Method for improving mechanical property of lotus fiber

A lotus fiber and performance technology, applied in the field of lotus fiber modification, can solve problems such as mechanical strength discount, achieve low equipment requirements, improve degumming rate, and facilitate post-processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

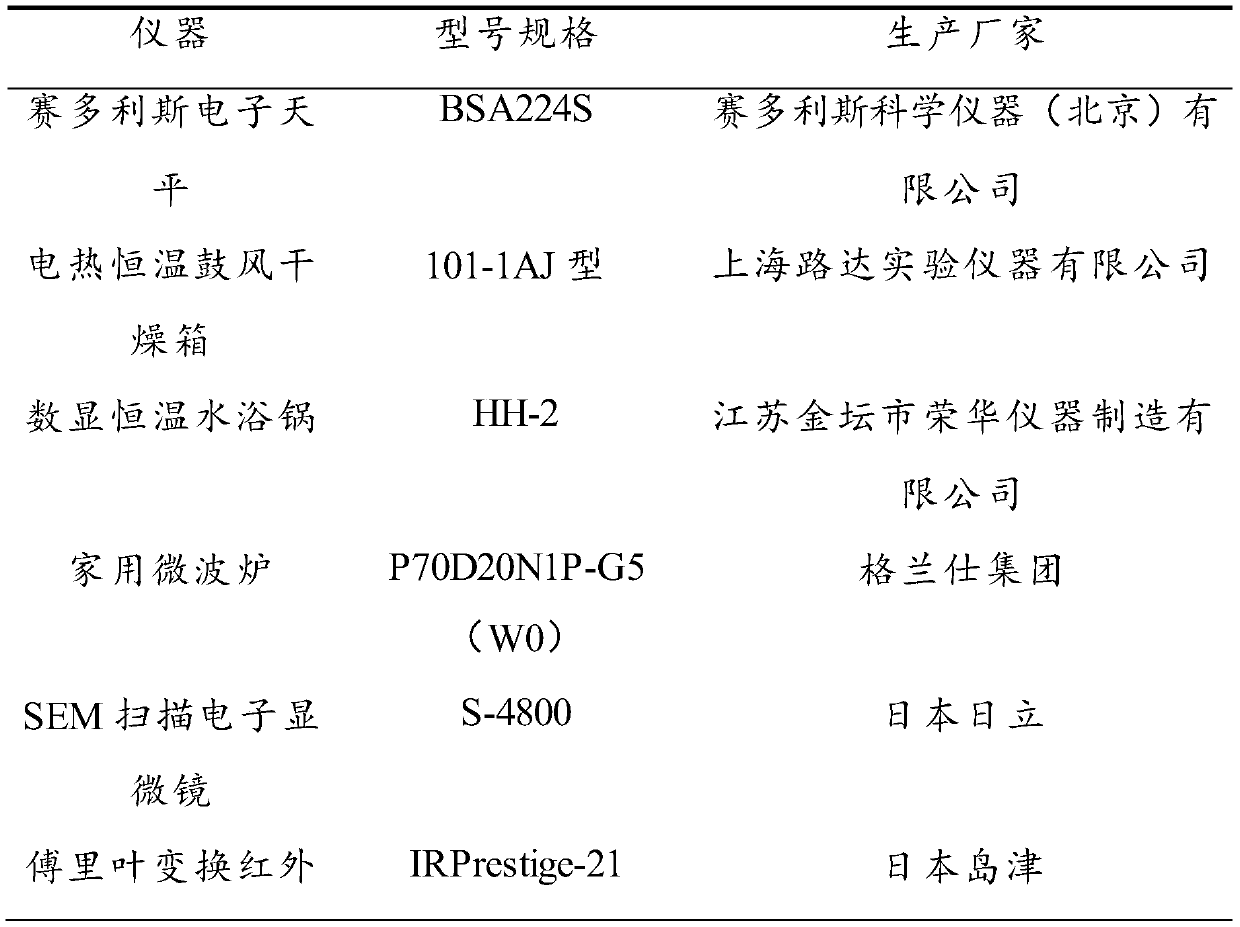

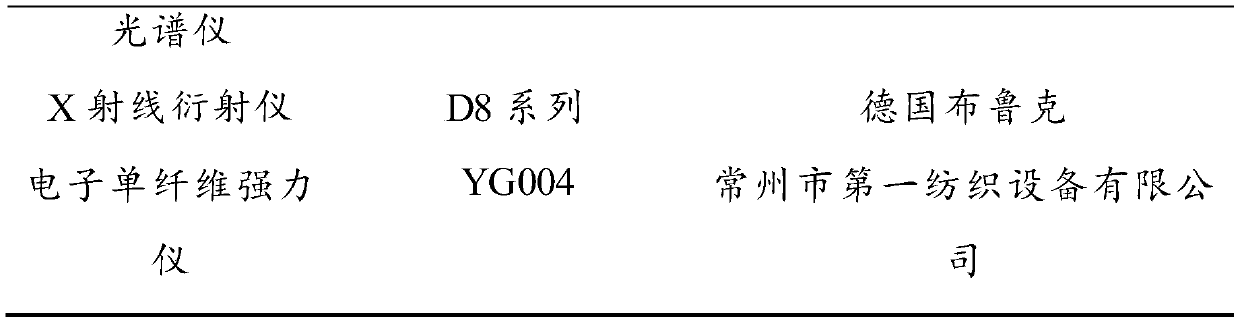

Method used

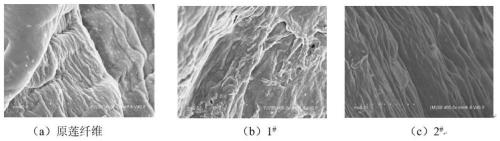

Image

Examples

Embodiment 1

[0029] The present embodiment provides a method for improving the mechanical properties of lotus fiber, and its specific processing method is as follows:

[0030] 1. Take fresh lotus fiber and soak it in a sulfuric acid solution with a mass-volume ratio of 1.8mL / L for 5-10min.

[0031] 2. Prepare a 1-ethyl-3-methylimidazole chloride solution with a concentration of 30g / L and heat it to 60°C, then add carboxymethylcellulose sodium in an amount of 4g / L. Before use, add 8g / L wheat bran, shake and mix for 1min to obtain a mixed solution, which is prepared and used immediately.

[0032] 3. Take out the lotus fiber soaked in acid, drain it, put the lotus fiber into the mixed solution in step 2 according to the addition amount of 100g / L, and microwave it for 20min under the condition of microwave power of 60w.

[0033] 4. After the microwave treatment, rinse the lotus fibers with 40° C. water. After the rinsing, boil the lotus fibers with 10% (m / V) sodium hydroxide solution for 10 m...

Embodiment 2

[0038] The present embodiment provides a method for improving the mechanical properties of lotus fiber, and its specific processing method is as follows:

[0039] 1. Take fresh lotus fiber and soak it in a sulfuric acid solution with a mass-volume ratio of 2.2mL / L for 5-10min.

