Electric control hydraulic driving system for industrial vehicle

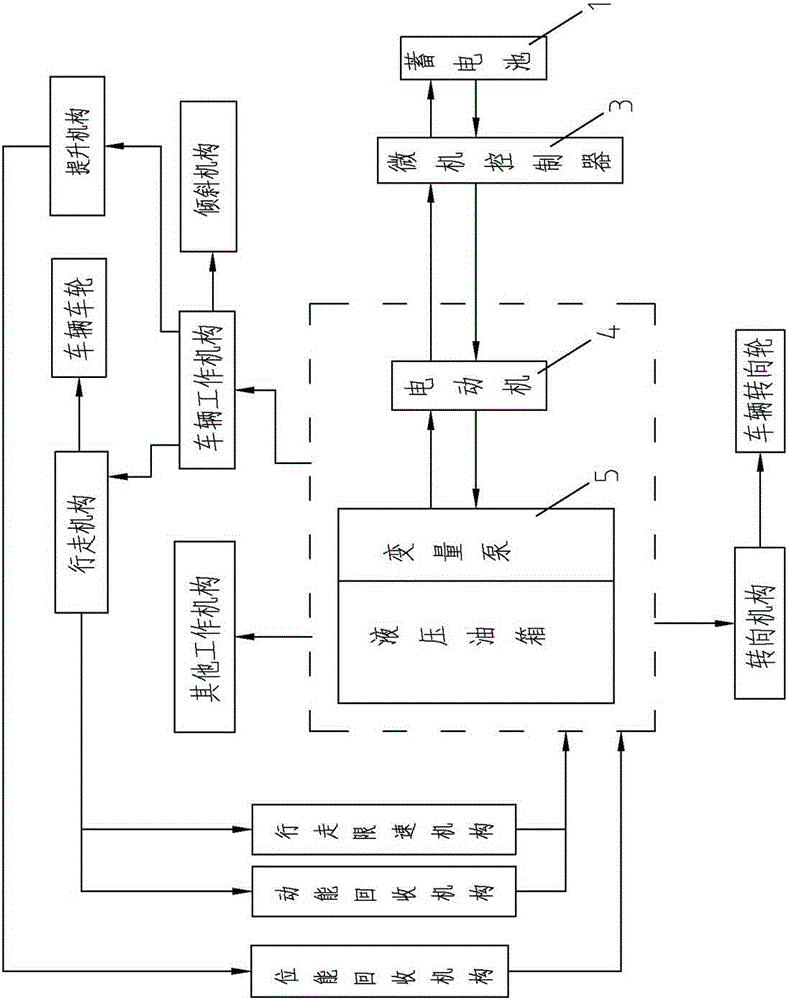

An electronically controlled hydraulic and drive system technology, applied in electric brake systems, fluid pressure actuation system components, control/regulation systems, etc., can solve problems such as component damage, increased cost and energy consumption, and affect loading and unloading efficiency. Achieve the effect of realizing kinetic energy recovery and potential energy recovery, improving discharge capacity efficiency, and avoiding loss of throttling and speed regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

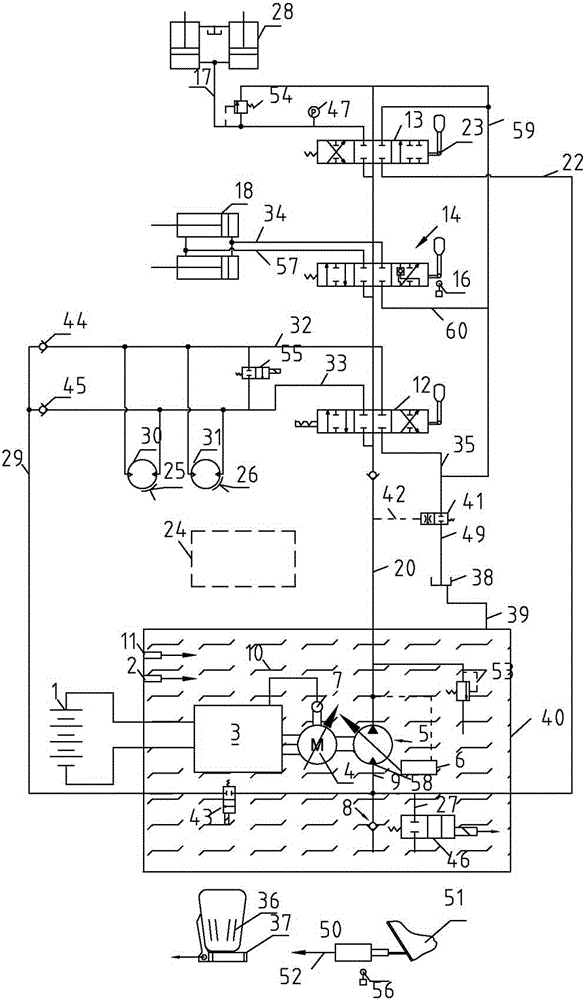

[0050] refer to figure 2 The hydraulic oil circuit diagram, specifically explaining the composition of each mechanism of the electronically controlled hydraulic drive system and how to realize the described functions.

