Actuator for a controlled coolant pump

A technology of cooling medium and actuator, applied in the direction of engine cooling, pump, pump device, etc., can solve the problem of delaying the rapid heating of the internal combustion engine, and achieve the effect of reducing the reliable function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

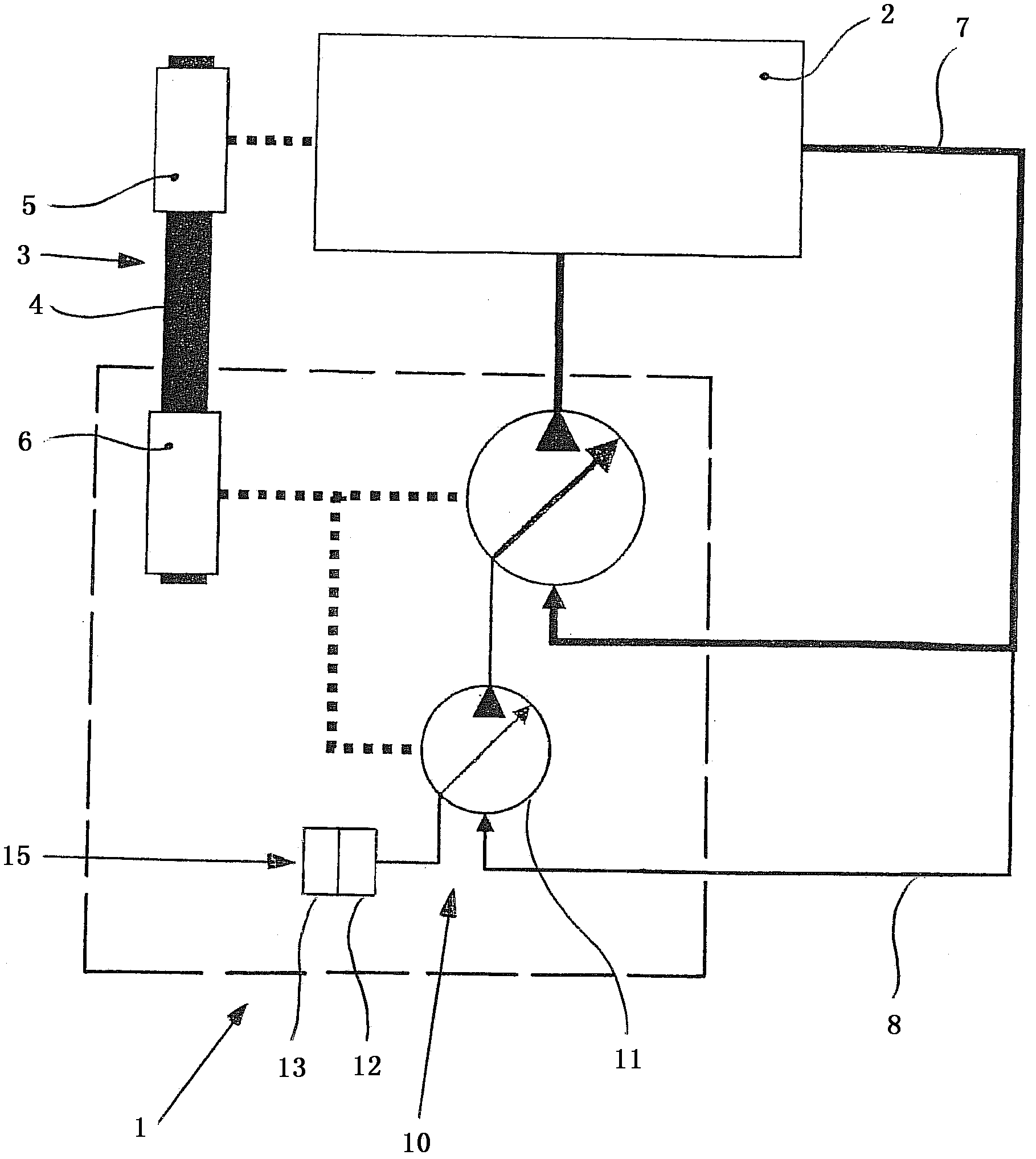

[0019] figure 1 All components of the regulated coolant pump 1 according to the invention are shown schematically. Coolant pump 1 , which is used specifically for cooling internal combustion engine 2 , is driven via traction drive 3 . The traction mechanism 4 of the traction drive 3 embodied as a belt drive connects a first belt pulley 5 , which is connected to a crankshaft (not shown) of the internal combustion engine 2 , to a second pulley 6 assigned to the coolant pump 1 . . The displacement or volume flow of the coolant pump 1 connected to the cooling circuit 7 can be adjusted or regulated by means of a hydraulically acting actuator 10 associated with the hydraulic circuit 8 and integrated in the coolant pump 1 . The structure of the actuator 10 comprises an eccentrically adjustable radial piston pump 11 cooperating with an actuating unit 15 comprising a linear free wheel 12 and a controllable adjustment element 13 .

