Patents

Literature

33results about How to "Easy to weld and form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

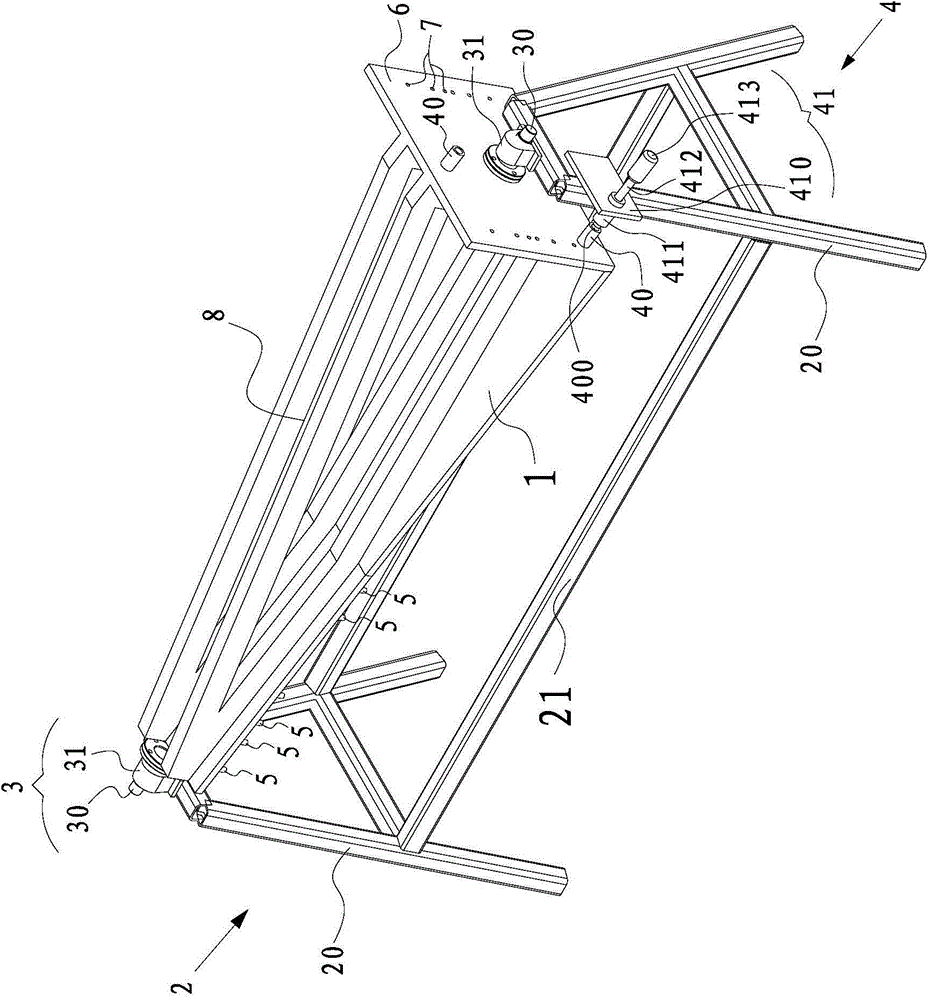

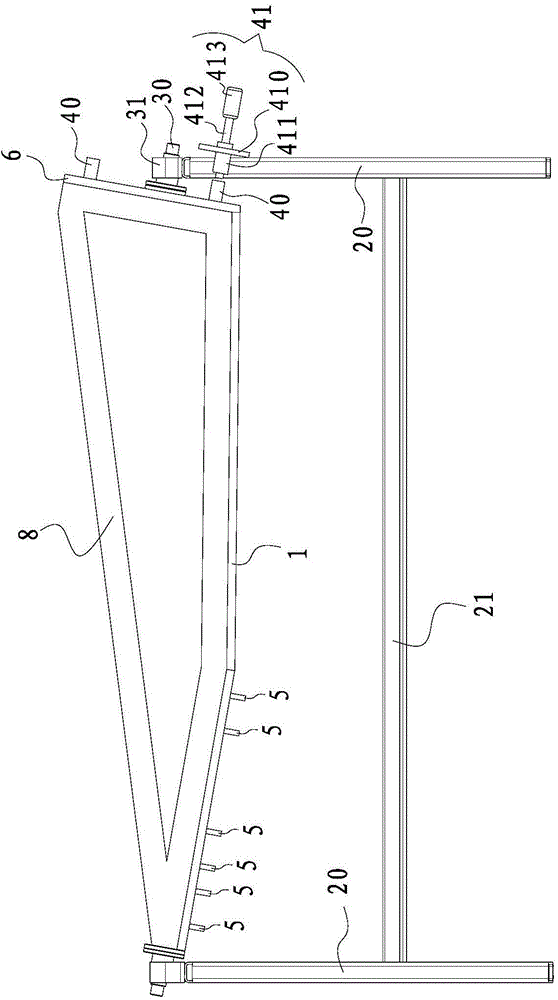

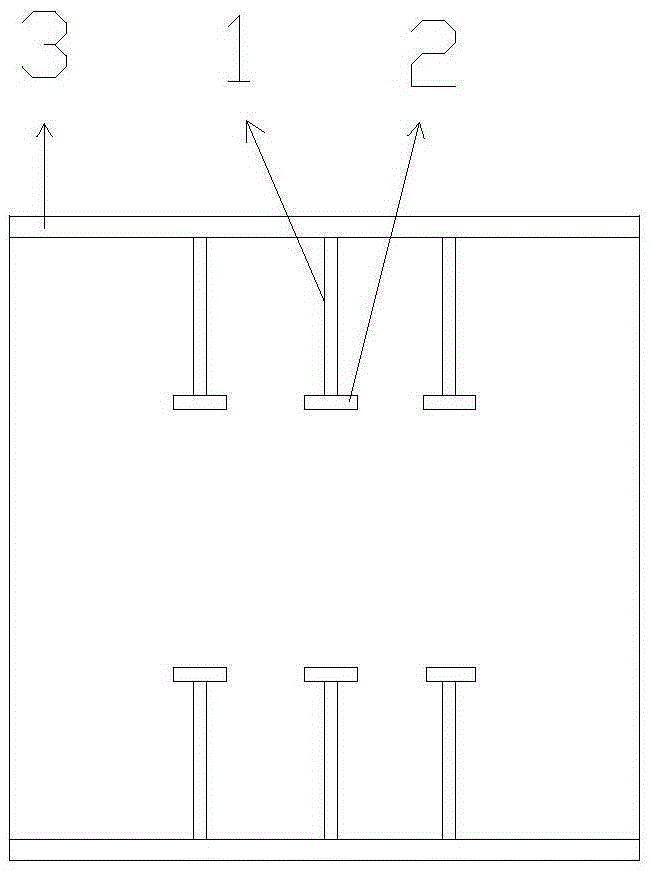

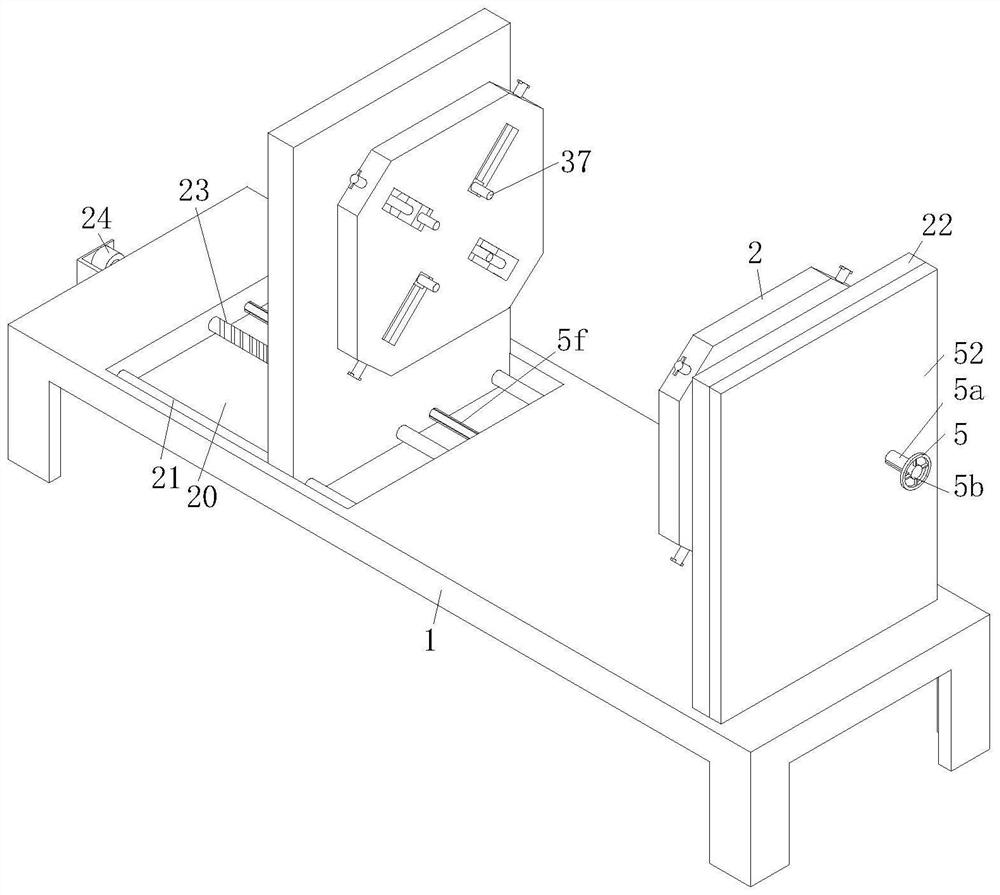

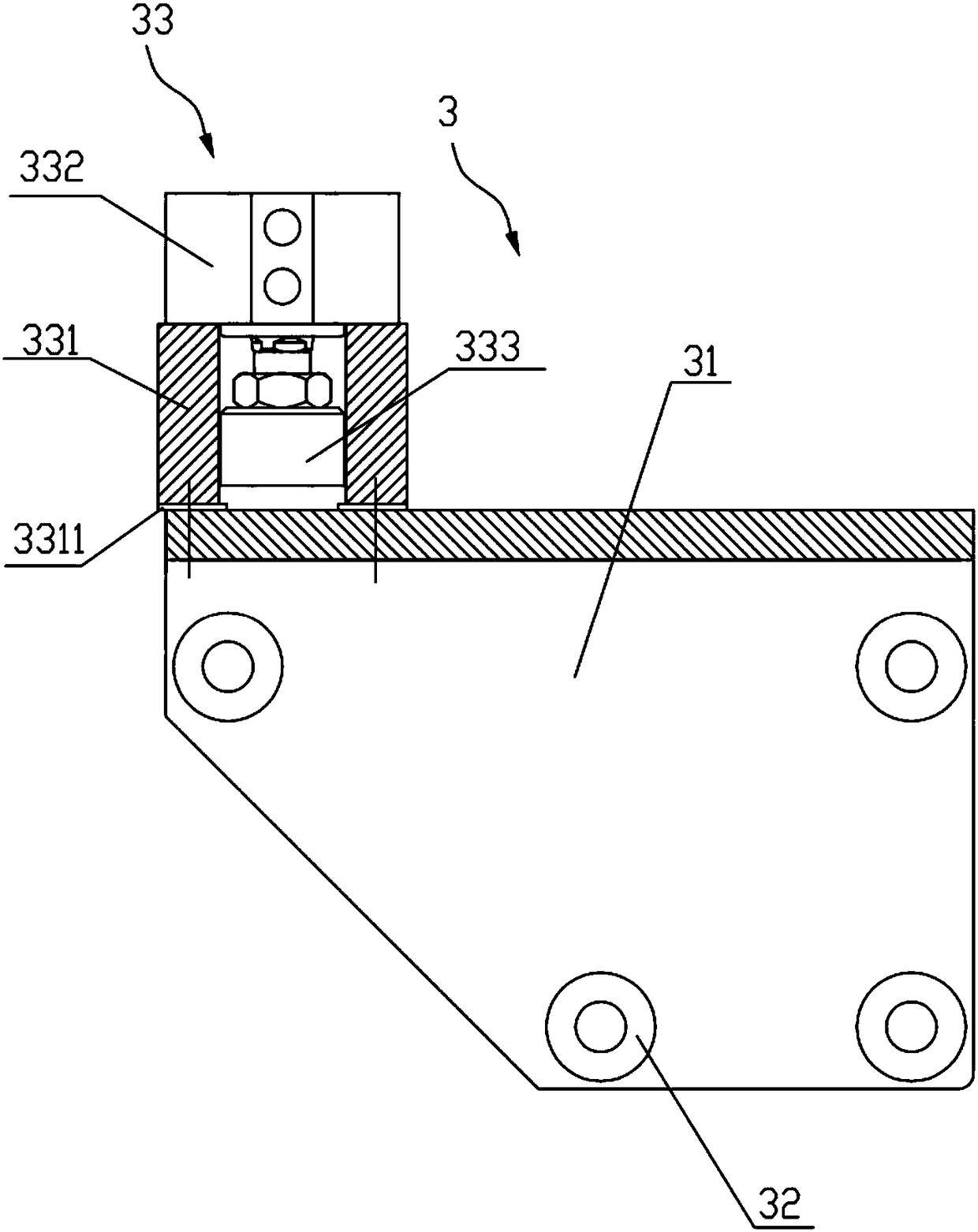

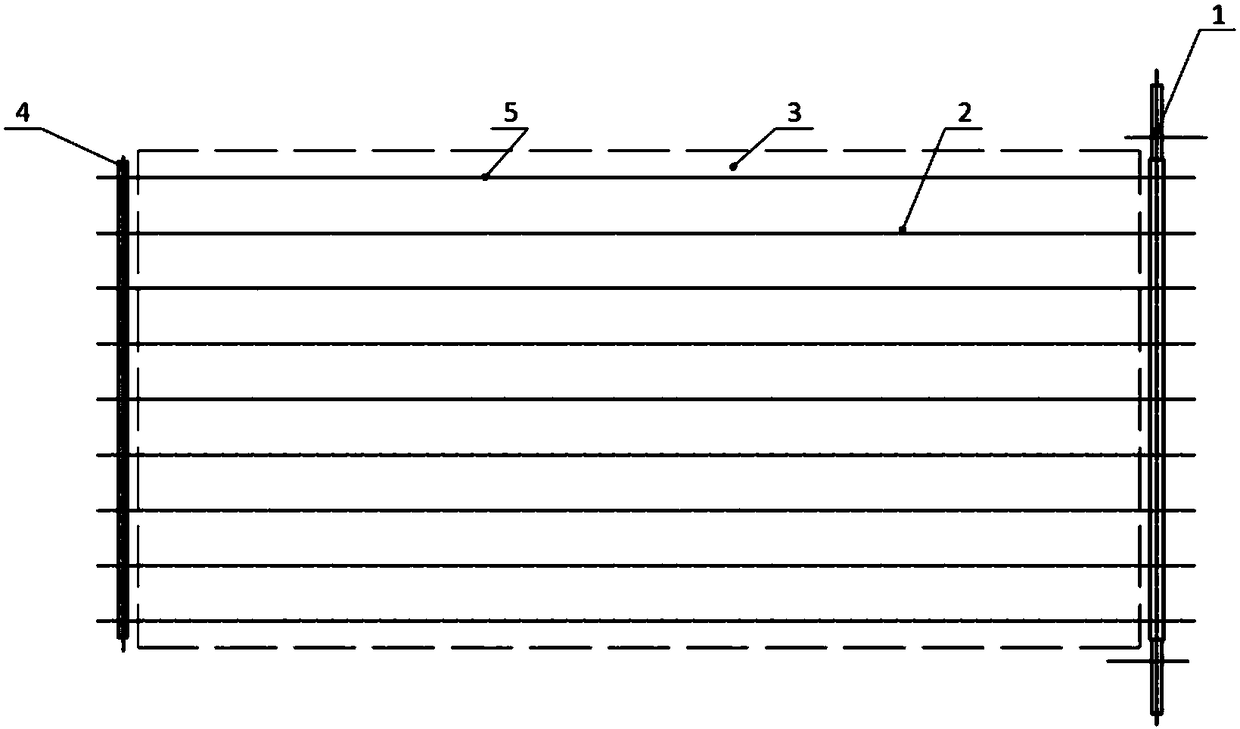

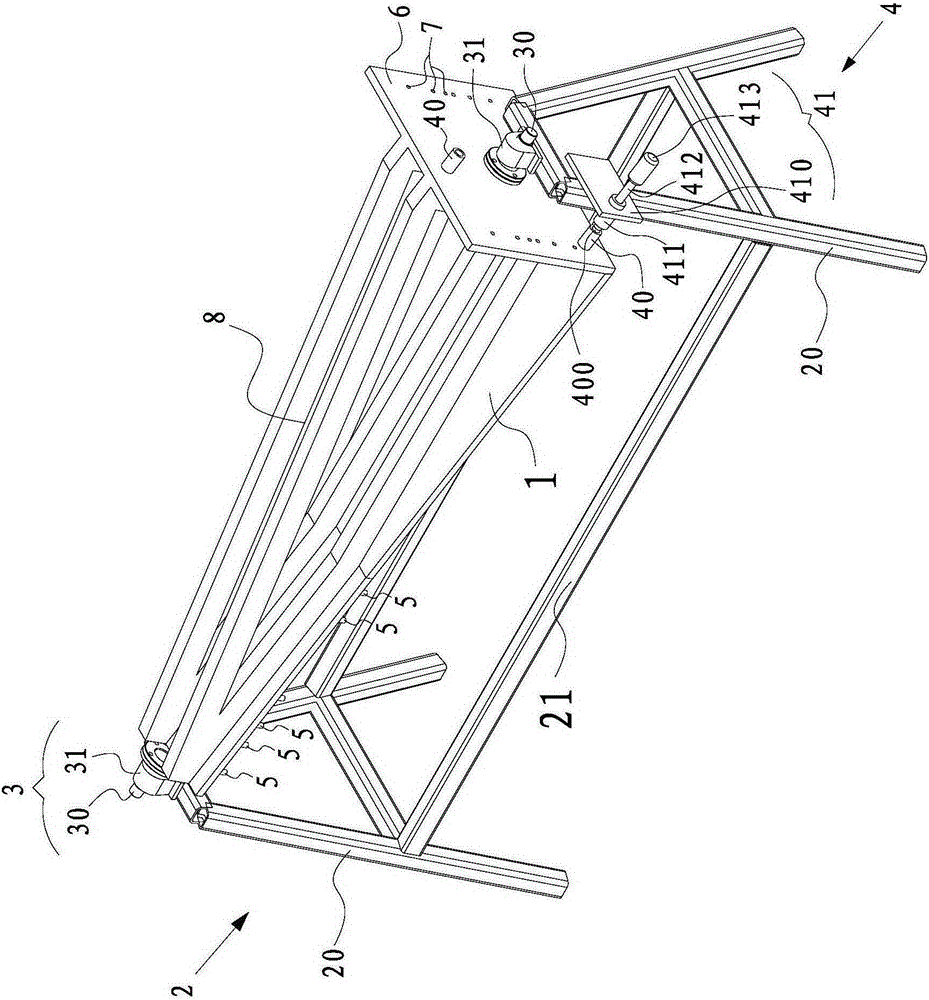

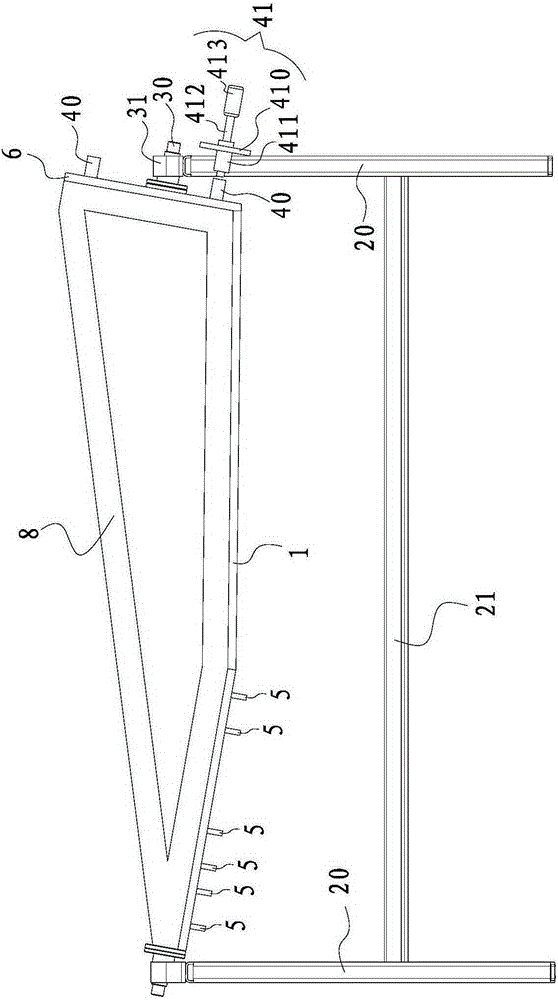

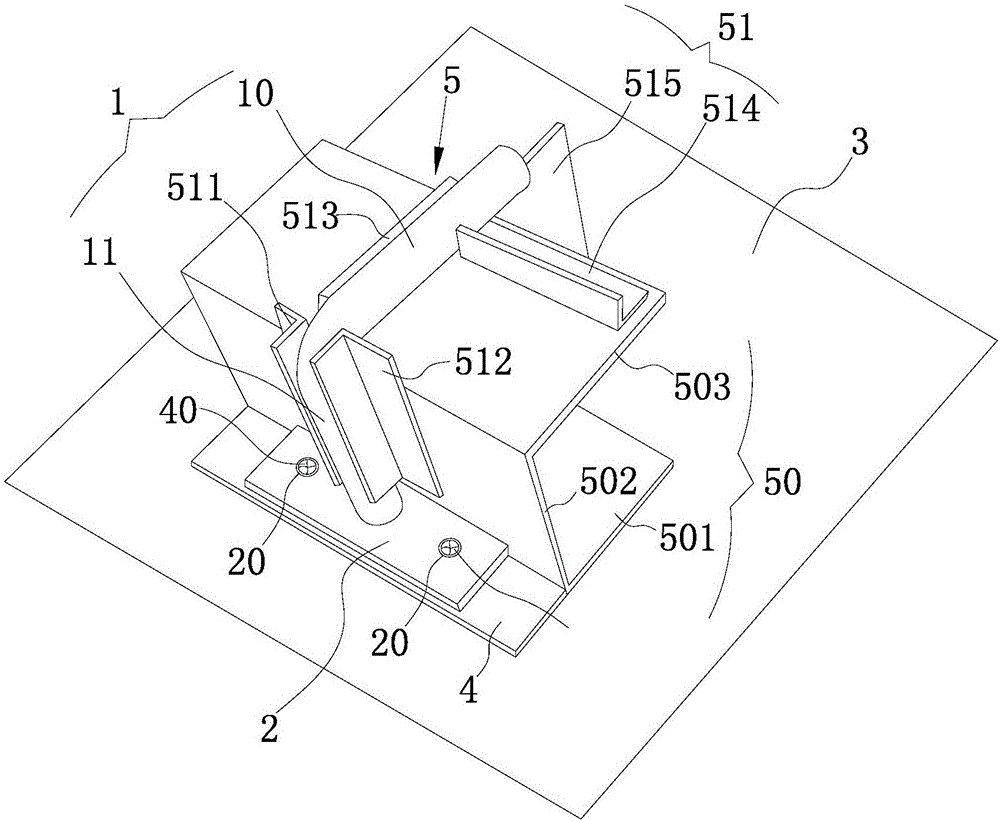

Special escalator welding forming clamp for elevator

ActiveCN104511712ARapid positioningEasy to weld and formWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsHandrail

