Method for extracting plant pectin from hemp skin

A hemp and pectin technology, which is applied in the field of new raw materials for extracting plant pectin, can solve the problems of serious environmental pollution of degumming liquid and the inability to recycle pectin, achieve rich pectin content, increase economic value, and be easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

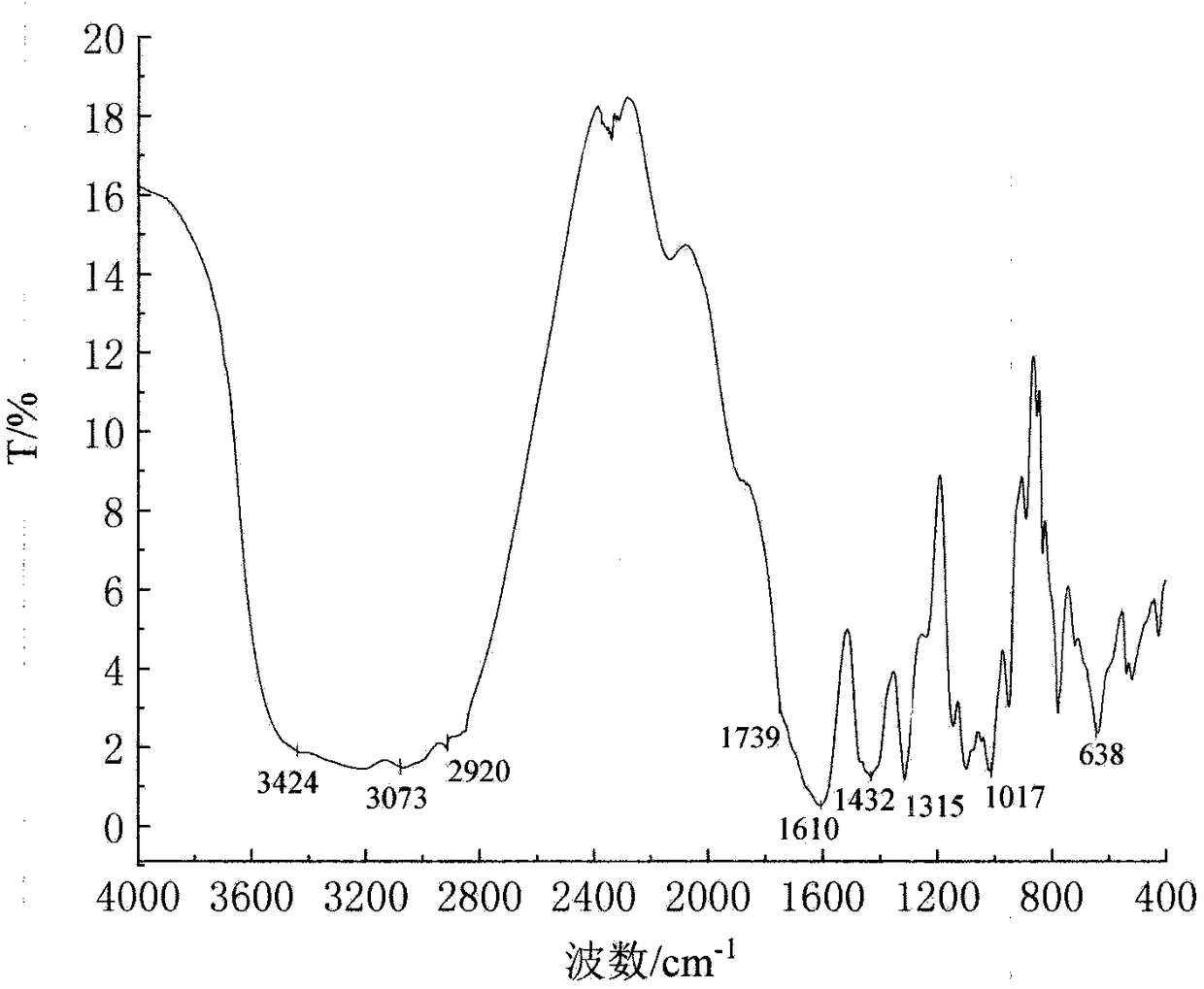

Image

Examples

Embodiment 1

[0025] 1. Ultrasonic pretreatment: cut cannabis into 5cm length, dry, weigh 5g, and simply wash with water; use ultrasonic wave under the conditions of ultrasonic frequency 40kHz, ultrasonic power 110W, temperature 50°C, solvent is water, and bath ratio 1:50 The hemp husk was ultrasonically processed by the processor for 35 minutes, washed and dried.

[0026] 2. Extract marijuana pectin with ammonium oxalate: prepare 3.5g / L ammonium oxalate aqueous solution with a bath ratio of 1:30, put the marijuana after ultrasonic pretreatment in the ammonium oxalate solution, and keep it warm for 50min at 95°C; take the degumming solution , filter with a 400-mesh filter cloth while it is hot; take the filtrate, adjust the pH to 4, concentrate to 15% in a rotary evaporator at 60°C, and then rapidly cool down to obtain a concentrated solution. Concentrating to 15% is the ratio of the volume of the concentrated solution to the volume of the degummed solution filtered while hot.

[0027] 3. ...

Embodiment 2

[0030] 1. Ultrasonic pretreatment: cut cannabis into 5cm length, dry, weigh 5g, and simply wash with water; use ultrasonic wave under the conditions of ultrasonic frequency 40kHz, ultrasonic power 120W, temperature 50°C, solvent is water, and bath ratio 1:50 The hemp husk was ultrasonically processed by the processor for 35 minutes, washed and dried.

[0031] 2. Extract marijuana pectin with ammonium oxalate: prepare 4g / L ammonium oxalate aqueous solution with a liquor ratio of 1:30, put the marijuana pretreated by ultrasonic waves into the ammonium oxalate solution, and keep it warm for 40min at 100°C; take the degumming solution, Filter while hot with a 400-mesh filter cloth; take the filtrate, adjust the pH to 4.5, concentrate to 20% in a rotary evaporator at 60°C, and then rapidly cool down to obtain a concentrated solution. Concentrating to 20% is the ratio of the volume of the concentrated solution to the volume of the degummed solution filtered while hot.

[0032] 3. P...

Embodiment 3

[0035] 1. Ultrasonic pretreatment: cut cannabis into 5cm length, dry, weigh 5g, and simply wash with water; use ultrasound under the conditions of ultrasonic frequency 40kHz, ultrasonic power 100W, temperature 50°C, solvent is water, and bath ratio 1:50 The hemp husk was ultrasonically processed by the processor for 40 minutes, washed and dried.

[0036] 2. Extract marijuana pectin with ammonium oxalate: prepare 3g / L ammonium oxalate aqueous solution with a bath ratio of 1:30, put the marijuana pretreated by ultrasonic waves into the ammonium oxalate solution, and keep it warm for 45min at 100°C; take the degumming solution, Filter while it is hot with a 400-mesh filter cloth; take the filtrate, adjust the pH to 5, concentrate to 20% in a rotary evaporator at 60°C, and then rapidly cool down to obtain a concentrated solution. Concentrating to 20% is the ratio of the volume of the concentrated solution to the volume of the degummed solution filtered while hot.

[0037] 3. Prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com