Longitudinal axial flow threshing device of whole-feed combine harvester

A technology for combine harvesters and threshing devices, which is applied in threshing equipment, agricultural machinery and implements, and applications. It can solve the problems of clogging of the feed inlet of the threshing drum, high cleaning loss, and small cleaning screen area, and achieve enhanced speed and efficiency. The effect of spreading strength, reducing the intensity of material handling, and correcting the unevenness of conveying materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below with reference to the accompanying drawings.

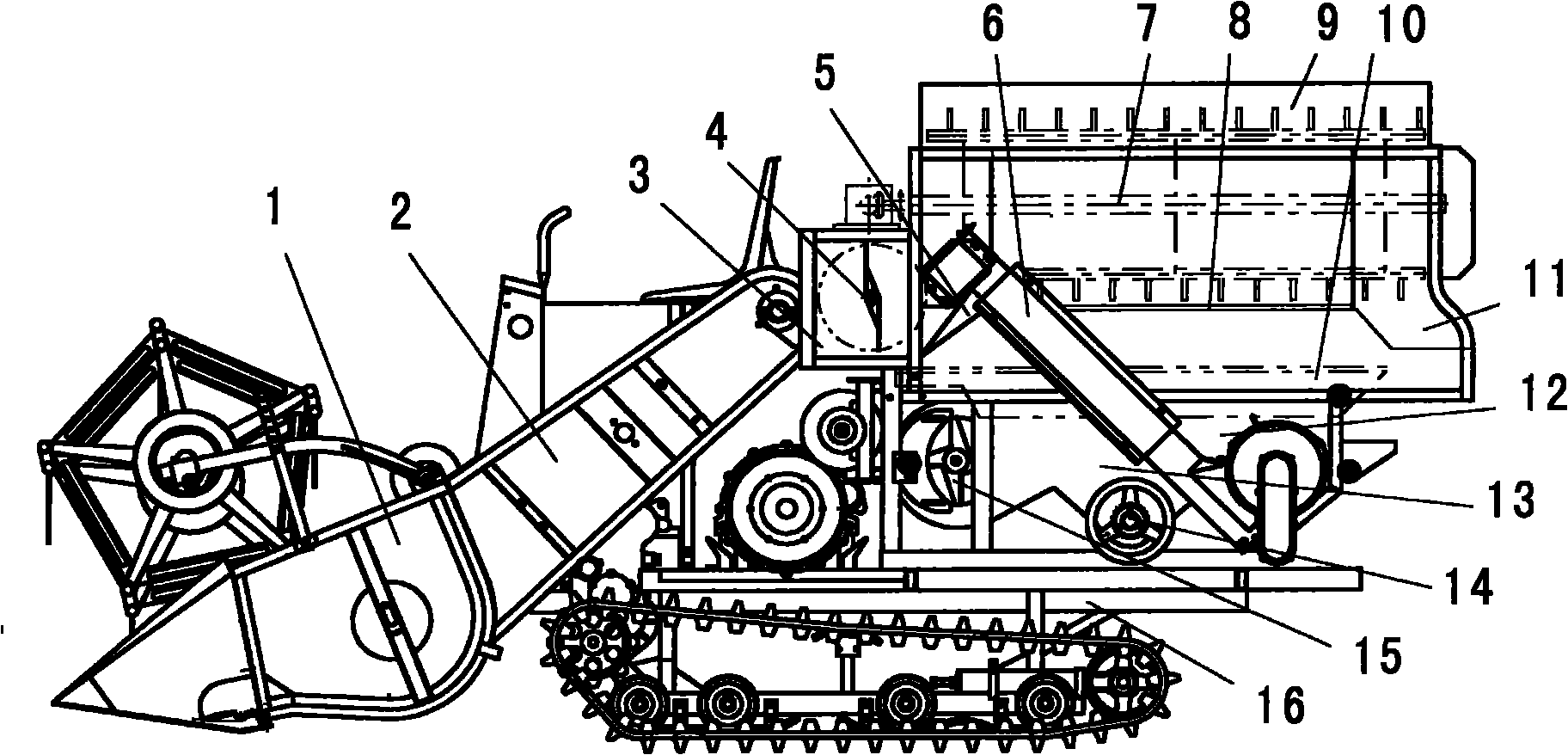

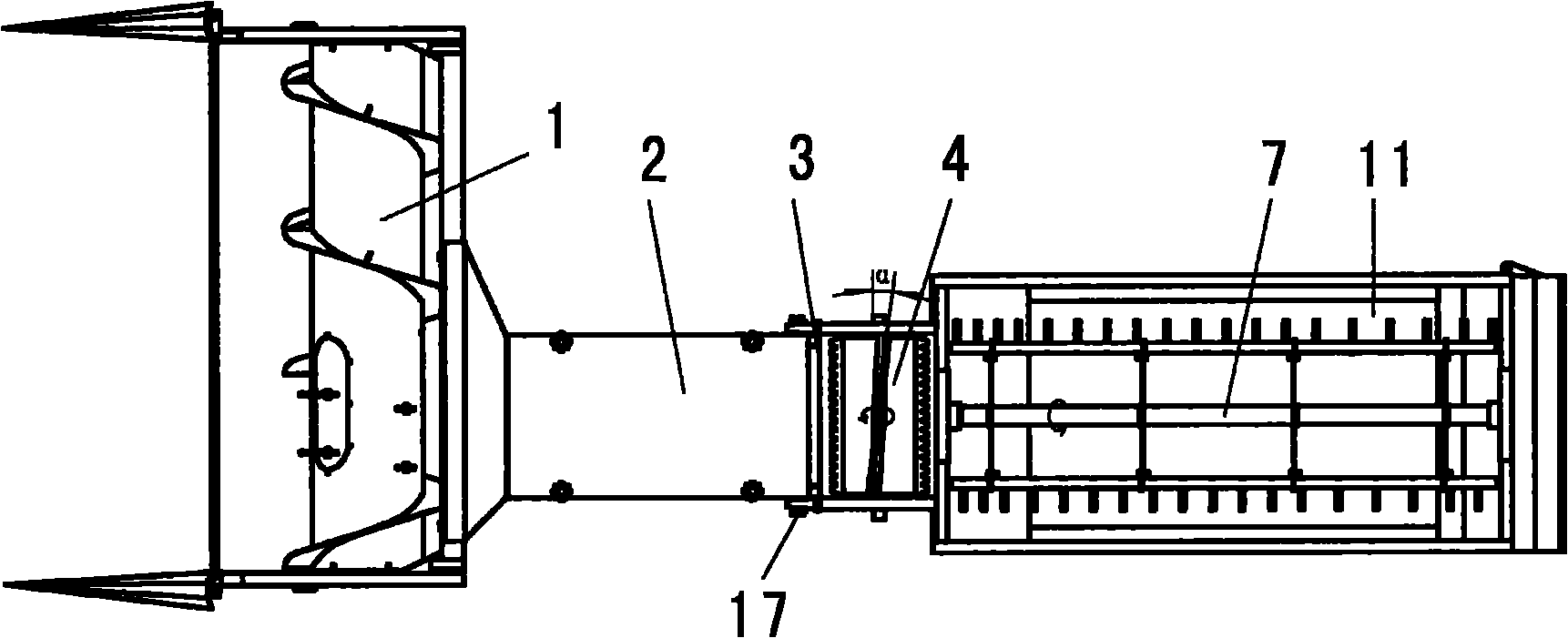

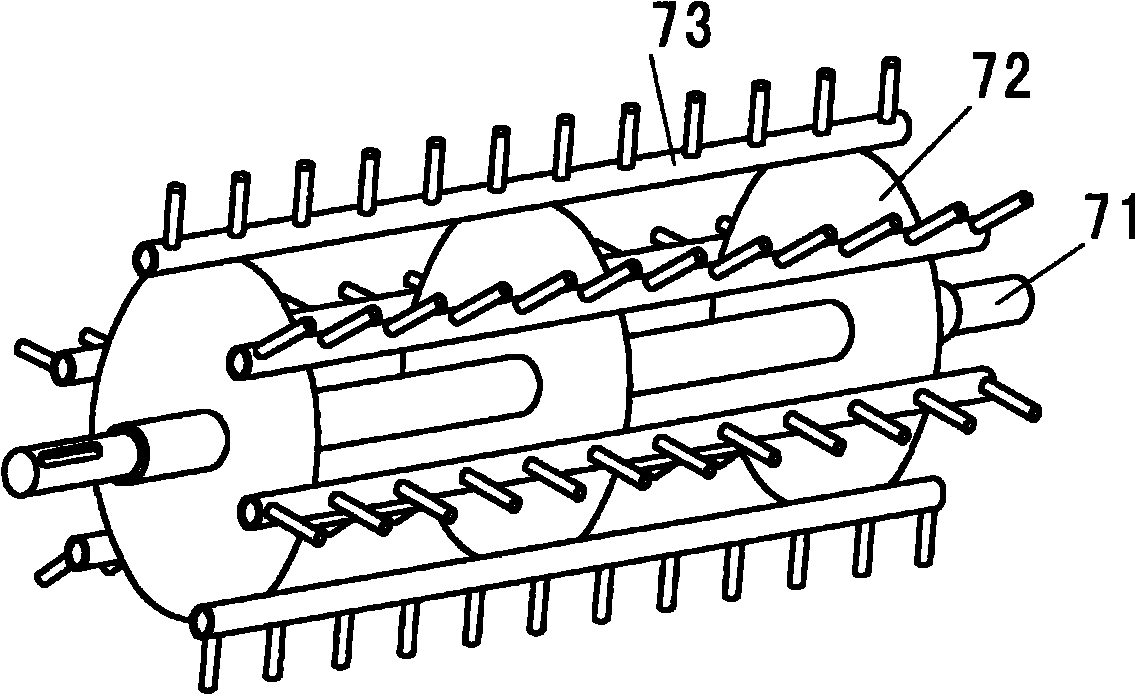

[0016] A threshing chamber 11 is installed on the chassis 16 of the full-feed combine harvester, and an intermediate delivery trough 2 is connected between the front end of the threshing drum of the threshing chamber 11 and the header 1 of the harvester. Inside the threshing chamber 11, a vertical threshing drum 7 whose axis is parallel to the advance direction of the harvester, a concave plate sieve 8, and a cleaning sieve 10 are installed from top to bottom. Inner front, fan 15 is installed at the bottom of cleaning sieve 10, and the threshing chamber space at the bottom of cleaning sieve 10 is formed by V-shaped plate respectively before main feed bin 13 and rear secondary feed bin 12. The full concentrate in the front main silo 13 is conveyed to the grain bin of the harvester through the conveying auger 14; Composed of a small re-extraction drum and a secondary lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com