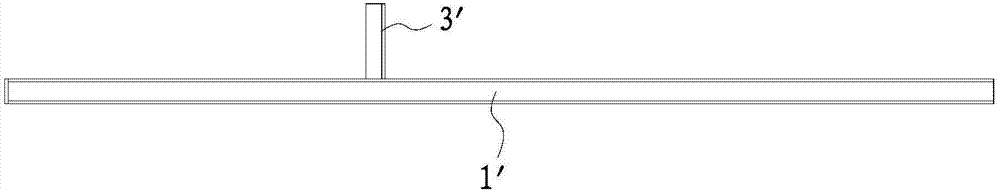

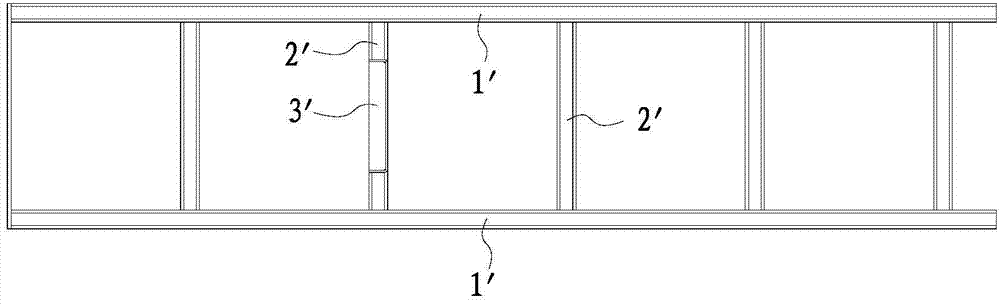

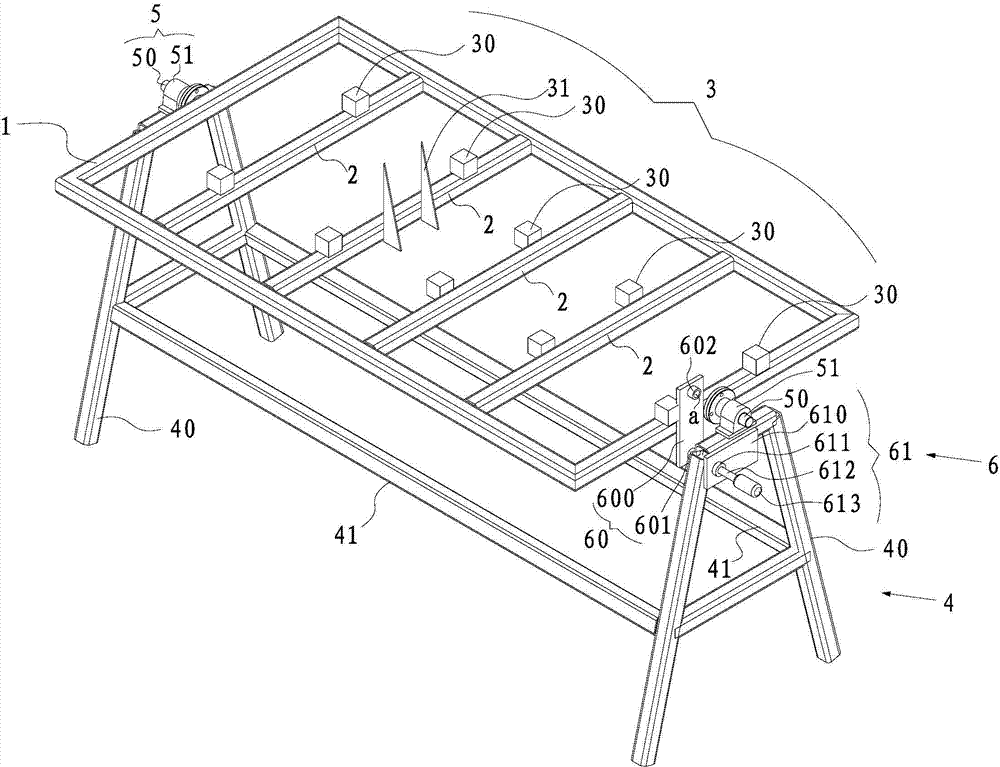

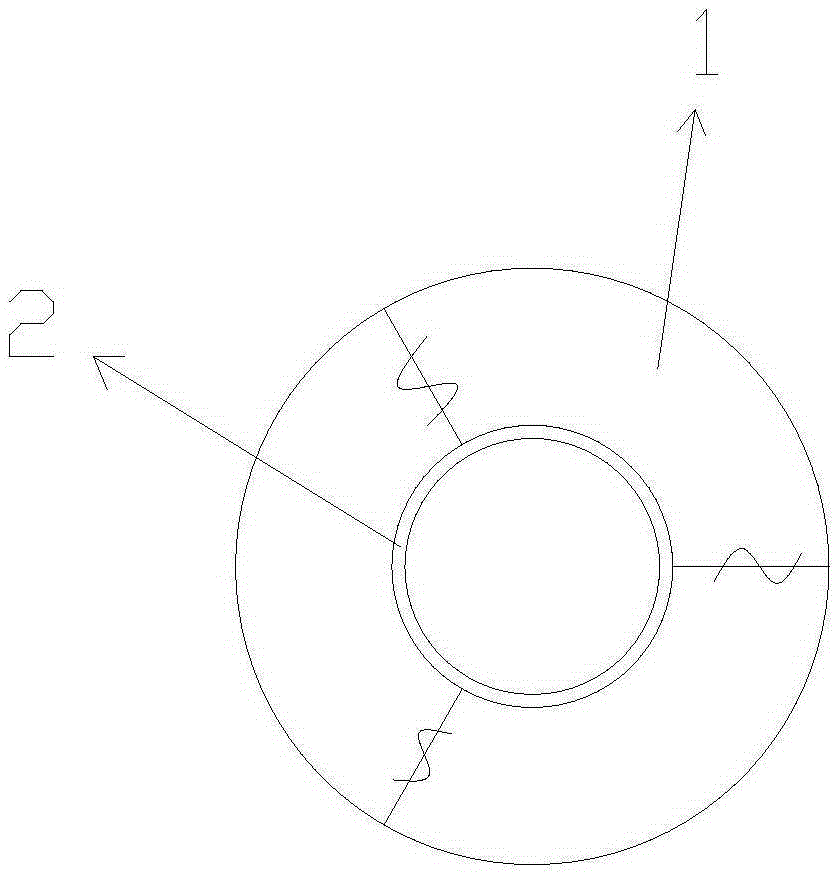

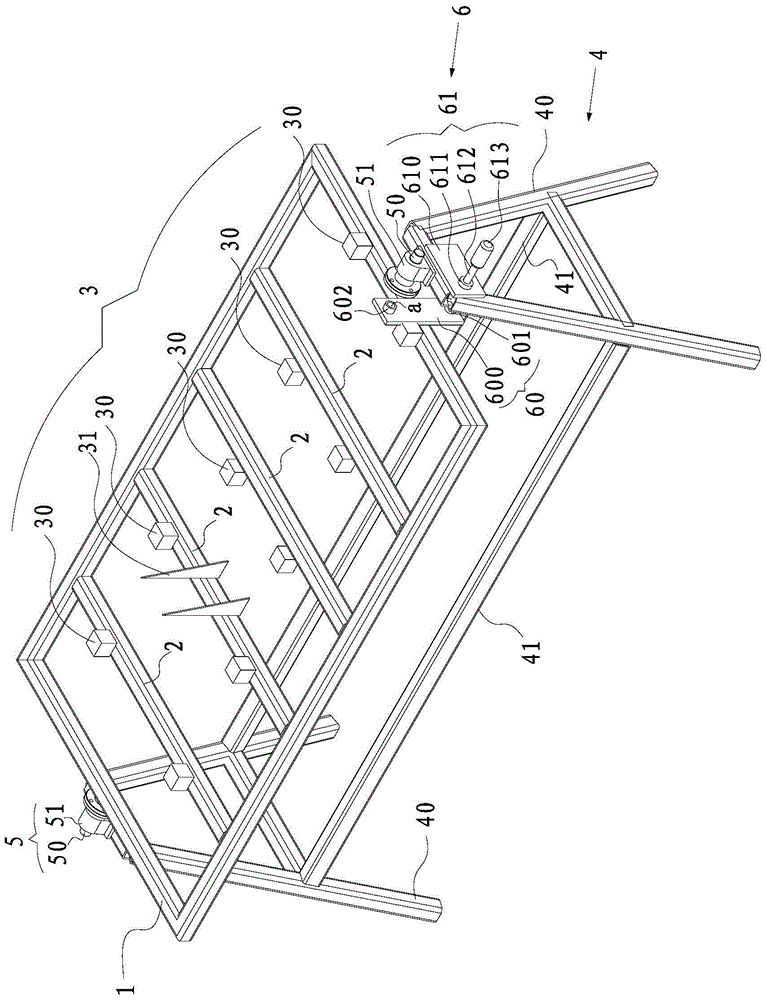

The invention relates to a special escalator welding forming clamp for an elevator. An escalator comprises handrail rods, cross rods and connecting parts; the clamp comprises a rectangular enclosure frame, a plurality of support rods arranged in the enclosure frame along the width direction of the enclosure frame, and locating pieces detachably arranged on the support rods, each locating piece comprises two locating blocks arranged on each support rod, and support plates vertically arranged on the support rods corresponding to the connecting parts, wherein the distance between two locating blocks on the same support rod is equal to the length of the cross rod and the width of the escalator, handrail rod holding spacer regions are formed between locating blocks with unequal spacing between each two locating blocks, a plurality of cross rods are arranged on the support rods, the cross rods with the connecting parts and the connecting parts are propped against the support plates, and the other cross rods are propped against the lateral surfaces of the two locating blocks. The special escalator welding forming clamp for the elevator is capable of quickly locating the handrail rods, cross rods and connecting parts, convenient to weld and form the escalator and simple in structure.

Owner:苏州威尔特铝合金升降机械有限公司

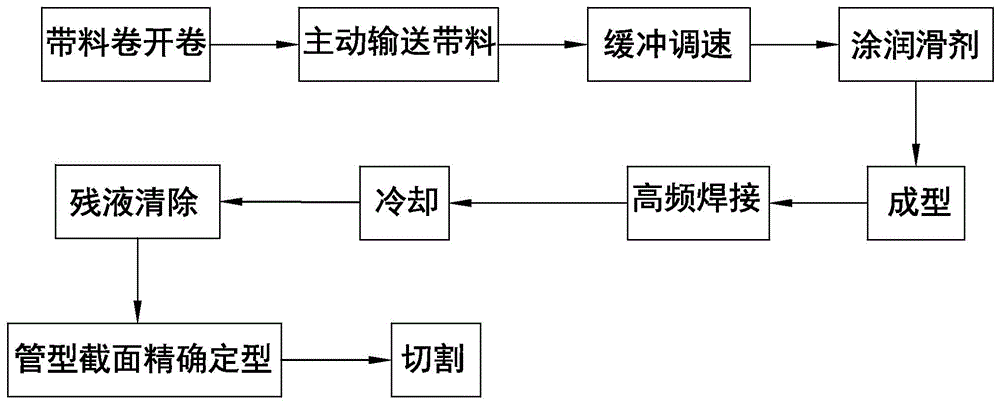

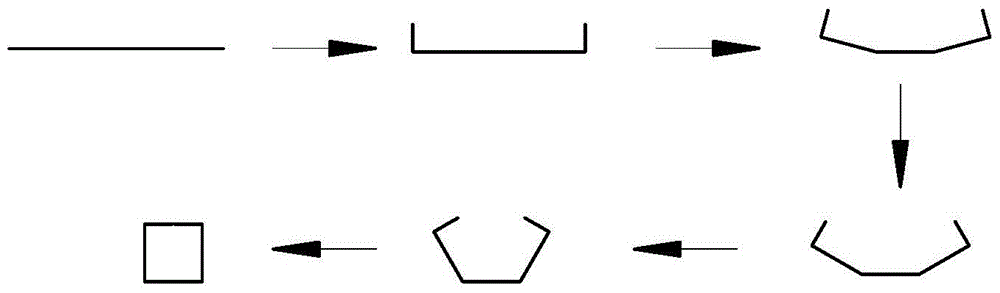

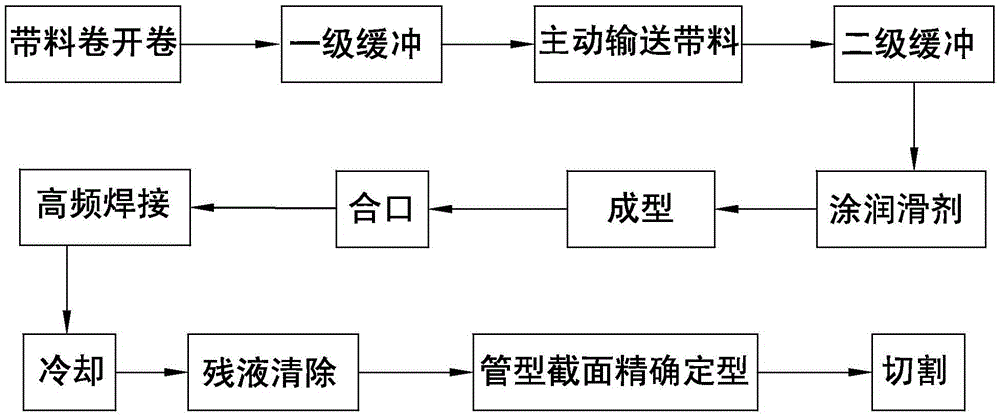

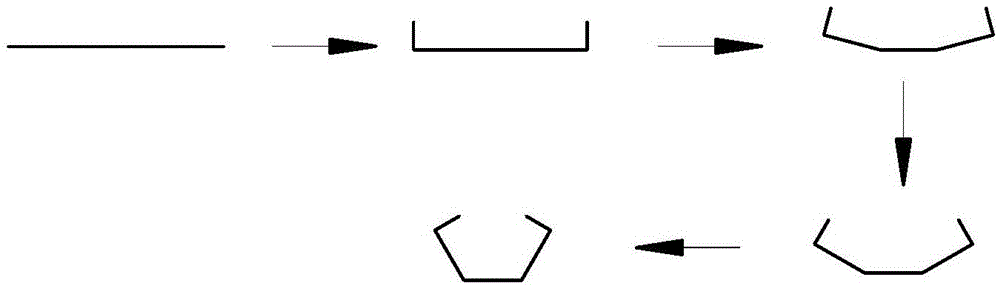

Machining method for thin-wall squared tube

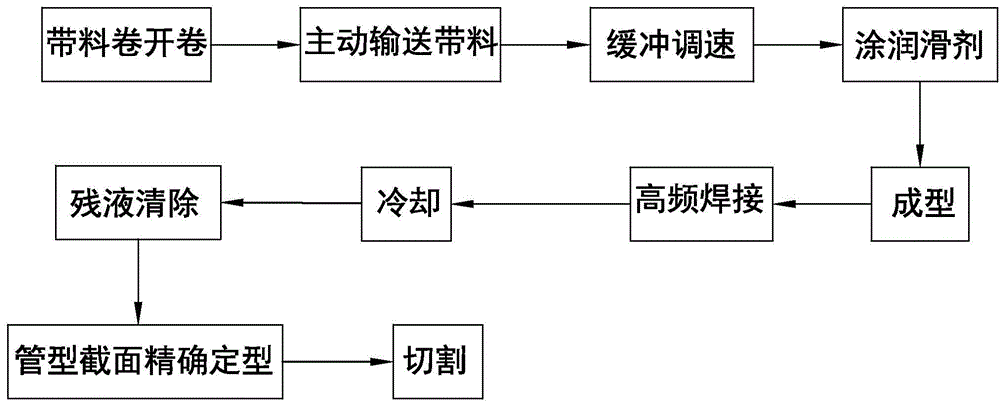

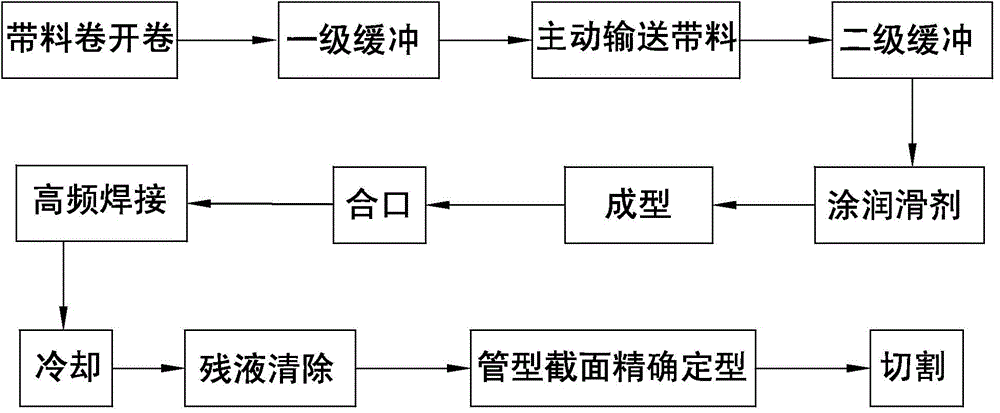

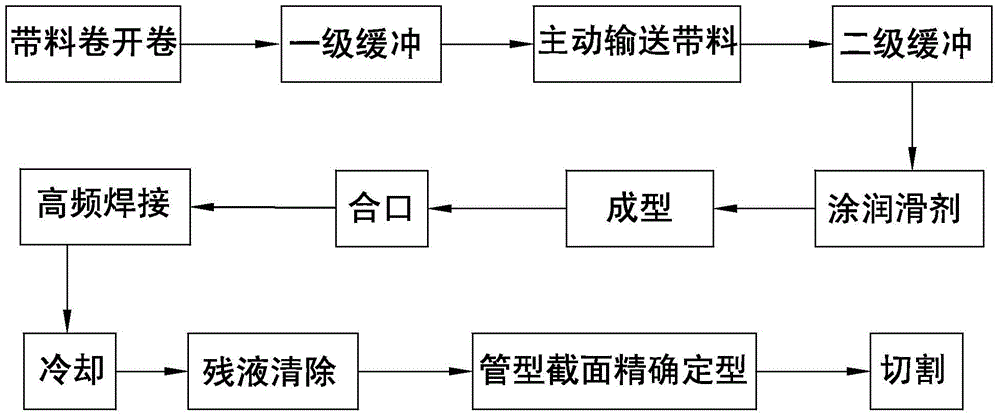

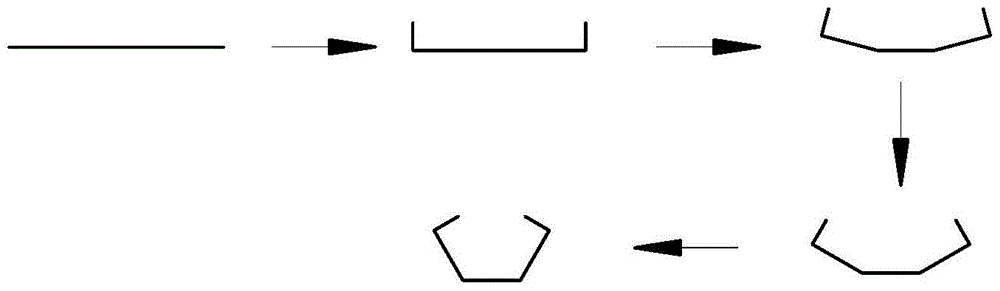

The invention discloses a machining method for a thin-wall squared tube and belongs to the technical field of square tube forming processes. The machining method for the thin-wall squared tube mainly includes the following steps that 1 a strip roll is decoiled, wherein the strip roll is unfolded and a strip is discharged; 2 the strip is conveyed actively, wherein the strip is discharged downstream under the action of traction force; 3 buffering speed governing is conducted, wherein the strip is discharged at a constant speed without the action of tensile force, and the active conveying frequency of the strip is controlled; 4 lubricant coating is conducted, wherein the two surfaces of the strip are coated with lubricants; 5 forming is conducted, wherein the strip is gradually bent in a cold mode, so that the strip forms a tube blank with a weld joint and a square section, and the weld joint is located on the upper surface of the tube blank; 6 high-frequency welding is conducted; 7 cooling is conducted; 8 residual liquor is cleaned away; 9 the tube section is accurately shaped; 10 cutting is conducted. The machining method solves the technical problems that existing thin-wall squared tubes are poor in forming quality and low in production efficiency, and the machining method is widely applied to manufacturing thin-wall squared tubes.