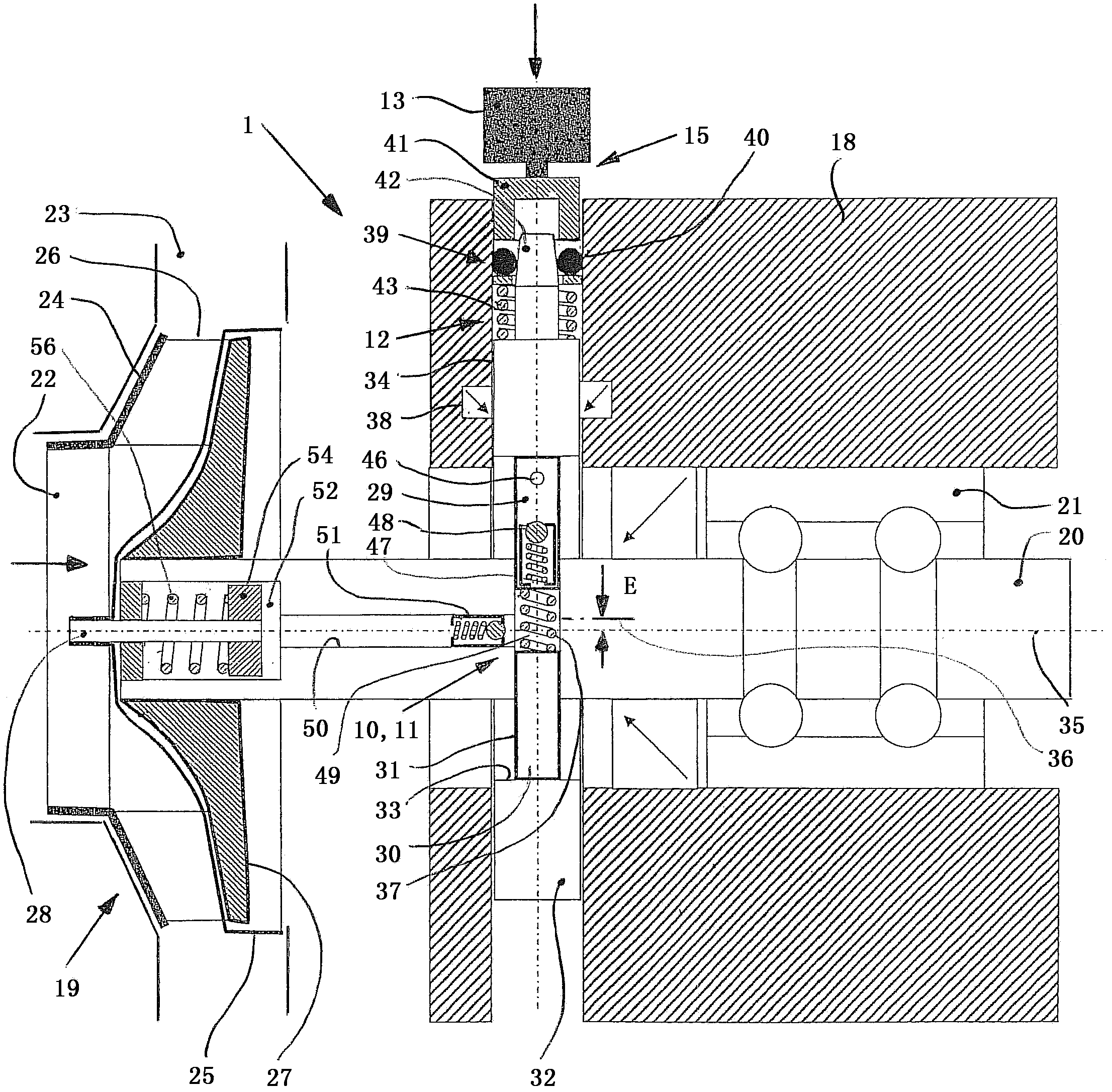

[0020] figure 2 The adjustable coolant pump 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com