Production method for coproducing unsaturated monoglyceride by using diglyceride enzyme method

A technology of diglyceride enzyme and production method, which is applied in the field of enzymatic production of unsaturated monoglyceride and diglyceride, can solve the problems of high difficulty, low reaction efficiency, inconvenient use of carrier regeneration, etc., and achieve the solution of acid Price issues, the effect of simplifying production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

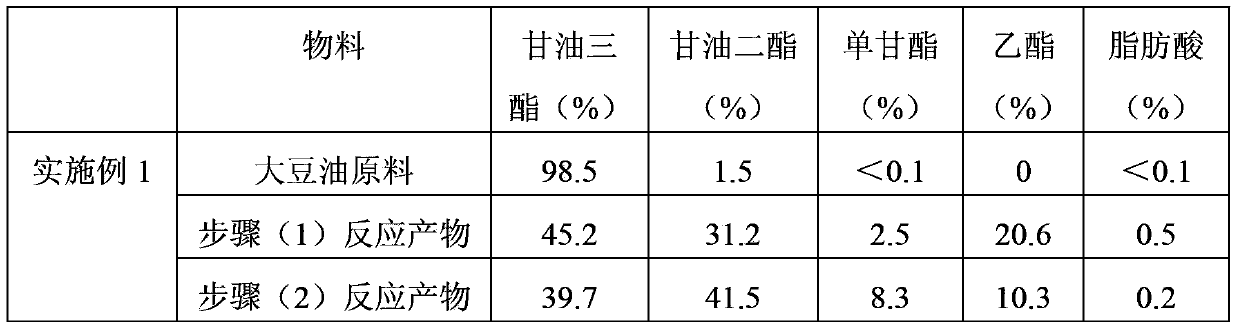

Embodiment 1

[0029]A method for enzymatically producing diglycerides by co-producing unsaturated monoglycerides, comprising the following steps:

[0030] Step (1), mix 5kg soybean oil and 0.3kg absolute ethanol, add 2g of immobilized lipase Novozyme 435 (supplied by Novozymes, Denmark), stir and react at 35°C for 3 hours, the formation rate of fatty acid ethyl ester is 20.6%, vacuum desorption Residual ethanol is removed to obtain alcoholysis products.

