Fully-degradable environment-friendly paper diaper

A fully degradable technology for diapers, applied in medical science, bandages, absorbent pads, etc., can solve the problems of little effect, environmental pollution, and high price of nano-silver, and achieve the goals of reducing processing costs, improving antibacterial ability, and increasing contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

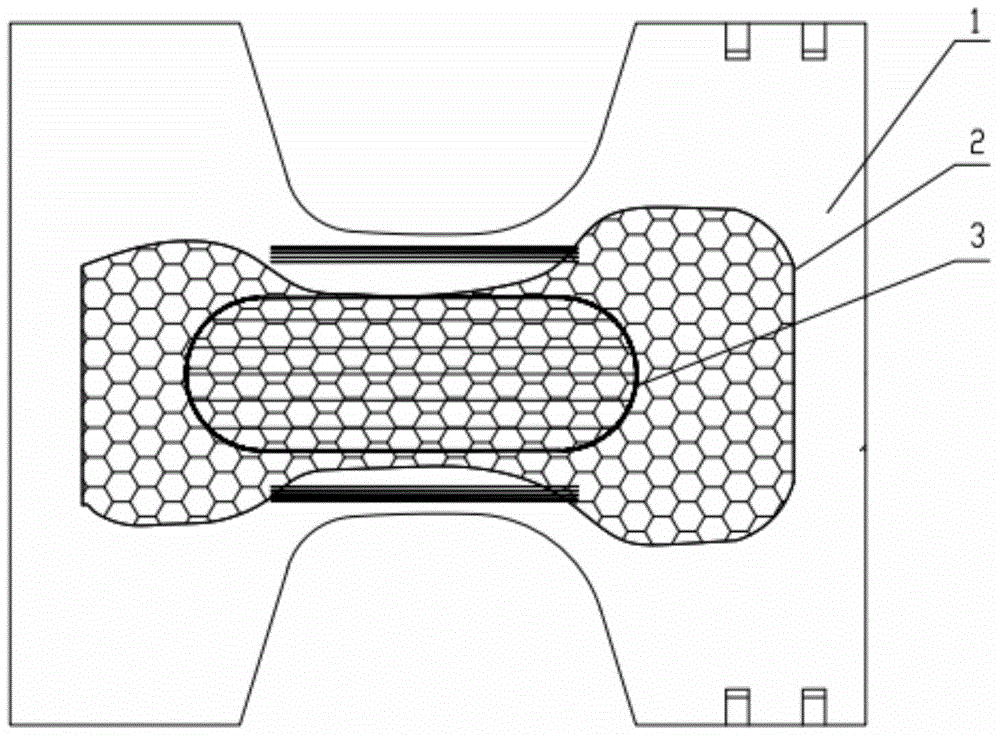

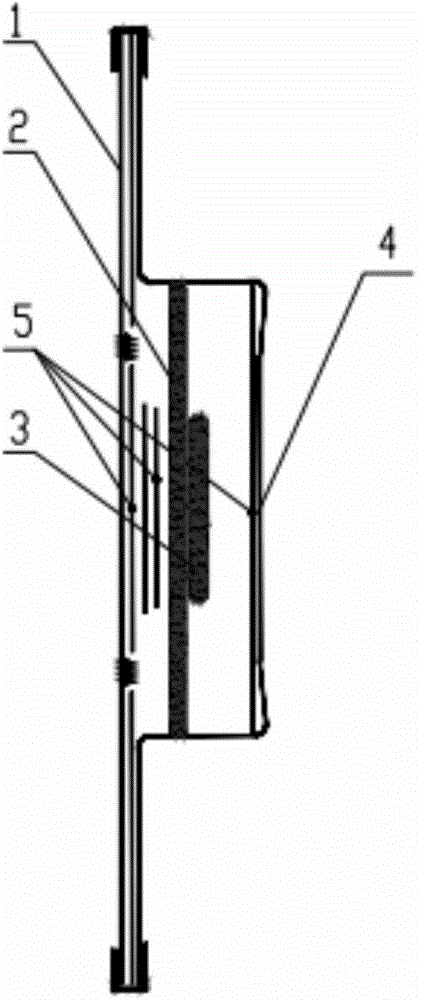

[0031] Such as figure 1 , figure 2 As shown, the antibacterial and deodorant paper diapers of the present invention include a blended base film 1 of PBAT and PLA and an absorber located in the middle of the base film 1, the absorber and the base film 1 are bonded by structural glue 5, and the base film 1 It is in the shape of "I", and the absorber includes a large cotton core 2, a small cotton core 3 and a natural plant fiber spunlace non-woven fabric 4 bonded with structural glue 5 in sequence. The large cotton core 2 is dumbbell-shaped, and the surface is provided with a diamond honeycomb The embossing structure is formed by dissolving the blend pulp of primary reed and bamboo, and polymer water-absorbing agent; the small cotton core 3 is elliptical, and the surface is provided with linear embossing. Treated sodium polyacrylate mixed with acid polymer water-absorbing agent. The dosage ratio of sodium polyacrylate and primary bamboo dissolving pulp in the small cotton core...

Embodiment 2-3

[0034] The structure of the antibacterial and deodorant paper diapers is the same as that of Example 1, except that 1g and 0.5g of ZEM enzymes are rotated and sprayed in the small cotton core.

[0035] Because the absorbent body is made of a mixture of original dissolving pulp and polymer, it has super liquid absorption; the small cotton core of the absorbent body is added with sodium polyacrylate after bridging treatment, which has a certain odor suppression function and can also improve liquid absorption. The absorption rate; the added ZEM enzyme can quickly absorb and decompose the odorous substances in the body fluid, and at the same time protect the skin; the non-woven fabric layer is made of spunlace non-woven fabric, which further improves the antibacterial ability; Wired embossing is conducive to the radial diffusion of liquid and improves the diffusion efficiency; the surface of the large cotton core is provided with diamond honeycomb embossing, which increases the con...

experiment example 1

[0037] Prepare a urine reagent for use. The content of each component in the reagent is 35.0 g of urea, 16.5 g of sodium chloride, 3.0 ml of phosphoric acid, 2.0 ml of sulfuric acid, 1.2 g of calcium phosphate, and 0.65 ml of ammonia water.

[0038] In a glass box with an operating port, draw 100ml of the prepared urine reagent with a disposable straw and inject it into 10 antibacterial diapers of Example 2 and the commercially available antibacterial and deodorant diapers with built-in bamboo charcoal strips for 1 minute, 5 Minutes, 10 minutes, 30 minutes, and 1 hour to observe the absorption, odor, surface color, and corrosion.

[0039] test results:

[0040] For the 10 diapers of Example 2, all the urine reagent in the straw was squeezed out within 5 seconds, and there was no residual floating liquid on the surface of the diapers. After 1 minute, the surface of the diaper is refreshing and semi-dry; after 5 minutes, the surface humidity of the diaper is further reduced.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com