Owner:JIANGSU ZHONGHAI HEAVY MACHINE TOOL

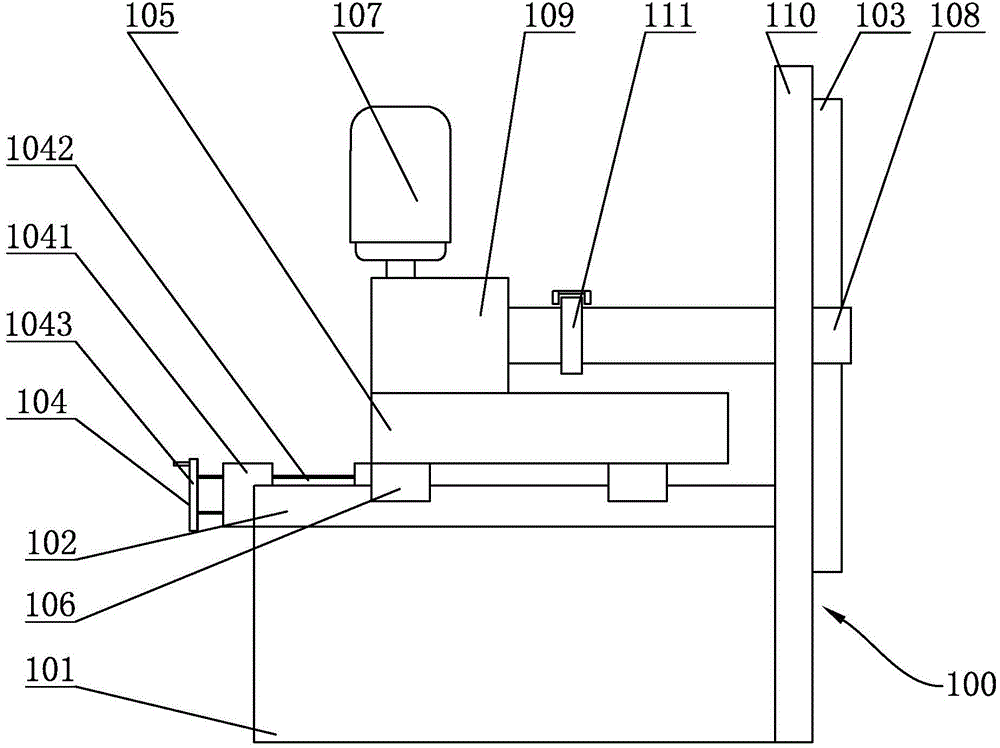

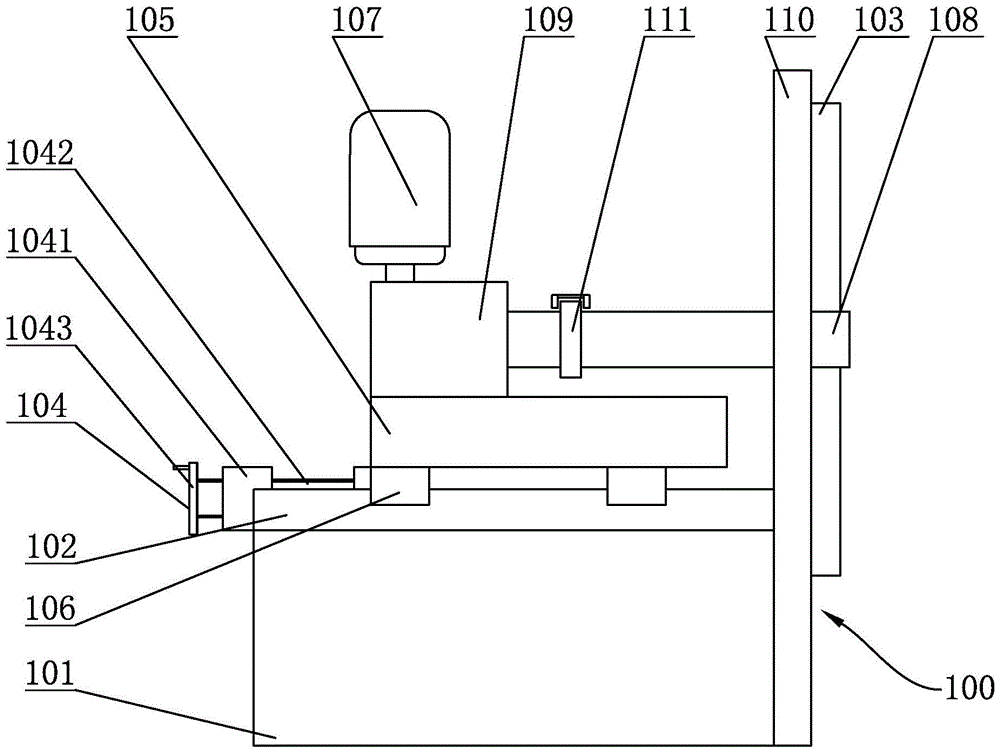

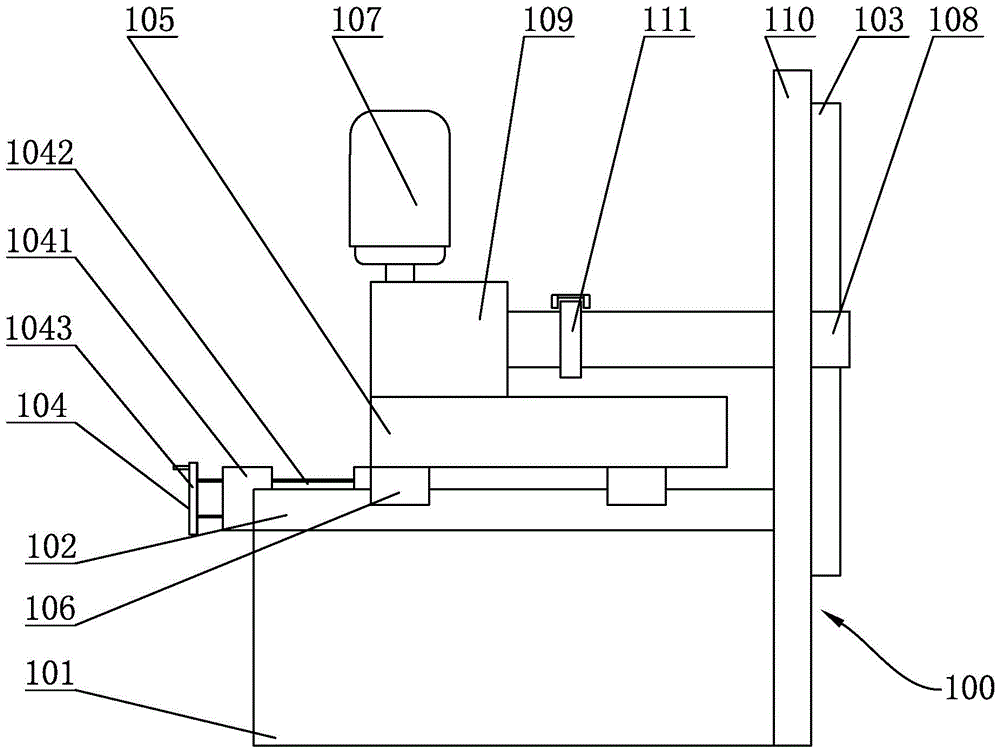

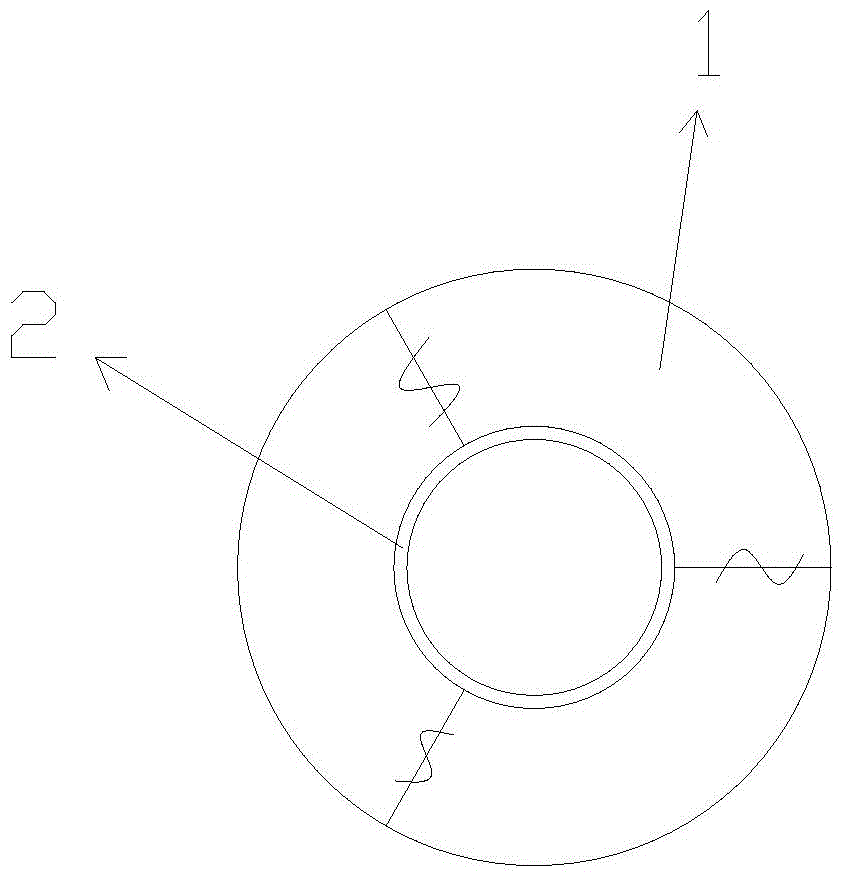

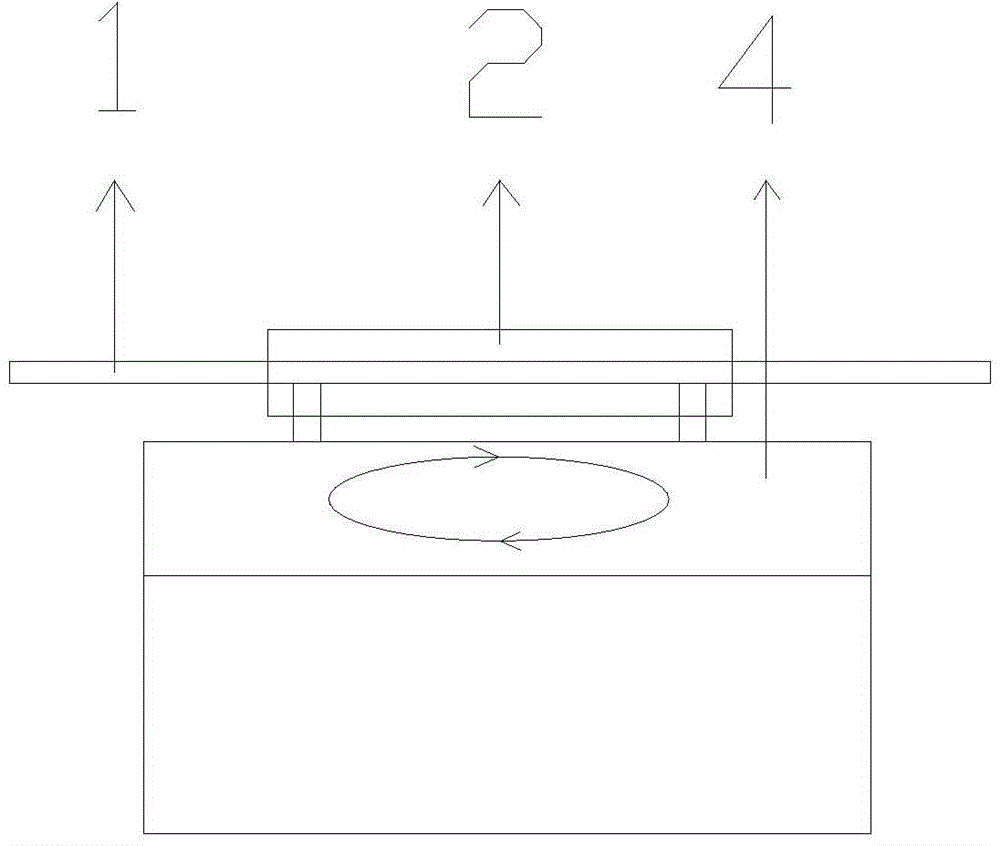

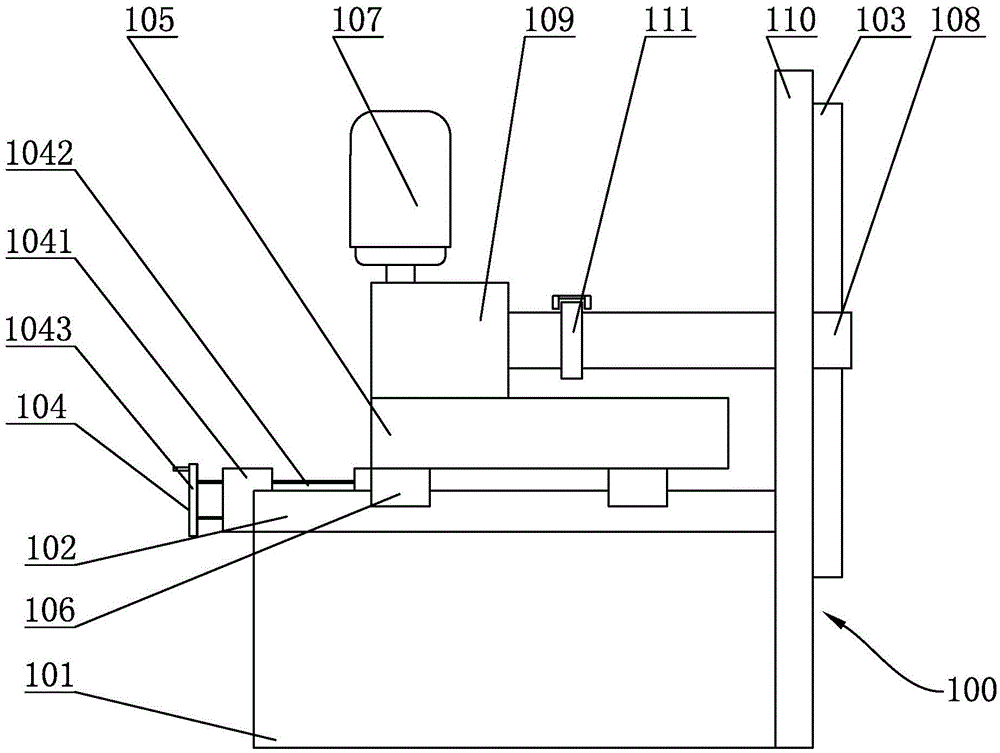

Machining device of square tubes made of thin-wall strips

InactiveCN104625753AEasy to weldEasy to weld and formOther manufacturing equipments/toolsEngineeringLubricant

The invention discloses a machining device of square tubes made of thin-wall strips and belongs to the technical field of square tube forming equipment. According to the strip conveying direction, the machining device mainly comprises a strip decoiling device, a primary buffering device, an active strip conveying device, a secondary buffering device, a strip surface lubricant coating device, a forming device, a tube blank shaping device, a high-frequency welding device, a post-welding cooling device, a surface residual liquid removing device, a square tube shaping device and a cutting device which are arranged in sequence. The machining device solves the technical problems that existing thin-wall square tubes are poor in forming quality and low in production efficiency, and the machining device is widely applied to manufacturing the thin-wall square tubes.

Owner:佛山市九钢制管有限公司

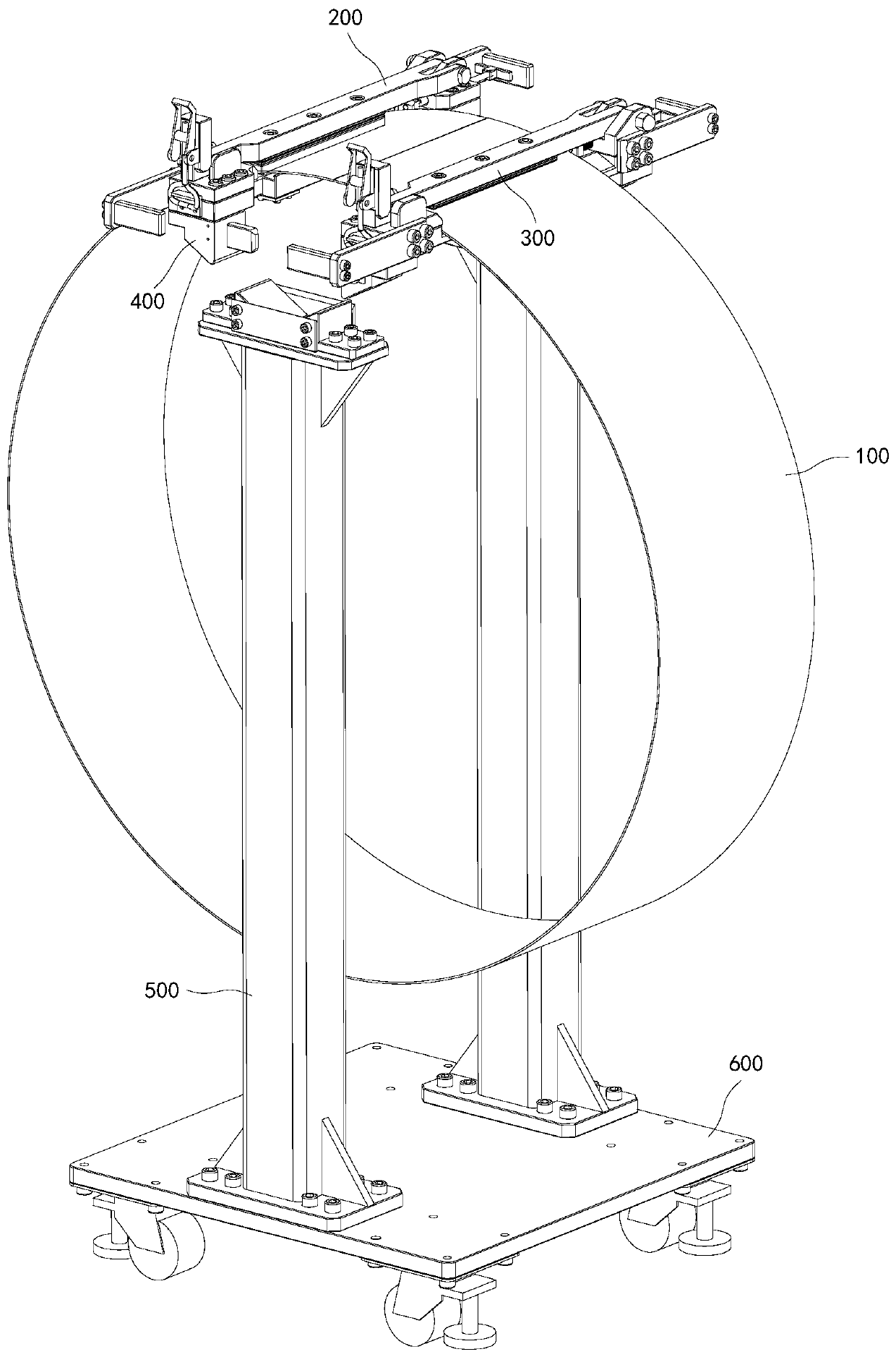

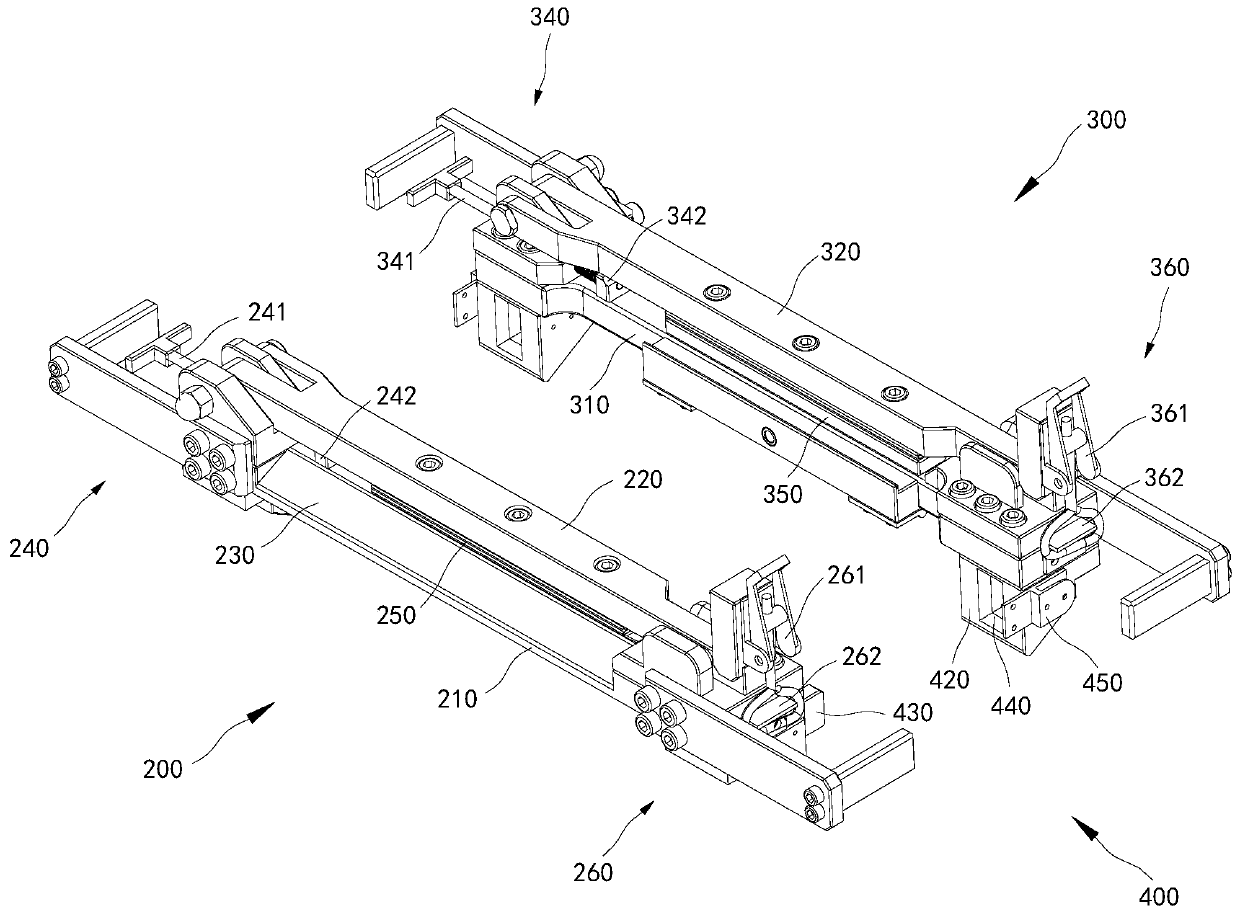

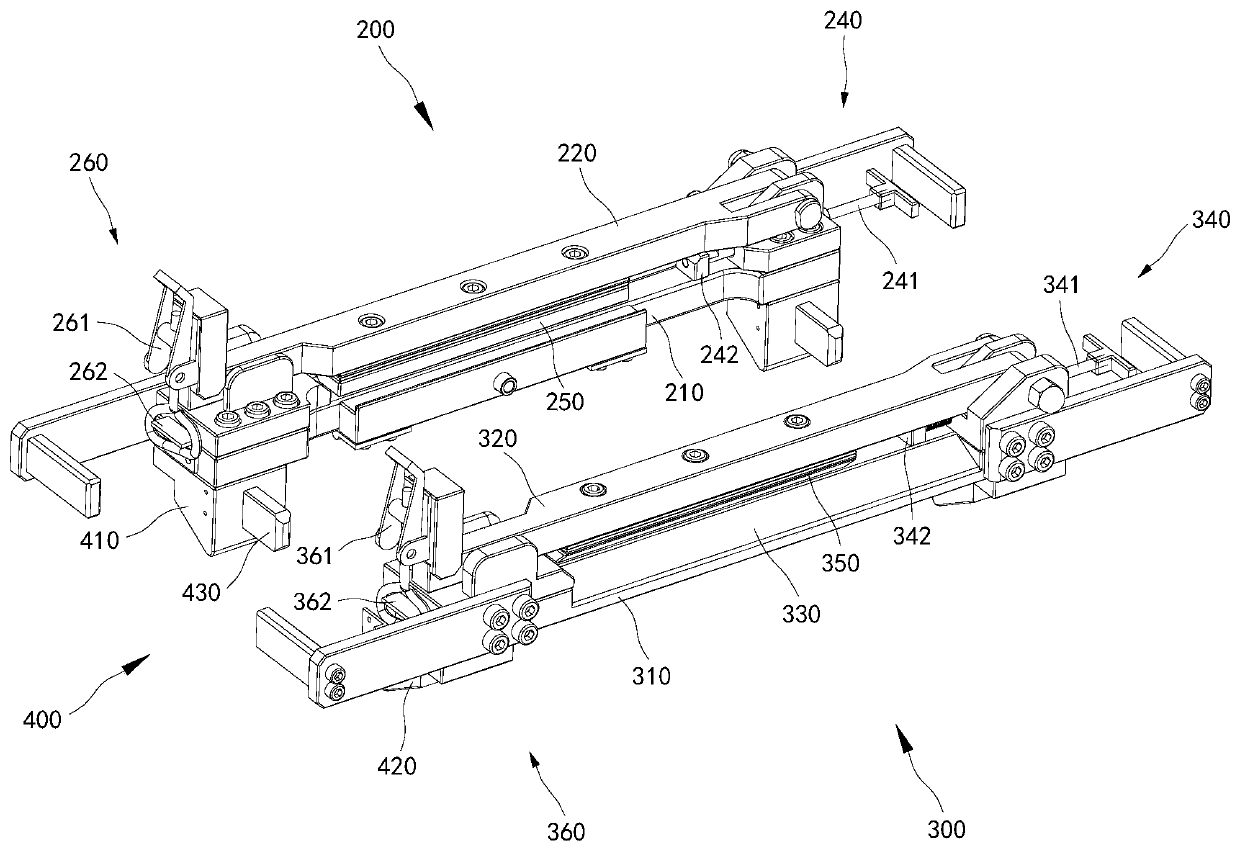

Welding fixture and welding cart

PendingCN110076516AGuaranteed uniformityImprove molding qualityWelding/cutting auxillary devicesAuxillary welding devicesButt jointEngineering

The invention discloses a welding fixture. The welding fixture comprises a first clamping mechanism, a second clamping mechanism and a connecting mechanism; the first clamping mechanism comprises a first fixing arm and a first pressing arm; the second clamping mechanism comprises a second fixing arm and a second pressing arm; and the connecting mechanism comprises a first fixing block and a secondfixing block, the first fixing block is provided with a connecting plate, and the second fixing block is provided with a connecting hole connected with the connecting plate in a buckling mode. One end of a workpiece is compressed on the first fixing arm through the first pressing arm, the other end of the workpiece is compressed on the second fixing arm through the second pressing arm, the two ends of the workpiece are quickly clamped and driven to be connected in a folding butt-joint mode, rolling and sizing of a metal plate are achieved through buckling connection of the connecting plate and the connecting hole, in-place folding butt-joint connection is achieved, and the edge rolling uniformity of the metal plate workpiece is guaranteed. The invention further provides a welding cart based on the welding fixture.

