Aerospace-grade germ fiber solid beverage

A solid drink and germ technology, applied in dairy products, milk preparations, applications, etc., can solve the problems of single ingredients, unfavorable promotion, and inability to meet energy and nutrients, so as to achieve comprehensive nutrition and avoid drink layering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

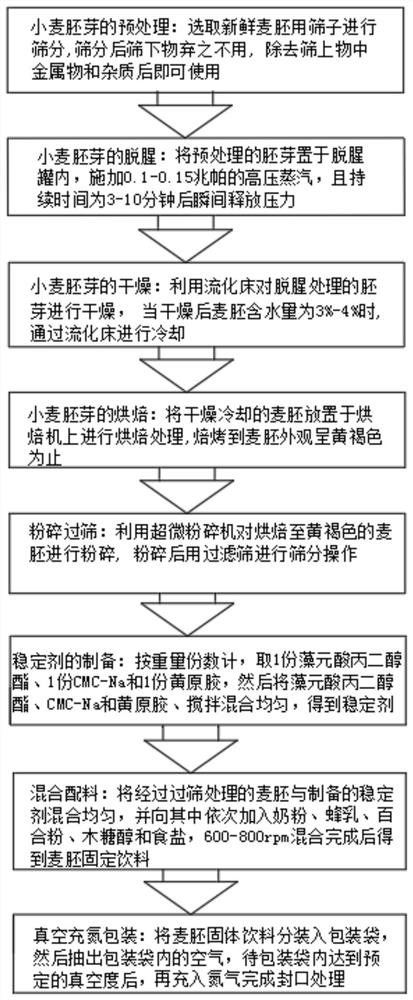

[0029] An aerospace-grade germ fiber solid drink, comprising the steps of:

[0030] Step 1. Pretreatment of wheat germ: Select fresh wheat germ and sieve it with a 30-mesh sieve. After sieving, the under-sieve is discarded, and the metal and impurities in the over-sieve are removed before use;

[0031] Step 2. Deodorization of wheat germ: put the pretreated germ in the deodorization tank, apply high-pressure steam of 0.1-0.15 MPa, and release the pressure instantly after the duration is 3-10 minutes;

[0032] Step 3. Drying of wheat germ: use a fluidized bed to dry the deodorized germ. The temperature of the hot air inlet of the fluidized bed is 115°C. to cool down;

[0033] Step 4. Baking of wheat germ: put the dried and cooled wheat germ on a roasting machine for roasting. The roasting temperature of the roasting machine is 160-170°C, and the thickness of the material layer of the roasting machine is not more than 1.5m. until the appearance of the embryo is yellowish brown...

Embodiment 2

[0039] An aerospace-grade germ fiber solid drink, comprising the steps of:

[0040] Step 1. Pretreatment of wheat germ: Select fresh wheat germ and sieve it with a 35-mesh sieve. After sieving, the undersieve is discarded, and the metal and impurities in the oversieve are removed before use;

[0041] Step 2. Deodorization of wheat germ: put the pretreated germ in the deodorization tank, apply high-pressure steam of 0.1-0.15 MPa, and release the pressure instantly after the duration is 3-10 minutes;

[0042] Step 3. Drying of wheat germ: use a fluidized bed to dry the deodorized germ. The temperature of the hot air inlet of the fluidized bed is 115°C. to cool down;

[0043] Step 4. Baking of wheat germ: put the dried and cooled wheat germ on a roasting machine for roasting. The roasting temperature of the roasting machine is 160-170°C, and the thickness of the material layer of the roasting machine is not more than 1.5m. until the appearance of the embryo is yellowish brown; ...

Embodiment 3

[0049] An aerospace-grade germ fiber solid drink, comprising the steps of:

[0050] Step 1. Pretreatment of wheat germ: Select fresh wheat germ and sieve it with a 40-mesh sieve. After sieving, the under-sieve is discarded, and the metal and impurities in the over-sieve are removed before use;

[0051] Step 2. Deodorization of wheat germ: put the pretreated germ in the deodorization tank, apply high-pressure steam of 0.1-0.15 MPa, and release the pressure instantly after the duration is 3-10 minutes;

[0052] Step 3. Drying of wheat germ: use a fluidized bed to dry the deodorized germ. The temperature of the hot air inlet of the fluidized bed is 115°C. to cool down;

[0053] Step 4. Baking of wheat germ: put the dried and cooled wheat germ on a roasting machine for roasting. The roasting temperature of the roasting machine is 160-170°C, and the thickness of the material layer of the roasting machine is not more than 1.5m. until the appearance of the embryo is yellowish brown; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com