Vacuum ceramic thermal baffle welded by metal solders and manufacturing method of thermal baffle

A technology of vacuum ceramics and heat insulation boards, applied in the direction of metal layered products, ceramic layered products, chemical instruments and methods, etc., can solve the problems of secondary damage, softening, poor thermal insulation performance, etc., and achieve high compressive strength and Bending strength, better heat and sound insulation performance, shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

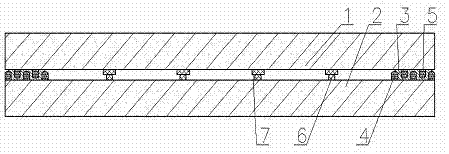

[0072] Example 1: see figure 1, the two heat shields are commercially available ceramic heat shields, one of which is a low-radiation heat shield with an aluminum film, and there are edge bands on the two heat shields. The production method is as follows: first After the ceramic heat insulation board is cleaned and dried, use printing technology to print the low-temperature glass powder paste on the two heat insulation boards to make edge banding frames. edge banding frame, the size of the edge banding frame of the upper insulation board is between the two edge banding frames of the lower insulation board, after the upper and lower insulation boards are combined, the edge banding frame of the upper insulation board can be embedded Fit between the two edge banding frames of the lower heat shield, each edge banding frame has a width of 1.5mm and a height of 0.7mm; secondly, send the two heat shields into the high temperature furnace respectively, and in the high temperature furn...

Embodiment 2

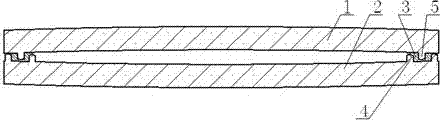

[0075] Example 2: see figure 2 , The vacuum heat insulation board is composed of an upper ceramic heat insulation board and a lower ceramic heat insulation board, and the two heat insulation boards are surrounded by edge sealing strips. The production method is as follows: firstly, according to the shape and size of the vacuum insulation panel to be produced, the metal stamping dies for the upper and lower insulation panels are respectively prepared. There are grooves around the mold to form the edge banding frame on the insulation panel. There is one edge banding frame on the upper heat shield, and two edge banding frames on the lower heat shield. The size of the edge banding frame on the upper heat After the hot plates are combined, the edge banding frame of the upper heat insulating plate can be fitted between the two edge banding bars of the lower heat insulating plate; secondly, the raw materials for making the ceramic heat insulating plate are put into the mold, and pre...

Embodiment 3

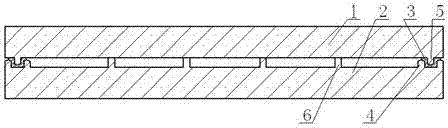

[0077] Embodiment 3: see image 3 , The vacuum insulation panel is composed of an upper ceramic insulation panel and a lower ceramic insulation panel, one of which is a low-emissivity ceramic insulation panel coated with aluminum film, and there are edge banding strips around the two insulation panels. The production method is as follows: First, according to the shape and size of the vacuum insulation panel to be produced, metal stamping dies for the upper and lower insulation panels are prepared respectively. The surface of the mold has grooves to form the edge banding frame and support on the insulation panel. The upper insulation board has one edge-seal frame, the lower insulation board has two edge-seal frames, and the size of the upper insulation board’s edge-seal frame is between the two edge-seal frames of the lower insulation board , after the upper and lower heat insulation boards are combined, the edge sealing frame of the upper heat insulation board can be fitted be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com