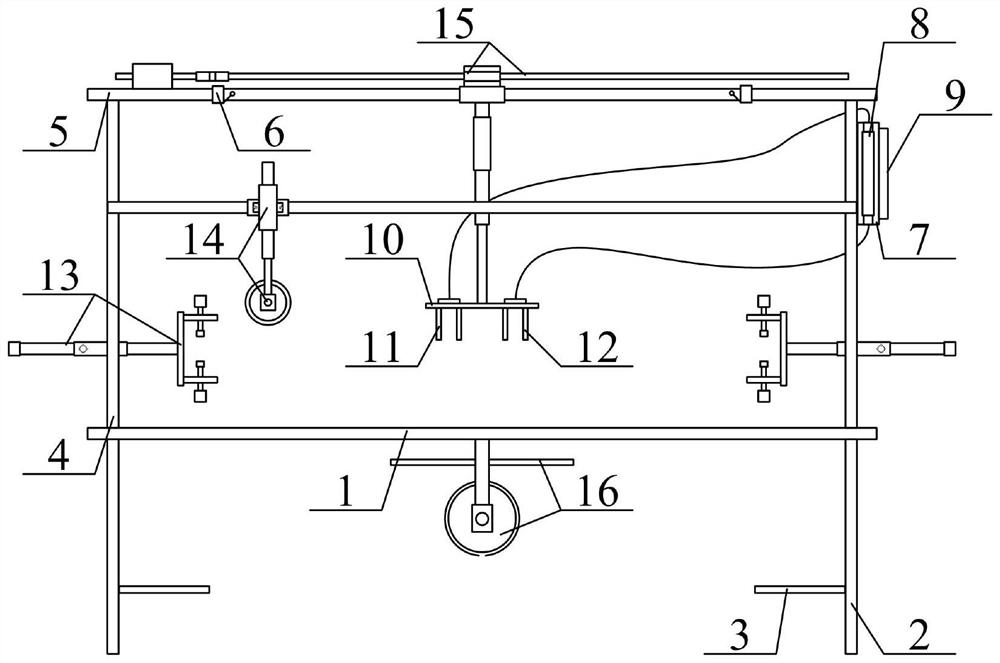

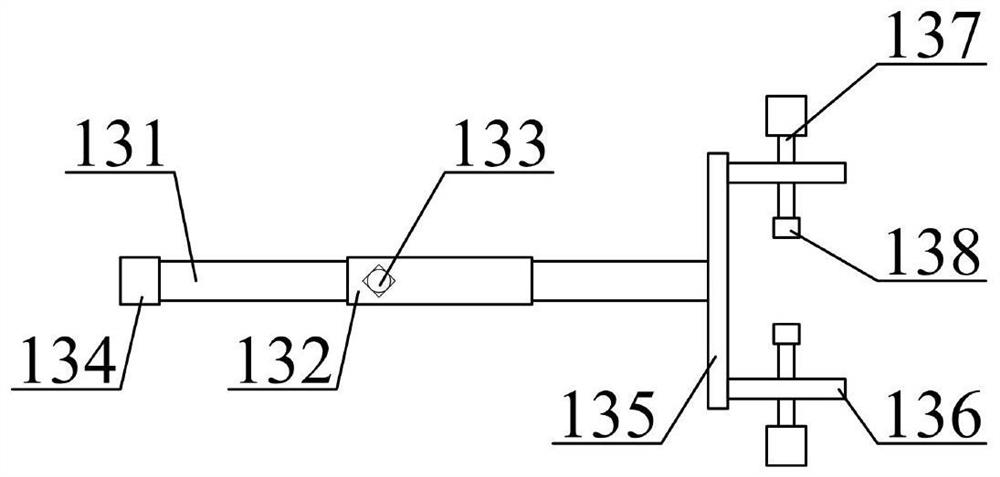

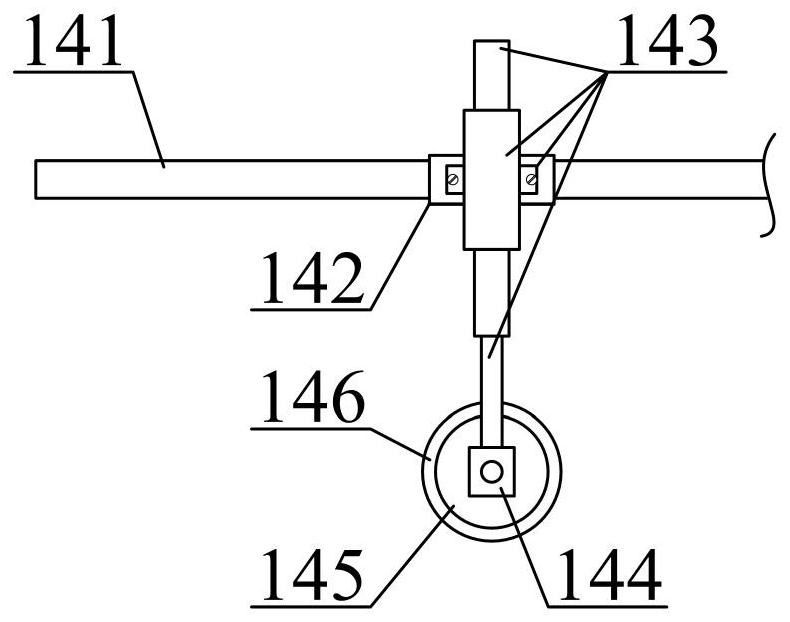

[0035] The present invention will be specifically described in conjunction with the accompanying drawings. figure 1 Attach figure 2As shown, a detection device of a coated glass includes a frame 1, a support leg 2, a baffle 3, a frame 4, a beam 5, a limit switch 6, a control cartridge 7, a host 8, alarm 9, a detection board 10 , Power supply emitter probe 11, power supply receiving pole probe 12, adjustable coating glass clamp structure 13, movable glass surface cleaning wheel structure 14, multi-position moving detection push rod structure 15 and dust detection Anti-confusing glass patch structure 16, the bottom of the rack 1 is connected to the support leg 2; the support of the support leg 2 in the left side, the support of the upper and right side provided by the left side. The inner lower part bolt between the legs 2 is connected to the baffle 3; the upper left and right side of the rack 1 is connected to the frame 4; the upper bolt between the frame 4 is connected to the beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com