Polymer electrolyte membrane and preparation method thereof, and polymer cell

A technology of electrolyte membrane and polymer, which is applied in the direction of secondary batteries, battery components, circuits, etc., can solve the problems of residual impurities, difficulty in realization, and unstable structure of polymer electrolyte membranes, and achieve excellent mechanical strength and self-sufficiency. Small discharge, good for storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

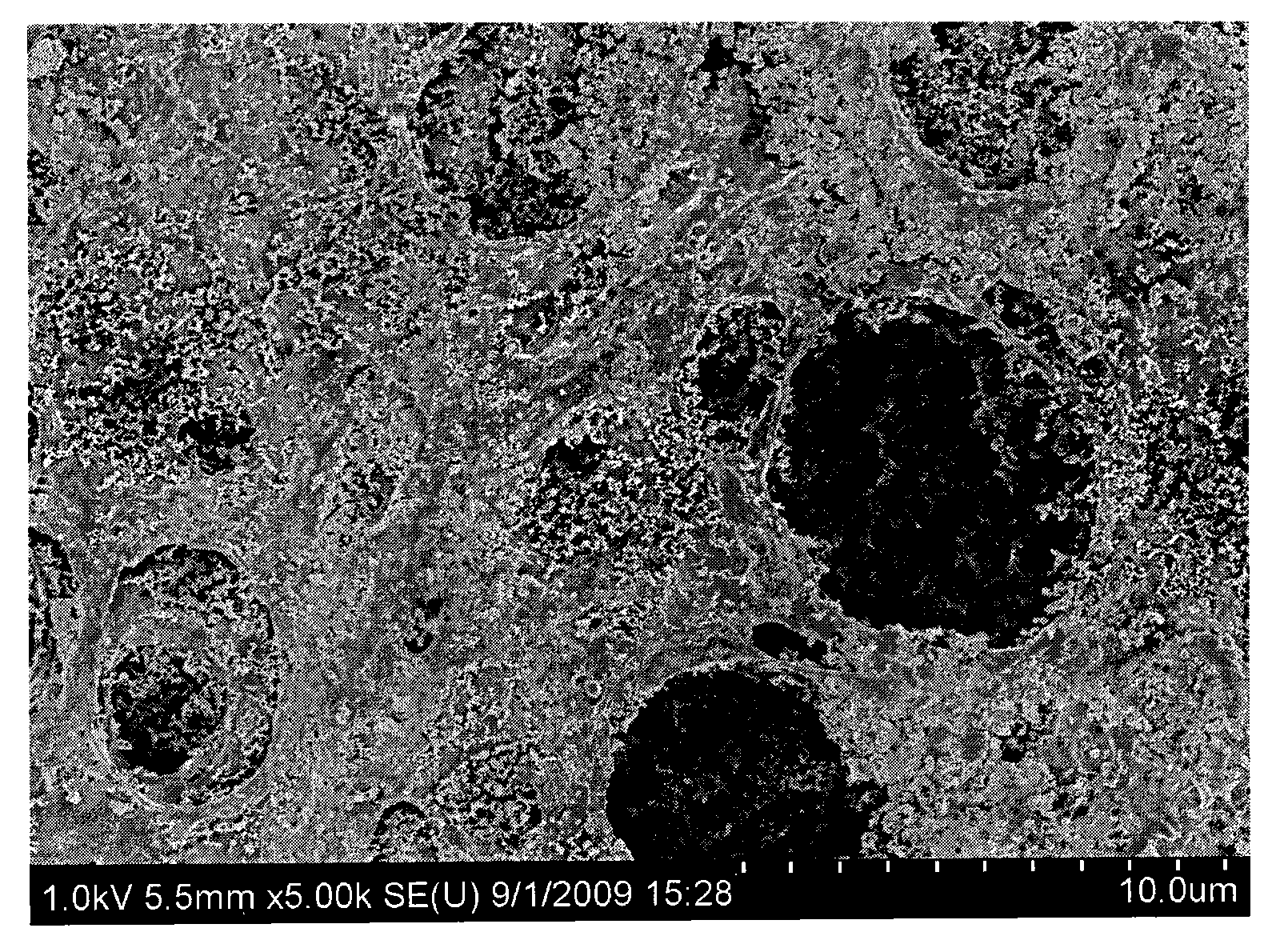

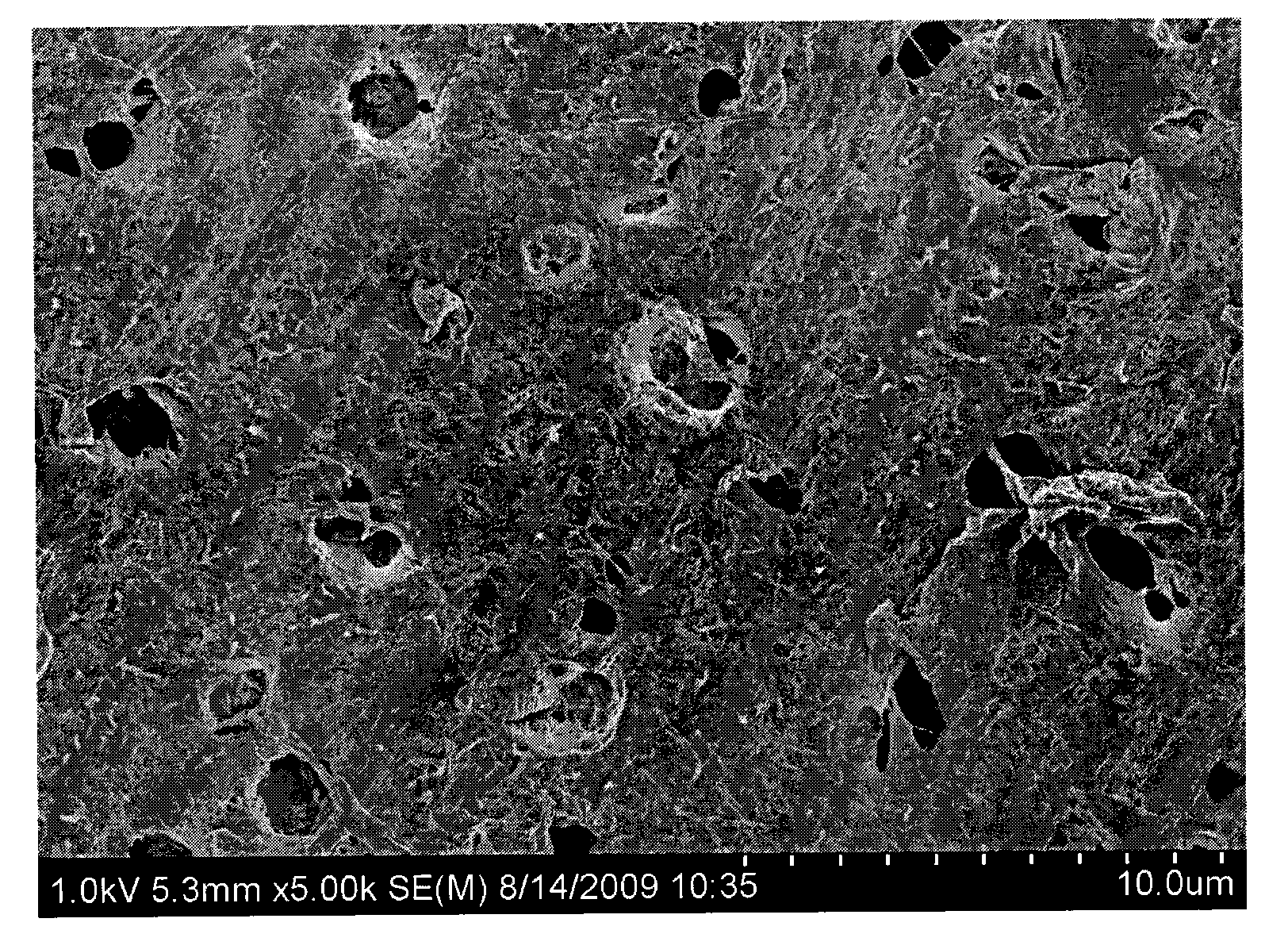

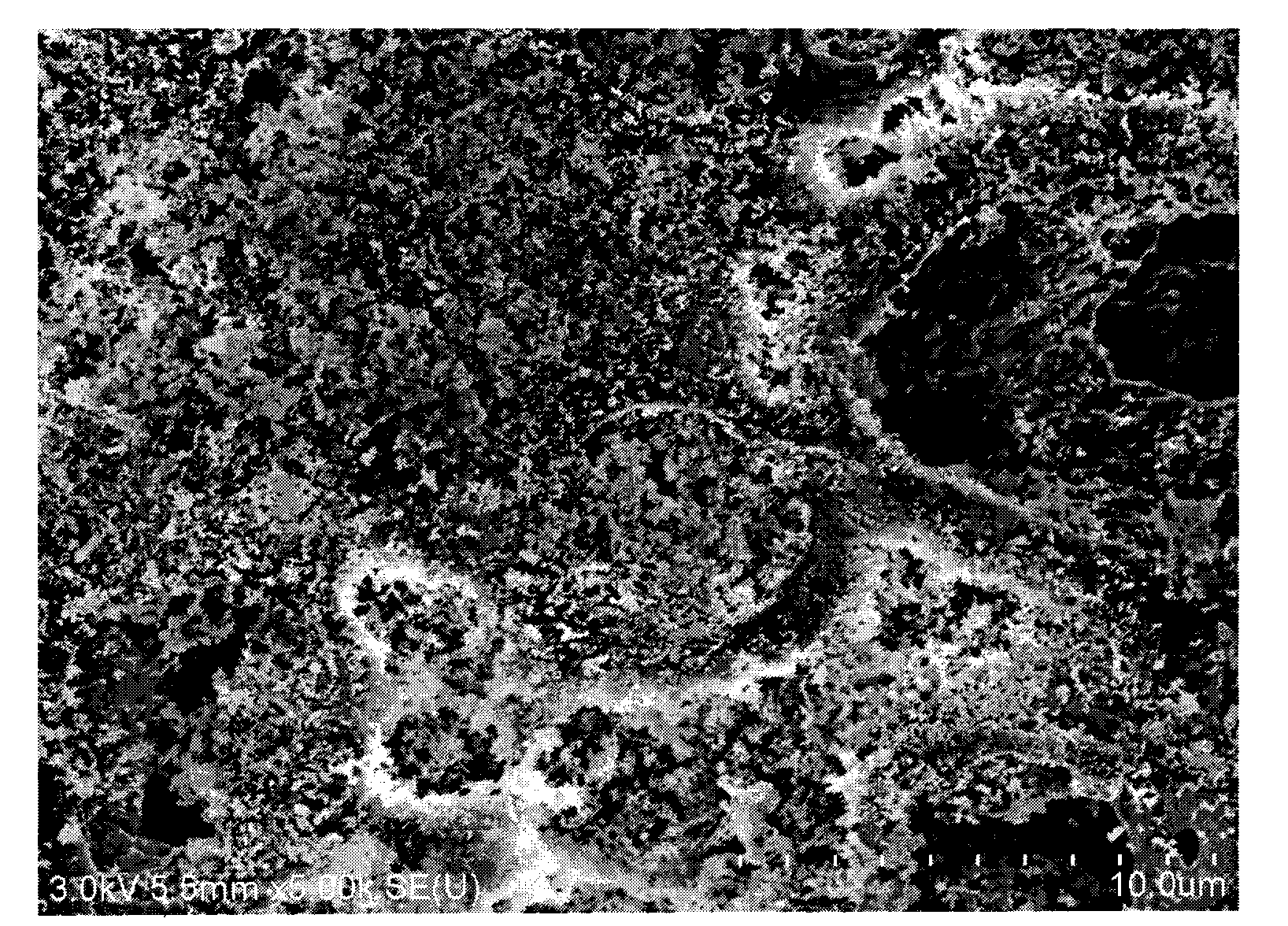

Image

Examples

Embodiment 1

[0037] Preparation of positive electrode

[0038] Add 100 parts by weight of LiCoO2, 3.5 parts by weight of binder polyvinylidene fluoride (PVDF), 4.5 parts by weight of conductive agent acetylene black into 70 parts by weight of N-methylpyrrolidone (NMP), and then fully mix in a vacuum mixer Stir to form a homogeneous cathode slurry. The resulting slurry was evenly coated on a 20 μm aluminum foil current collector by a coating machine, dried at 130° C., cut and rolled to obtain a positive electrode sheet with a thickness of about 125 μm.

[0039] Preparation of negative electrode