Owner:佛山汇百盛激光科技有限公司

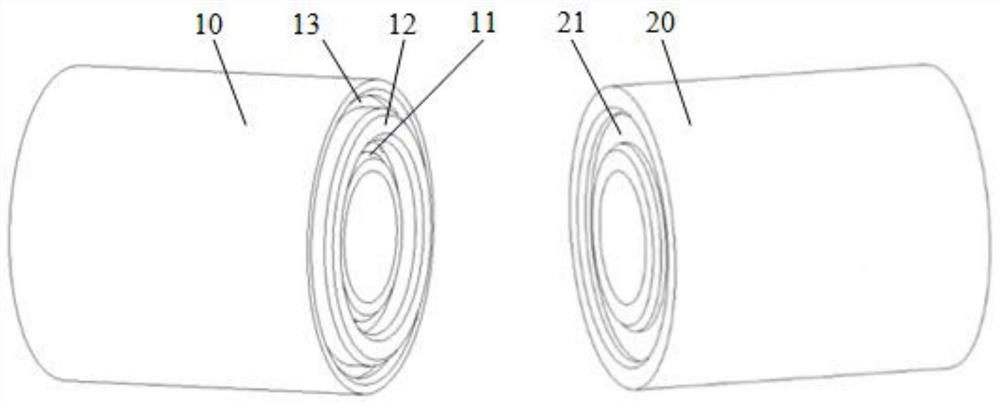

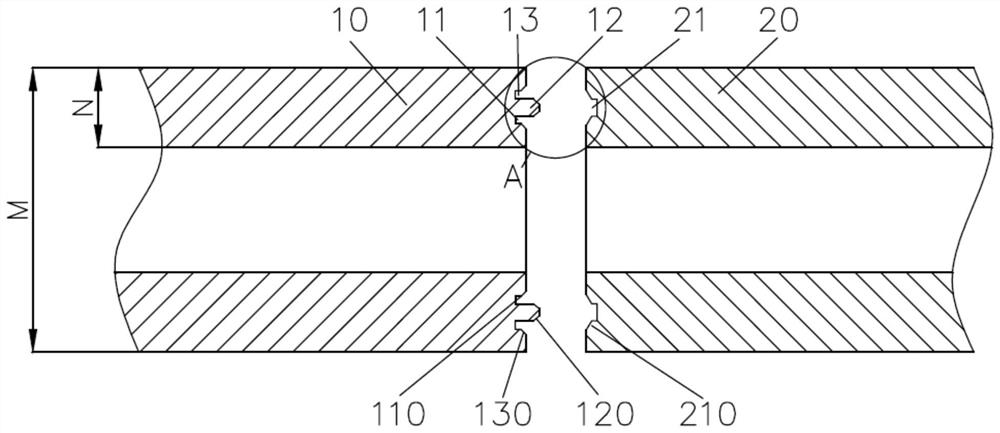

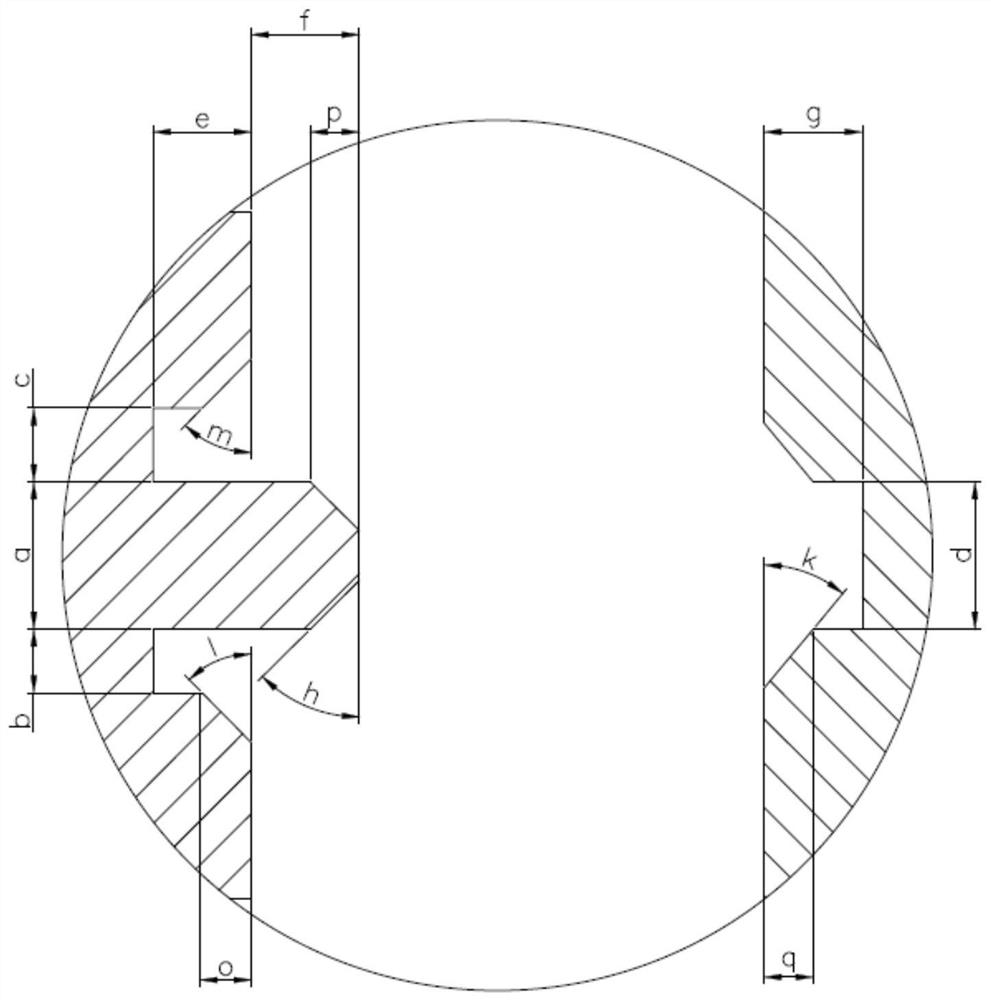

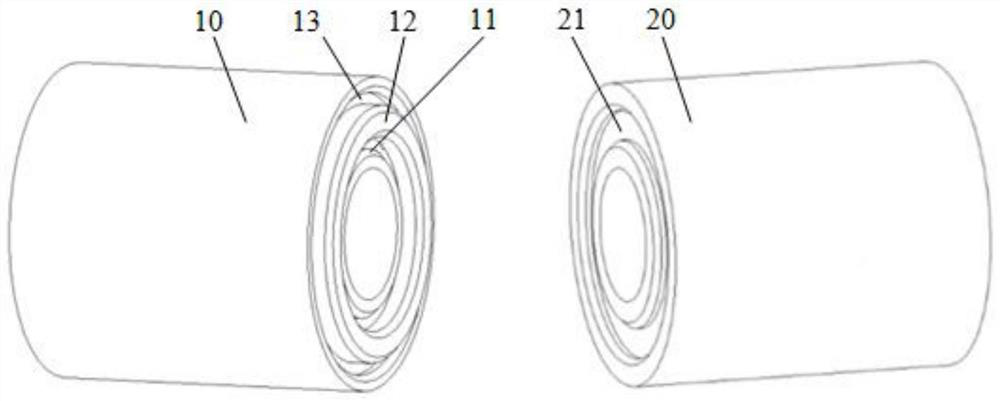

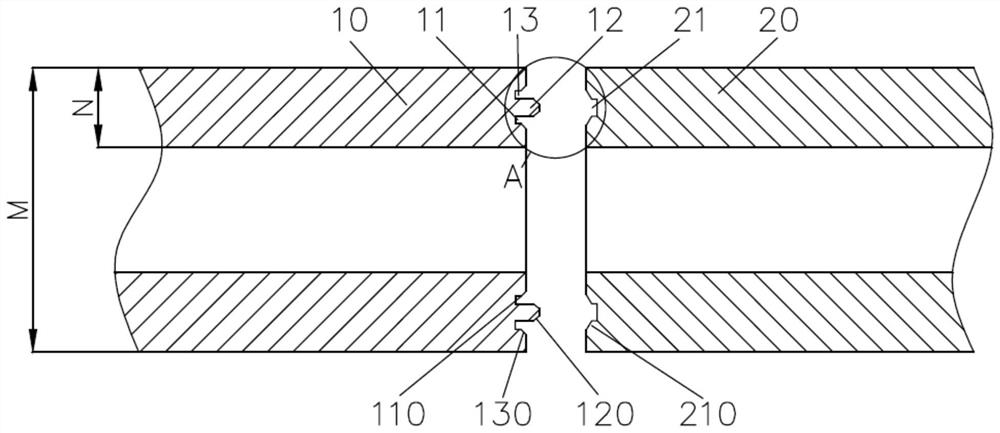

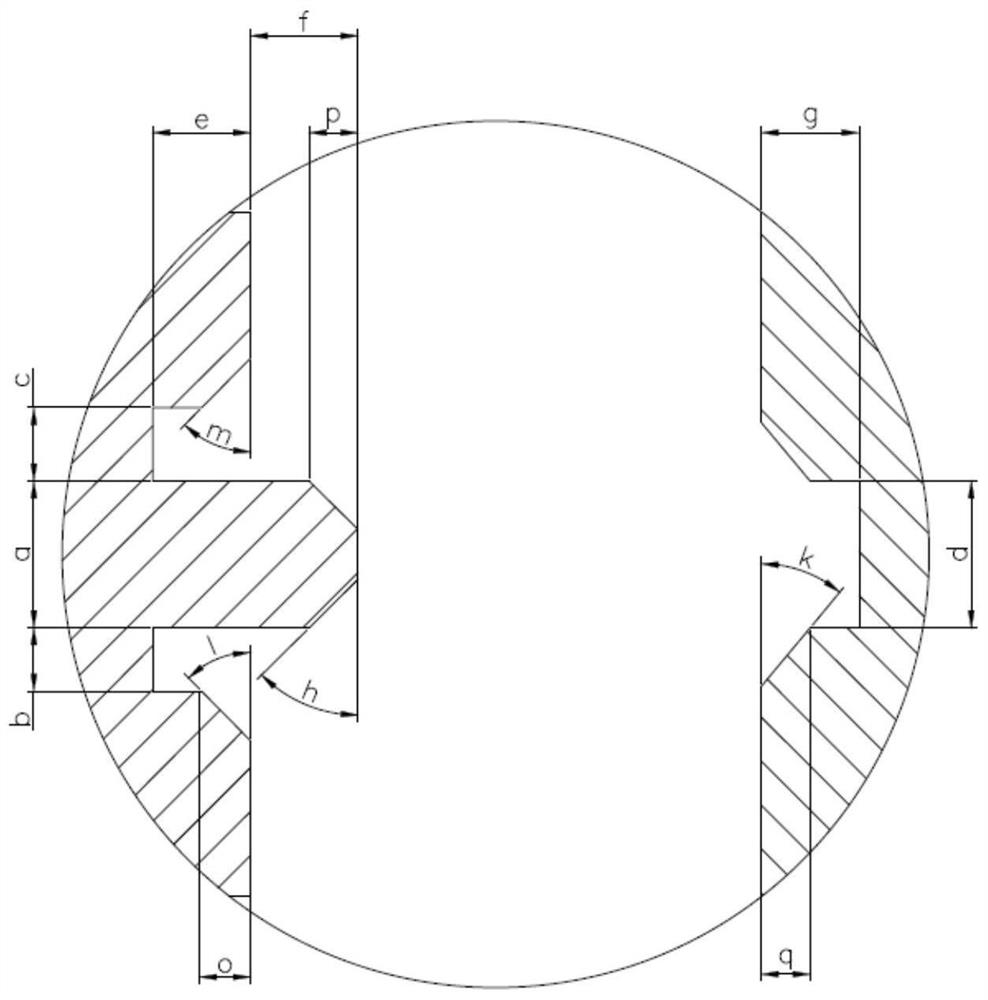

Friction welding method for bidirectional embedding and mechanical reinforcing of heterogeneous materials

ActiveCN113967785AImprove welding effectReduce stressNon-electric welding apparatusFriction weldingStructural engineering

The invention provides a friction welding method for bidirectional embedding and mechanical reinforcing of heterogeneous materials. The method sequentially comprises the following steps that S001, structural design of a welding joint is carried out; S002, a welding clamping tool carries out machining; S003, treatment before welding is conducted; S004, friction welding is carried out; and S005, post-welding treatment is carried out. According to the method, welding joint structures of an inner groove (11), a boss (12) and an outer groove (13) are sequentially machined on a to-be-welded end face of a hard material with high strength and high hardness from a central shaft to the outside, and a welding joint structure of a welding groove (21) is machined on a to-be-welded face of a soft material with low strength and low hardness. W-shaped two-way embedding and mechanical reinforcing between the heterogeneous materials is achieved, the welding area is gradually increased to improve welding forming and promote improvement of the welding capacity, the problems that after the heterogeneous materials are welded, a connector is low in axial and radial strength, poor in toughness, large in stress and the like are effectively solved, the welding efficiency is high, and the welding quality is good.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

A processing device for preparing square tubes with thin-walled belt materials

InactiveCN104625753BEasy to weldEasy to weld and formOther manufacturing equipments/toolsEngineeringLubricant

The invention discloses a machining device of square tubes made of thin-wall strips and belongs to the technical field of square tube forming equipment. According to the strip conveying direction, the machining device mainly comprises a strip decoiling device, a primary buffering device, an active strip conveying device, a secondary buffering device, a strip surface lubricant coating device, a forming device, a tube blank shaping device, a high-frequency welding device, a post-welding cooling device, a surface residual liquid removing device, a square tube shaping device and a cutting device which are arranged in sequence. The machining device solves the technical problems that existing thin-wall square tubes are poor in forming quality and low in production efficiency, and the machining device is widely applied to manufacturing the thin-wall square tubes.

Owner:佛山市九钢制管有限公司

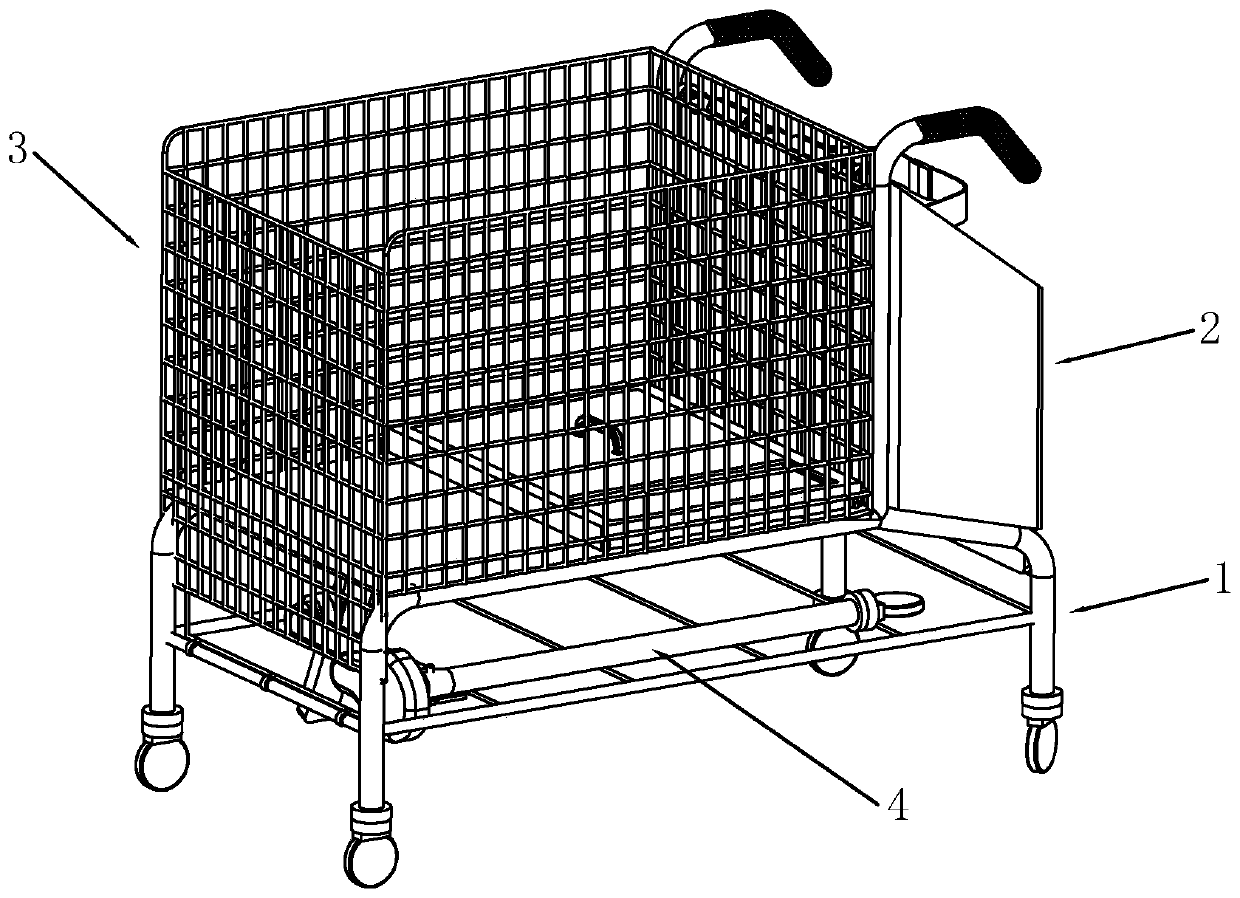

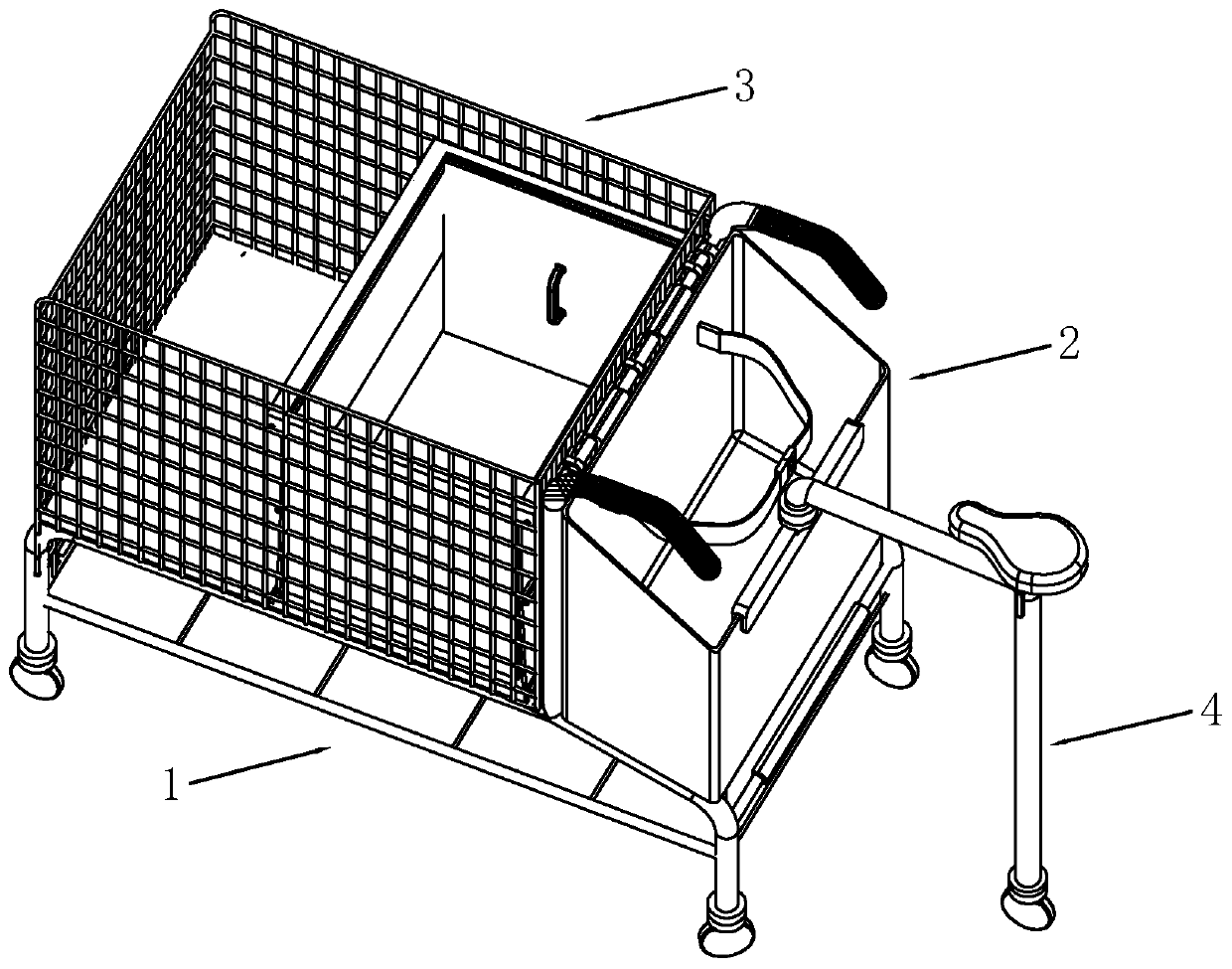

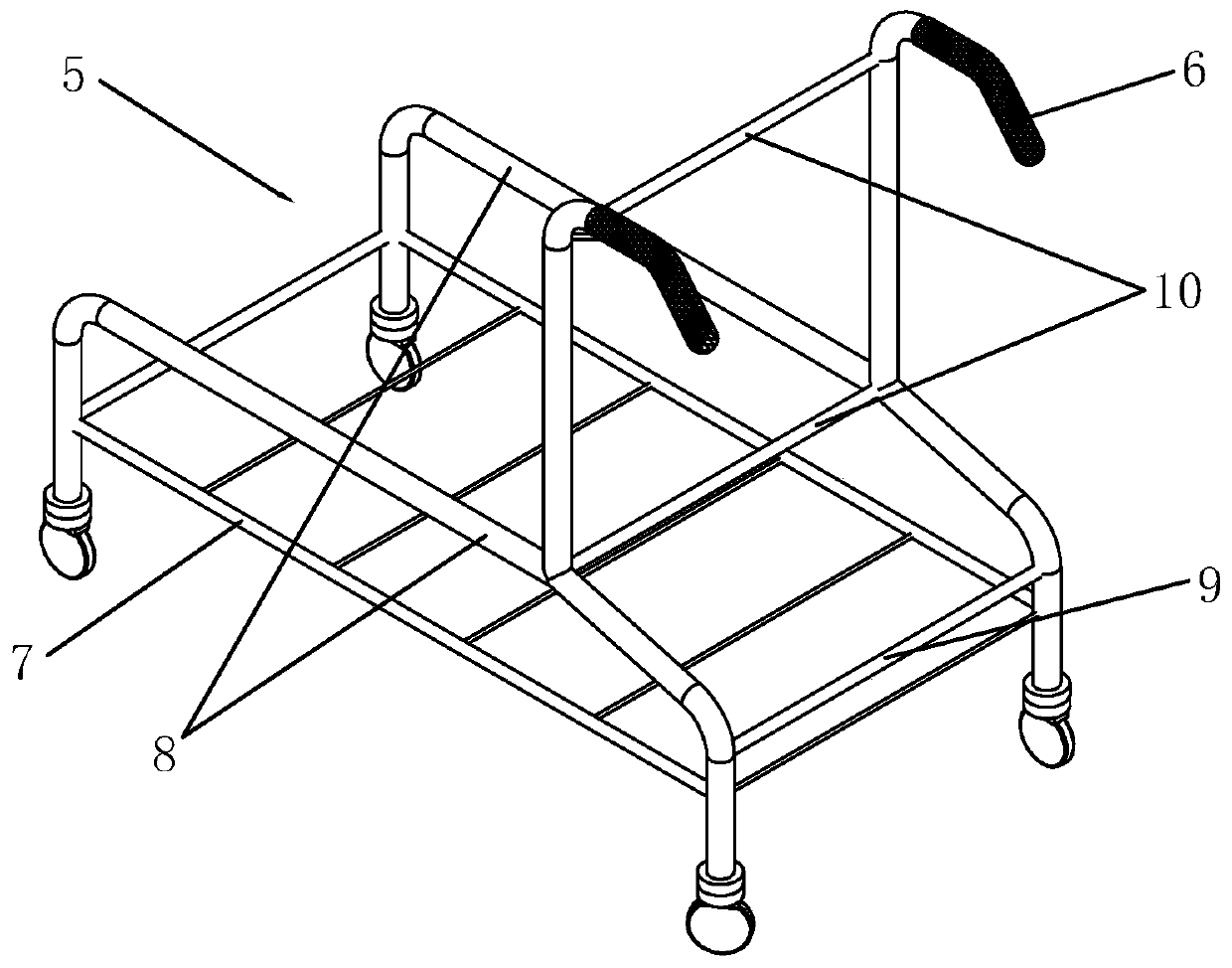

Multifunctional cart used in supermarket

InactiveCN109910965AEasy to install and disassembleFor quick maintenanceHand carts with multiple axesHand cart accessoriesCartHandrail

The invention provides a multifunctional cart used in a supermarket, and aims to solve the technical problems that the conventional cart is too simple, the space of shopping articles can be greatly occupied if a shopper puts a baby into the cart, in addition, potential safety danger can be caused if the baby sits in the cart, the shopper needs to take care of the baby all the time and cannot focuson shopping, and the like. The multifunctional cart used in the supermarket comprises a moving base, a baby tank, a chair and a shopping frame, wherein the moving base comprises a base frame and a handle; the base frame comprises a bottom plate, a fixing rack, a first support rod and a second support rod; the bottom plate is horizontally arranged; the fixing rack is vertically fixed on the bottomplate; the first support rod is horizontally fixed on the fixing rack; the second support rod is horizontally fixed on the fixing rack; the second support rod is positioned above the first support rod; the handle is fixed at the upper end of the fixing rack; an anti-sliding sleeve is arranged on the handle. The multifunctional cart has the advantages of being good in functionality.

