Intelligent separate control type hydraulic synchronous jacking system and method for replacing bridge support through same

A hydraulic synchronous jacking and hydraulic system technology, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as unsynchronized jacking, potential safety hazards, uneven jack force, etc., to reduce leakage, Solve the problem of internal leakage and the effect of not easy to generate heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

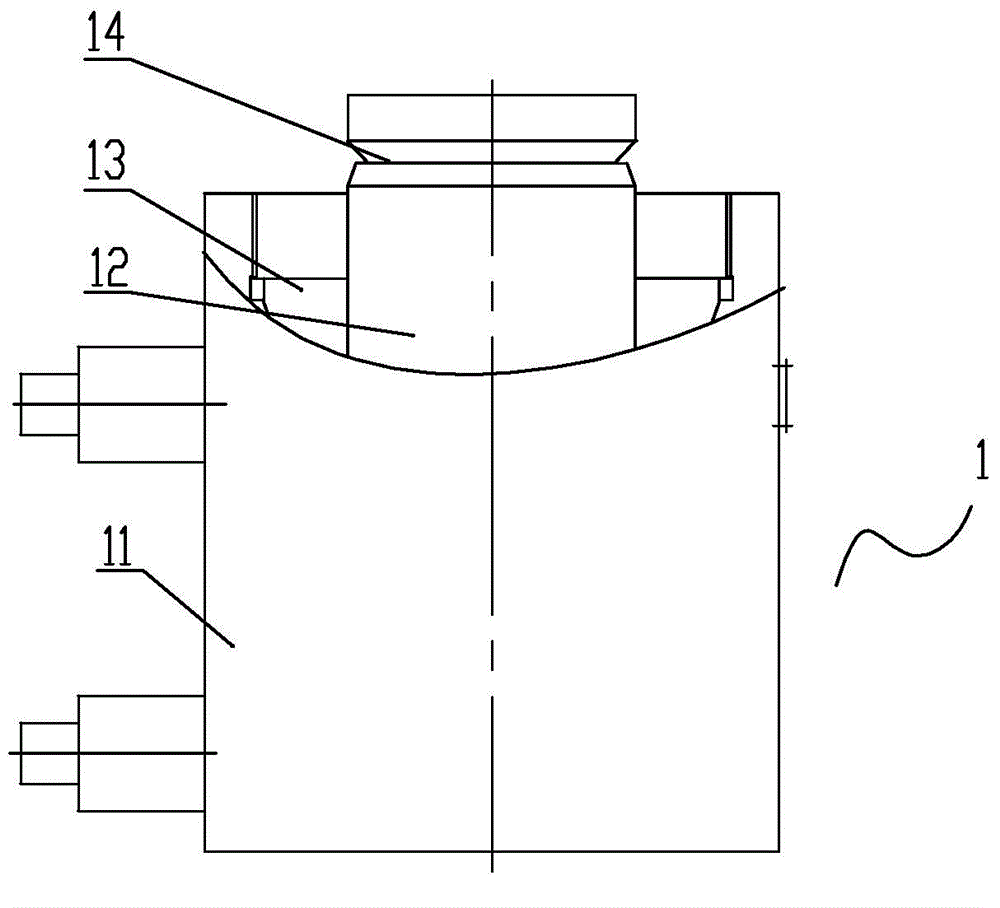

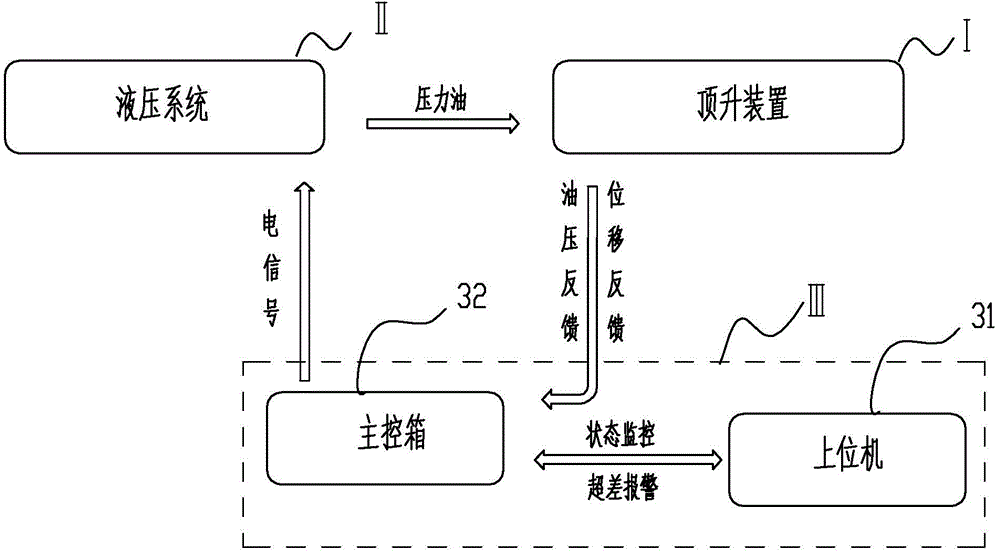

[0070] An intelligent split-control hydraulic synchronous jacking system, including jacking device I, hydraulic system II and control system III;