[0040] 100 parts by weight of negative electrode active material graphite, 1.0 parts by weight of conductive agent carbon black, 3.5 parts by weight of binder styrene-butadiene rubber (SBR) emulsion and 1.0 parts by weight of carboxymethyl cellulose (CMC), are added to 120 parts by weight of deionized , and then stirred in a vacuum mixer to form a stable and uniform negative electrode slurry. Th...

Embodiment 2

[0051] The positive electrode, negative electrode, electrolyte, polymer electrolyte membrane, and battery were prepared in the same manner as in Example 1, except that the preparation of the polymer electrolyte membrane was as follows:

[0052] 20wt% polyacrylonitrile (PAN) (molecular weight: 15w-19w; melting point: 154°C), 10wt% tetraethyl orthosilicate, 55wt% acetone, plasticizer 15wt% toluene, and a small amount of LiOH , at 40°C, stir evenly with a magnetic stirrer, and prepare a polymer solution (pH=7.5).

[0053] The above-mentioned polymer solution was dipped and coated on the surface of the separator, and the acetone and toluene were removed by ventilating and baking, so that a polymer electrolyte membrane with a thickness of 5 μm was formed on the surface of the separator.

[0054] The porosity, specific surface area and puncture strength of the polymer electrolyte membrane prepared above were measured by the same test method as above, and the test results are shown i...

Embodiment 3

[0056] The positive electrode, negative electrode, electrolyte, polymer electrolyte membrane, and battery were prepared in the same manner as in Example 1, except that the preparation of the polymer electrolyte membrane was as follows:

[0057] 20wt% polyethylene oxide (molecular weight 13w-17w; melting point 156°C), 10wt% tetraethyl orthosilicate, 55wt% acetone, plasticizer 15wt% toluene, and a small amount of LiOH, Stir evenly with a magnetic stirrer at 40°C to prepare a polymer solution (pH=7.5).

[0058] The above-mentioned polymer solution was dipped and coated on the surface of the separator, and the acetone and toluene were removed by ventilating and baking, so that a polymer electrolyte membrane with a thickness of 5 μm was formed on the surface of the separator.

[0059] The porosity, specific surface area and puncture strength of the polymer electrolyte membrane prepared above were measured by the same test method as above, and the test results are shown in Table 1. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com