Owner:陈科

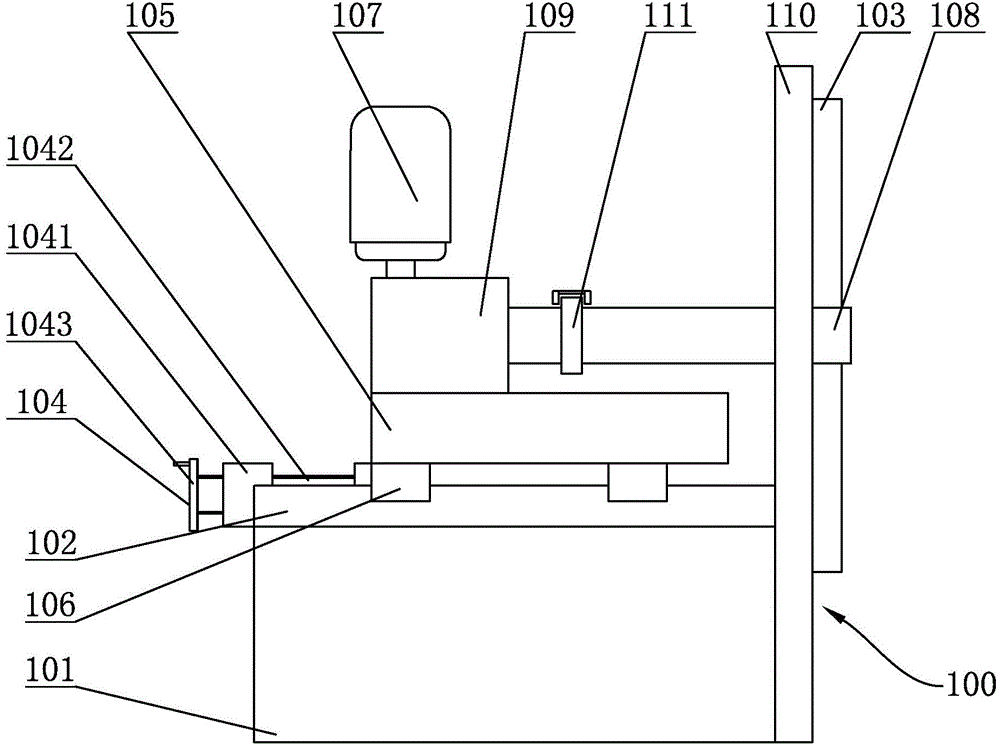

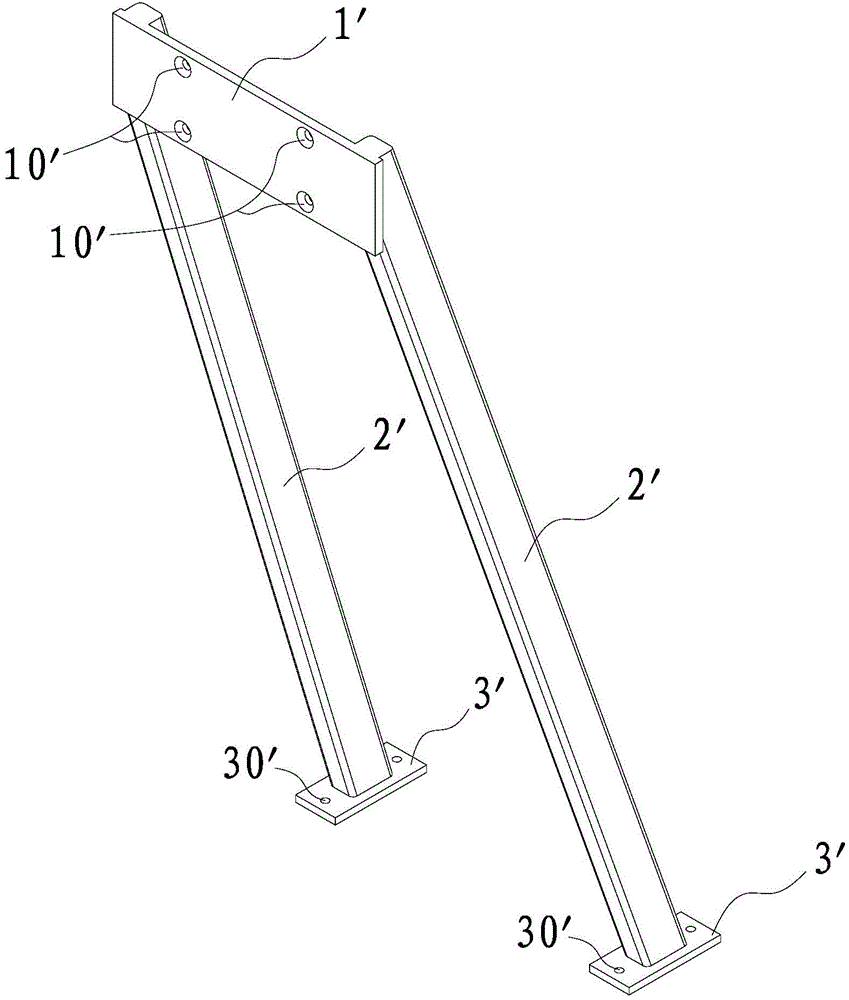

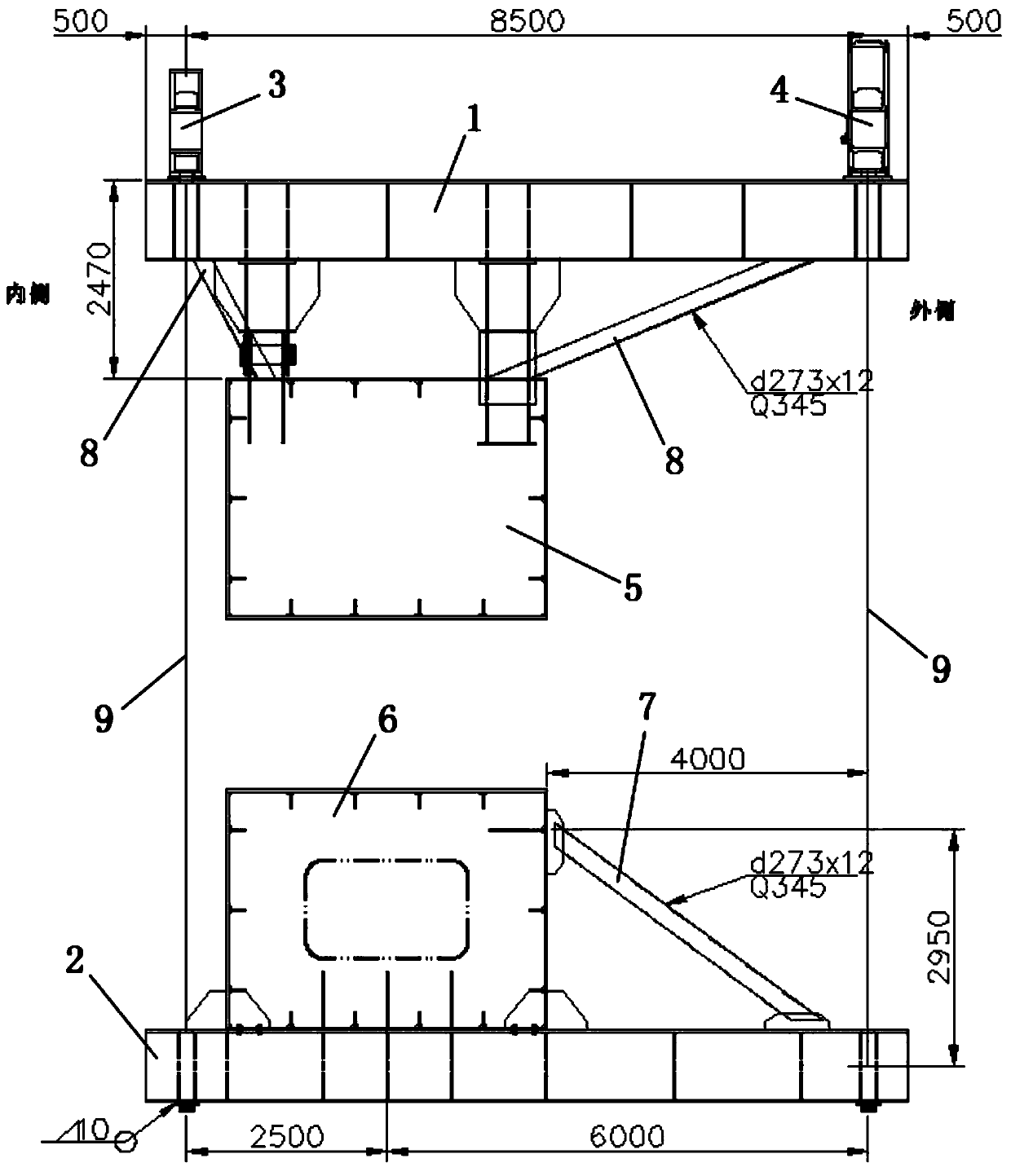

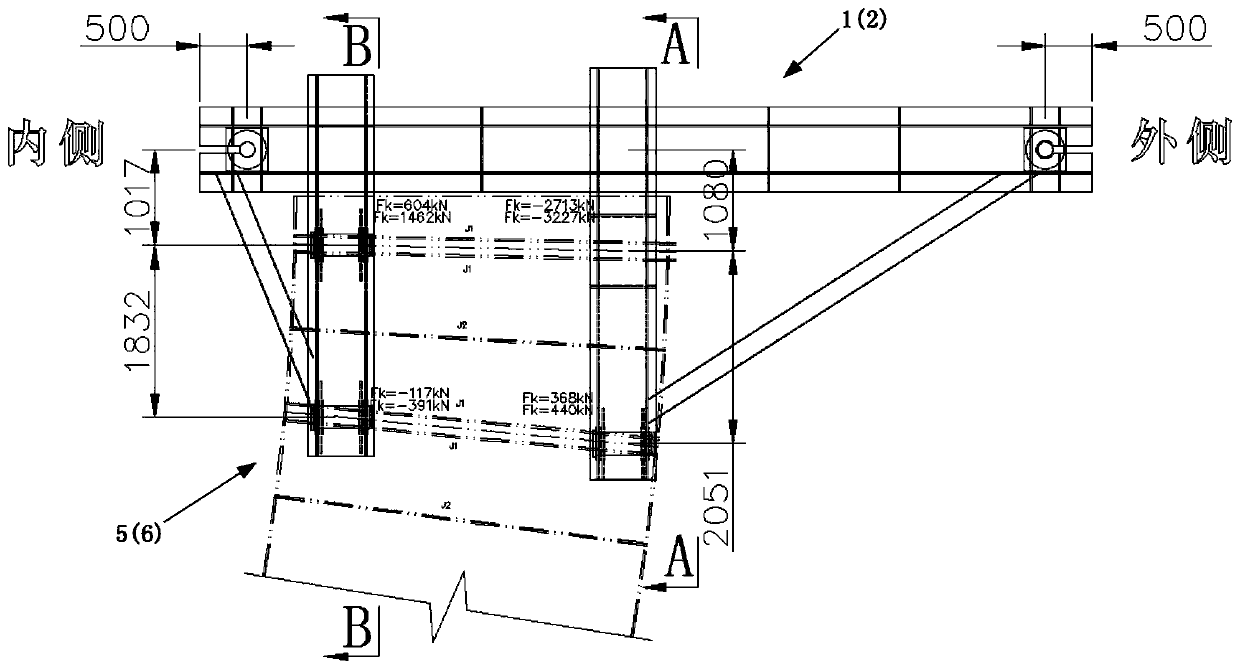

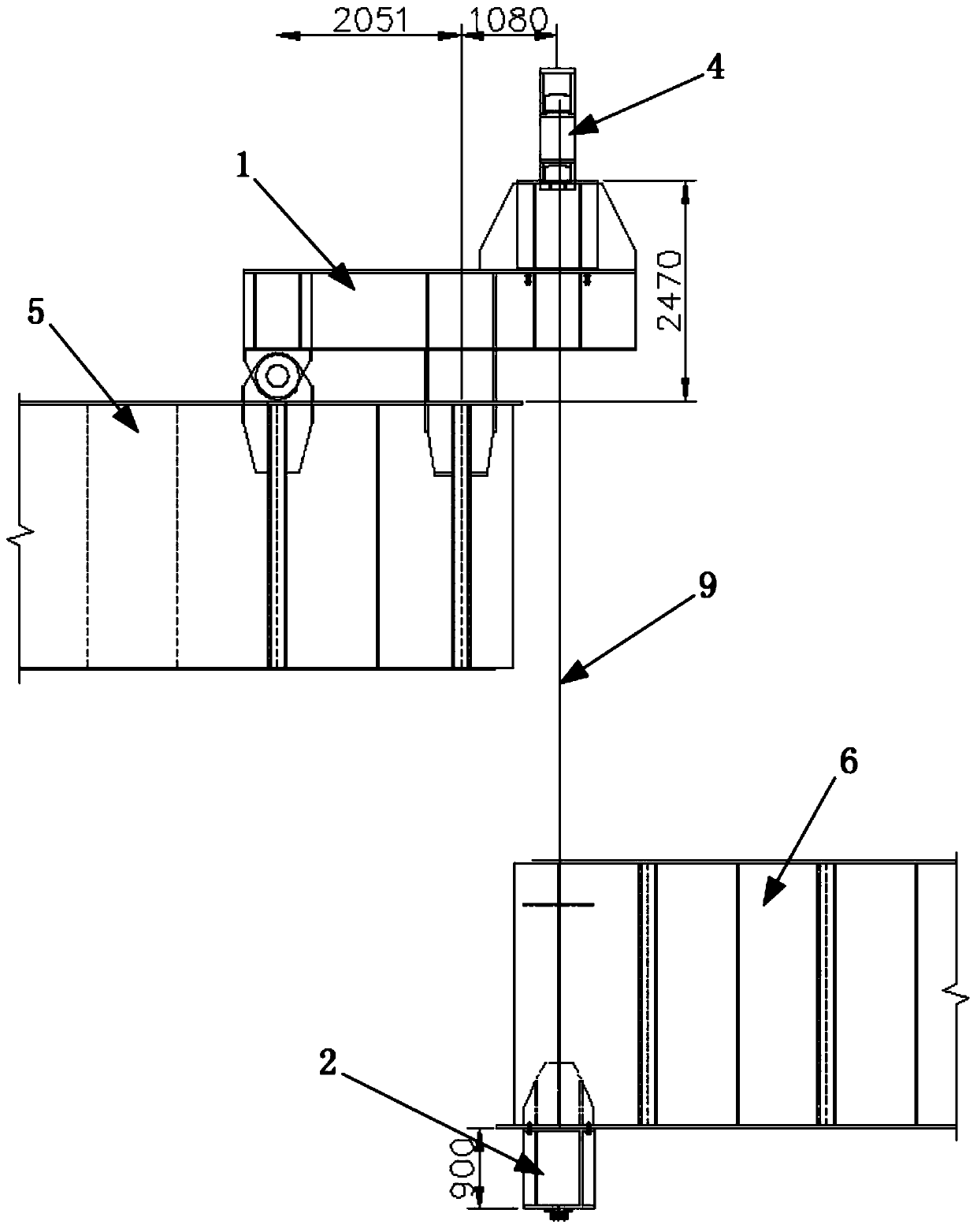

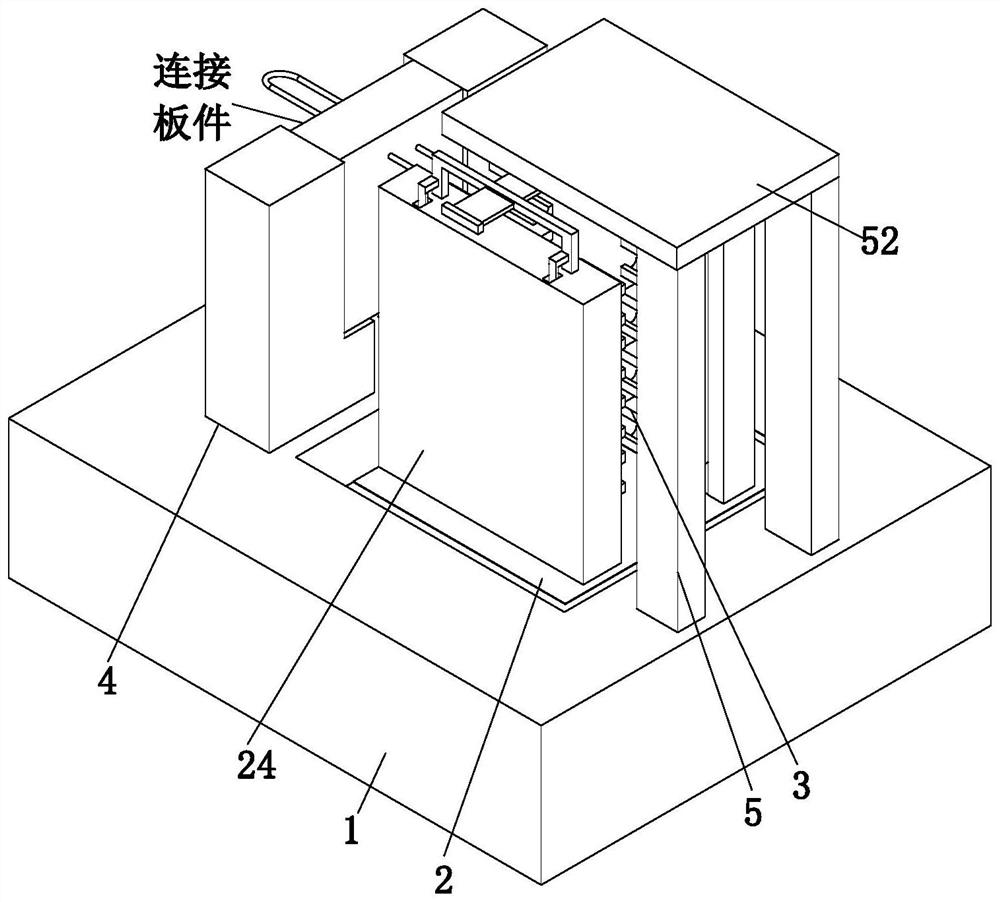

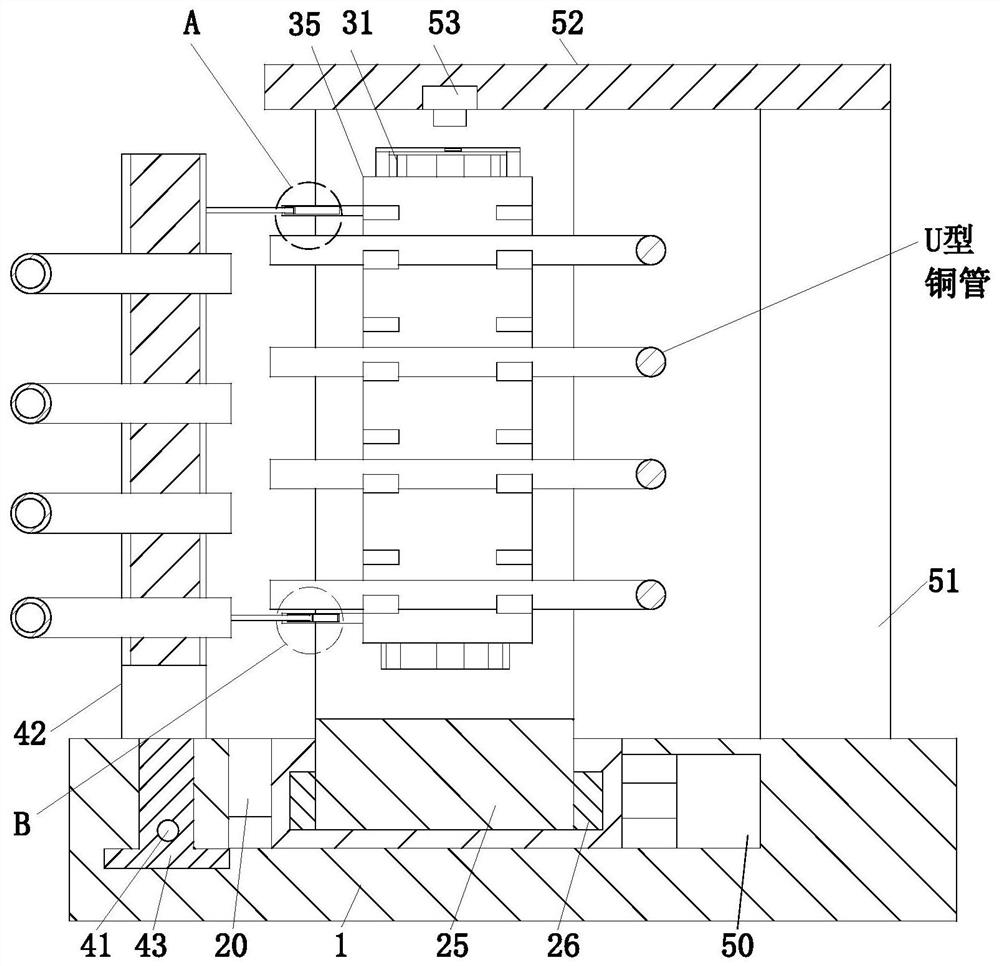

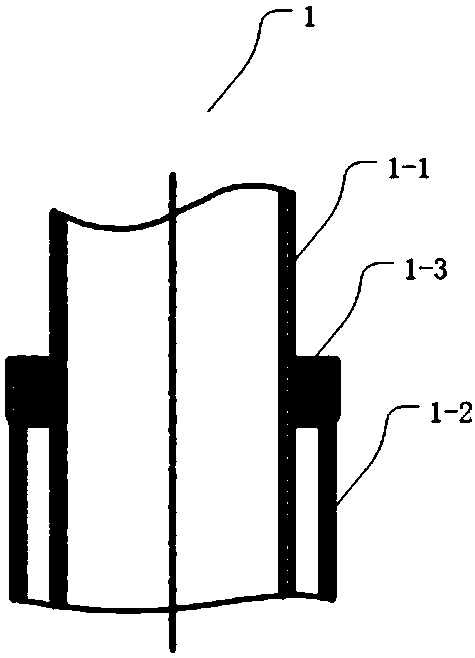

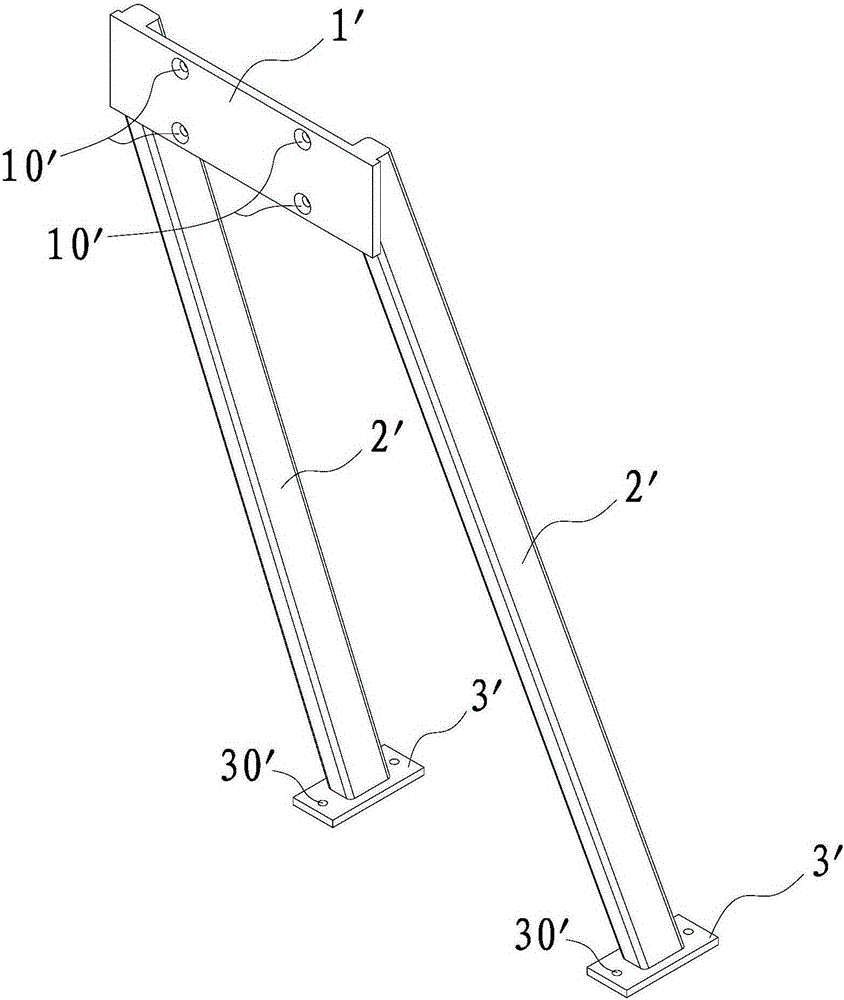

Clamp formed by welding inclined strut special for lifter

ActiveCN104526233AEasy to weld and formSimple structureWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsMechanical engineering

The invention relates to a clamp formed by welding an inclined strut special for a lifter. The inclined strut comprises an upper mounting plate, jackstays and a lower mounting plate, wherein a first connecting hole and a second connecting hole are formed in the upper mounting plate and the lower mounting plate respectively; the clamp comprises a clamp body, a positioning bolt, a positioning template and a positioning hole formed in the positioning template; an inclined plane is arranged on the clamp body, the positioning bolt is perpendicularly arranged on the inclined plane, the inclined plane and the positioning template are perpendicular to each other, the upper mounting plate is fixed on the positioning bolt through the first connecting hole, and the two ends of the upper mounting plate extends out of the clamp body; the lower positioning plate corresponds to the positioning hole through the second connecting hole and is fixedly connected with the positioning hole by using an out-connection piece, a spacing frame used for separating the two jackstays is further arranged on the clamp plate, and the side portions of the jackstays abut against the spacing frame and the two ends of the jackstays make full contact with the upper mounting plate and the lower mounting plate respectively. The clamp formed by welding an inclined strut special for the lifter can rapidly complete positioning of the upper mounting plate, the lower mounting plate and the jackstays. The welding fabrication of the inclined strut is very convenient.

Owner:苏州威尔特铝合金升降机械有限公司

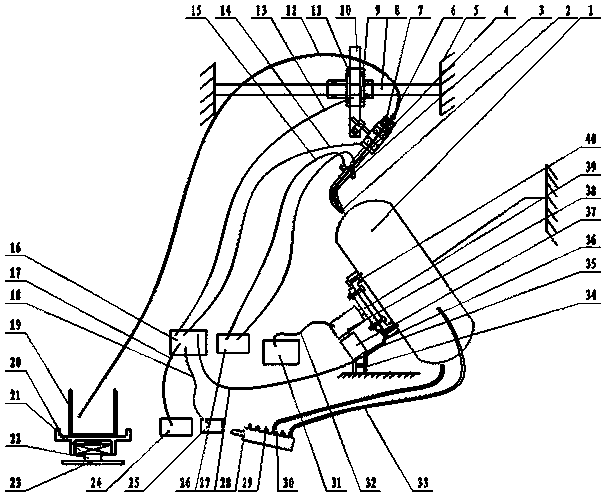

Eccentric arc-shaped ring corridor segment high-altitude lifting tool and lifting method thereof

PendingCN110293341ASimple structureScientific and reasonable designWelding/cutting auxillary devicesLifting framesEngineeringCantilever

The invention discloses an eccentric arc-shaped ring corridor segment high-altitude lifting tool and a lifting method thereof. The problem that when an eccentric arc-shaped ring corridor segment in the prior art is lifted, deflection caused by eccentricity causes the condition that opening-aligned welding molding cannot be achieved after lifting is solved. The high-altitude lifting tool comprisesupper lifting outwards-extending type cantilever steel beams, lower lifting outwards-extending type cantilever steel beams, first lifting oil cylinders and second lifting oil cylinders. The lifting method mainly comprises the steps of correspondingly installing the upper lifting outwards-extending type cantilever steel beams and the lower lifting outwards-extending type cantilever steel beams on high-altitude arc-shaped ring corridor segments and eccentric arc-shaped ring corridor segments correspondingly, the lower lifting outwards-extending type cantilever steel beams are connected with thefirst lifting oil cylinders and the second lifting oil cylinders through steel wire ropes, and then the eccentric arc-shaped ring corridor segments can be raised to the 100 m high altitude at the constant speed and are in opening-aligned connection with the two high-altitude arc-shaped ring corridor segments for welding and fixing. The outwards-extending type cantilever steel beams are arranged toadjust the core positions of the eccentric arc-shaped ring corridor segments, it is ensured that the eccentric arc-shaped ring corridor segments do not deflect during lifting, safety in the lifting process is ensured, and smooth aligned welding after lifting in place is achieved.

Owner:CHINA MCC5 GROUP CORP

Both-way stainless steel pipe welding method

ActiveCN107309529AImprove mechanical propertiesEasy to weld and formArc welding apparatusWelding/soldering/cutting articlesHydrogenNitrogen

The invention discloses a both-way stainless steel pipe welding method. The method comprises the steps that firstly, first-time welding is conducted, nitrogen and hydrogen mixed gas serves as front protection gas, the welding speed ranges from 150 mm / min to 170 mm / min, the temperature at the welding position is controlled to range from 200 DEG C to 230 DEG C, and after the process is finished, leading-in of back protection gas continues till the temperature at the welding position is lowered to 150-170 DEG C; secondly, second-time welding is conducted, nitrogen and hydrogen mixed gas serves as front protection gas, the welding speed ranges from 200 mm / min to 230 mm / min, the temperature at the welding position is controlled to range from 280 DEG C to 290 DEG C, and after the process is finished, leading-in of back protection gas continues till the temperature at the welding position is lowered to 270 DEG C; thirdly, third-time welding is conducted, and the temperature at the welding position is controlled to range from 270 DEG C to 273 DEG C; and fourthly, passivation treatment is conducted on the welding position. According to the both-way stainless steel pipe welding method, welding forming is improved, and damage to compositions of original materials at the welding position is reduced.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

Large-size aluminum-steel reaction auxiliary heating and toughening friction welding method

ActiveCN113967784AGrain refinementImprove toughnessNon-electric welding apparatusFriction weldingUltimate tensile strength