[0071] The jacking device I described above is the actuator of the synchronous jacking system, which relies on the synchronous extension cylinder of the jack to lift the upper structure of the bridge, and after replacing the bridge support, relies on the jack to lower the beam synchronously;

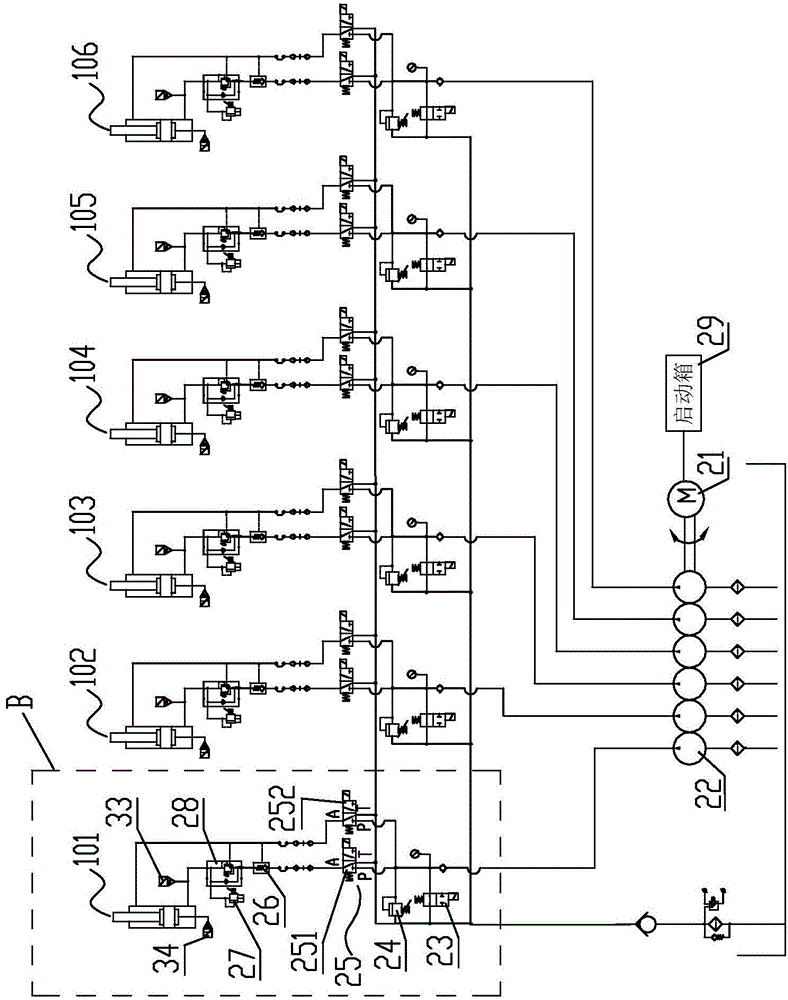

[0072] The hydraulic system II is the power source of the jacking system, and performs relevant actions according to the instructions of the control system to drive the extension and retraction cylinders of the jack;

[0073] Control system Ⅲ is the brain of the jacking system, commanding the system to operate according to the prescribed steps; at the same time monitoring the movement posture of the components in real time, once the system is out of tolerance, the system will immediately alarm and stop to ensure the safety of the components; ...

Embodiment 2

[0089] A method for replacing bridge supports. The method is to use the intelligent split-control hydraulic synchronous jacking system composed of jacking device I, hydraulic system II and control system III described in Embodiment 1 of the present invention for bridge support replacement. The method for replacing the bridge support adopts the jacking device I as the actuator of the synchronous jacking system, which relies on the synchronous extension cylinder of the jack to lift the upper structure of the bridge, and after replacing the bridge support, relies on the jack to lower the beam synchronously; The hydraulic system II is used as the power source of the jacking system, and relevant actions are executed according to the instructions of the control system to drive the extension and retraction cylinders of the jack; the control system III directs the system to act according to the prescribed steps; at the same time, it monitors the movement posture of the components in rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com