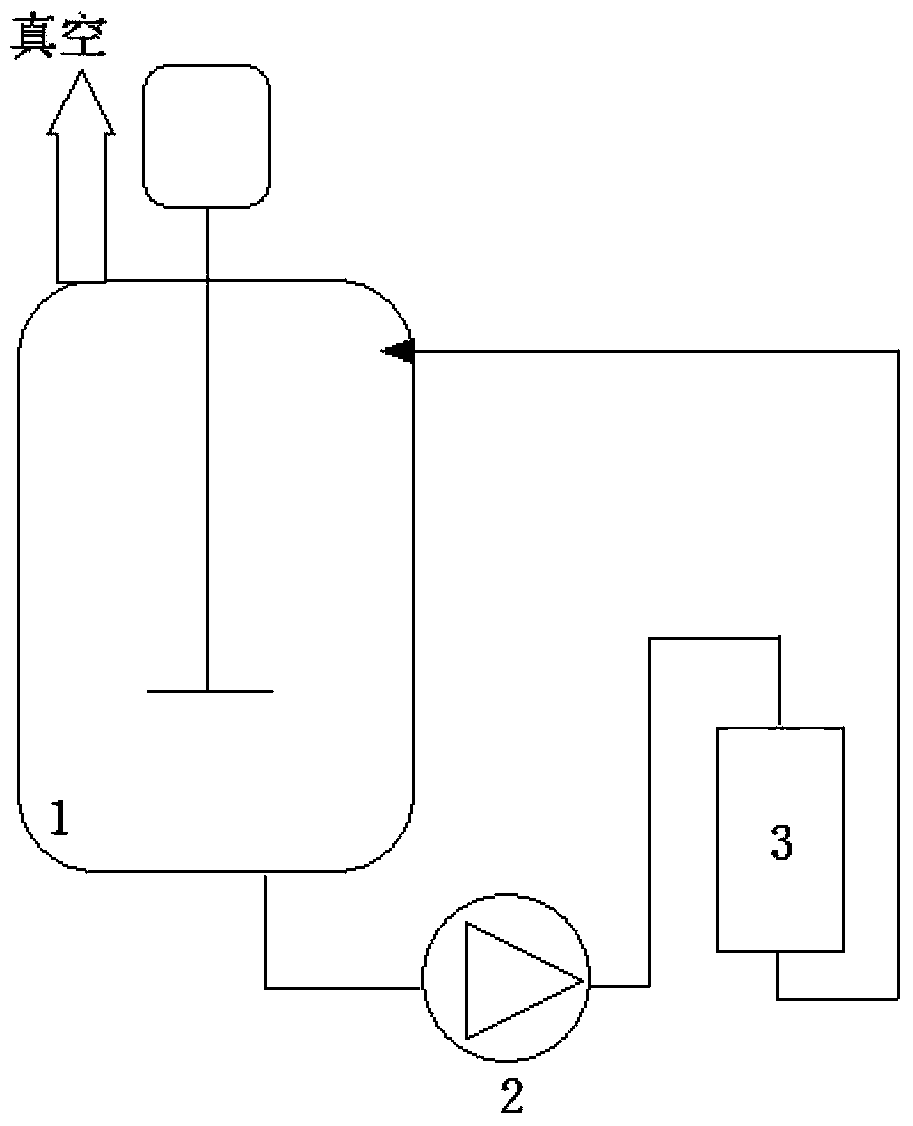

[0031] In step (2), 3kg of alcoholysis product is loaded into such as figure 1 In the raw material storage tank 1 shown, add 0.3kg glycerin, the material circulates through the packed bed enzyme reactor 3 of immobilized lipase under the action of pump 2, the reaction temperature is 60 ℃, adopts immobilized lipase Novozyme 435, the enzyme The filling amount is 10g, react under normal pressure for 1 hour, then control the absolute pressure of the reaction to 10pa, and then discharge after reacting for 3 hours. The composition of the analysi...

Embodiment 2

[0034] A method for enzymatically producing diglycerides by co-producing unsaturated monoglycerides, comprising the following steps:

[0035] Step (1), mix 5kg soybean oil and 0.3kg absolute ethanol, add 2g of immobilized lipase Novozyme 435 (provided by Novozymes, Denmark), stir and react at 35°C for 0.5 hours, the ethyl ester formation rate is 9.8%, and vacuum remove Ethanol remains to obtain alcoholysis products.

[0036] In step (2), 3kg of alcoholysis product is loaded into such as figure 1 Add 0.15kg of glycerol to the raw material storage tank shown, and the material circulates through the packed bed enzyme reactor of immobilized lipase under the action of the pump. The reaction temperature is 60°C, and the immobilized lipase Novozyme 435 is used. It was 10g, first reacted under normal pressure for 6 hours, then the absolute pressure of reaction was controlled to be 100pa, and discharged after 24 hours of reaction, its composition was analyzed in Table 1.

[0037] In ...

