Friction welding method for bidirectional embedding and mechanical reinforcing of heterogeneous materials

A heterogeneous material, friction welding technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of high stress, low radial strength, poor toughness, etc., to save welding costs, improve welding The effect of improving the welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

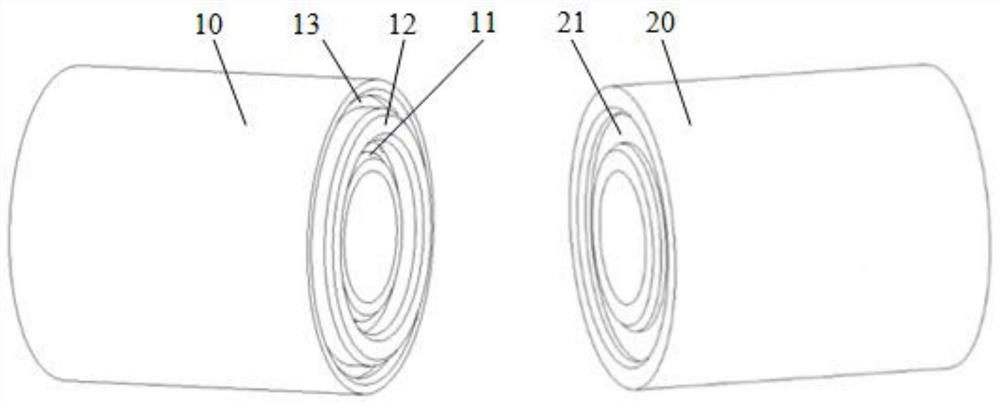

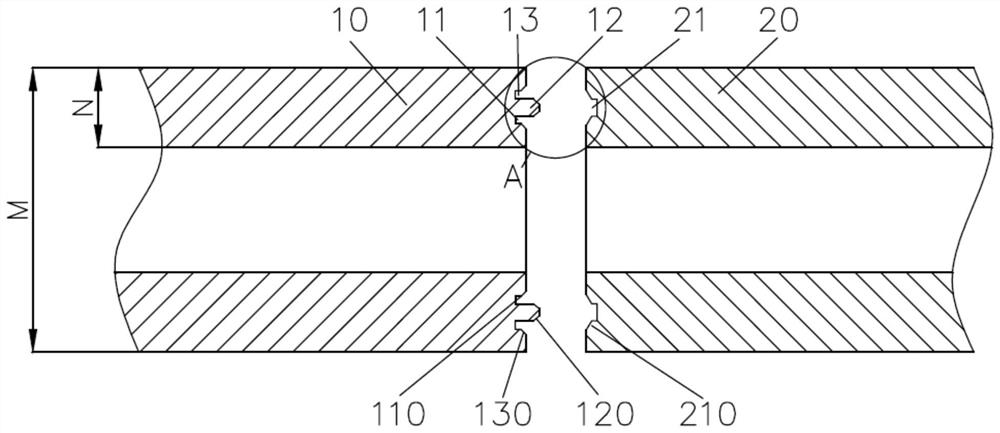

[0035] This embodiment takes high-strength steel and aluminum alloy pipe fittings as an example, such as Figure 1~3 As shown, a friction welding method for two-way embedded mechanical reinforcement of heterogeneous materials is characterized in that:

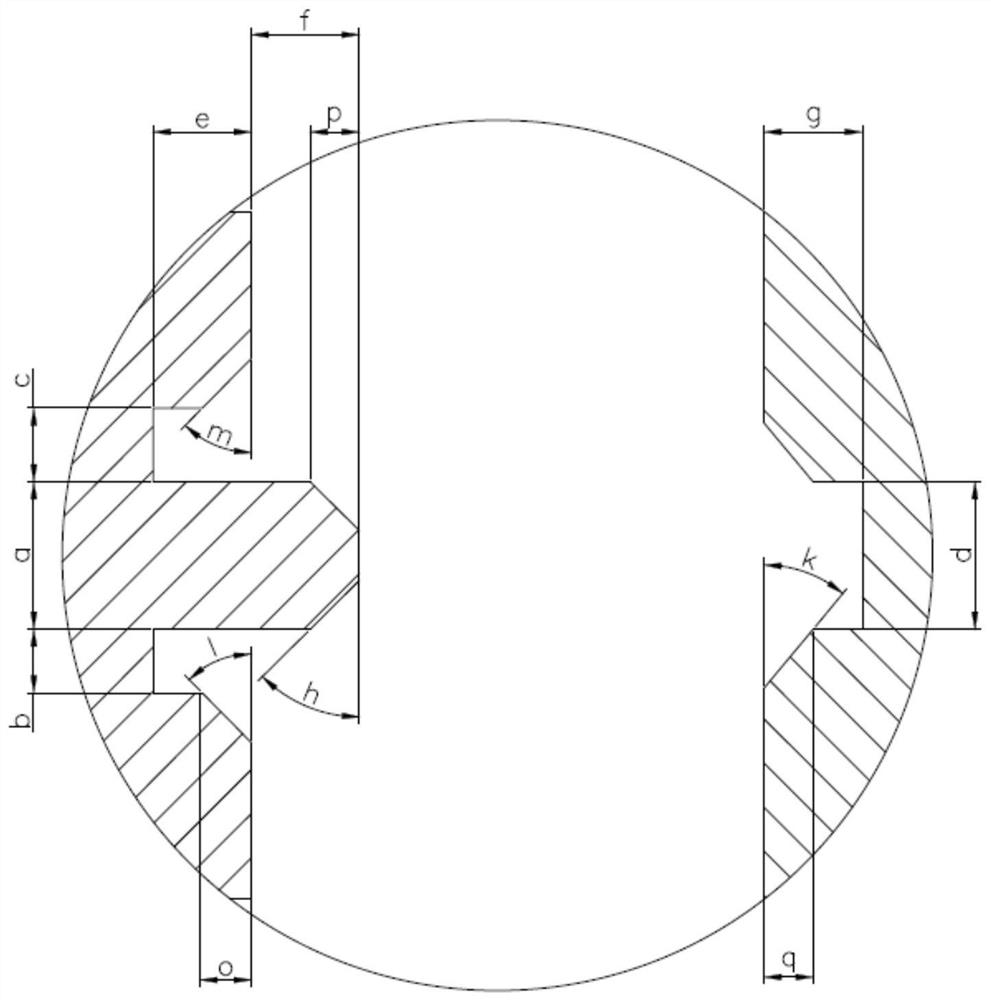

[0036] S001. Structural design of welded joints: For high-strength steel pipe fittings 10 with high strength and high hardness, an annular inner groove 11, an annular boss 12 and an annular outer groove are sequentially processed outward from the central axis on the end surface to be welded 13, and the inner groove 11 and the outer groove 13 are close to the boss 12, and the inner groove 11, the boss 12, the outer groove 13, and the high-strength steel pipe fitting 10 are coaxial; for aluminum alloy pipe fittings with low strength and low hardness 20. An annular welding groove 21 is processed on the surface to be welded and the welding groove 21 corresponds to the boss 12. The welding groove 21 is coaxial with the aluminum allo...

Embodiment 2

[0045] This embodiment takes high-strength steel and aluminum alloy pipe fittings as an example, such as Figure 1~3 As shown, a friction welding method for two-way embedded mechanical reinforcement of heterogeneous materials is characterized in that:

[0046] S001. Structural design of welded joints: for high-strength steel pipe fittings 10 with high strength and high hardness, an annular inner groove 11, an annular boss 12 and an annular outer concave are sequentially processed outward from the central axis on the end surface to be welded groove 13, and the inner groove 11 and the outer groove 13 are close to the boss 12, the inner groove 11, the boss 12, the outer groove 13, and the high-strength steel pipe fitting 10 are coaxial; for aluminum alloys with low strength and low hardness The pipe fitting 20 has an annular welding groove 21 processed on its surface to be welded and the welding groove 21 corresponds to the boss 12. The welding groove 21 is coaxial with the alumi...

Embodiment 3

[0055] This embodiment takes high-strength steel and aluminum alloy pipe fittings as an example, such as Figure 1~3 As shown, a friction welding method for two-way embedded mechanical reinforcement of heterogeneous materials is characterized in that:

[0056] S001. Structural design of welded joints: for high-strength steel pipe fittings 10 with high strength and high hardness, an annular inner groove 11, an annular boss 12 and an annular outer concave are sequentially processed outward from the central axis on the end surface to be welded groove 13, and the inner groove 11 and the outer groove 13 are close to the boss 12, the inner groove 11, the boss 12, the outer groove 13, and the high-strength steel pipe fitting 10 are coaxial; for aluminum alloys with low strength and low hardness The pipe fitting 20 has an annular welding groove 21 processed on its surface to be welded and the welding groove 21 corresponds to the boss 12. The welding groove 21 is coaxial with the alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com