[0040] 2. Prepare a 1-ethyl-3-methylimidazole chloride solution with a concentration of 10g / L and heat it to 55°C, then add carboxymethylcellulose sodium in an amount of 2g / L. Before use, add 3g / L wheat bran, shake and mix for 2 minutes to obtain a mixed solution, which is prepared and used immediately.

[0041] 3. Take out the lotus fiber soaked in acid, drain and put the lotus fiber into the above mixture according to the addition amount of 120g / L, and microwave it for 30min under the condition of microwave power of 20w.

[0042] 4. After the microwave treatment, rinse the lotus fiber with 35° C. water, and boil the lotus fiber with 8% (m / V) sodium hydroxide solution for 60 minutes under the condition...

Embodiment 3

[0047] The present embodiment provides a method for improving the mechanical properties of lotus fiber, and its specific processing method is as follows:

[0048] 1. Take fresh lotus fiber and soak it in a sulfuric acid solution with a mass-volume ratio of 0.6mL / L for 5-10min.

[0049] 2. Prepare a solution of 1-ethyl-3-methylimidazole chloride with a concentration of 45g / L and heat it to 70°C, then add sodium carboxymethyl cellulose in an amount of 5g / L. Before use, add 10g / L wheat bran, shake and mix for 3 minutes to obtain a mixed solution, which is prepared and used immediately.

[0050] 3. Take out the lotus fiber soaked in acid, drain it, put the lotus fiber into the above mixture according to the addition amount of 150g / L, and microwave it for 5 minutes under the condition of microwave power of 80w.

[0051] 4. After the microwave treatment, rinse the lotus fiber with 45°C clear water, and boil the lotus fiber with 12% (m / V) sodium hydroxide solution for 30 minutes und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com