The invention provides a large-size aluminum-steel reaction auxiliary heating and toughening friction welding method. According to the method, two-way embedded structure design is conducted on a welding joint of an aluminum component (20) and a steel component (10), and a welding auxiliary layer is arranged at the welding joint. According to the two-way embedded structure design, specifically, an annular steel inner groove (11), an annular steel boss (12) and an annular steel outer groove (13) are sequentially machined in the to-be-welded face of the steel component (10) from a center shaft to the outside, and an annular aluminum groove (21) is machined in the to-be-welded face of the aluminum component. The welding auxiliary layer comprises a reaction transition layer (51), a reinforcing and toughening layer (52) and a reaction auxiliary heating layer (53). The method effectively solves the problems that in the welding process of the steel component and the aluminum component, a large number of brittle intermetallic compounds are likely to be generated, the stress of a welded joint is large, the strength of the welded joint is low, and toughness is poor, friction welding between the large-size aluminum component and the large-size steel component is achieved, the welding efficiency is high, and the welding quality is good.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Open arc on-line surfacing repair device and method for grinding roller of medium-speed mill

PendingCN110539124ASave human effortSave moneyCooled electrode holdersWelding accessoriesSurface layerMaterial resources

The invention relates to an open arc on-line surfacing repair device and method for a grinding roller of a medium-speed mill. The open arc on-line surfacing repair device comprises a PLC welding control box, and an electric welding machine, a welding trolley, a double-drive wire feeder and a limit switch which are connected with the PLC welding control box. A grinding roller driving device is arranged at the bottom of the grinding roller; a welding gun is arranged on the surface of the grinding roller; the rear end of the welding gun sequentially communicates with the double-drive wire feederand a welding wire straightening mechanism through a connecting rod; a welding wire placed on a wire feeding device penetrates into a wire inlet of the welding wire straightening mechanism; and the double-drive wire feeder is mounted on the welding trolley through a welding gun angle adjusting mechanism. On-line surfacing repair is carried out on the grinding roller without disassembling the grinding roller, so that a large amount of manpower and material resources are capable of being saved and the repair period is capable of being shortened. The open arc on-line surfacing repair method mainly ensures that each performance of a surfacing layer meets repair requirements by selecting welding parameters and welding modes.

Owner:甘肃酒钢集团西部重工股份有限公司

Welding process for stiffener rings between topside blocks and jackets

The invention relates to a process for welding reinforcing rings between a topside module and a jacket. The process includes the following steps: (1) one reinforcing ring serves as a unit, and welding prefabrication of the reinforcing rings and internal flange rings is carried out on the exterior of the jacket and the exterior of the topside module; when prefabrication is carried out, one reinforcing ring is divided into a plurality of arc-shaped plates, and then the multiple arc-shaped plates are spliced together to form the overall reinforcing ring; (2) the flange rings are placed on a potension meter, and are welded to the arc-shaped plates through a submerged arc welding machine to conduct pairing; (3) K-shaped notches are formed in the edges of the outer sides of the reinforcing rings, the flange rings are clamped through clamps, and then the reinforcing rings are placed into pipes to conduct pairing; (4) reputedly executing the step (1) and the step (2) until the overall welding process is completed. By means of the process, a large amount of in-pipe welding work is avoided, the operation environment of an operator is improved, and the operation safety is greatly improved. In addition, the requirement for operating skills of the operator is greatly reduced, and the construction efficiency is greatly improved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

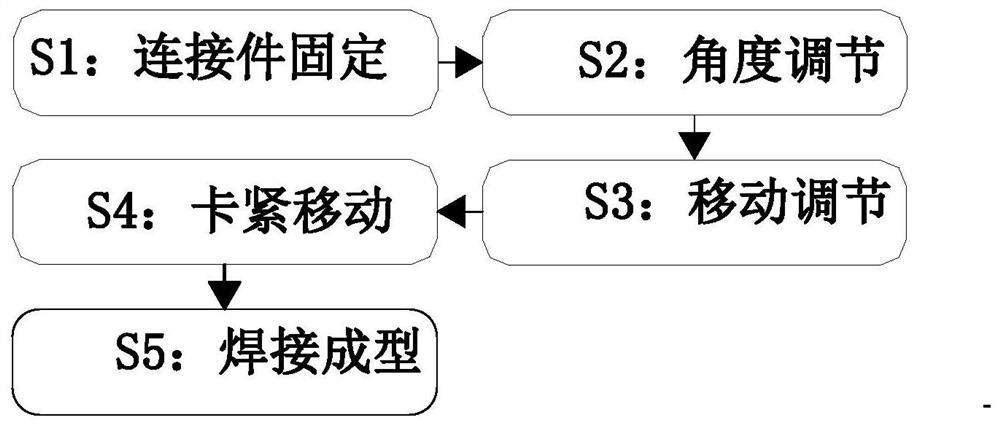

A Welding Forming Process for Fabrication of Pipe Truss Steel Structure

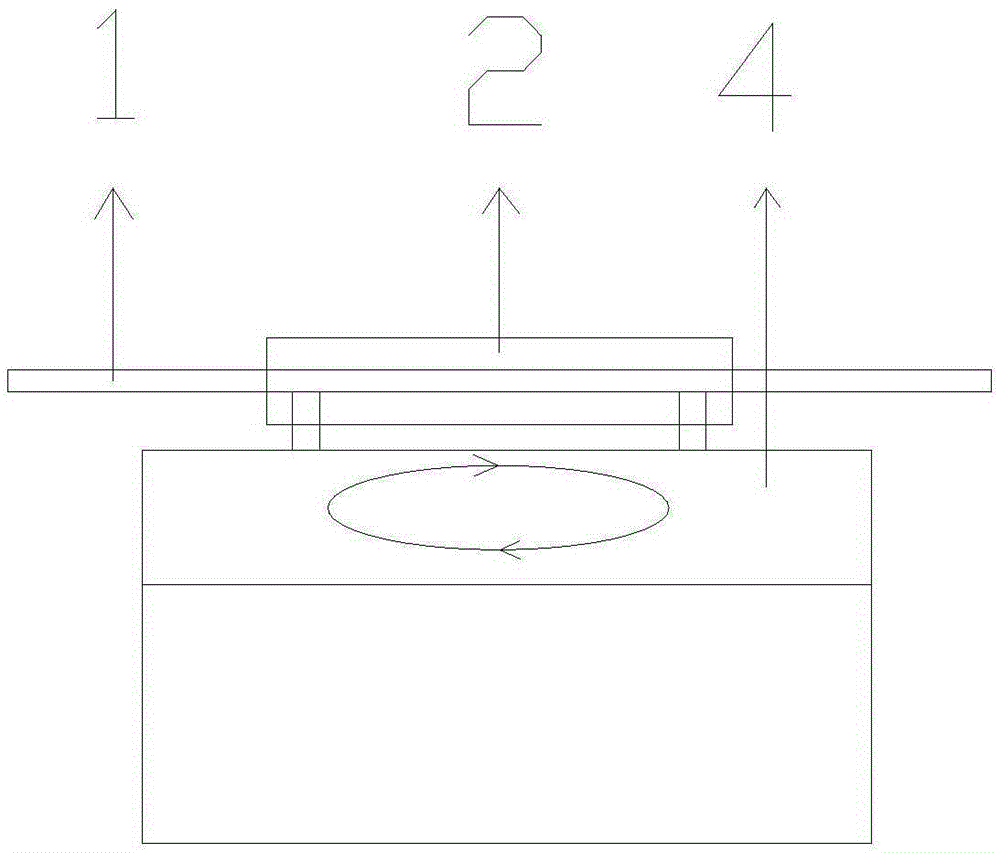

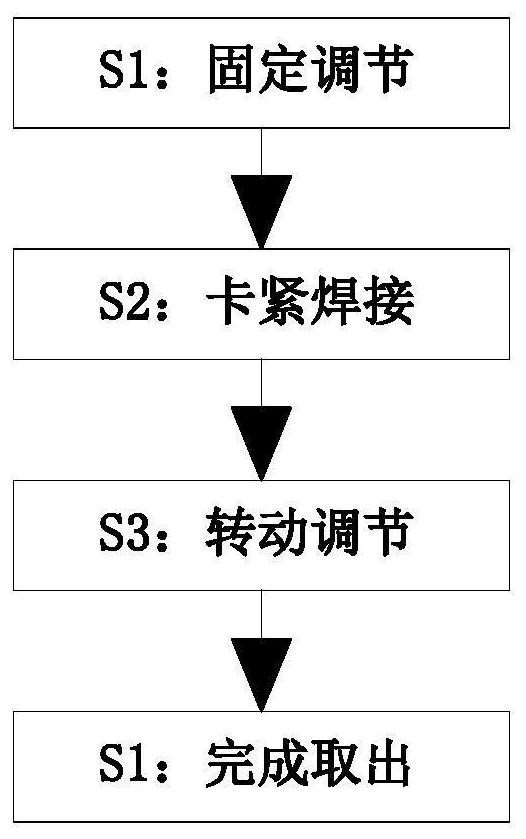

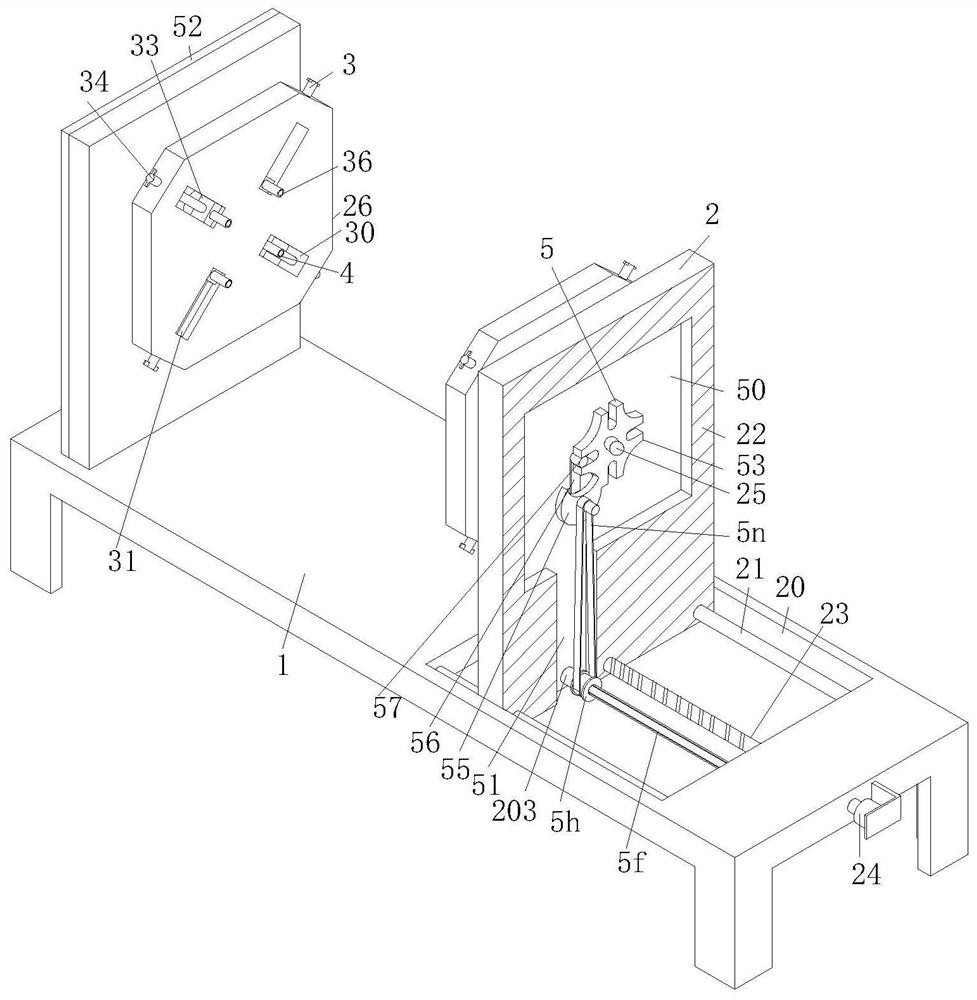

ActiveCN113210914BEasy to weld and formImprove welding convenienceWelding/cutting auxillary devicesAuxillary welding devicesWeldingManufacturing engineering

The invention relates to a welding and forming process for making a steel structure of a pipe truss, which uses a welding and forming device for making a steel structure of a pipe truss. and a rotating mechanism, the upper end surface of the workbench is provided with a fixing mechanism, an adjusting mechanism and a rotating mechanism are arranged on the fixing mechanism, and a locking mechanism is arranged on the adjusting mechanism, and the locking mechanism adopted in the present invention can lock one end of the pipe truss Fix on the positioning hollow column, and then adjust the distance between the pipe truss rods sleeved on the positioning hollow column through the adjustment mechanism, which can be fixed for different sizes of pipe trusses, which is convenient for operators to weld the pipe trusses At the same time, the rotating mechanism can drive the pipe truss to rotate, avoiding rotating welding around the welding shape of the pipe truss, thereby improving the welding convenience of the welding personnel.

