Fully-balanced type double-row radial plunger pump

A balanced, radial column technology, applied in the direction of pumps, multi-cylinder pumps, liquid displacement machinery, etc., can solve the problems of bulky mass, reduced stability, complicated maintenance, etc., to improve performance, improve output performance, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

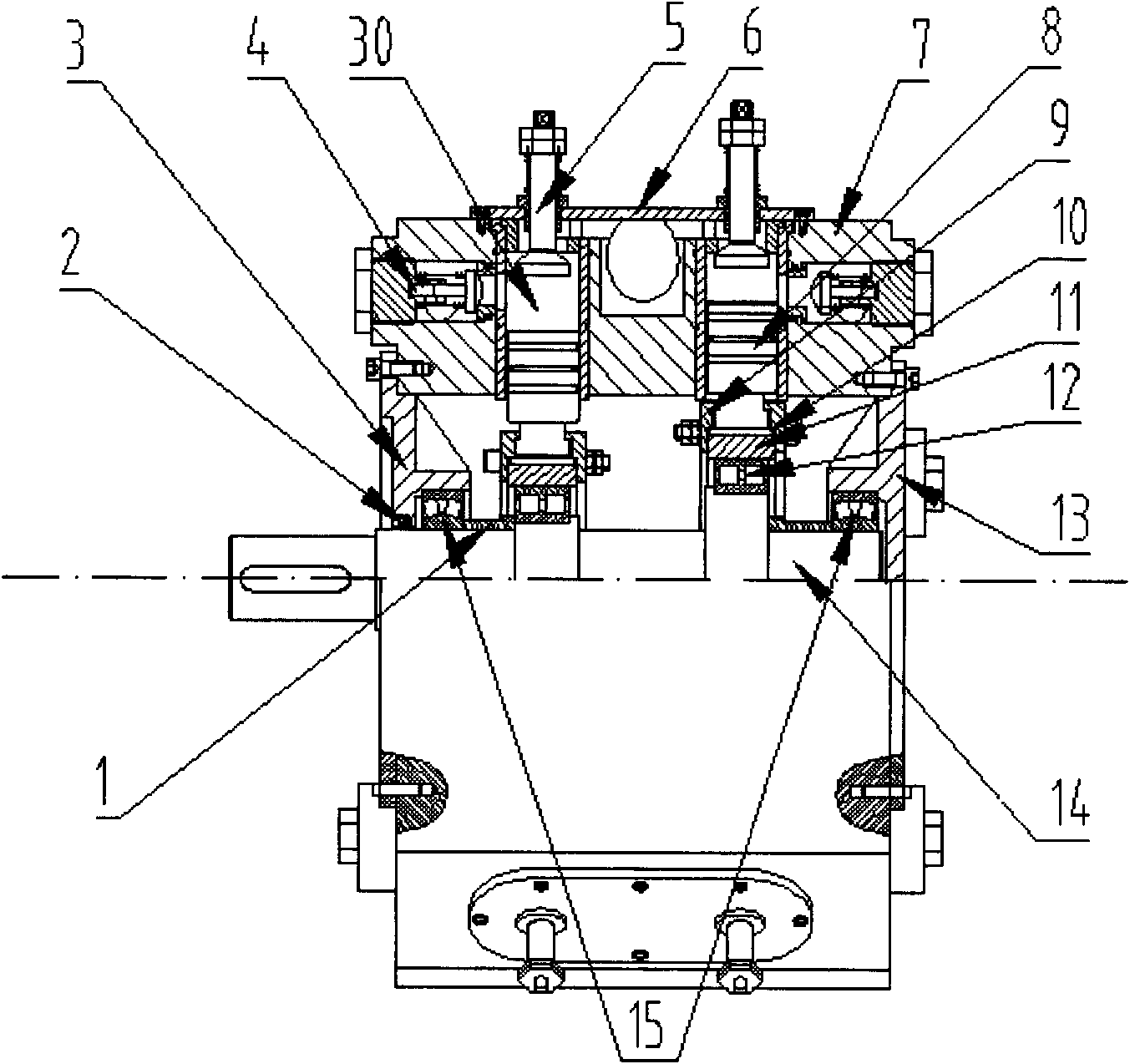

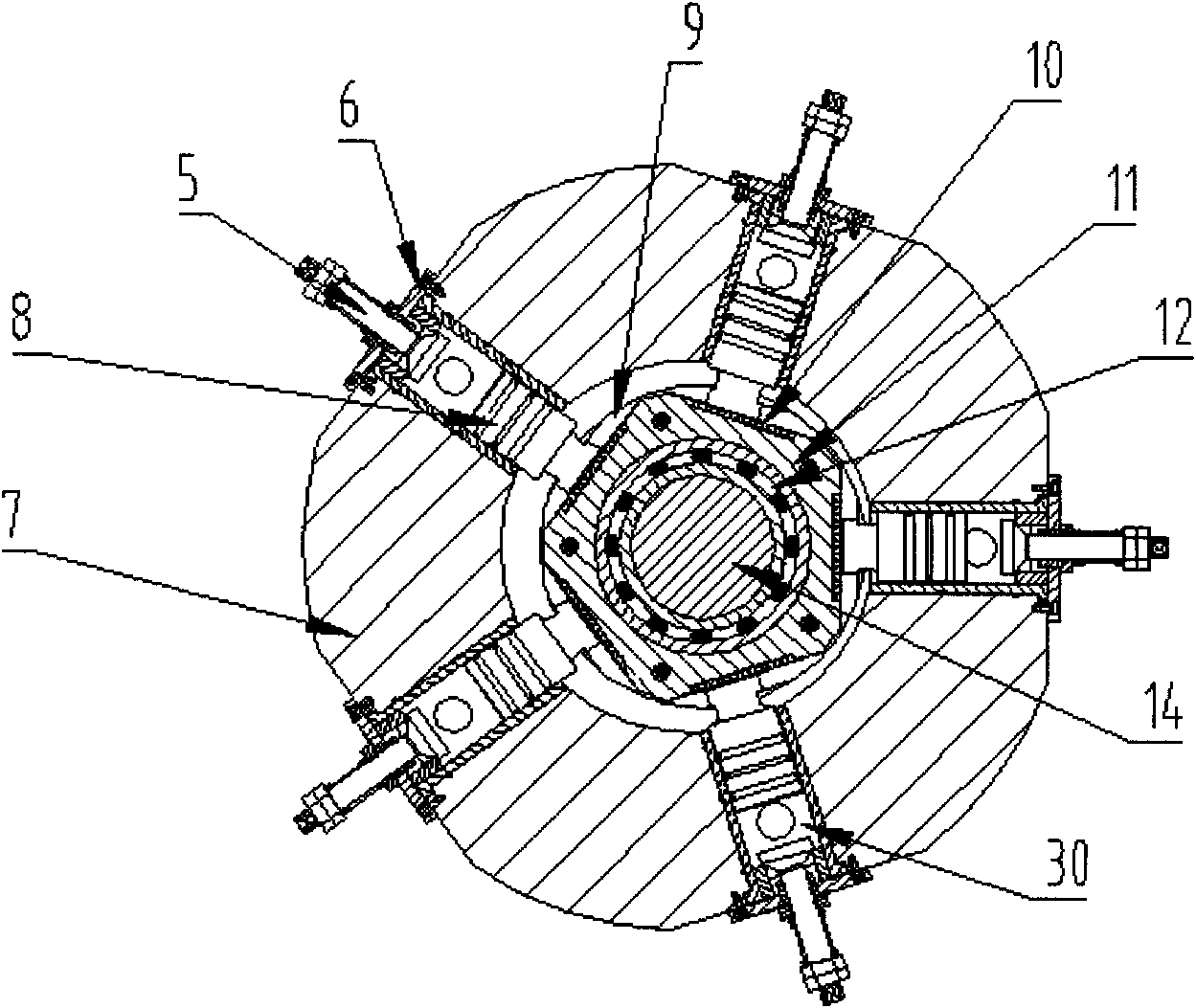

