Wire feeder control circuit

A technology for controlling circuits and wire feeders, used in manufacturing tools, arc welding equipment, welding equipment, etc., can solve the problems of easy soldering, difficulty in changing speed, adhesion, etc., to reduce welding spatter, improve welding The effect of output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

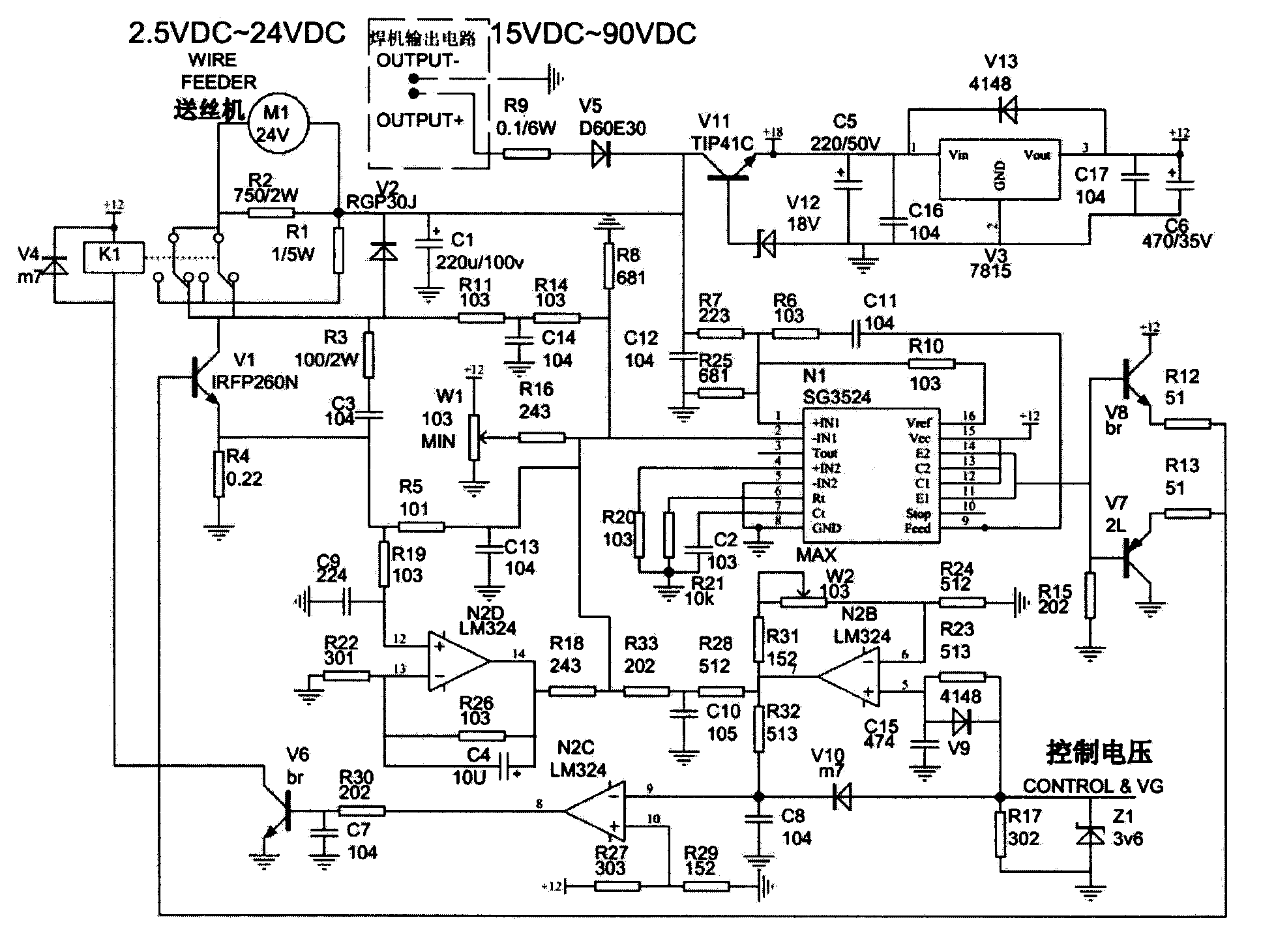

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing, the present invention is further described in detail:

[0013] The invention relates to a control circuit of a wire feeder, including a power supply, a single-chip microcomputer, and a wire feeder. The power supply: the output voltage (arc voltage) of the welding machine is used as an energy source to provide the voltage of the wire feeder, which overcomes the need to use a lot of power The large industrial frequency transformer is insufficient as the power supply of the wire feeder, which saves energy, materials and weight.

[0014] The output voltage of the welding machine is rectified and filtered by V5 and C1, and divided into two circuits. One path is used as the main power supply for the wire feeder; the other path provides +18V and +12V through V11 and V12, and is used as the power supply for the control circuit.

[0015] The control voltage is added to pin ⑨ of N2LM324 through V10, and compared with the voltage of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com