Radial piston rolling ball type end face valve low-speed high-torque hydraulic motor

A rolling ball, end face technology, applied in the motor field, can solve the problems of inconvenient installation, space limitation, application field and scope restriction, etc., and achieve the effect of stable work, good contact and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

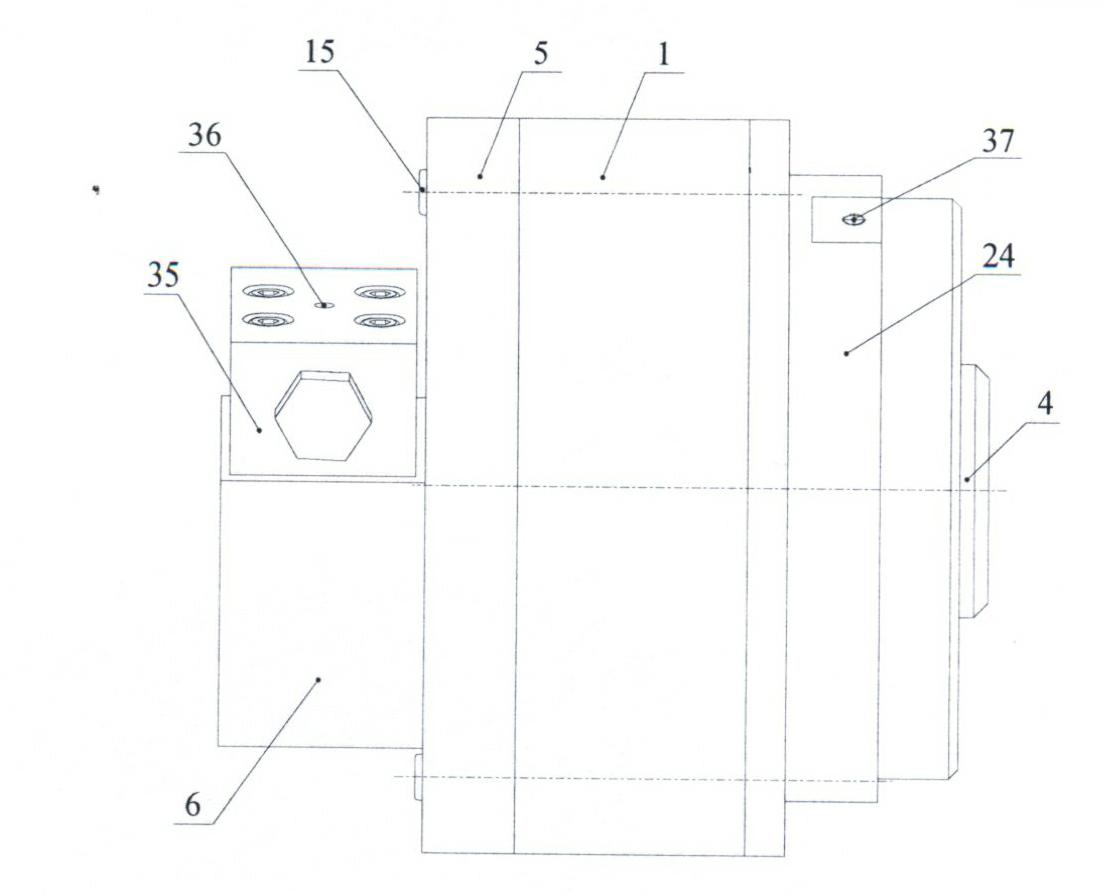

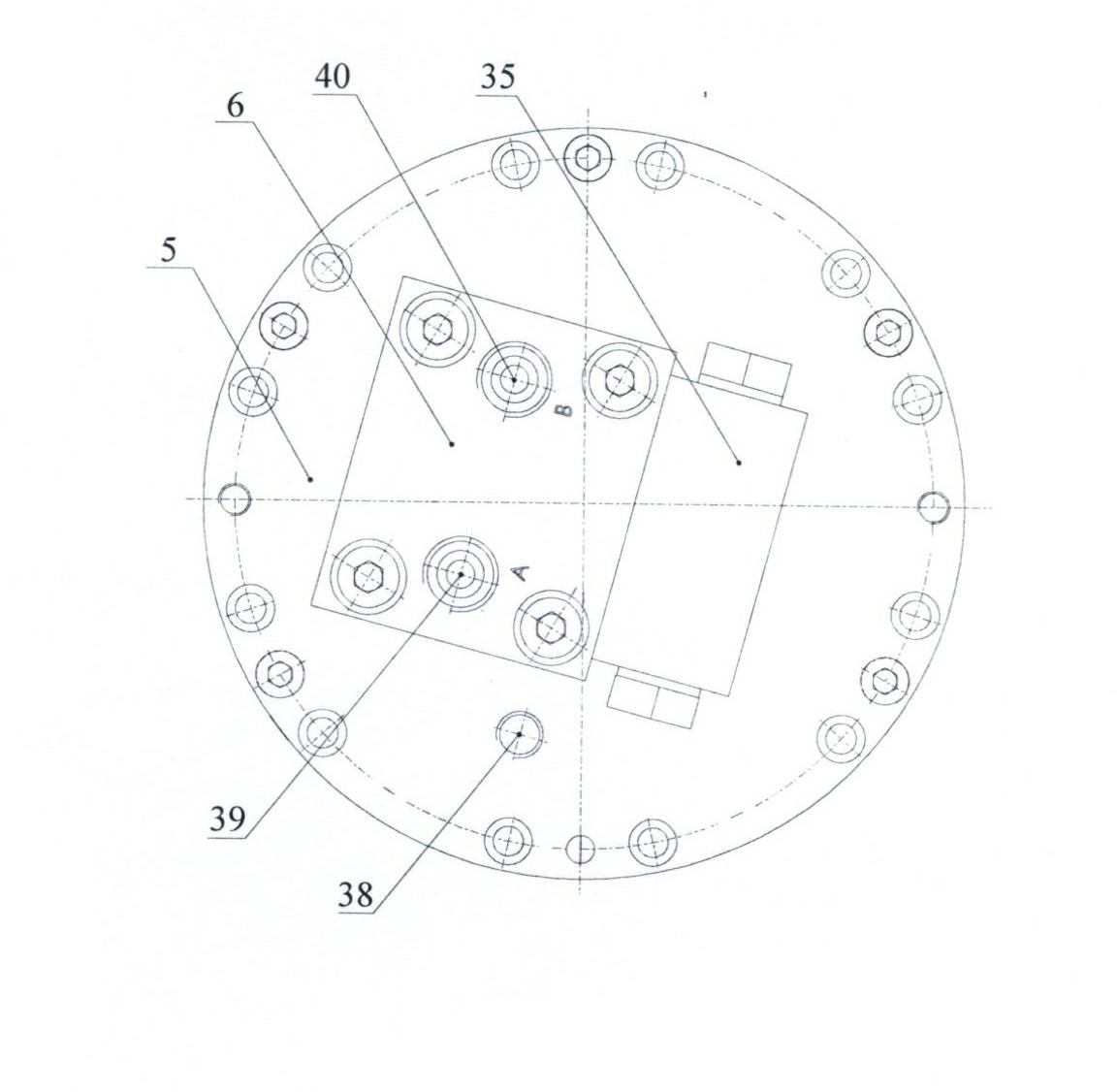

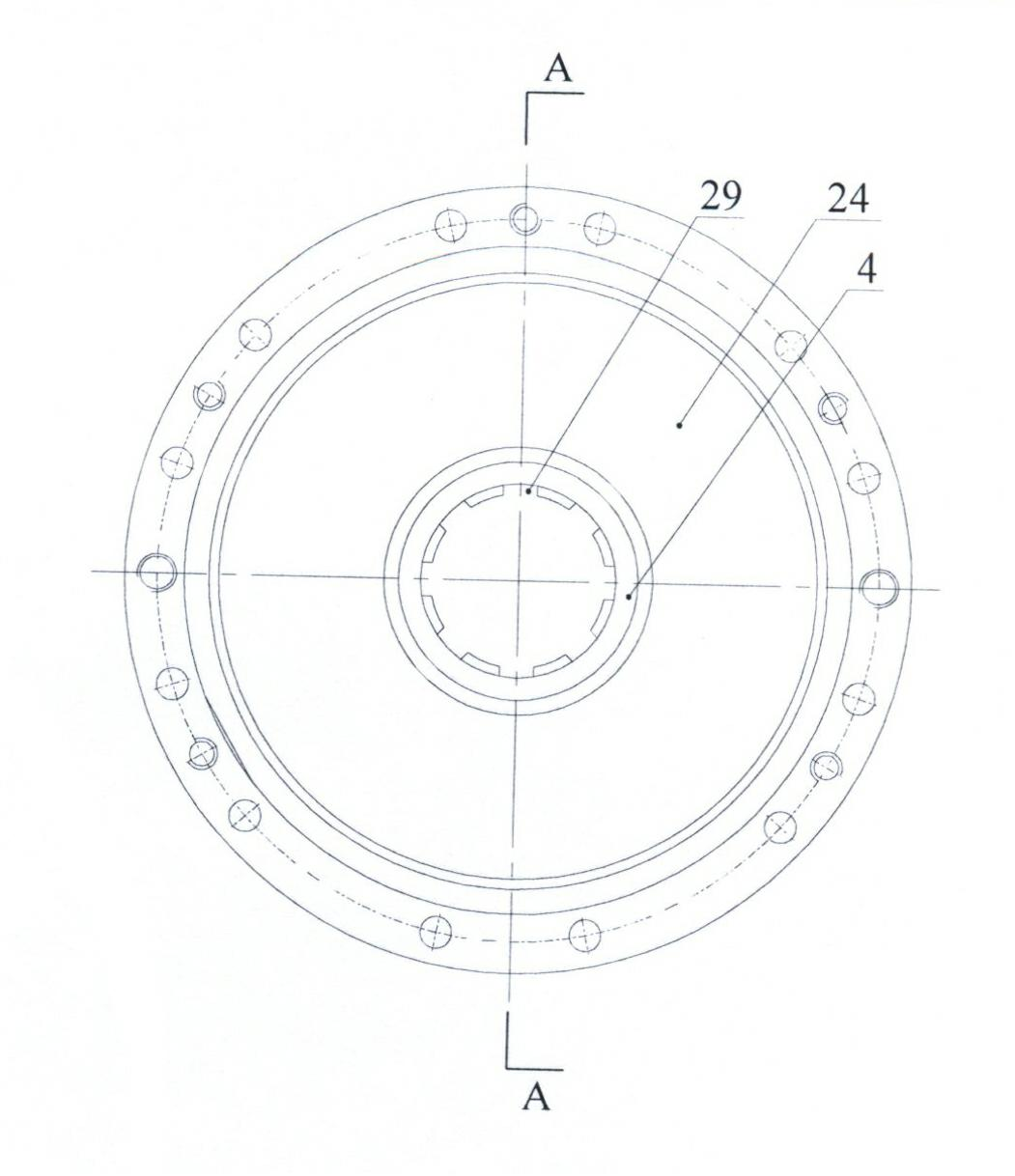

[0063] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a radial piston rolling ball hydraulic motor with an end face distribution pair includes a water block 6, a shuttle valve 35, a flow distribution plate 5, a rotor 4, a stator 1, a thrust ring 22, a right end cover 24, and a shuttle valve 35 It is fixed on the waterway block 6 by four