Grinding and polishing device

A polishing device and a technology for fixing the base, which are applied in the direction of grinding drive devices, grinding/polishing equipment, grinding machines, etc., can solve the problems of dangerous operation, difficult fixing of sandpaper, and easy rubbing by workpieces, etc., to reduce the linear speed, device Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

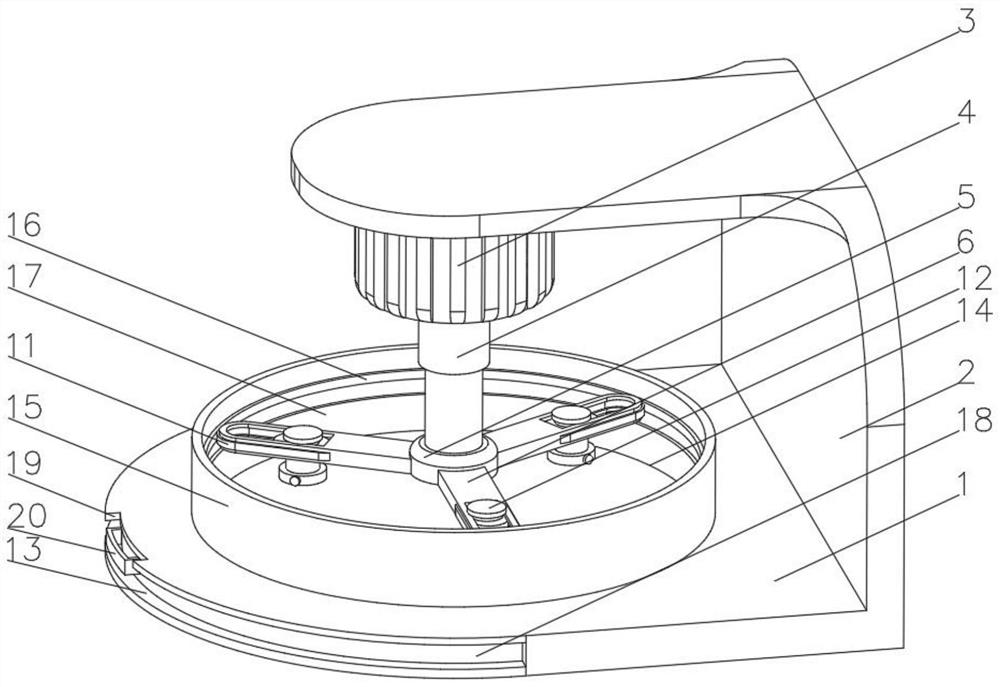

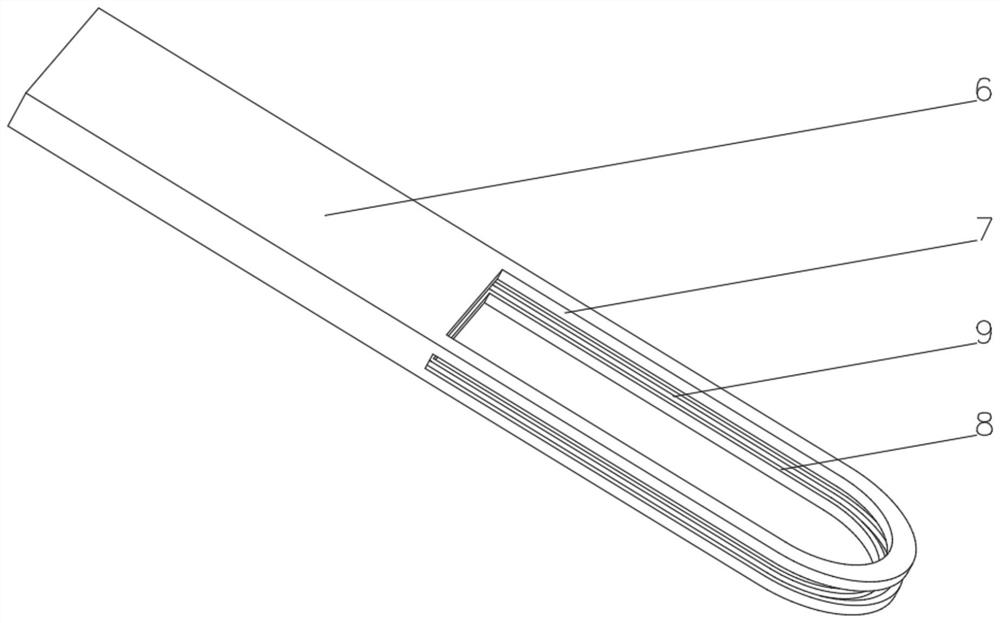

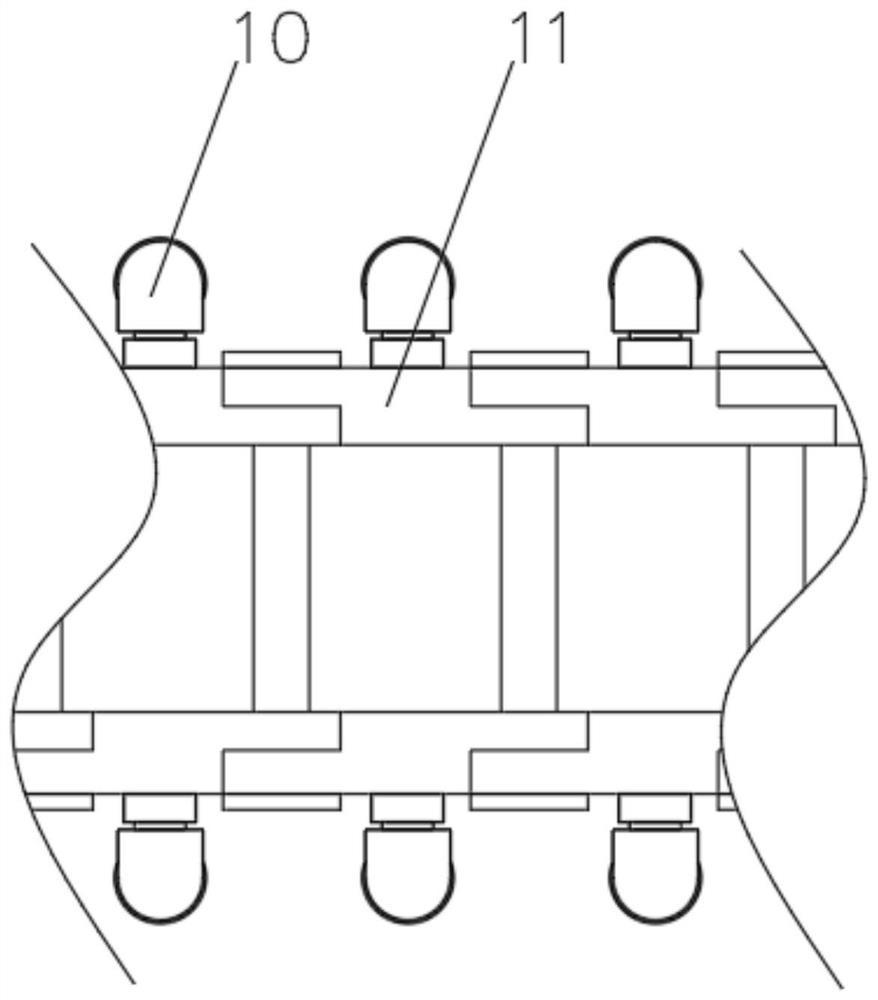

[0032] see Figure 1-5, the present invention provides a technical solution: a grinding and polishing device, comprising a fixed base 1, a support 2 is fixedly connected to one side of the top of the fixed base 1, a drive motor 3 is fixedly connected to the bottom of the support 2, and the drive shaft of the drive motor 3 is fixedly connected to There is a telescopic rod 4, the end of the telescopic rod 4 away from the drive motor 3 is fixedly connected to the control panel 5, the side of the control panel 5 is fixedly connected to the support rod 6, and the top of the end of the support rod 6 away from the control panel 5 is provided with a sliding hole 7, the sliding hole 7 The inner wall is provided with a slideway 8, and both sides of the inner wall of the slideway 8 are provided with a chute 9, and the inner wall of the chute 9 is slidingly connected with a double-headed pulley 10, and the bottom side of the double-headed pulley 10 runs through the chute 9 and extends to t...

Embodiment 2

[0036] see Figure 1-6 On the basis of Embodiment 1, the present invention provides a technical solution: the fixing device 12 includes a fixed plate 121, the top of the fixed plate 121 penetrates and is fixedly connected with a rotating column 122, the bottom of the rotating column 122 is fixedly connected with a clamp 123, and the rotating column 122 The part inside the fixed plate 121 runs through and is fixedly connected with a gear 124, the top of the rotating column 122 is fixedly connected with a guide plate 125, one side of the fixed plate 121 is fixedly connected with an electric telescopic rod 126, and both sides of the fixed plate 121 extend to the slideway 8 It is inside and slidingly connected with the inner wall of the slideway 8. Both sides of the gear 124 pass through the fixed plate 121 and extend to the inside of the slideway 8. The part of the gear 124 located inside the slideway 8 meshes with the tooth chain 11. The electric telescopic rod 126 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com