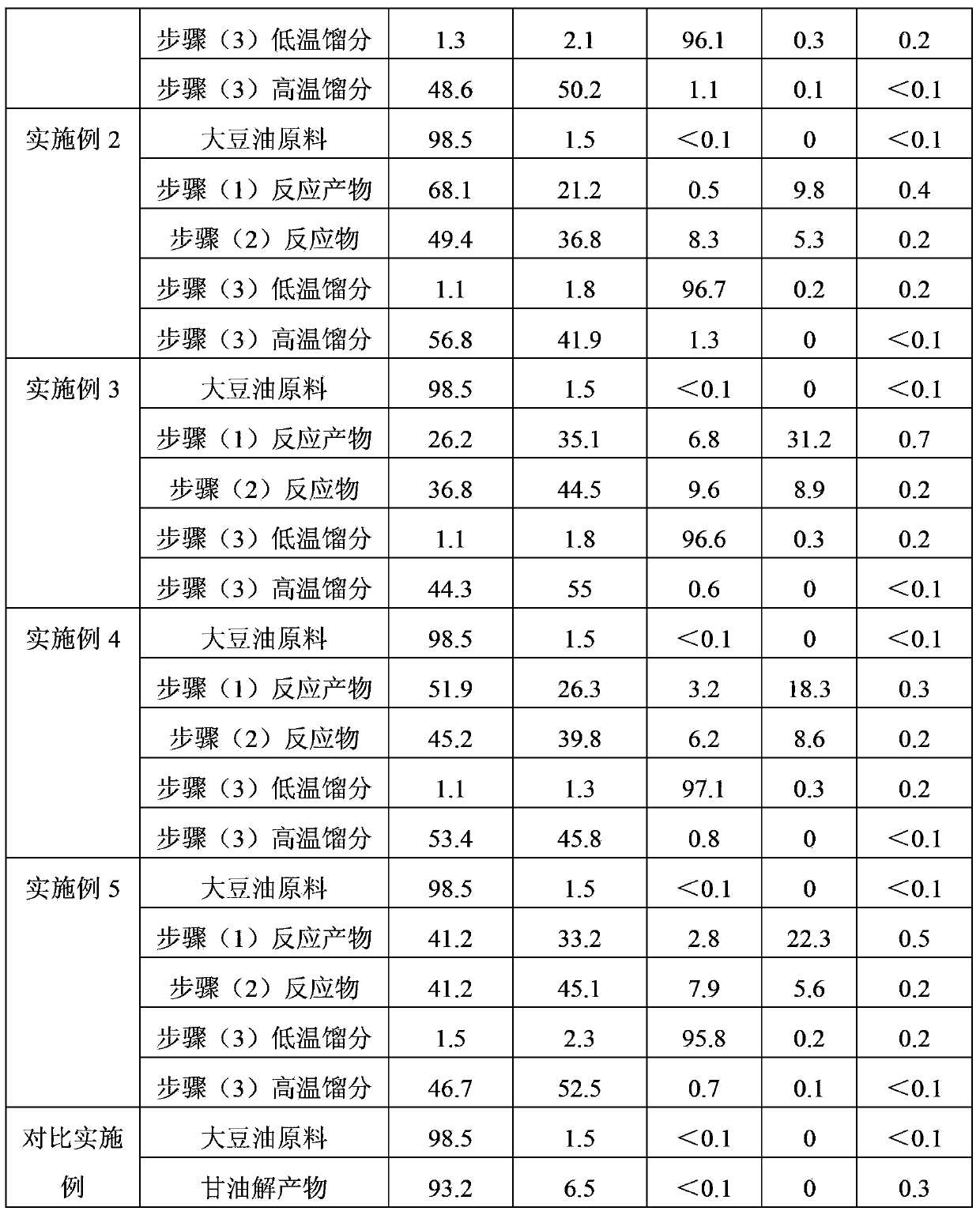

Embodiment 3

[0039] A method for enzymatically producing diglycerides by co-producing unsaturated monoglycerides, comprising the following steps:

[0040] Step (1), mix 5kg of soybean oil and 0.3kg of absolute ethanol, add 2g of immobilized lipase Novozyme 435 (provided by Novozymes, Denmark), stir and react at 35°C for 5 hours, the measured ethyl ester formation rate is 31.2%, vacuum removal Ethanol remains to obtain alcoholysis products.

[0041] In step (2), 3kg of alcoholysis product is loaded into such as figure 1 Add 0.45kg of glycerol to the raw material storage tank shown, and the material circulates through the packed bed enzyme reactor of immobilized lipase under the action of the pump. The reaction temperature is 60°C, and the immobilized lipase Novozyme 435 is used. It was 10g, first reacted under normal pressure for 3 hours, then the absolute pressure of the reaction was controlled to be 200pa, and the material was discharged after 12 hours of reaction, and its composition wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com