Owner:山东华亿钢机股份有限公司

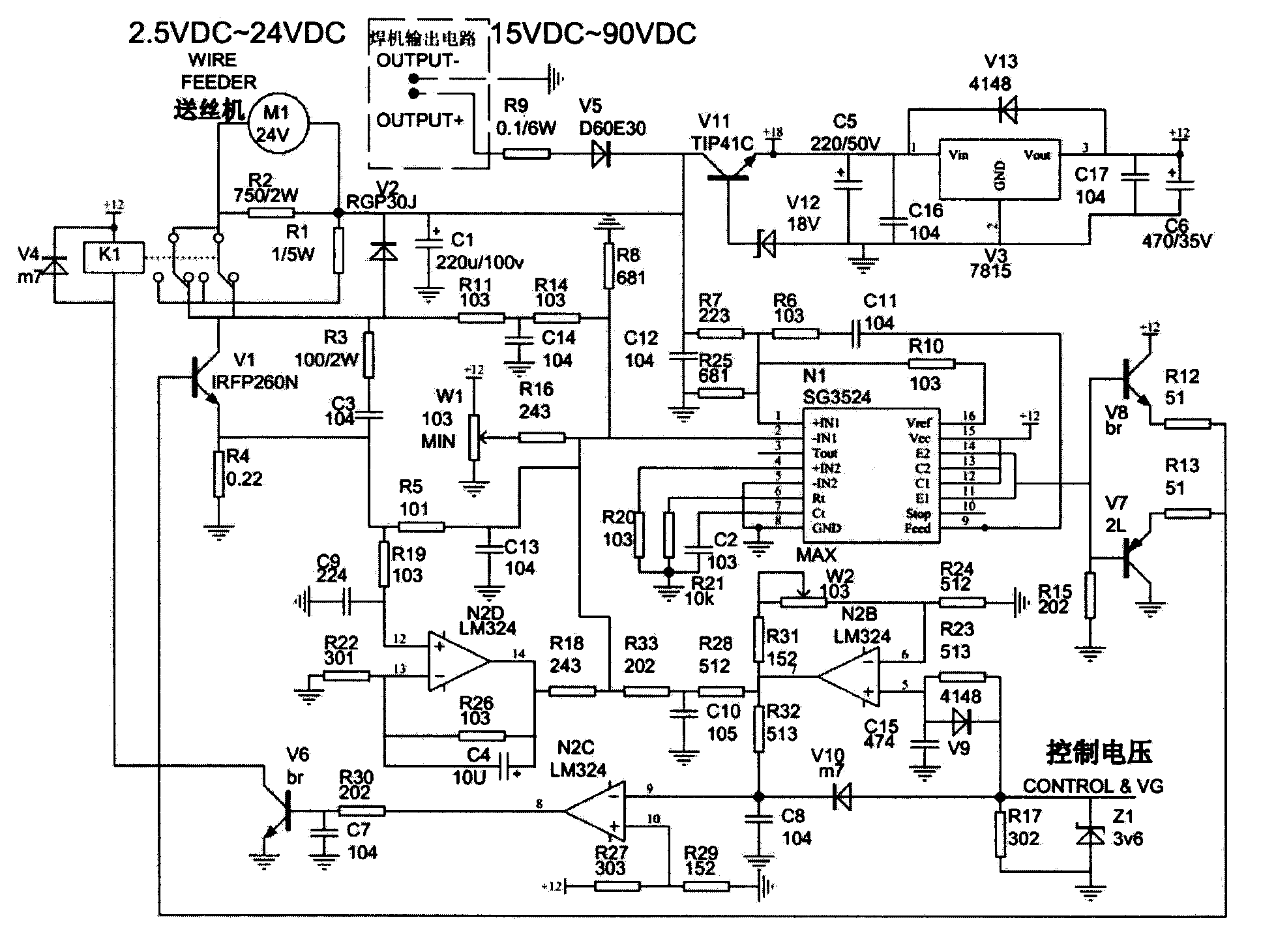

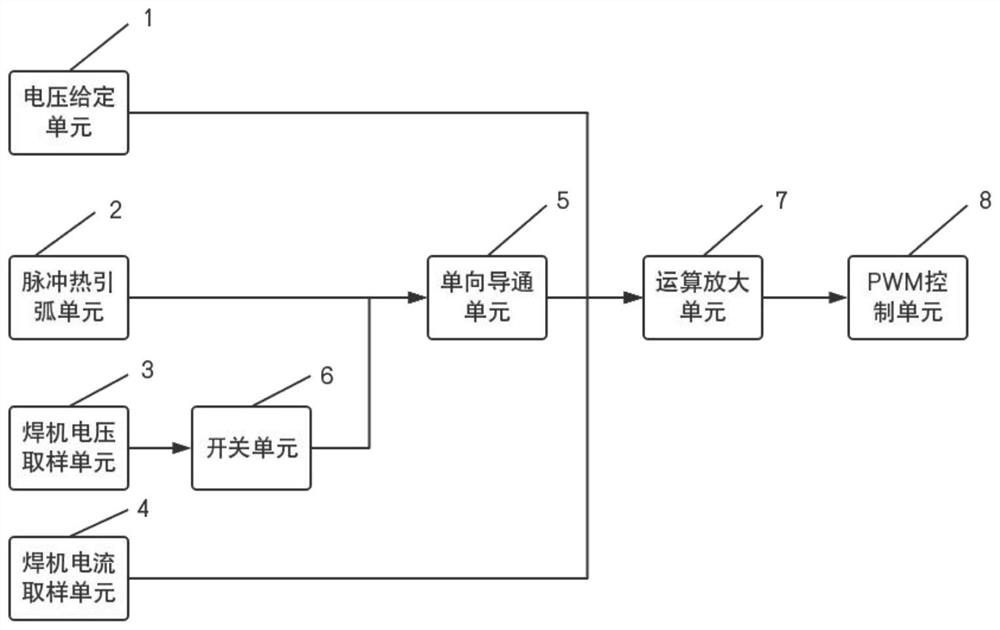

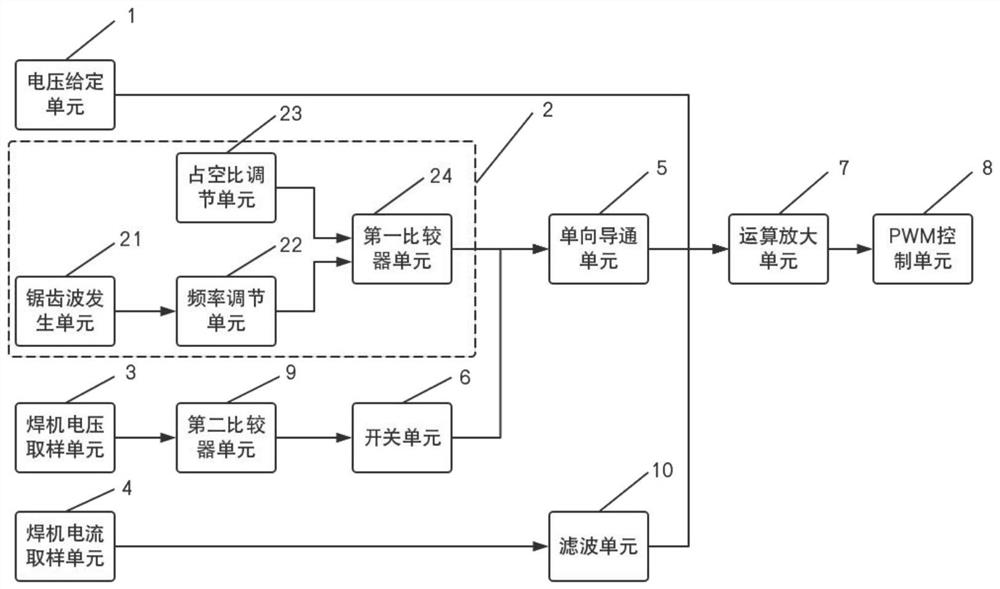

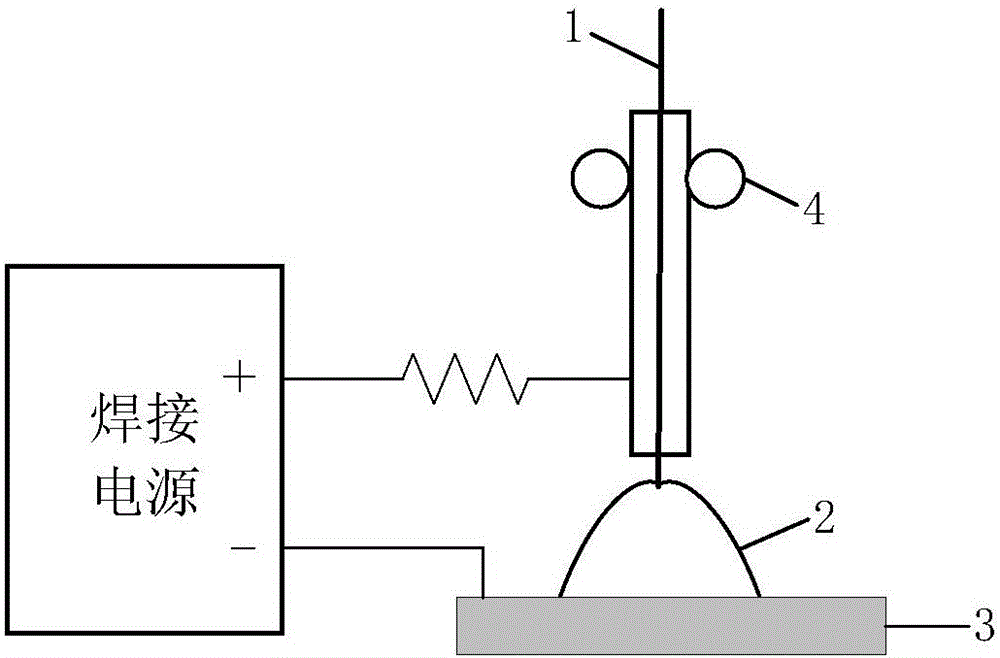

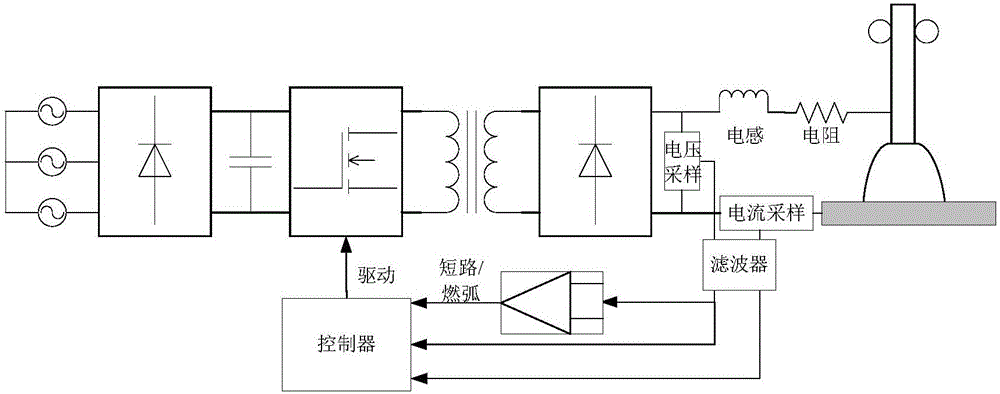

Wire feeder control circuit

ActiveCN103084707BImprove output efficiencyAvoid disturbanceArc welding apparatusControl theorySingle chip

The invention relates to a wire feeder control circuit. The wire feeder control circuit comprises a power source, a single chip microcomputer and a wire feeder. Output voltage of the power source is output voltage of a welding machine, is rectified and filtered through V5 and C1 and is divided into two branches. One branch of the output voltage is used by the power source as a main power source. The other branch of the output voltage passes through V11 and V12 and provides direct current of +18V and +12V as a power source of a control loop. The power source is connected with an end 1 of the single chip microcomputer through R7, and ends from 11 to 14 of the single chip microcomputer are connected with the wire feeder after passing through V7, V8, R12, R13 and V1. Compared with the prior art, arc voltage of the welding machine is used as the power source, high and low states of the arc voltage limit the upper limit of wire feeding speed at the same time, and welding wires can be prevented from being bonded to work-pieces effectively. The wire feeding speed disturbs along with changes of the arc voltage, melting point transition is benefited, welding spatter is reduced, and welding forming is improved. Besides, output efficiency of the welding machine is improved, cost is reduced, and a wire feeding circuit can be arranged in an integrated machine and can be arranged in the wire feeder, and is not restrained by the length of connecting wires.

Owner:NANTONG FREE MECHANTRONIC CO LTD

A fixture specially used for the welding and forming of the escalator of the elevator

ActiveCN104511712BRapid positioningEasy to weld and formWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsEngineering

The invention relates to a fixture specially used for welding and forming an escalator of an elevator. The escalator includes a handrail bar, a cross bar, and a connecting part. The fixture includes a rectangular frame and a plurality of braces arranged in the frame along the width direction rod, and a positioning piece detachably arranged on the pole, the positioning piece includes two positioning blocks respectively arranged on each pole, and a support plate vertically arranged on the pole at the corresponding position of the connecting part, wherein The distance between two positioning blocks on the same support rod is equal to the length of the cross bar and the width of the escalator, and the space between the positioning blocks with different distances between each two positioning blocks forms a space for placing the handrail bar. A plurality of cross bars are erected on the struts respectively, the cross bars provided with the connecting portion and the connecting portion collide against the support plate together, and the rest of the cross bars lean against the sides of the two positioning blocks. The invention can quickly position the handrail bar, the cross bar and the connecting part, is very convenient for the welding and forming of the escalator, and has a simple structure.

Owner:苏州威尔特铝合金升降机械有限公司

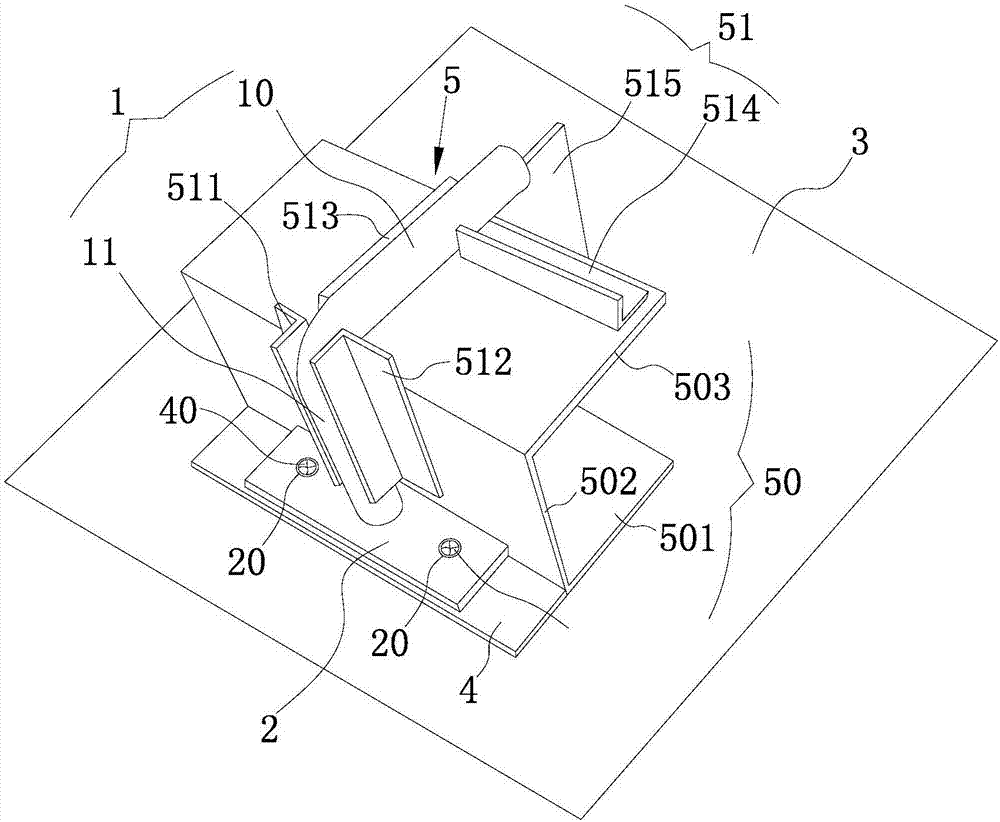

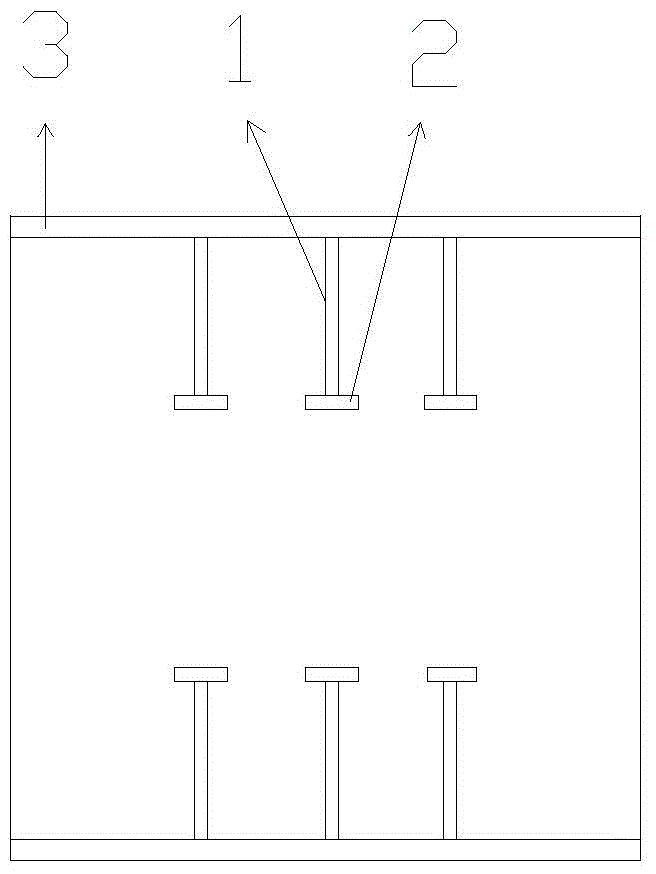

A positioning tool for welding and forming a right angle elbow type connecting seat

ActiveCN106378569BAccurate and fast positioningEasy to weld and formWelding/cutting auxillary devicesAuxillary welding devicesMarine engineeringPositioning system

The invention relates to a positioning tool for welding forming of a quarter bend type connecting base. The connecting base comprises a quarter bend and a connecting piece, wherein the quarter bend is provided with a horizontal part and a vertical part, and the connecting piece is provided with connecting holes. The positioning tool comprises a horizontally-arranged platform, a first positioning base located on the platform and used for placing the connecting piece, and a second positioning base next to one side of the first positioning base so that the vertical part of the placed quarter bend can be perpendicular to the platform, wherein the first positioning base is provided with pilot pins matched with the connecting holes, and when positioning and welding are carried out, the connecting piece is positioned on the first positioning base, the bottom end portion of the vertical part of the quarter bend is erected on the middle portion of the connecting piece located on the first positioning base. The positioning tool can quickly and accurately achieve position of the quarter bend and the connecting piece, and therefore welding forming of the quarter bend type connecting base can be facilitated; and the positioning tool is simple in structure, convenient to implement and low in cost.

Owner:JIANGSU SHA ZHOU ELECTRIC

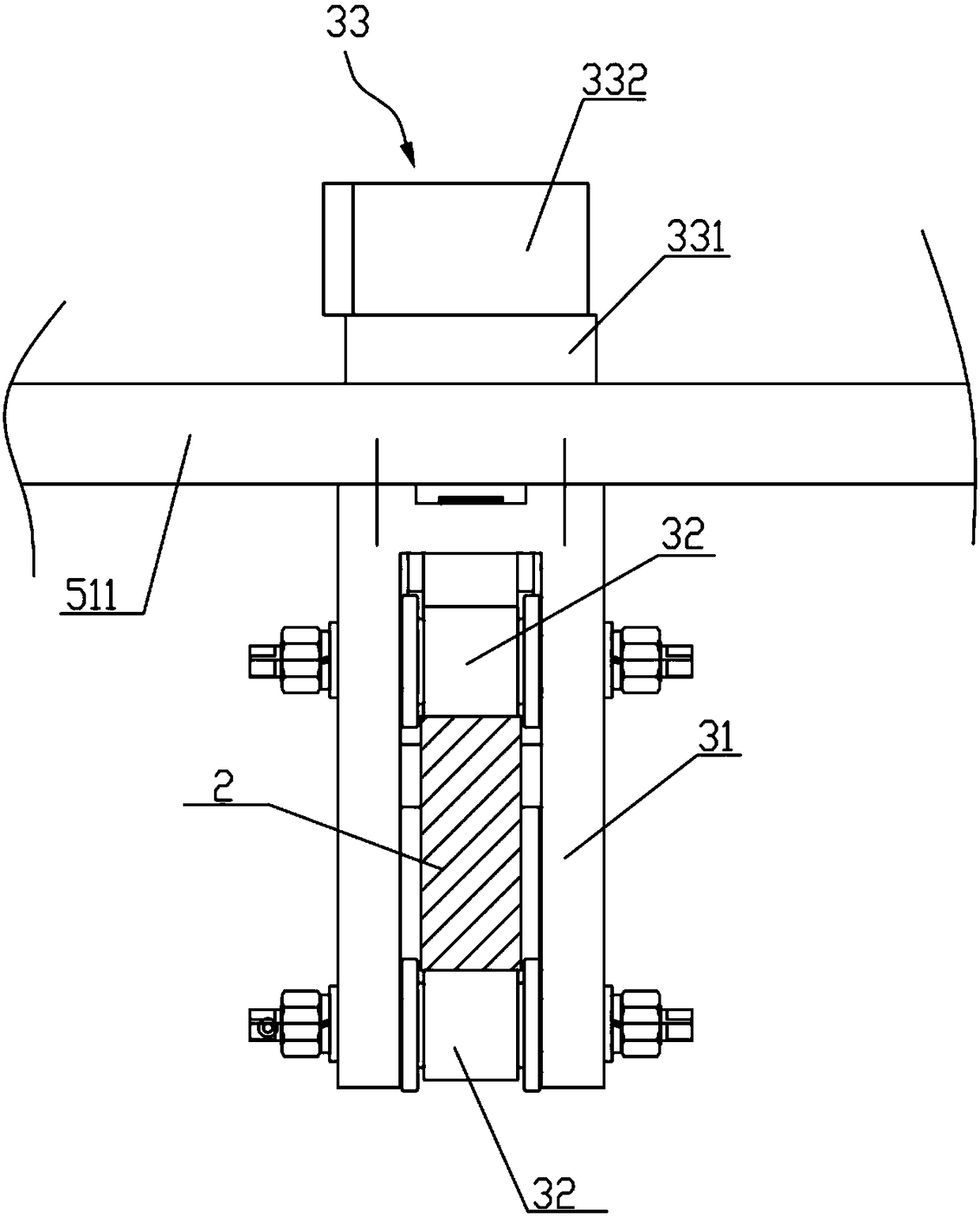

Welding processing technology for copper pipe of air conditioner condenser

InactiveCN112809230AEasy to weld and formAvoid unsafe situationsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining process

Owner:盐城志焕网络科技有限公司

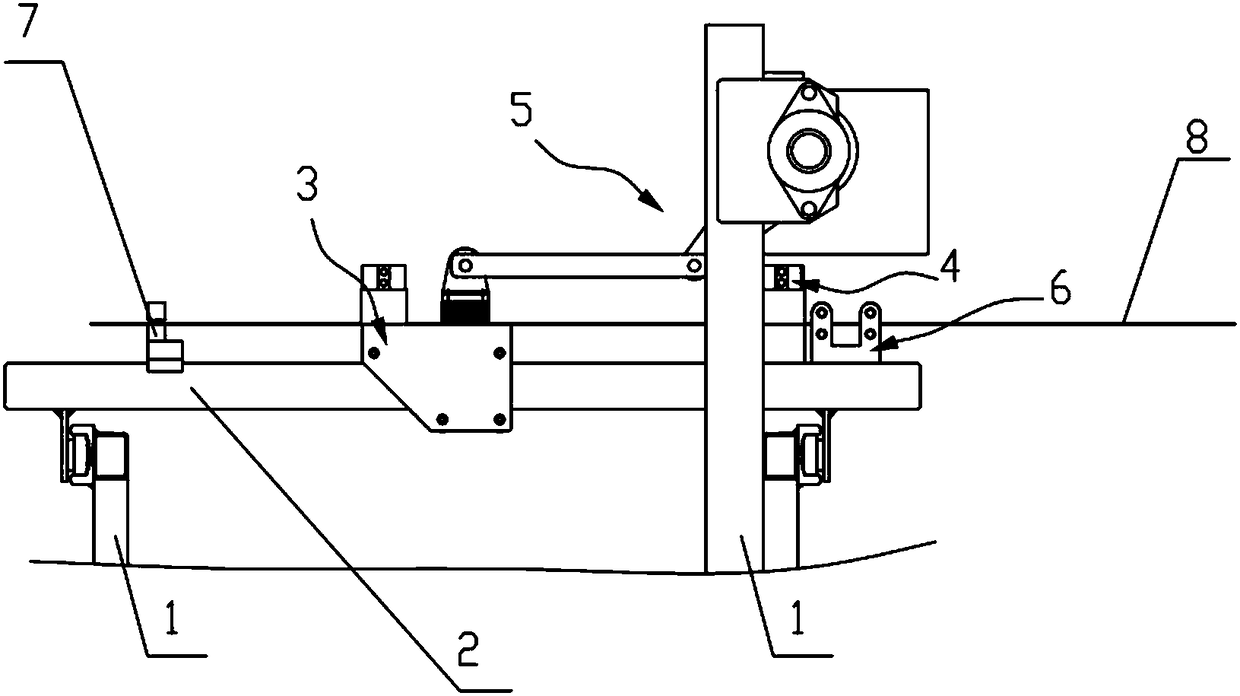

Steel strip feeding mechanism and welding robot provided with same

PendingCN108500521AImplement progressive deliveryEasy to weld and formWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSteel belt

The invention discloses a steel strip feeding mechanism and a welding robot provided with the same and relates to the technical field of steel strip transmission. The steel stripe feeding mechanism comprises a rack, a guide rail, a limiting part and a feeding part, wherein the guide rail is arranged on the rack in the feeding direction of the steel strip; the limiting part is fixed to the guide rail and can limit the steel strip to move in the feeding direction; the feeding part is slidably arranged on the guide rail, and the steel strip can be fixed to the feeding part and can move along withthe feeding part. The welding robot comprises at least one steel strip feeding mechanism. According to the steel strip feeding mechanism, when the feeding part is relatively far from the limiting part, the limiting part fixes the steel strip, the feeding part slides toward the direction close to the limiting part, then the steel strip is fixed to the feeding part, the limiting part loosens the steel strip to feed the steel strip toward the feeding direction along with the feeding part, and the limiting part and the feeding part are matched to transfer the steel strip gradually, so that the steel strip meshes are welded and formed conveniently.

