Diglyceride lipin production method

A technology of diglyceride and production method, applied in fatty acid esterification, organic chemistry and other directions, can solve problems such as high cost and insufficient economy, and achieve the effect of reducing separation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

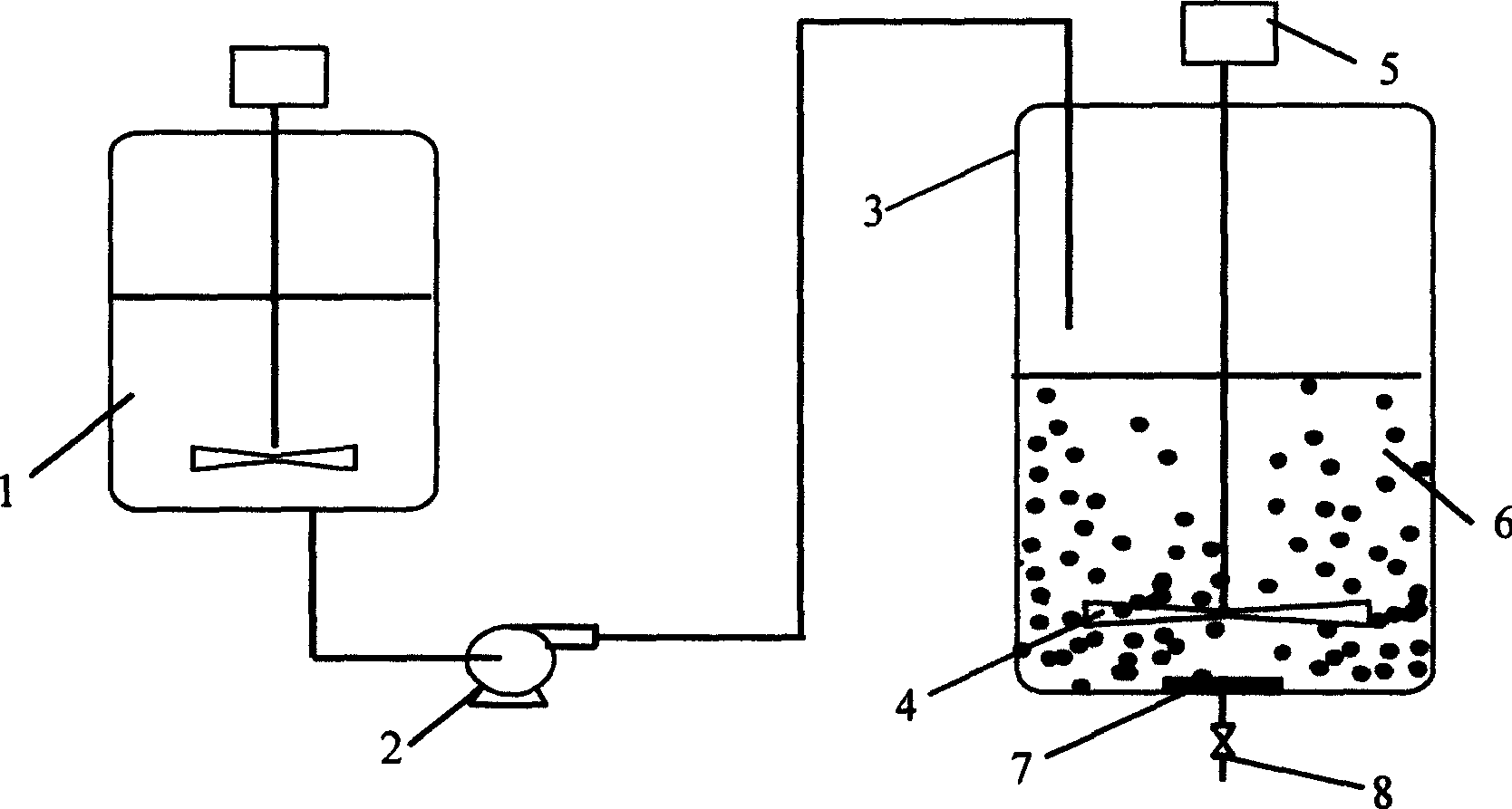

[0038] Mix 50g and 100g of dry glycerin and white clay respectively to obtain adsorbed glycerin. Such as figure 1 As shown, the adsorbed glycerin and 1000g of refined rice bran oil are premixed in tank 1, and the mixture of solid adsorbed glycerin and oil is pumped into tank 3 through pump 2, and then 200 g of immobilized lipase Lipozyme TL IM is added at 20°C Under the condition of 60 revolutions per minute, the diglyceride content reached the maximum for 72 hours after the reaction was filtered to remove the immobilized enzyme and glycerin adsorption material in the reaction product, and then the monoglyceride and fatty acid were removed by molecular distillation at 190°C and 1.2 Pa The diglyceride grease was obtained, and the results are shown in Tables 1 and 2.

Embodiment 2

[0040] The temperature is 50°C, the amount of enzyme added is 40g, and the reaction time is 24 hours. The rest is the same as in Example 1. The results are shown in Tables 1 and 2.

Embodiment 3

[0042] Same as Example 1, except that the amount of enzyme added is 80g, the reaction temperature is 40°C, and the reaction time is 28 hours. The results are shown in Tables 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com