Preparation technique of sisal fiber

A sisal fiber and preparation technology, applied in the field of textile processing, can solve the problems of low breaking strength, excessive use of chemical reagents to pollute the environment, high residual glue rate, etc., and achieve the effects of reduced residual glue rate, easy control, and increased degumming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

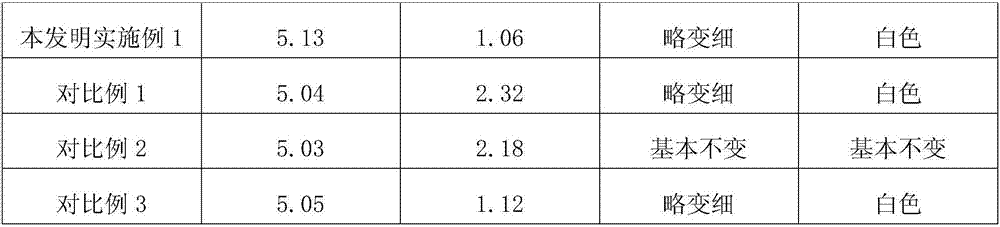

Examples

Embodiment 1

[0036] A kind of preparation technology of sisal fiber is characterized in that, comprises the following steps:

[0037] (1) Pretreatment: flatten the harvested fresh sisal leaves and put them into a roller compactor repeatedly and completely until no water comes out, soak them in 12% acetic acid solution at room temperature for 60 minutes, and finally soak the soaked sisal leaves Rinse with clear water to pH=6-7, and dry to obtain cleaned sisal leaves;

[0038](2) Corona discharge treatment: put the dried sisal fiber into a high-voltage corona discharge zone for 20 seconds, the voltage of the treatment is 8kv, and the treatment temperature is 60°C.

[0039] (3) Ultrasonic vibration: take the sisal leaves treated by corona discharge, put them into NaOH solution according to the mass ratio of sisal leaves and NaOH solution as 1:3, and ultrasonically vibrate at an ultrasonic frequency of 30KHz and an ultrasonic power of 4000W For 1 hour, the mass concentration of NaOH in the Na...

Embodiment 2

[0045] A kind of preparation technology of sisal fiber is characterized in that, comprises the following steps:

[0046] (1) Pretreatment: flatten the harvested fresh sisal leaves and put them into the rolling machine repeatedly and completely rolling until no water comes out, soak them in 13% acetic acid solution at room temperature for 50min, and finally soak the soaked sisal leaves Rinse with clear water to pH=6-7, and dry to obtain cleaned sisal leaves;

[0047] (2) Corona discharge treatment: put the dried sisal fibers into a high-voltage corona discharge zone for treatment for 23 seconds, the treatment voltage is 7kv, and the treatment temperature is 65°C.

[0048] (3) Ultrasonic vibration: Take the sisal leaves treated by corona discharge, put them into NaOH solution according to the mass ratio of sisal leaves and NaOH solution as 1:4, and ultrasonically vibrate at an ultrasonic frequency of 33KHz and an ultrasonic power of 3700W 1.3 hours, the mass concentration of Na...

Embodiment 3

[0054] A kind of preparation technology of sisal fiber is characterized in that, comprises the following steps:

[0055] (1) Pretreatment: flatten the harvested fresh sisal leaves and put them into a roller compactor repeatedly and completely until no water comes out, soak them in 15% acetic acid solution for 40 minutes at room temperature, and finally soak the soaked sisal leaves Rinse with clear water to pH=6-7, and dry to obtain cleaned sisal leaves;

[0056] (2) corona discharge treatment: put the dried sisal fiber into a high-voltage corona discharge zone for 25s, the voltage of the treatment is 6kv, and the temperature of the treatment is 70°C;

[0057] (3) Ultrasonic vibration: Take the sisal leaves after corona discharge treatment, put them into NaOH solution according to the mass ratio of sisal leaves and NaOH solution as 1:5, and ultrasonically vibrate 1.5 at the ultrasonic frequency of 35KHz and ultrasonic power of 3500W. hour, the mass concentration of NaOH in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com