bolts 8, the waterway block 6 is fixed on the distribution plate 5 by four bolts 9, and the rotor 4 is installed on the protruding shaft of the flow distribution plate 5. After assembly, the supporting shaft and the rotor 4 will form a A cavity 31, the thrust ring 22 is installed between the rotor 4 and the right end cover 24, the right end cover 24 has four rectangular slots 59, and the thrust ring 22 has four rectangular keys 55, which can be restricted after being put in. Rotate in the axial direction, the bolt 15 connects the distribution plate 5, the stator 1 and the right end cover 24 to form a whole, add a lip seal ring ...

Embodiment 2

[0077] Such as 32, Figure 33 and Figure 34 As shown in the figure, a radial piston rolling ball hydraulic motor with an end surface distribution pair includes a water block 6, a shuttle valve 35, a flow distribution plate 5', a rotor 4', a stator 1, a thrust ring 22, and a right end cover 24, except Except for the distribution plate 5' and the rotor 4', the structure and assembly of the remaining parts are the same as those in Embodiment 1; Figure 35-Figure 42As shown, the end surface of the distribution plate 5' is an arc surface, and the end surface of the rotor 4' is an arc surface. On the inner end surface of the flow distribution plate 5', there are six evenly distributed inner semicircular rectangular grooves 41 along the radial direction to the center of the circle. Each inner semicircular rectangular groove 41 communicates with the annular flow channel 45 on the end face, and six uniformly distributed outer semicircular rectangular grooves 43 are opened on the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com