Owner:TJK MACHINERY TIANJIN

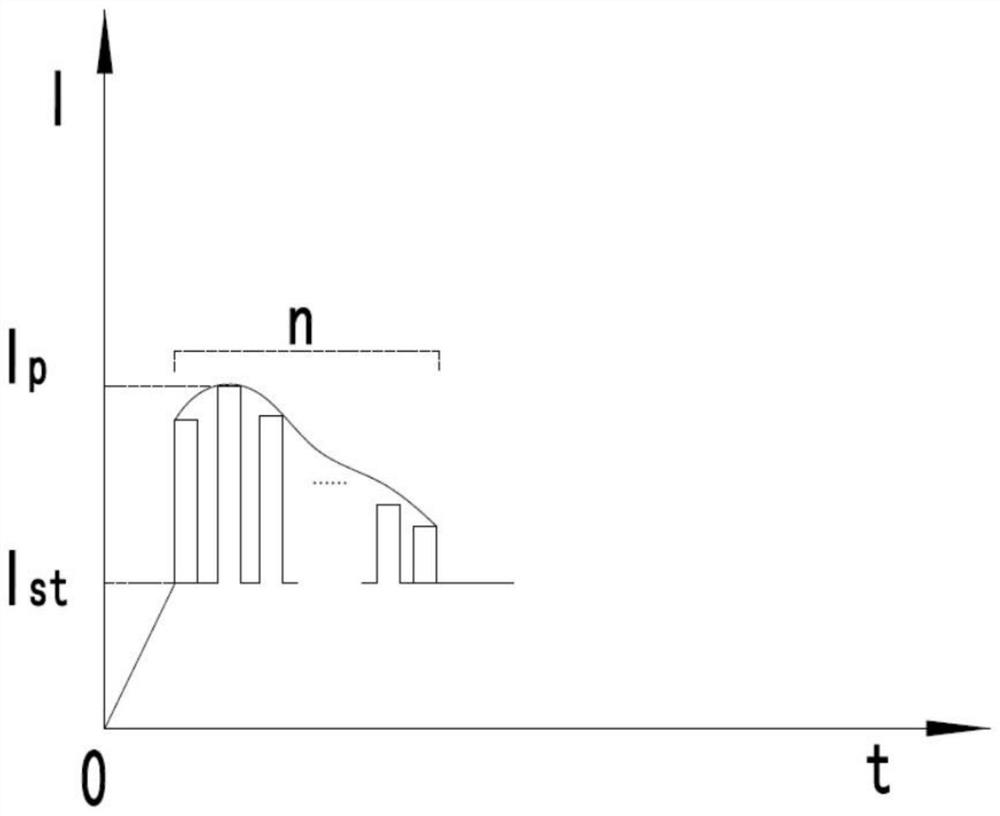

A control method and control system for arc ignition of an inverter manual arc welding machine

ActiveCN110877137BImprove arc striking effectImprove the success rate of arc strikingArc welding apparatusControl systemThin slab

The present invention relates to a control method and control system for arc ignition of an inverter manual arc welding machine. The welding current of the welding power supply becomes the pulse square wave arc ignition current. After the arc ignition of the inverter manual arc welding machine power supply is successful, the pulse thermal arc ignition signal is turned off, and the normal welding current is restored, and the arc burns normally. strike the arc. The invention is suitable for welding plates of different thicknesses, especially suitable for manual arc welding of thin plates, and has the characteristics of easy arc starting, high arc starting success rate, good welding shape, difficult welding deformation and high welding strength.

Owner:SHANGHAI HUGONG ELECTRIC WELDING MACHINE MFG

Method for preparing bottled multi-element mixed gas

ActiveCN102900950BImprove the mechanical properties of the weldGood welding performanceContainer filling under pressureGas cylinderShielding gas

The invention discloses a method for preparing bottled multi-element mixed gas. The method is characterized by comprising the following steps of: (A) connecting a qualified gas bottle to a port of a filling busbar; (B) vacuumizing the gas bottle and a filling pipeline system, and controlling the volume content of oxygen in the gas bottle and the filling pipeline system to be less than and equal to 3*10<-6> and the volume content of water to be less than and equal to 3*10<-6>; (C) filling argon into vacuumized gas bottle to serve as base gas, and controlling pressure in the gas bottle to be 0.1 MPa; (D) filling gas in an argon and nitrogen mixed gas container into the gas bottle in the step (C), and controlling pressure in the bottle to be 0.2 MPa; (E) filling helium into the gas container in the step (D), and controlling pressure in the bottle to be 3.3 MPa; and (F) when the wall of the bottle is cooled to room temperature, filling the argon into the gas bottle in the step (E), and controlling pressure in the bottle to be 9.9 to 10.1 MPa to obtain the helium, nitrogen and argon bottled multi-element mixed gas. The method is mainly applied to protective gas for welding core aluminum alloy parts of high-speed railways.

Owner:HUNAN TIEDA ENERGY TECH

A kind of processing method of thin-walled square tube

The invention discloses a machining method for a thin-wall squared tube and belongs to the technical field of square tube forming processes. The machining method for the thin-wall squared tube mainly includes the following steps that 1 a strip roll is decoiled, wherein the strip roll is unfolded and a strip is discharged; 2 the strip is conveyed actively, wherein the strip is discharged downstream under the action of traction force; 3 buffering speed governing is conducted, wherein the strip is discharged at a constant speed without the action of tensile force, and the active conveying frequency of the strip is controlled; 4 lubricant coating is conducted, wherein the two surfaces of the strip are coated with lubricants; 5 forming is conducted, wherein the strip is gradually bent in a cold mode, so that the strip forms a tube blank with a weld joint and a square section, and the weld joint is located on the upper surface of the tube blank; 6 high-frequency welding is conducted; 7 cooling is conducted; 8 residual liquor is cleaned away; 9 the tube section is accurately shaped; 10 cutting is conducted. The machining method solves the technical problems that existing thin-wall squared tubes are poor in forming quality and low in production efficiency, and the machining method is widely applied to manufacturing thin-wall squared tubes.

Owner:JIANGSU ZHONGHAI HEAVY MACHINE TOOL

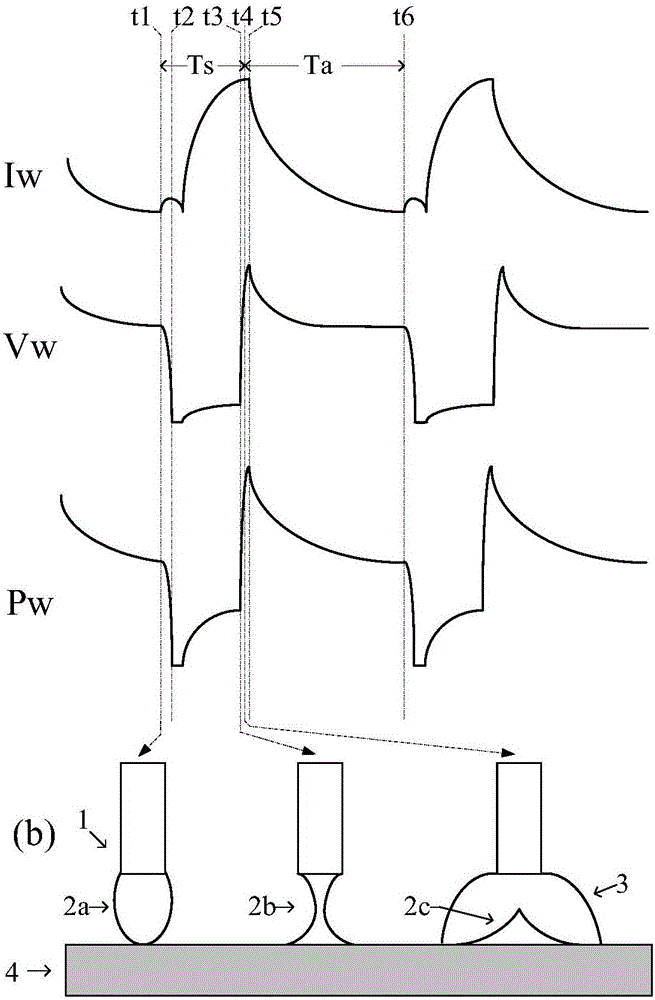

Detection method of droplet necking in molten electrode arc welding

ActiveCN103962686BImprove real-time performanceIncrease authenticityArc welding apparatusPower flowElectric arc

The invention discloses a consumable electrode electric arc welding droplet necking detection method. When welding short circuit and arcing need to be judged in a consumable electrode welding system based on an inverter power supply, sampling is conducted on an output current of the inverted power supply, the variable slope of the output current is calculated, the variable slope of the output current is compared with a short circuit threshold value and an arcing threshold value respectively, and the result is used as a judging criterion about whether short circuit and arcing occur or not. According to the consumable electrode electric arc welding droplet necking detection method, necking judgment real-time performance and authenticity are good, welding forming can be improved, welding spatter can be reduced, and good welding arc dynamic characteristics can be achieved.

Owner:SHENZHEN MEGMEET ELECTRICAL CO LTD

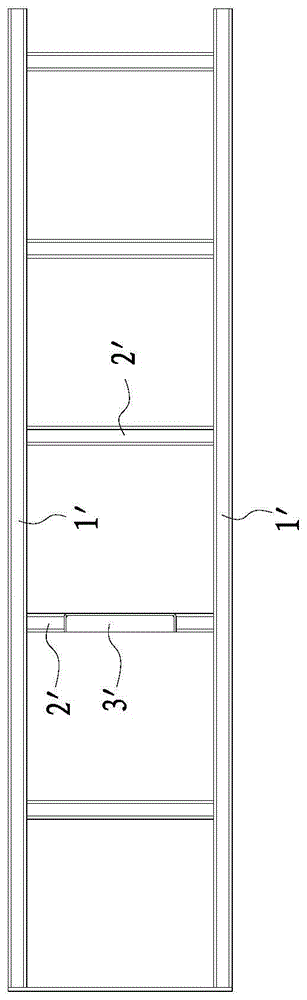

Heat-pipe type flat plate collector

PendingCN108592421AReasonable structureHigh efficiency factorSolar heating energyFluid circuit connectionsCollection systemEngineering

The invention discloses a heat-pipe type flat plate collector. The heat-pipe type flat plate collector comprises an external frame, a heat absorption plate core and light-transmitting glass. The heatabsorption plate core is arranged inside the external frame, and the light-transmitting glass is arranged on the upper portion of the external frame. The heat absorption plate core is an overall-heat-pipe type heat absorption plate core and is composed of a cold fluid passage pipe, heat transfer pipes, a heat absorption film, flow collecting pipes and a flow return pipe. The cold fluid passage pipe comprises an inner pipe body, an outer pipe body and a blocking plate, and the blocking plate is welded between the inner pipe body and the outer pipe body. The heat transfer pipes, the heat absorption film, the flow collecting pipes, the flow return pipe and the outer pipe body are made of aluminum. The heat transfer pipes and the flow return pipes are welded between the outer pipe body and theflow collecting pipe in parallel to form a pipe assembly, and the heat absorption film is welded to the pipe assembly. A cooling medium is transmitted to the upper end of the inner pipe body from thelower end, and the pipe assembly is filled with a phase change medium. The heat-pipe type flat plate collector provided by the invention is reasonable in structure, the problems that a flat plate heat collection system is large in flowing resistance and uneven in flow distribution are solved, the efficiency factor of the collector is improved, and the effective utilization rate of energy is increased.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI +1

Process for welding reinforcing rings between topside module and jacket

ActiveCN104439652AImprove working environmentImprove securityArc welding apparatusSubmerged arc weldingPipe welding

The invention relates to a process for welding reinforcing rings between a topside module and a jacket. The process includes the following steps: (1) one reinforcing ring serves as a unit, and welding prefabrication of the reinforcing rings and internal flange rings is carried out on the exterior of the jacket and the exterior of the topside module; when prefabrication is carried out, one reinforcing ring is divided into a plurality of arc-shaped plates, and then the multiple arc-shaped plates are spliced together to form the overall reinforcing ring; (2) the flange rings are placed on a potension meter, and are welded to the arc-shaped plates through a submerged arc welding machine to conduct pairing; (3) K-shaped notches are formed in the edges of the outer sides of the reinforcing rings, the flange rings are clamped through clamps, and then the reinforcing rings are placed into pipes to conduct pairing; (4) reputedly executing the step (1) and the step (2) until the overall welding process is completed. By means of the process, a large amount of in-pipe welding work is avoided, the operation environment of an operator is improved, and the operation safety is greatly improved. In addition, the requirement for operating skills of the operator is greatly reduced, and the construction efficiency is greatly improved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Method for preparing bottled multi-element mixed gas

ActiveCN102900950AImprove the mechanical properties of the weldGood welding performanceContainer filling under pressureGas cylinderBusbar

The invention discloses a method for preparing bottled multi-element mixed gas. The method is characterized by comprising the following steps of: (A) connecting a qualified gas bottle to a port of a filling busbar; (B) vacuumizing the gas bottle and a filling pipeline system, and controlling the volume content of oxygen in the gas bottle and the filling pipeline system to be less than and equal to 3*10<-6> and the volume content of water to be less than and equal to 3*10<-6>; (C) filling argon into vacuumized gas bottle to serve as base gas, and controlling pressure in the gas bottle to be 0.1 MPa; (D) filling gas in an argon and nitrogen mixed gas container into the gas bottle in the step (C), and controlling pressure in the bottle to be 0.2 MPa; (E) filling helium into the gas container in the step (D), and controlling pressure in the bottle to be 3.3 MPa; and (F) when the wall of the bottle is cooled to room temperature, filling the argon into the gas bottle in the step (E), and controlling pressure in the bottle to be 9.9 to 10.1 MPa to obtain the helium, nitrogen and argon bottled multi-element mixed gas. The method is mainly applied to protective gas for welding core aluminum alloy parts of high-speed railways.

Owner:HUNAN TIEDA ENERGY TECH

A processing method for preparing square tubes with thin-wall strips

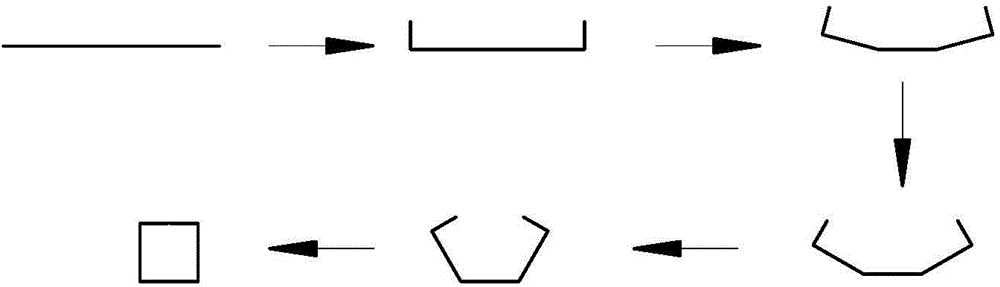

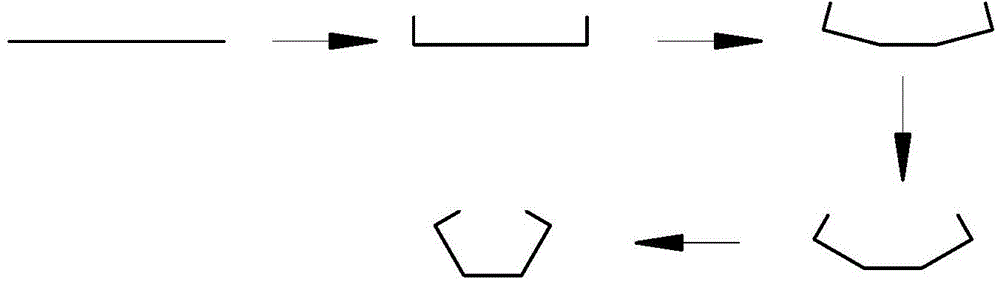

The invention discloses a machining method of thin-walled strip prepared square tubes, and belongs to the technical field of square tube forming technology. The method mainly comprises the following steps: firstly, uncoiling of a strip coil: uncoiling a strip coil and outputting a strip, secondly, primary buffering: enabling the strip to be at a tensioning state, thirdly, actively conveying the strip: enabling the strip to be downward output to the downstream under the action of traction force, and forming openings in edges of the two sides of the strip during conveying, fourthly, secondary buffering: enabling the strip to be output at a constant speed, without the action of traction force, and controlling the active conveying frequency of the strip, fifthly, application of a lubricant, sixthly, forming, seventhly, closing the opening, eighthly, welding at high frequency, ninthly, cooling, tenthly, eliminating residual liquor, eleventhly, accurately sizing a tube section, and twelfthly, cutting. The method solves the technical problems that the existing thin-walled square tubes are poor in forming quality and low in production efficiency, and can be widely applied to the manufacture of thin-walled square tubes.

Owner:马秋梅

Production formula of gold wavy inter-chip and production process of production formula

InactiveCN111979442AAvoid deformationHigh hardnessElectrophoretic coatingsJewelleryElectrophoresesMinor metals

The invention discloses a production formula and a production process of a gold wavy inter-chip. The production formula is prepared from the following raw material in parts by weight: 99.92-99.97 parts of gold and 0.03-0.08 part of alloy metal, wherein the metal alloy comprises copper, silver, sodium and trace metal elements in weight ratio of 48: 23: 10: 19. According to the production formula disclosed by the invention, the hardness and tension of the gold ornament are effectively improved, it is guaranteed that the gold content is not lower than 99.92%; in the production process assembly link, the necklace is placed in borax water to be soaked, welding forming is more convenient, and the problem that a necklace body can be melted in the traditional gold high-temperature welding is solved; in the aspect of color treatment, traditional gold cannot be electroplated and colored and can be oxidized along with time changes; the oxidation resistance of the necklace body can be greatly improved by adopting a gold salt electrophoresis adsorption mode, and meanwhile, the color is brighter, the color and luster retention time is longer, and compared with traditional gold, the acid frying link is omitted, and the gold necklace is more environmentally friendly and healthier to the human body.

Owner:深圳市凯仕莱珠宝有限公司

A fixture specially used for the welding and forming of the diagonal brace of the elevator

ActiveCN104526233BEasy to weld and formSimple structureWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsStructural engineering

The present invention relates to A fixture specially used for the welding and forming of the diagonal brace of the elevator. The diagonal brace includes an upper mounting plate, a support rod, and a lower mounting plate. First and second connecting holes are respectively provided on the upper and lower mounting plates. The fixture includes a fixture body , positioning bolts, positioning templates, positioning holes arranged on the positioning templates, the fixture body has a slope, the positioning bolts are vertically arranged on the slopes, and the slopes are perpendicular to the positioning templates, and the upper mounting plate is fixed on the positioning board through the first connecting hole. Bolt, and the two ends of the upper mounting plate protrude from the fixture body, the lower mounting plate corresponds to the positioning hole through the second connecting hole and is fixedly connected with the external connecting piece, and the fixture body is also equipped with two support rods Separate limit frame, one side of the strut is in contact with the limit frame, and the two ends are in full contact with the upper and lower mounting plates respectively 。 The invention can quickly complete the positioning of the upper and lower mounting plates and the braces, and is very convenient for the welding and forming of the diagonal braces 。

Owner:苏州威尔特铝合金升降机械有限公司

Positioning tool for welding forming of quarter bend type connecting base

ActiveCN106378569AAccurate and fast positioningEasy to weld and formWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention relates to a positioning tool for welding forming of a quarter bend type connecting base. The connecting base comprises a quarter bend and a connecting piece, wherein the quarter bend is provided with a horizontal part and a vertical part, and the connecting piece is provided with connecting holes. The positioning tool comprises a horizontally-arranged platform, a first positioning base located on the platform and used for placing the connecting piece, and a second positioning base next to one side of the first positioning base so that the vertical part of the placed quarter bend can be perpendicular to the platform, wherein the first positioning base is provided with pilot pins matched with the connecting holes, and when positioning and welding are carried out, the connecting piece is positioned on the first positioning base, the bottom end portion of the vertical part of the quarter bend is erected on the middle portion of the connecting piece located on the first positioning base. The positioning tool can quickly and accurately achieve position of the quarter bend and the connecting piece, and therefore welding forming of the quarter bend type connecting base can be facilitated; and the positioning tool is simple in structure, convenient to implement and low in cost.

Owner:JIANGSU SHA ZHOU ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com