A light-to-heat conversion material and its preparation method

A technology of photothermal and metal ions, which is applied in the direction of wave energy or particle radiation treatment materials, pharmaceutical formulations, medical preparations containing active ingredients, etc., can solve the problems of poor cell compatibility, low near-infrared photothermal efficiency, and high cost. The preparation method is simple, the effect of accelerating cell proliferation and promoting tissue regeneration is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A. Dissolve chitosan and silk fibroin in water to form a 30mg / mL mixture of chitosan / silk fibroin (CS / SF) (the mass ratio of chitosan / silk fibroin is 2:1) .

[0040] B. Disperse TA evenly in the chitosan / silk fibroin mixture obtained in step A to make the concentration 0.3mg / mL, and then add Fe dropwise to the mixture 3+ solution and make the concentration of iron ions in the mixed solution 0.15mg / mL.

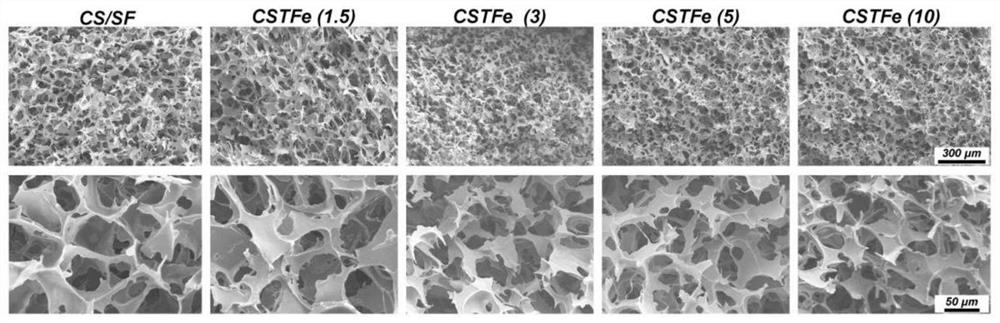

[0041]C. Put the mixed solution prepared in step B into a mold, transfer it to a low-temperature environment to condense it into ice, and finally dry it by freeze-drying technology to form an antibacterial skin dressing with near-infrared light and heat. The morphology of the prepared dressing was characterized, and the results were as follows: figure 1 As shown, it can be seen that the resulting dressing has a rich porous structure. CSTFe(1.5) refers to the scaffold structure composed of chitosan, silk protein, tannic acid and iron ions, in which TA, Fe 3+ The conte...

Embodiment 2

[0052] A. Dissolve hyaluronic acid and collagen in water to prepare a 30 mg / mL hyaluronic acid / collagen mixture (the mass ratio of hyaluronic acid / collagen is 1:1).

[0053] B. Evenly disperse TA into the hyaluronic acid / collagen mixture prepared in step A to make the concentration 0.2mg / mL, and then add V to the mixture dropwise. 3+ solution and make the concentration of vanadium ions in the mixed solution 0.1mg / mL.

[0054] C. Put the mixed solution prepared in step B into a mold, transfer it to a low-temperature environment to condense it into ice, and finally dry it by freeze-drying technology to form an antibacterial skin dressing with near-infrared light and heat.

Embodiment 3

[0056] A. Sodium alginate and albumin were dissolved in water to form a 40 mg / mL sodium alginate / albumin mixture (the mass ratio of sodium alginate / albumin was 3:1).

[0057] B. Evenly disperse TA into the sodium alginate / albumin mixture prepared in step A to make the concentration 1mg / mL, and then add Fe dropwise to the mixture 3+ And the concentration of iron ions in the mixed solution was 0.5 mg / mL.

[0058] C. Put the mixed solution prepared in step B into a mold, transfer it to a low-temperature environment to condense it into ice, and finally dry it by freeze-drying technology to form an antibacterial skin dressing with near-infrared light and heat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com