[0051] The hydraulic oil tank is a multi-stage combined hydraulic oil tank, and the multi-stage combined hydraulic oil tank includes a lower oil tank 40, and an oil temperature sensor 2, a microcomputer controller 3, an electric motor 4, a variable displacement pump 5, and a speed sensor 7 are installed in the lower oil tank 40 , first check valve 8, hydraulic oil 10, liquid level sensor 11, kinetic energy regeneration solenoid valve 43, potential energy regeneration solenoid valve 46; motor 4 is coaxially connected with variable displacement pump 5; liquid level sensor 11 and oil temperature sensor 2 output The information is input to the microcomputer controller 3, and when the microcomputer controller 3 detects that the liquid level of the hydraulic oil 10 ...

Embodiment 2

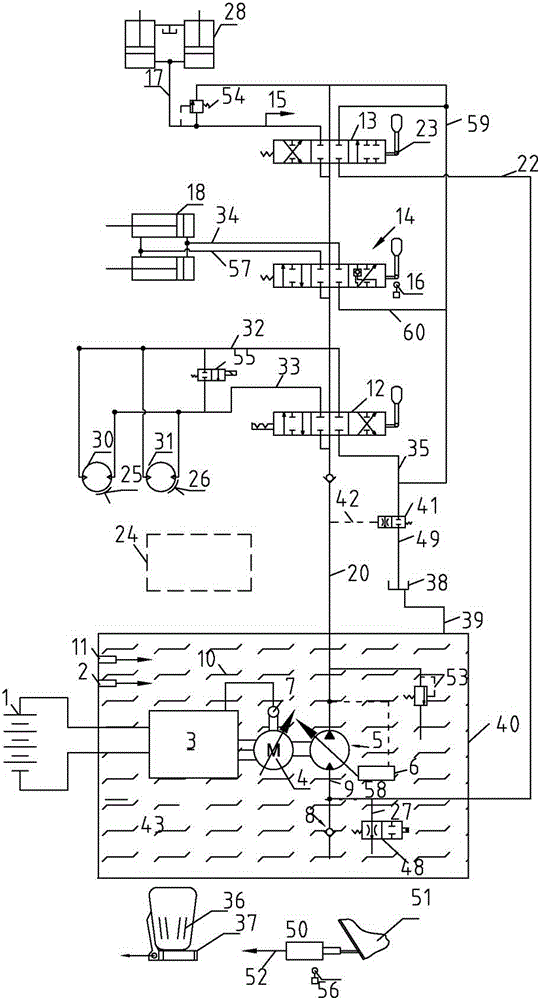

[0078] image 3 and figure 2 In comparison, the potential energy recovery mechanism is different, and other mechanisms are the same; specifically, the potential energy regeneration hydraulic valve 48 is used to replace the potential energy regeneration solenoid valve 46, and the oil circuit 15 is used to replace the pressure sensor 47 accordingly. For brevity, image 3 The kinetic energy recovery mechanism is omitted.

[0079] When the lift reversing valve 13 handle is switched to downshift, if the lift cylinder 28 is heavy-duty, the load hydraulic oil in the lift cylinder 28 pushes the potential energy regeneration hydraulic valve 48 through the oil circuit 15 to be in a closed circuit state, and the lift cylinder 28 The load hydraulic oil enters the oil inlet 58 of the variable pump 5 through the oil circuit 17, the lift reversing valve 13, and the oil circuit 22; due to the action of the first check valve 8, the variable variable pump 5 becomes a hydraulic motor at this ...

Embodiment 3

[0082] Figure 4 and image 3 Compared with that, a priority valve 19 is added, and other mechanisms are the same. For brevity, Figure 4 The kinetic energy recovery mechanism is omitted.

[0083] When the accelerator pedal 36 is stepped on, the accelerator sensor 37 sends an instruction to the microcomputer controller 3, and the motor 4 drives the variable pump 5 to output the hydraulic oil through the pipeline 20, and the hydraulic oil is delivered to the priority valve 19, and the output pipeline of the priority valve 19 is divided into two roads, One way is connected to the steering gear 24 (the effect of the priority valve 19 is to ensure the oil consumption of the steering gear 24), and the other way is connected to the travel reversing valve 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com