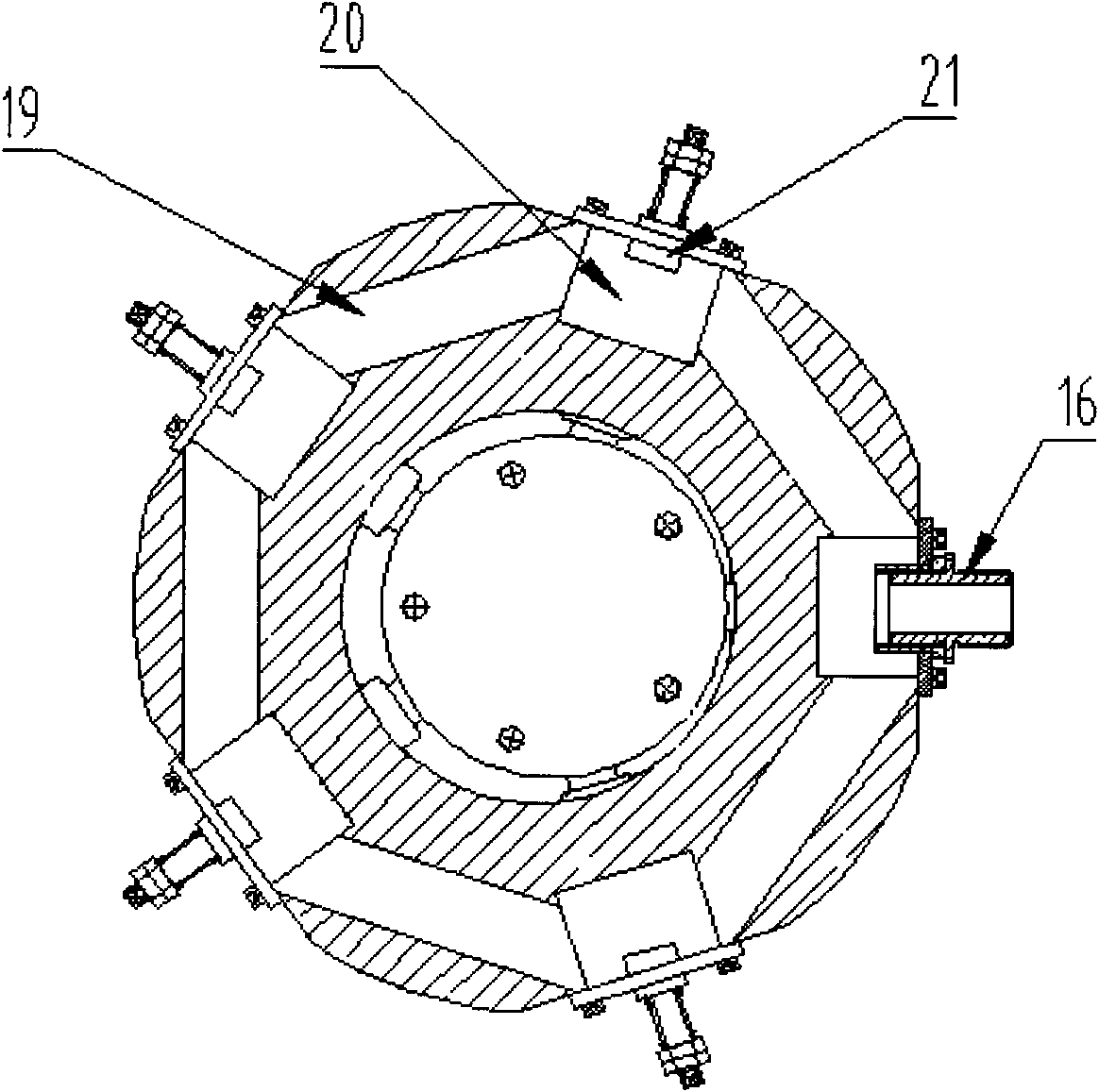

[0019] refer to figure 1 , a fully balanced double-row radial piston pump, including a pump body 7, a front end cover 3 on the left side of the pump body 7, and a rolling bearing 15 pressed inside the front end cover 3, the rolling bearing 15 is installed on the eccentric shaft 14, and the positioning sleeve 1. It is located inside the rolling bearing and close to the side of the eccentric part of the eccentric shaft 14. A rolling bearing 12 is installed outside the eccentric part of the eccentric shaft 14. The rolling bearing 12 is connected with the uniformly distributed plungers 8 through a coupling mechanism. The plungers 8 are arranged in double rows. There is a suction system in the middle of the row of plungers, and a discharge system on the other side of each row of plungers. The plunger 8 is located in the plunger chamber 30. The pump body 7 is equipped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com