Method for increasing silk degumming rate

A technology of degumming and degumming rate of silk is applied in the field of degumming, which can solve the problems of low degumming efficiency and high cost, and achieve the effects of good gloss and hand feeling, improving quality and improving whiteness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

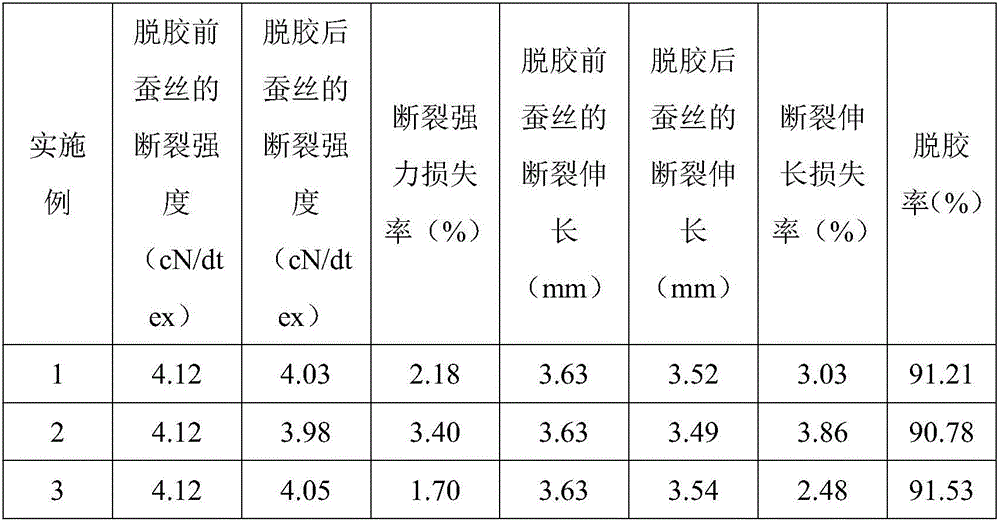

Examples

preparation example Construction

[0044] The preparation method of described silk degumming agent, comprises the following steps:

[0045] S11: Mix ammonia water and sodium silicate, heat up to 45-48°C and stir to dissolve, and prepare mixed solution I;

[0046] S12: Add surfactant, penetrant, dispersant, co-solvent to the mixed solution I prepared in step S11, heat to 52-58°C, stir for 18- 26min to prepare the mixed solution II;

[0047] S13: stop the heating and ultrasonic action, add a stabilizer to the mixed solution II prepared in step S12, and stir for 6-8 minutes at a rotation speed of 200-300 r / min to prepare the mixed solution III;

[0048] S14: Adding a regulator and water to the mixed solution III prepared in step S13 to make the pH value 9.2-10.5 to prepare a silk degumming agent;

[0049] S2: Add the silk obtained by filtering in step S1 into a mixed solution of ethanol with a mass concentration of 34%-39% and tartaric acid with a mass concentration of 12%-23%, heat to 74-78°C, keep it for 15-22...

Embodiment 1

[0055] A method for improving silk degumming rate, comprising the following steps:

[0056] S1: Immerse the silk to be treated in the silk degumming agent, heat to 48°C under airtight conditions, stir for 75min at an ultrasonic power of 150W, and a stirring speed of 110r / min, and filter to obtain silk;

[0057] The silk degumming agent, in parts by weight, includes the following raw materials: 130 parts of ammonia water, 60 parts of sodium silicate, 15 parts of surfactant, 3 parts of penetrating agent, 1.6 parts of dispersant, 2.5 parts of regulator, cosolvent 2.4 parts, 1.2 parts of stabilizer;

[0058] The mass concentration of the ammoniacal liquor is 25%;

[0059] The surfactant is polyacrylamide;

[0060] The penetrating agent is potassium alkylbenzenesulfonate;

[0061] Described dispersant is potassium lauryl sulfate;

[0062] The regulator is acetic acid;

[0063] Described cosolvent is sodium salicylate;

[0064] The stabilizer is boron nitride;

[0065] The prep...

Embodiment 2

[0075] A method for improving silk degumming rate, comprising the following steps:

[0076] S1: Immerse the silk to be treated in the silk degumming agent, heat it to 45°C under airtight conditions, stir for 92min at an ultrasonic power of 120W, and a stirring speed of 90r / min, and filter to obtain silk;

[0077] The silk degumming agent, in parts by weight, includes the following raw materials: 104 parts of ammonia water, 42 parts of sodium silicate, 11 parts of surfactant, 1.8 parts of penetrating agent, 1.2 parts of dispersant, 2 parts of regulator, cosolvent 1.8 parts, 0.9 parts of stabilizer;

[0078] The mass concentration of the ammoniacal liquor is 22%;

[0079] The surfactant is polyacrylamide;

[0080] The penetrating agent is potassium alkylbenzenesulfonate;

[0081] Described dispersant is potassium lauryl sulfate;

[0082] The regulator is acetic acid;

[0083] Described cosolvent is sodium salicylate;

[0084] The stabilizer is boron nitride;

[0085] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com